Tread rubber for tire of dune buggy

A technology for tread rubber and ATV, applied in the field of rubber materials, can solve the problems of low mechanical properties such as wear resistance, tear resistance and puncture resistance, decreased mechanical properties of tread rubber, and expensive natural rubber. Improved tear and puncture resistance, improved processability, green rubber and carbon black savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

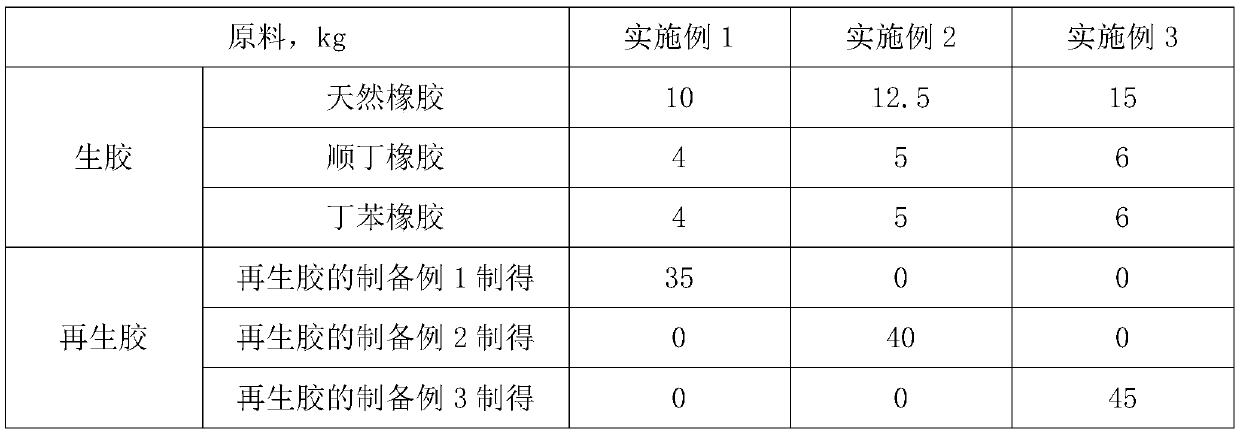

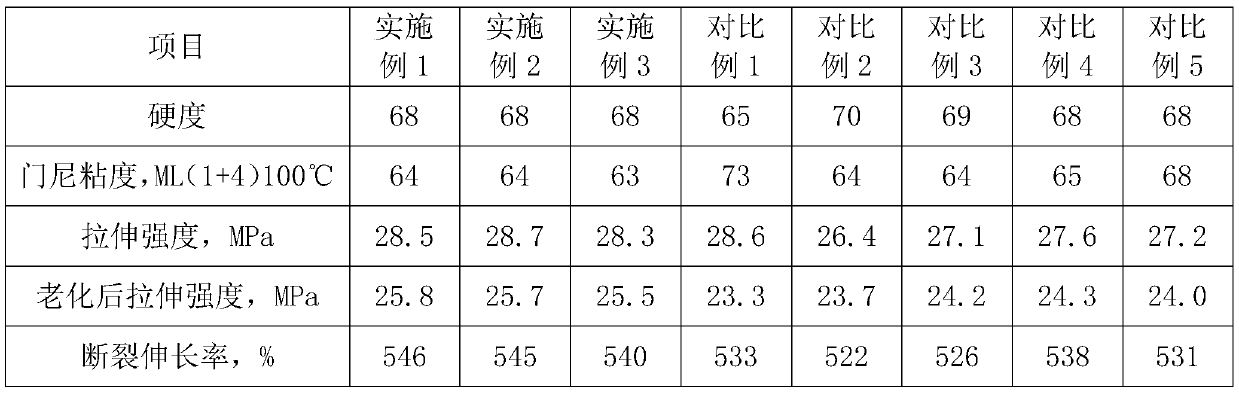

Examples

preparation example 1

[0037]Preparation example 1 of modified pottery clay: 1. add 10% of its weight to the potter's clay with a 5wt% hydrochloric acid solution to obtain acidified potter's clay;

[0038] ②The acidified pottery clay was roasted at 600°C for 2 hours, crushed and sieved to obtain roasted pottery clay;

[0039] ③ Take 30kg of water, 10kg of polyvinylpyrrolidone, 4kg of microcrystalline cellulose, 3kg of sodium lauryl sulfate, 0.3kg of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, and mix Uniform, get the modifier;

[0040] ④Add 10% modifier by weight to the calcined pottery clay, stir at 1000r / min for 20min, dry at 120°C for 6h, and then pulverize through a 100-mesh sieve to obtain modified pottery clay.

preparation example 2

[0041] Preparation example 2 of modified pottery clay: 1. add 15% of its weight to the potter's clay with a 5wt% hydrochloric acid solution to obtain acidified potter's clay;

[0042] ②The acidified pottery clay was roasted at 650°C for 3 hours, crushed and sieved to obtain roasted pottery clay;

[0043] ③ Take 30kg of water, 12.5kg of polyvinylpyrrolidone, 5kg of microcrystalline cellulose, 4kg of sodium lauryl sulfate, and 0.4kg of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, Mix evenly to obtain modifier;

[0044] ④Add 11% modifier by weight to the calcined pottery clay, stir at 1500r / min for 25min, dry at 120°C for 6h, and then pulverize through a 100-mesh sieve to obtain modified pottery clay.

preparation example 3

[0045] Preparation example 3 of modified pottery clay: 1. add 20% of its weight of 5wt% hydrochloric acid solution to pottery clay to obtain acidified pottery clay;

[0046] ②The acidified pottery clay was roasted at 700°C for 4 hours, crushed and sieved to obtain roasted pottery clay;

[0047] ③ Take 30kg of water, 15kg of polyvinylpyrrolidone, 6kg of microcrystalline cellulose, 5kg of sodium lauryl sulfate, 0.5kg of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, and mix Uniform, get the modifier;

[0048] ④Add 12% modifier by weight to the calcined pottery clay, stir at 2000r / min for 30min, dry at 120°C for 6h, and then pulverize through a 100-mesh sieve to obtain modified pottery clay.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com