Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Achieving superhydrophobicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

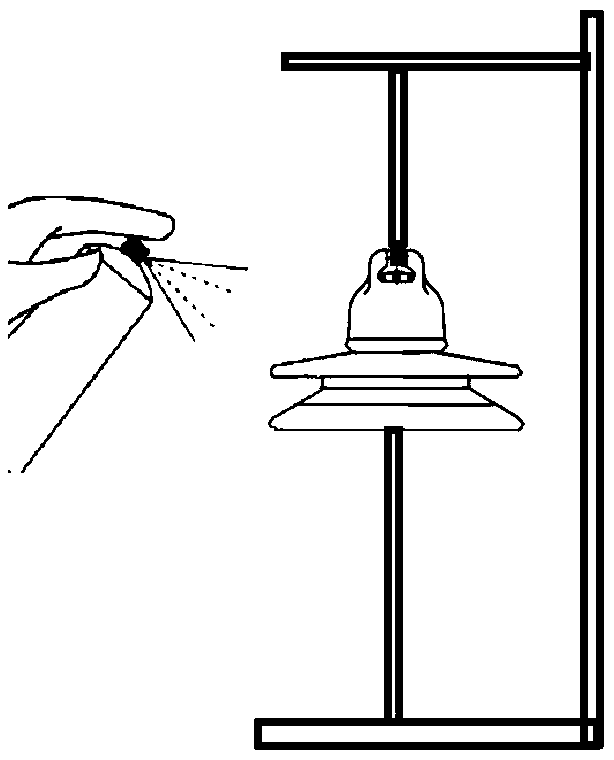

Super-hydrophobic conformal coating, and preparation method and application method thereof

InactiveCN107446424AImprove overall performanceGood weather resistanceAntifouling/underwater paintsPretreated surfacesChemistryNanometre

The invention discloses a super-hydrophobic conformal coating, and a preparation method and an application method thereof. The super-hydrophobic conformal coating is composed of, by mass, 5 to 40% of fluorocarbon resin, 10 to 30% of fluorosilicon resin, 20 to 60% of an organic solvent, 10 to 30% of silica, 1 to 10% of titanium dioxide, 1 to 10% of polytetrafluoroethylene, 0.1 to 0.5% of a catalyst, and 1 to 5% of a curing agent. According to the preparation method, the ingredients are subjected to stirring mixing and ultrasonic uniform dispersion in sequence at a certain ratio. According to the application method, the super-hydrophobic conformal coating is subjected to direct spraying or brush coating onto the surfaces of insulators and outdoor electric power facilities; the thickness of obtained coating layers is controlled to be 0.1 to 0.5mm preferably; and 20 to 60min of normal temperature curing is needed. The preparation method is simple; the cost is low; the super-hydrophobic conformal coating is convenient to use, possesses extremely high hydrophobicity and weatherability, is capable of realizing self cleaning, is a nanometer composite hybrid normal-temperature cured fluorocarbon coating, is capable of realizing stain prevention, pollution flashover prevention, and corrosion prevention of insulators and outdoor electric power facilities effectively, and is promising in application prospect.

