Foam warm-mixing SMA-13 asphalt mixture, preparation method and performance evaluation method thereof

An asphalt mixture and foam technology, which is applied in ceramic products, applications, climate change adaptation, etc., can solve the problem of not giving full play to the warm mix asphalt technology, energy saving and emission reduction, unstable road performance of the mixture, and imperfect additive evaluation methods, etc. problems, to reduce the temperature, reduce the degree of aging, reduce the generation of harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

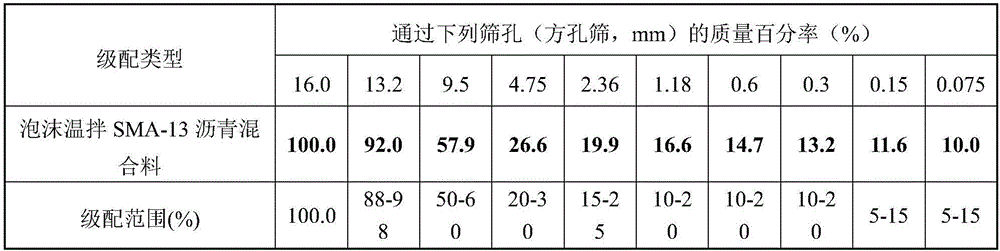

Embodiment 1

[0025] Foam warm mix SMA-13 asphalt mixture composition (parts by weight) of the present invention:

[0026] 1) Mineral material: 400 parts of 1# material, 340 parts of 2# material, 50 parts of 3# material, 110 parts of 4# material, 100 parts of mineral powder;

[0027] 2) Foamed asphalt: 61 parts of SBS modified asphalt, 1.83 parts of foaming water.

[0028] The production equipment that the foam warm mix SMA-13 asphalt mixture of the present invention adopts is:

[0029] 1) The foamed asphalt production equipment can guarantee the maximum air pressure of 1000kPa, the maximum water pressure of 1000kPa, and the asphalt pressure of 1000kPa. It can adapt to the asphalt temperature of 155-165°C, and can continuously produce foamed asphalt under a certain amount of water, and The quality of foamed asphalt produced in each batch can reach 10-20kg;

[0030] 2) Use a horizontal mixing pot that matches the foaming equipment. It is required that the horizontal mixing pot can meet...

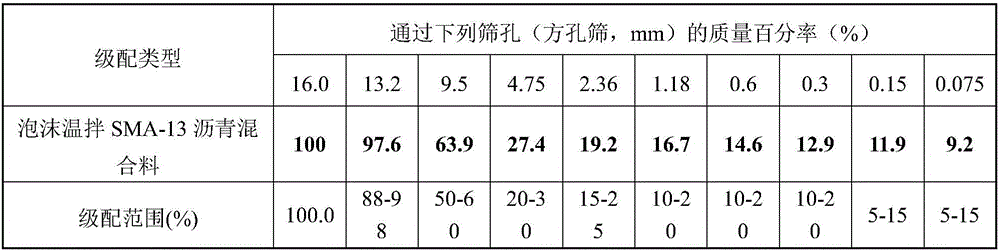

Embodiment 2

[0039] Composition of foam warm mix recycled asphalt mixture (parts by weight):

[0040] 1) Mineral material: 430 parts of 1# material, 320 parts of 2# material, 50 parts of 3# material, 90 parts of 4# material, 110 parts of mineral powder;

[0041] 2) Foamed asphalt: 60 parts of SBS modified asphalt, 1.8 parts of foaming water.

[0042] Indoor production equipment is the same as embodiment 1.

[0043] The preparation method of the foam warm mix SMA-13 asphalt mixture comprises the following steps:

[0044] 1) Put the heated coarse aggregate, fine aggregate, and lignin fiber in a mixing pot, and mix properly with a small shovel.

[0045] 2) Spray the foamed modified asphalt foamed in the room directly into the mixing pot, and fully mix the SMA-13 mixture (120°C~160°C) for 1-2min.

[0046] 3) Suspend mixing, add heated mineral powder, continue mixing until uniform, and keep the asphalt mixture within the required mixing temperature range, the total mixing time is 4min, a...

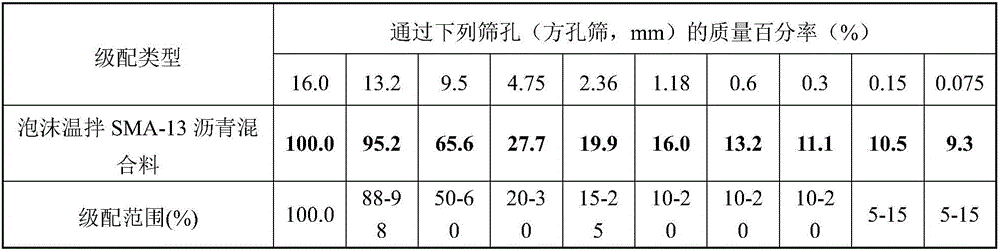

Embodiment 3

[0051] Composition of foam warm mix recycled asphalt mixture (parts by weight):

[0052] 1) Mineral material: 370 parts of 1# material, 360 parts of 2# material, 60 parts of 3# material, 120 parts of 4# material, 90 parts of mineral powder;

[0053] 2) Foamed asphalt: 61 parts of SBS modified asphalt, 1.83 parts of foaming water.

[0054] Indoor production equipment is the same as embodiment 1.

[0055] The preparation method of the foam warm mix SMA-13 asphalt mixture comprises the following steps:

[0056] 1) Put the heated coarse aggregate, fine aggregate, and lignin fiber in a mixing pot, and mix properly with a small shovel.

[0057]2) Spray the foam-modified asphalt foamed in the room directly into the mixing pot, and fully mix the SMA-13 mixture (130℃~160℃) for 1-1.5min.

[0058] 3) Suspend mixing, add heated mineral powder, continue mixing until uniform, and keep the asphalt mixture within the required mixing temperature range, the total mixing time is 3 to 4 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com