High-heat-resistance modified PGA material and preparation method thereof

A highly heat-resistant and modified technology, applied in the field of PGA materials, which can solve problems such as low glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

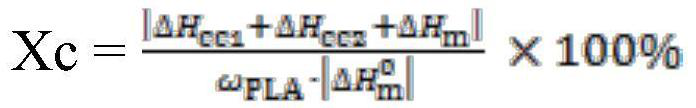

Image

Examples

preparation example Construction

[0026] The present invention provides a kind of preparation method of the highly crystalline modified PGA material described in above-mentioned technical scheme, comprises the following steps:

[0027] The polyglycolic acid resin, the filler, the castor oil mixture and the nucleating agent are mixed, extruded and granulated, and dried to obtain the modified PGA material.

[0028] In the present invention, the temperature of the feeding section in the extrusion granulation process is preferably 120-140°C, more preferably 130°C; the temperature of the mixing section is preferably 210-230°C, more preferably 220°C; the temperature of the extrusion section Preferably it is 220-240 degreeC, More preferably, it is 230 degreeC. The invention adopts a twin-screw extruder for extrusion granulation, and the aspect ratio of the extruder is at least 1:75.

[0029] In the present invention, the extrusion granulation adopts the method of water-stretching; the temperature of the water is 75°...

Embodiment 1

[0042] Composition according to raw material weight ratio: 1 part of nucleating agent, 80 parts of polyglycolic acid resin (PGA), 15 parts of filler, 30 parts of castor oil mixture; Described nucleating agent is inositol; Described filler is edible starch; Described The polyglycolic acid resin has a weight average molecular weight of 200,000 g / mol and a melting point of 220°C; the castor oil mixture is a mixture of castor oil and methanol with a purity of 90%, and the mass ratio of castor oil to methanol is 8:2.

[0043] First mix the above raw materials with a high-speed mixer for 1 hour, and then put them into twin-screw extruders for granulation; the length-to-diameter ratio of the twin-screw extruder must be at least 1:75, while the temperature of the feeding section is kept at about 130°C, and the temperature of the mixing section is 220°C, the temperature of the extrusion section is kept at about 230°C; the granulation is carried out by means of water-stretching, and the ...

Embodiment 2

[0049] Composition according to the weight ratio of raw materials: 0.5 parts of nucleating agent, 75 parts of polyglycolic acid resin (PGA), 10 parts of filler, 20 parts of castor oil mixture; Described nucleating agent is sebacic acid xylhydrazide; Described filler is Nano-montmorillonite; the weight-average molecular weight of the polyglycolic acid resin is 100,000 g / mol, and the melting point is 230°C; the castor oil mixture is a mixture of castor oil and methanol with a purity of 90%, and the mass ratio of castor oil and methanol is 8:2.

[0050] First mix the above raw materials with a high-speed mixer for 1 hour, and then put them into twin-screw extruders for granulation; the length-to-diameter ratio of the twin-screw extruder must be at least 1:75, while the temperature of the feeding section is kept at about 130°C, and the temperature of the mixing section is 220°C, the temperature of the extrusion section is kept at about 230°C; the granulation is carried out by mean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com