Owner:昆明理工大电力工程技术有限公司

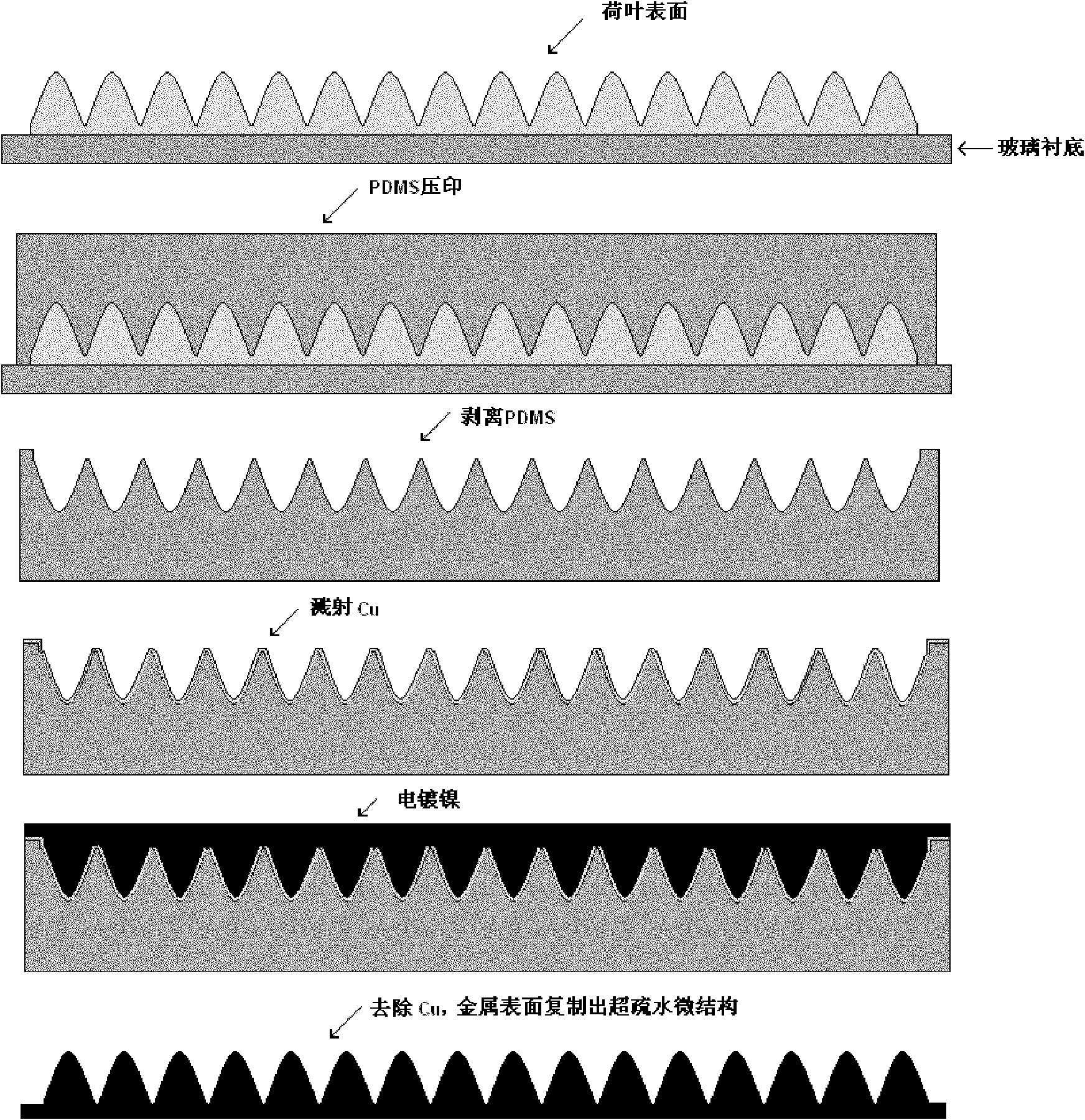

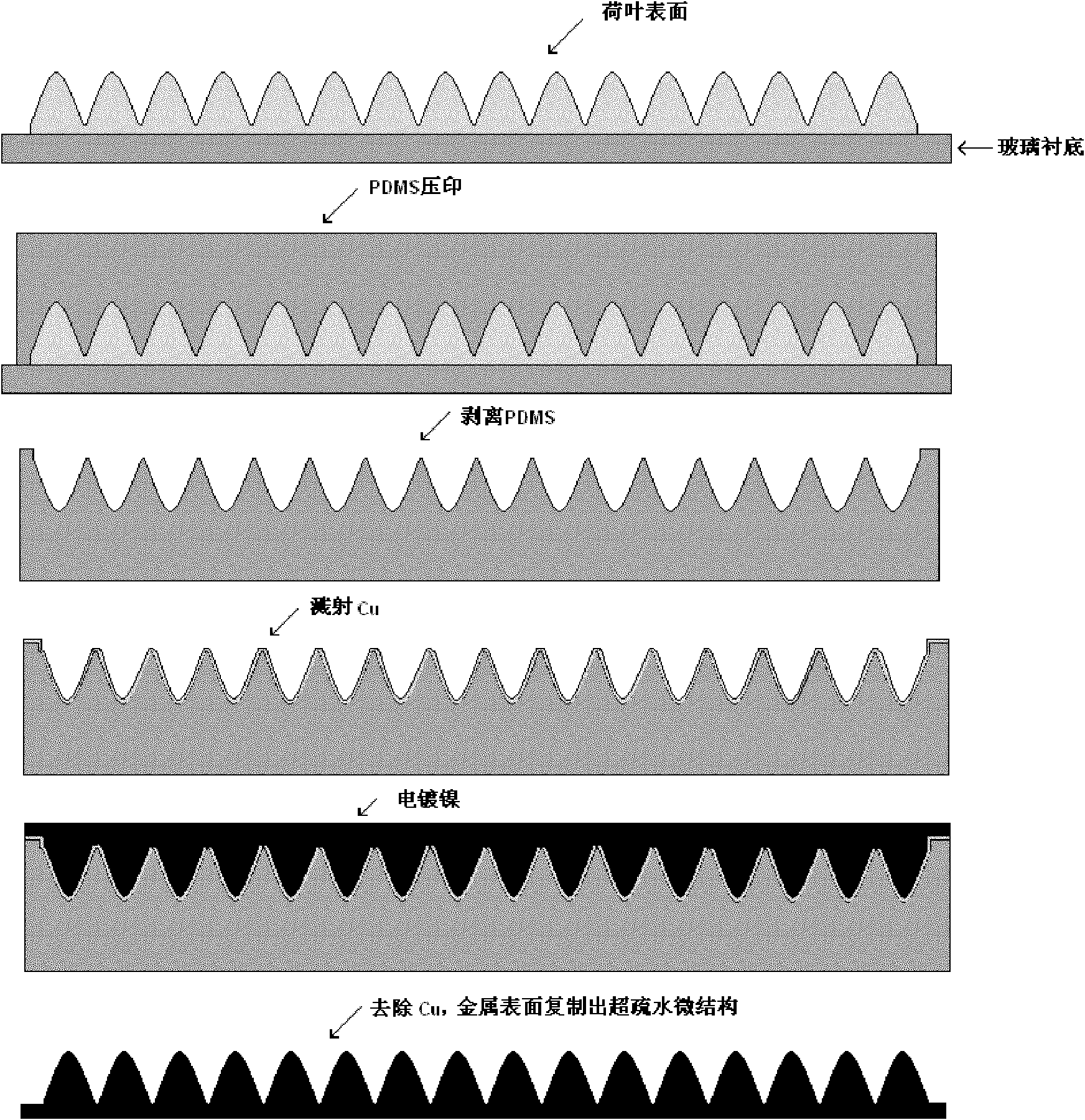

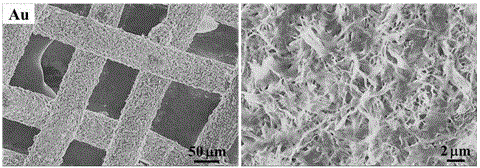

Preparation method of metal-base superhydrophobic material

InactiveCN102011153AHigh cost savingsEasy to moveElectroforming processesMetallic materialsStrong acids

The invention relates to a preparation method of a metal-base superhydrophobic material, belonging to the technical field of superhydrophobicity. The method comprises the following steps: using a pretreated hydrophobic substrate as the template; duplicating with dimethyl polysiloxane to obtain a disordered array structure; growing engineering metal material on the disordered array structure, and coating a low-surface-energy layer, so as to realize the superhydrophobicity. The method does not need to use strong acid or toxic substances, thereby being safe and environment-friendly; the materials used in the technique are easy to obtain and cheap; and the metal-base superhydrophobic material has the advantages of favorable metallic conductivity, high strength, favorable mechanical properties and the like, and the application range is greatly widened as compared with the that of prior polymer superhydrophobic material.

