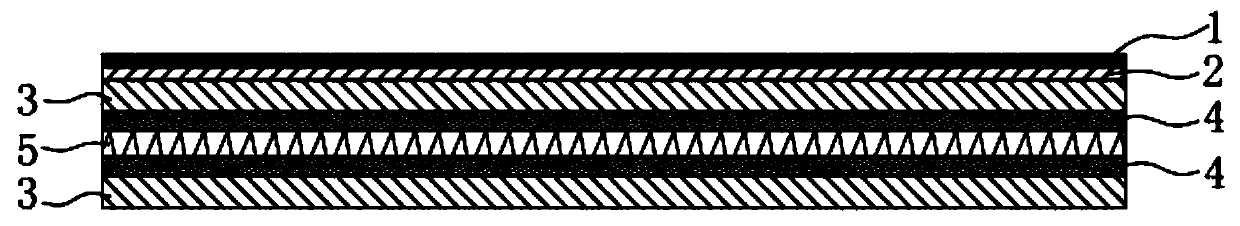

Coating composite material and preparation method thereof

A composite material and coating technology, applied in coating, textile and papermaking, etc., can solve the problems of affecting the appearance of the membrane structure, cumbersome operation process, etc., and achieve strong shielding properties, high thermal insulation effect, and improved peel strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] S1: Select the gram weight as 260g / m 2 1. The substrate layer is made of plain weave structure polyester fabric with polyester fiber linear density of 1000dtex;

[0075] S2: First weigh the following raw materials in parts by weight: 100 parts of PVC paste resin, 3.5 parts of liquid calcium-zinc composite stabilizer, 40 parts of plasticizer, 35 parts of flame-retardant plasticizer, 4 parts of decabromodiphenylethane, three 4 parts of antimony oxide, 3.2 parts of zinc borate, 2 parts of zinc hydroxystannate, 7 parts of vinyl chloride-vinyl acetate copolymer resin, stir well, then grind twice on the three-roller mill, add 8 parts of bonding agent while stirring agent, 2 parts of cross-linking agent, 8 parts of cross-linking aid and 12 parts of viscosity reducer, and finally stirred at high speed for 30 minutes to obtain a flame-retardant PVC primer paste slurry, which was dipped and rolled by rubber wheels. Under tension traction, evenly coat the flame retardant PVC base...

Embodiment 2

[0081] The only difference with Example 1 is that the raw materials of the flame-retardant PVC primer layer in Example 2 are: 100 parts of PVC paste resin, 3.5 parts of liquid calcium-zinc composite stabilizer, 40 parts of plasticizer, and 35 parts of flame-retardant plasticizer , 3 parts of decabromodiphenylethane, 3 parts of antimony trioxide, 2.4 parts of zinc borate, 1.5 parts of zinc hydroxystannate, 5 parts of vinyl chloride-vinyl acetate copolymer resin, 8 parts of binder, 2 parts of crosslinking agent , 8 parts of cross-linking auxiliary agent, 10 parts of viscosity reducer.

Embodiment 3

[0083] The only difference from Example 1 is that the raw materials of the flame-retardant PVC primer layer in Example 3 are: 100 parts of PVC paste resin, 3.5 parts of liquid calcium-zinc composite stabilizer, 40 parts of plasticizer, and 35 parts of flame-retardant plasticizer , 4 parts of decabromodiphenylethane, 4 parts of antimony trioxide, 3.2 parts of zinc borate, 2 parts of zinc hydroxystannate, 5 parts of vinyl chloride-vinyl acetate copolymer resin, 5 parts of binder, 1.5 parts of crosslinking agent , 6 parts of cross-linking auxiliary agent, 7 parts of viscosity reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com