Wet-mixing modified asphalt emulsion and preparation method

A technology of modified asphalt and emulsion, applied in building thermal insulation materials, on-site coagulating pavement, building components, etc., can solve the problems of difficult to increase the amount of SBS, difficult to obtain high asphalt content storage stability, etc., and achieve production costs. Low, excellent performance, high emulsion concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024]In the preparation method of the modified asphalt emulsion provided by the present invention, it is preferable to swell the elastomeric polymer before adding the modified asphalt stabilizer. Usually, the mixture of asphalt and elastomeric polymer is stirred at 100-200°C for more than 0.2 hours to swell the elastomeric polymer; it can be stirred before or after the colloid mill, or it can be stirred for a period of time After passing through the colloid mill and then stirring for a period of time, the total stirring time is preferably 0.2-1 hour.

[0025] One of the preparation methods of the modified asphalt emulsion for warm mixing provided by the present invention is to heat the asphalt raw material to 100-200°C, preferably 130-195°C, and then control the temperature, add elastomer polymer to it, and stir to make the elastomer The polymer is uniformly dispersed and fully swollen. The stirring time is usually not less than 0.2 hours, preferably 0.2-1 hour. Usually, the ...

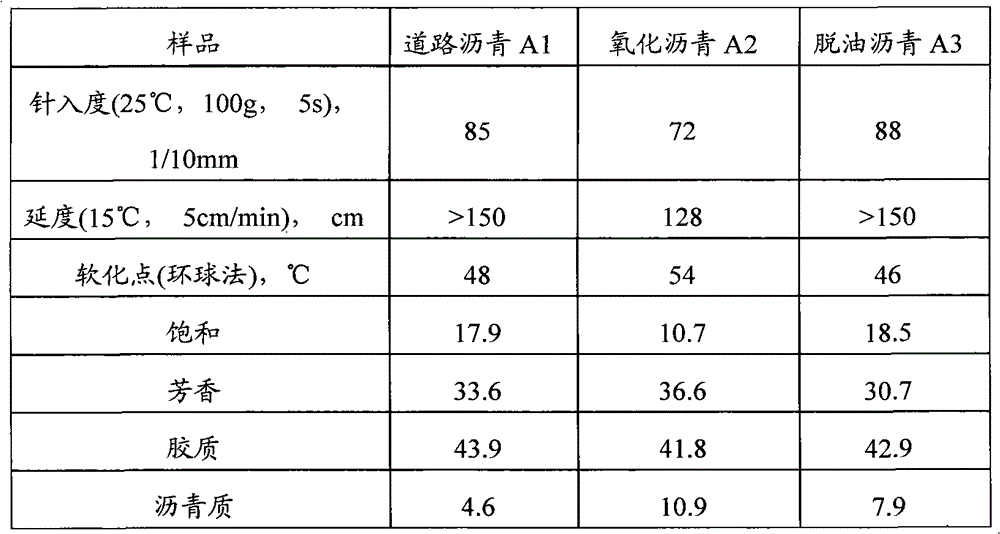

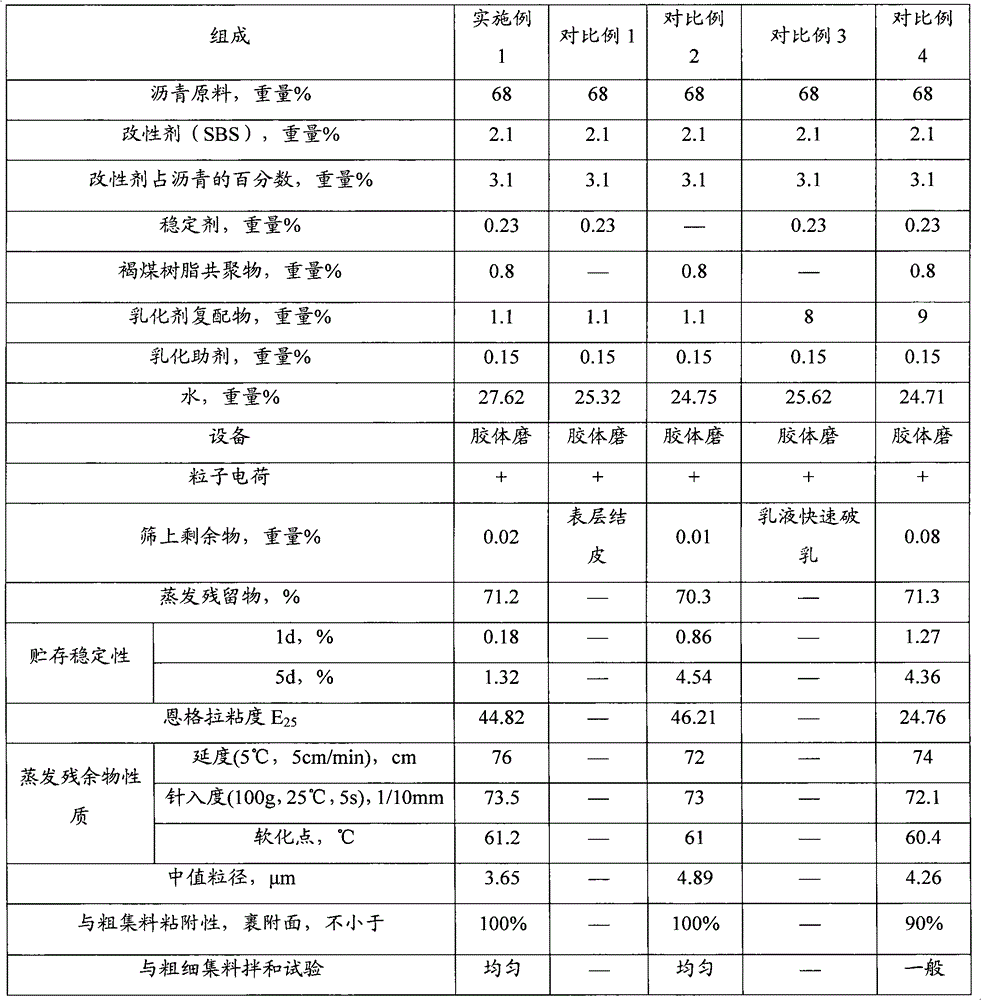

Embodiment 1