Owner:SHANGHAI JIAO TONG UNIV

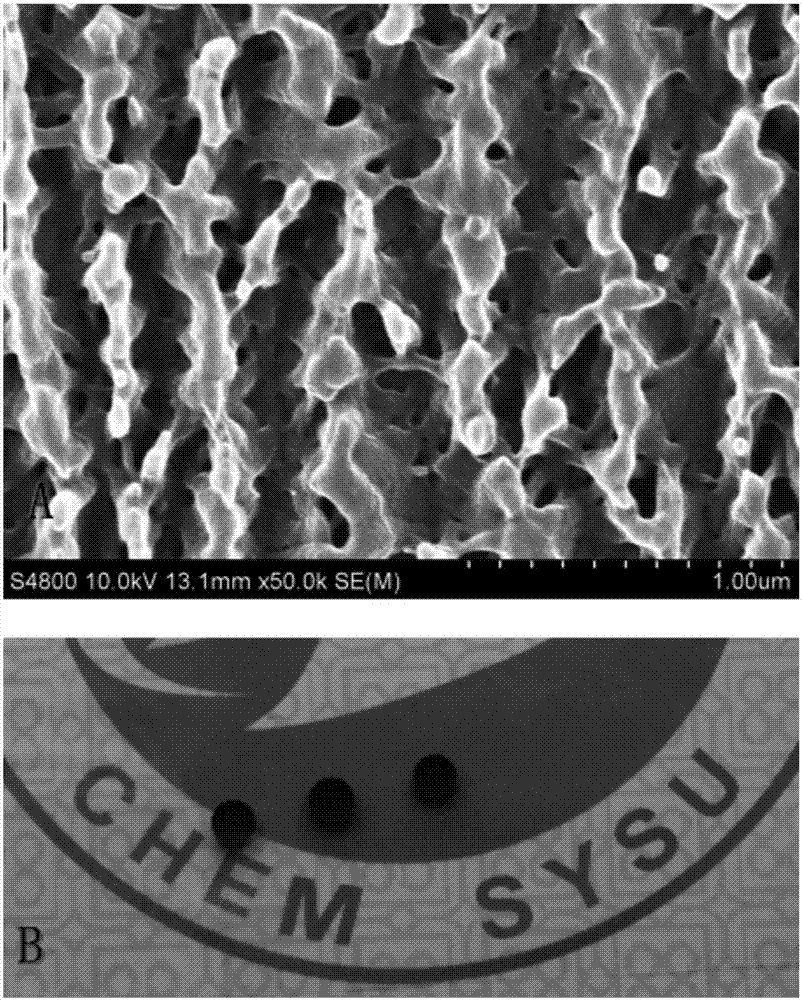

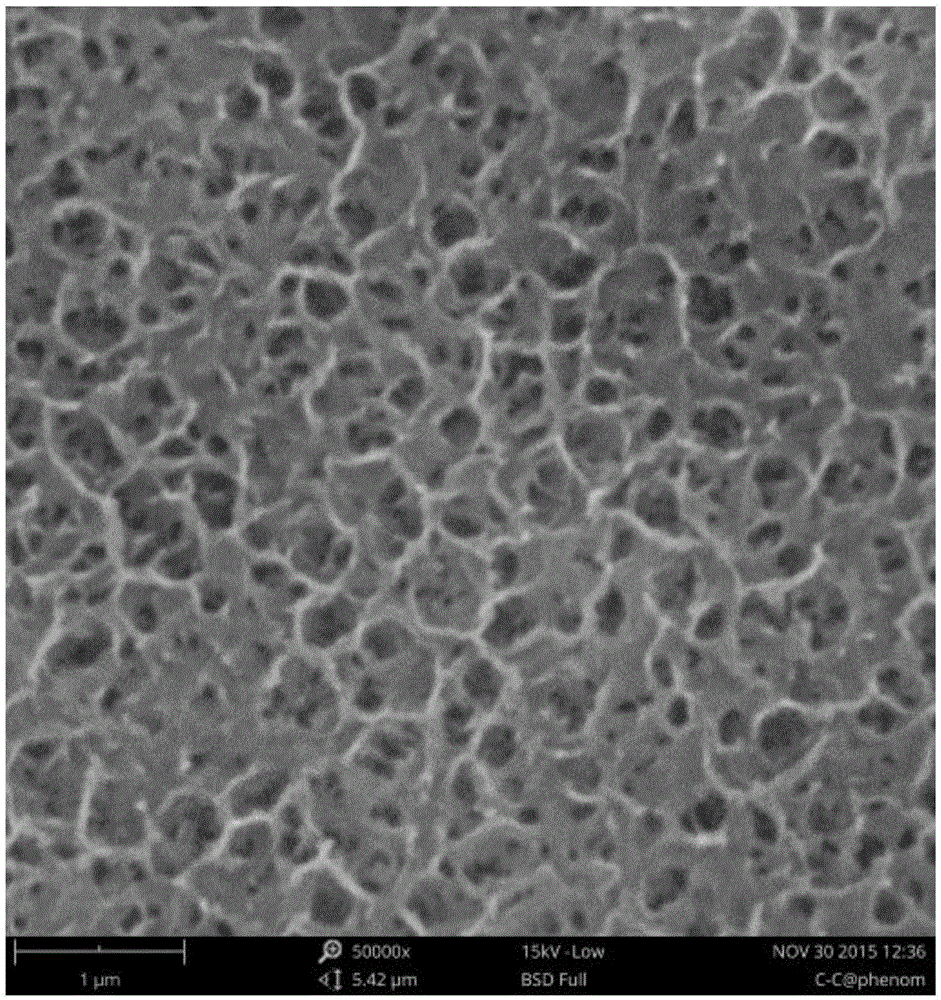

Preparation method for transparent super hydrophobic polymer thin films

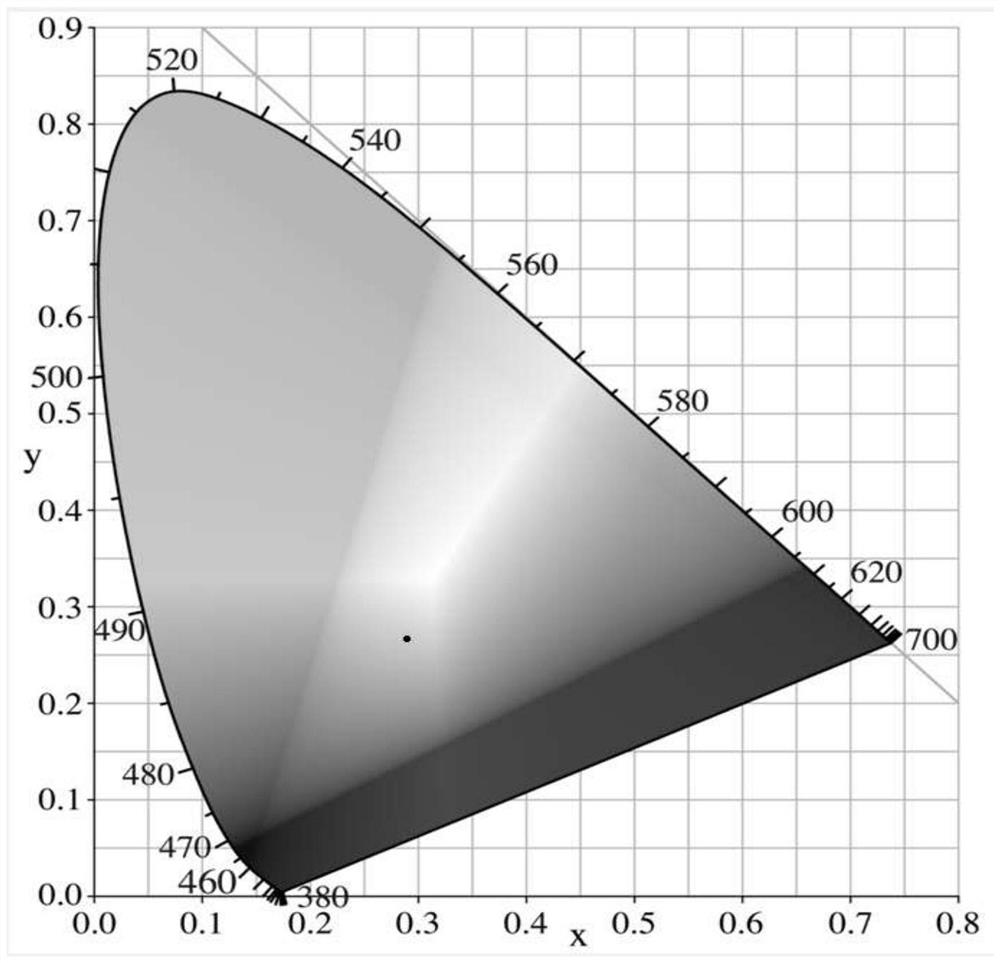

The invention provides a preparation method for transparent super hydrophobic polymer thin films; the transparent polymer thin films are prepared by tape casting or directional stretching and other molding processes, a special structure of nano mastoids and grooves is formed on the surface of the polymer thin films by a supercritical CO2 foaming method, and super hydrophobicity and low reflection are achieved while the transparency is kept. The method is suitable for various thermoplastic polymer thin films, and all the thermoplastic transparent polymer thin films with various thickness and areas can be made to have super hydrophobic surfaces by the method. By adjusting supercritical CO2 foaming technological conditions including the temperature, the pressure, the soaking time and the pressure relief