Preparation method of asphalt concrete warm mixing rutting and cracking resisting agent

A kind of asphalt concrete, warm mixing technology, applied in the field of asphalt concrete additives, can solve the problems that it is difficult to take into account the high, low temperature and water damage performance of asphalt mixture, the fluidity of asphalt mixture is reduced, and the degree of compaction is insufficient, so as to improve workers The effect of working environment quality, improving softening point, and reducing processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

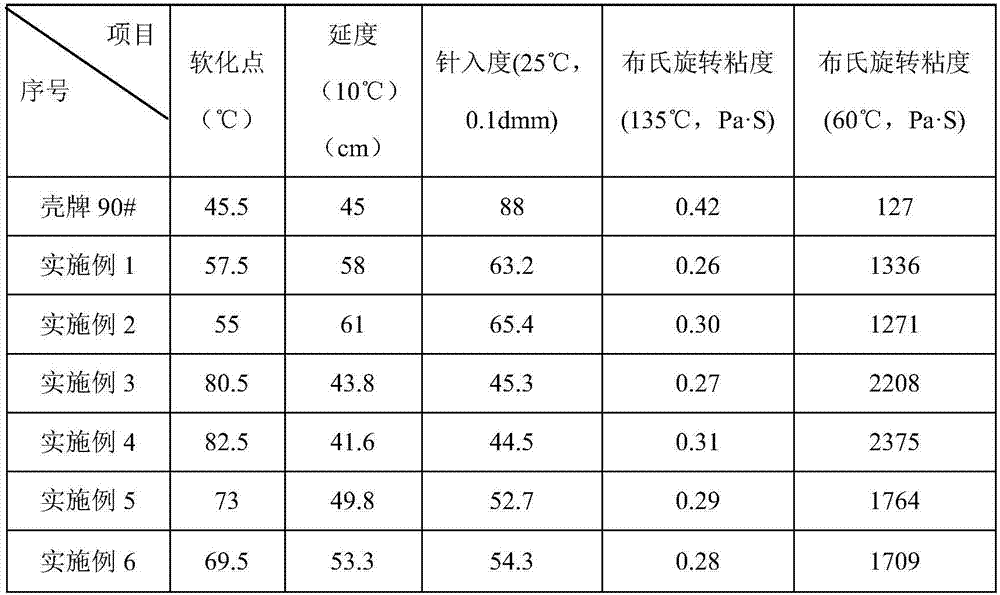

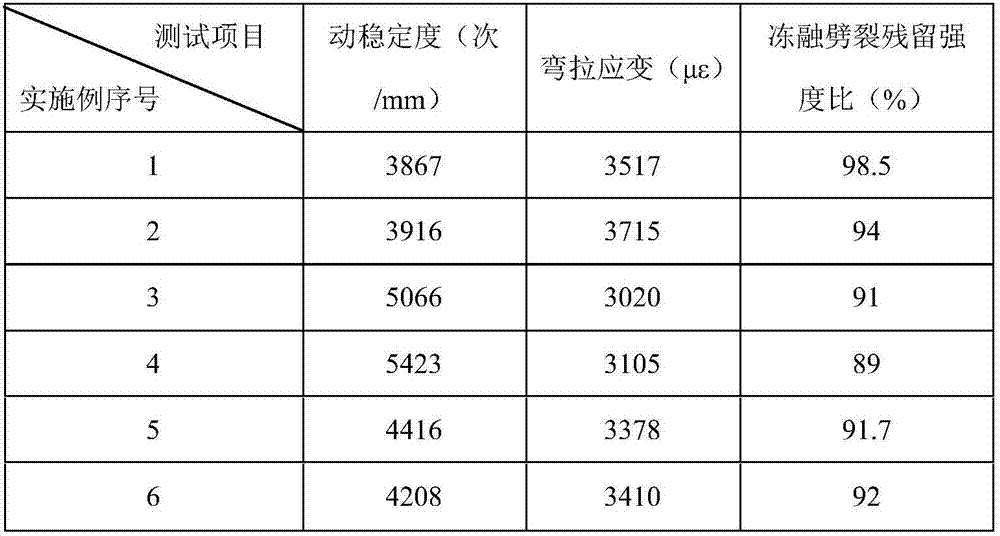

Examples

Embodiment 1

[0027] 1) 80 parts by mass of modified polyethylene wax, 10 parts by mass of oxidized polyethylene wax, 5 parts by mass of Fischer-Tropsch wax, 5 parts by mass of hot-melt EVA and 1 part by mass of dicumyl hydroperoxide at 160°C Fully mix in the kettle, and react for 30 minutes to obtain a modified mixture;

[0028] 2) Then 3 parts by mass of ethylenediamine, 5 parts by mass of tallow amine, 1 part by mass of adipate, 4 parts by mass of n-butanol and 1 part by mass of tall oil are added to the above mixture for melt blending and control The temperature is 135-140°C, and then through the granulation tower to obtain the warm-mix anti-rutting agent.

Embodiment 2

[0030] 1) With 85 parts by mass of modified polyethylene wax, 10 parts by mass of epoxidized polyethylene wax, 5 parts by mass of Fischer-Tropsch wax, 5 parts by mass of abietic acid and 1.5 parts by mass of dicumyl hydroperoxide, at 160 ° C Fully mix in the reaction kettle, and react for 30 minutes to obtain the modified mixture;

[0031] 2) Then 2 parts by mass of fatty glycerol, 8 parts by mass of fatty acid amide, 1 part by mass of glycerol, 4 parts by mass of n-butanol and 1 part by mass of tall oil pitch are added to the above mixture, melt blending, and control The temperature is 135-140°C, and then through the granulation tower to obtain the warm-mix anti-rutting agent.

Embodiment 3

[0033] 1) With 85 parts by mass of modified polyethylene wax, 10 parts by mass of epoxidized polyethylene wax, 5 parts by mass of Fischer-Tropsch wax, 5 parts by mass of abietic acid and 1.5 parts by mass of dicumyl hydroperoxide, at 160 ° C Fully mix in the reaction kettle, and react for 30 minutes to obtain the modified mixture;

[0034] 2) Then 2 parts by mass of fatty glycerine, 8 parts by mass of pyrimethanil acetate, 1 part by mass of citric acid ester, 4 parts by mass of n-butanol and 1 part by mass of tall oil pitch are added to the above mixture for melting Blending, controlling the temperature at 135-140°C, and then passing through a prilling tower to obtain a warm-mix anti-rutting agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com