[0041] Heat 680g of road asphalt A1 to a temperature of 170°C, then add 21g of elastomer polymer SBS-B1 (see Table 1) under stirring, stir for 20 minutes, pass through a colloid mill for high-speed shear dispersion, and then add 2.3g of sulfur under stirring , reacted for 4 hours to obtain modified asphalt, then added 8g lignite resin copolymer under stirring, stirred for 15 minutes, then kept warm (the temperature was 150-170°C) for subsequent use, and was recorded as CW1; 6.5g lignin polyamine, 2.5g Lauryl polyoxyethylene tetradecyl ammonium chloride, 2g octylphenol polyoxyethylene (12) ether, 1.5g sodium benzoate mixture are mixed with 276.2g water, stirring makes each component dissolve, obtains emulsifier aqueous solution , and then heated to 65°C; the prepared CW1 was mixed with an emulsifier aqueous solution and fully sheared and dispersed with a colloid mill, and condensed by a condenser to obtain a modified asphalt emulsion. The properties are shown in Table 3. It can...

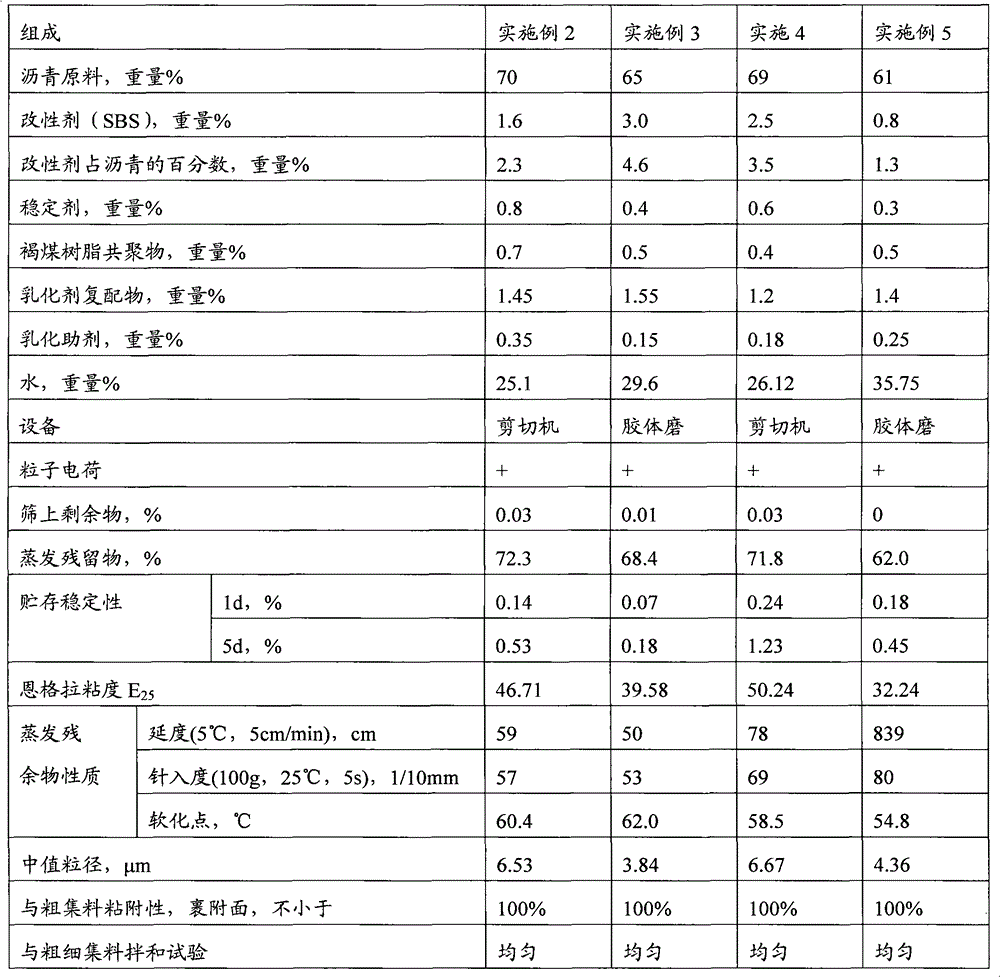

Embodiment 2

[0051] Heat 700g of road asphalt A1 to a temperature of 180°C, add 16g of elastomer polymer SBS-B1 under stirring, stir for 30 minutes, pass through a colloid mill to shear and disperse, then add 8g of zinc oxide under stirring at 180°C, and stir for 5 hours. Add 7g lignite resin, and then keep the temperature at 180°C to obtain the product CW2; 10g nonylphenol polyoxyethylene ether ethyl dimethyl tetradecyl ammonium chloride, 2.5g lignin polyamine, 2g octylphenol polyoxyethylene (10) The mixture of ether and 3.5g polyethylene glycol (6000) and distearic acid ester (the weight ratio of polyethylene glycol and distearic acid ester is 1: 1) is mixed with 251g water, stirs to make each group Partially dissolved to obtain an aqueous emulsifier solution, which was then heated to 50°C. The prepared product CW2 was mixed with an emulsifier aqueous solution and sheared and dispersed with a shearing machine. After condensation, a modified asphalt emulsion was obtained. The properties a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com