rate, and with utilization of a covering object to limit the gas diffusion rate of the thin film surface, the nano structure (the nano mastoid size, the groove depth and width and the like) of the thin film surface can be adjusted conveniently, and thus the super hydrophobicity is achieved while the transparency of the polymer thin films is kept.

Owner:SUN YAT SEN UNIV

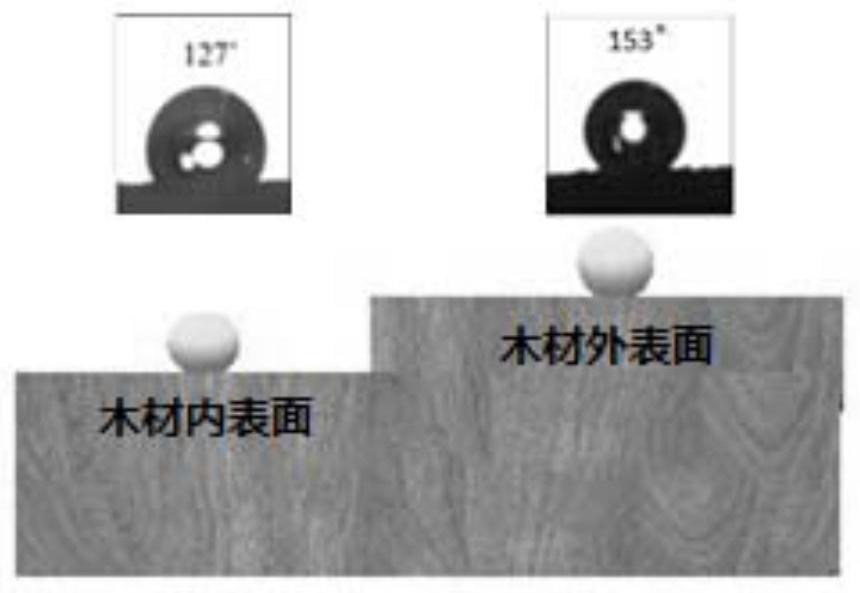

Preparation method of super-hydrophobic-hydrophilic wood with intelligent temperature response

InactiveCN104802249AGood self-cleaning effectAdhesiveWood treatment detailsWood impregnation detailsTemperature responseAlcohol

The invention relates to a preparation method of super-hydrophobic-hydrophilic wood with intelligent temperature response and belongs to the field of super-hydrophobic wood. The super-hydrophobic wood prepared by the method has the hydrophilic reversible characteristic which is not owned by the previous super-hydrophilic wood. A contact angle between the super-hydrophobic wood and water is greater than 150 degrees; a rolling angle is smaller than 10 degrees; the super-hydrophobic-hydrophilic wood is excellent in super-hydrophobic performance and good in self-cleaning performance. The preparation method of the super-hydrophobic-hydrophilic wood with the intelligent temperature response comprises the following steps: soaking the wood in a silicon dioxide aqueous solution, drying, then uniformly and dropwise coating the surface of the wood with polycaprolactone dissolved in a mixed solution of methyl alcohol and chloroform, and finally drying in vacuum. The wood shows the intelligent temperature response in the cross section. The method is simple in process, low in cost, short in period, low in energy consumption and free of special complicated equipment; the prepared super-hydrophobic-hydrophilic wood with the intelligent temperature response is capable of converting the wettability for hundreds of times under high and low temperatures; the prepared super-hydrophobic-hydrophilic wood has a great application prospect in the future.

Owner:GUANGDONG YIHUA TIMBER IND

Micro-injection molding mould with super-hydrophobic surface of micro-nano composite structure and micro-injection molding method

ActiveCN107199671AEasy and flexible installationEasy to disassemble flexiblyElectrochemical machining apparatusCleaning using liquidsMicro structureMicro nano

The invention discloses a micro-injection molding mould with a super-hydrophobic surface of a micro-nano composite structure and a micro-injection molding method. The mould comprises a fixed template. A movable template which can move up and down is arranged below the fixed template, an injection molding cavity is formed between the fixed template and the movable template, and a mould core is mounted in the injection molding cavity; the mould cover comprises a stainless steel made micro punched-plate and a nano aluminum alloy plate. And a micro-structure surface of the micro punched-plate and a nano structure surface of the nano aluminum alloy plate are laminated and overlaid. The mould disclosed by the invention is simple and practical. The prepared super-hydrophobic surface is good in hydrophobic property, surface treatment steps in a later period are reduced, and the problem that in the prior art, the processing difficulty of the super-hydrophobic surface is great, the mould core is poor in tolerance and the prepared super-hydrophobic surface is poor in hydrophobic property.

Owner:CENT SOUTH UNIV

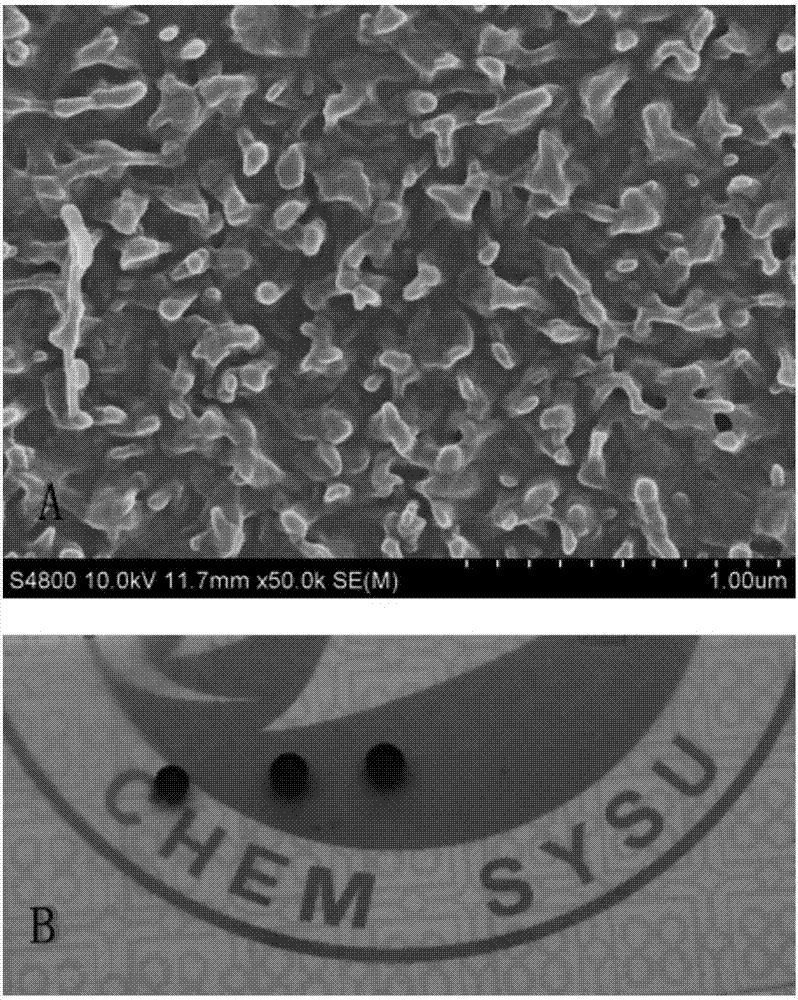

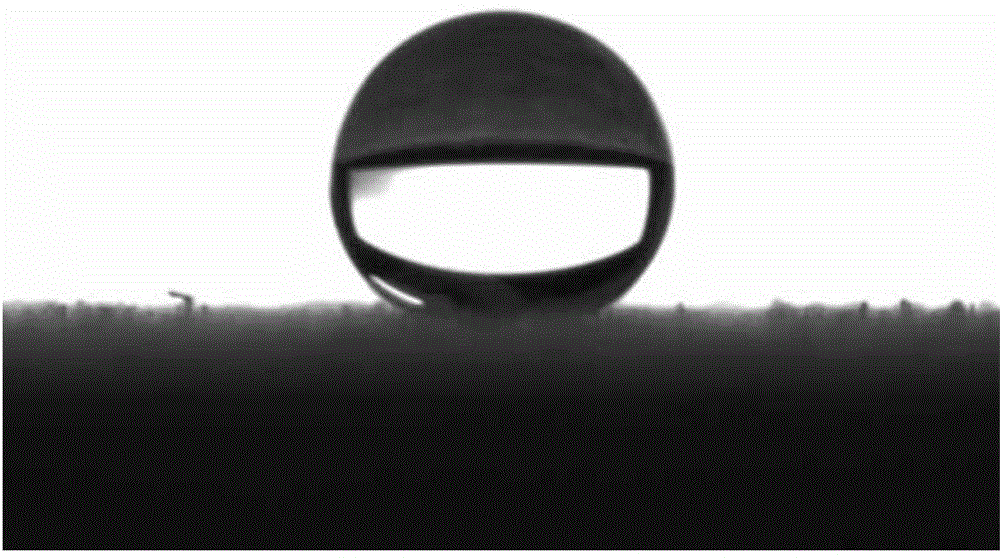

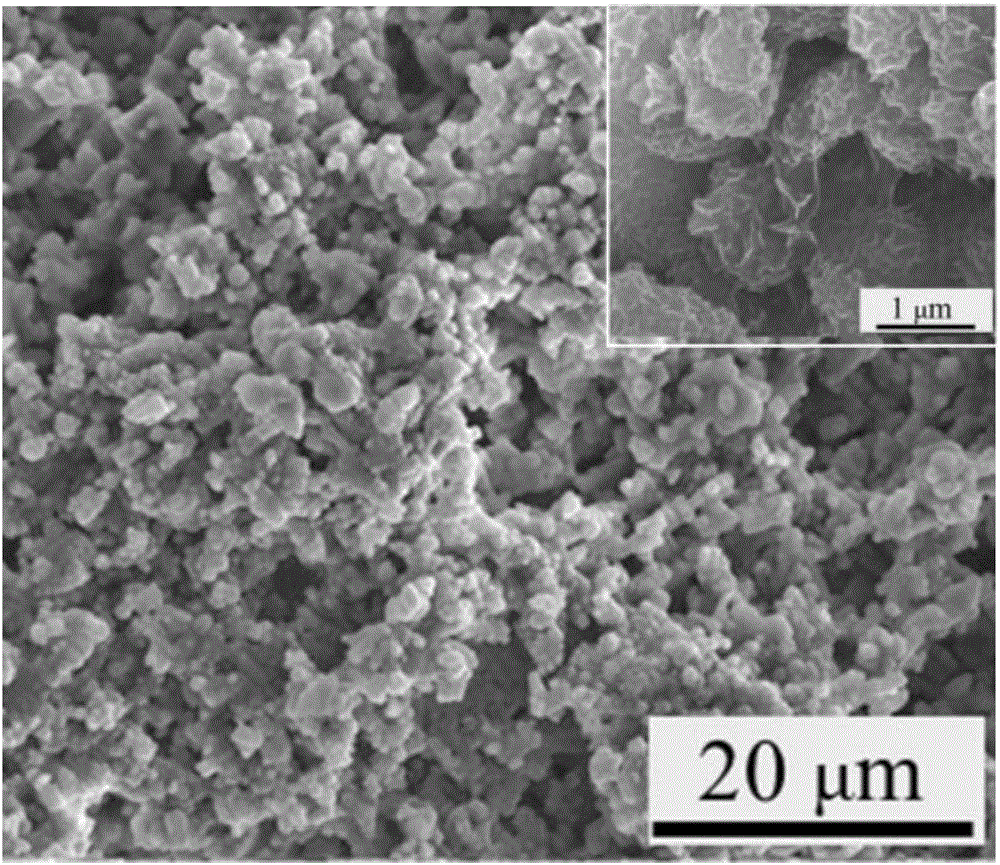

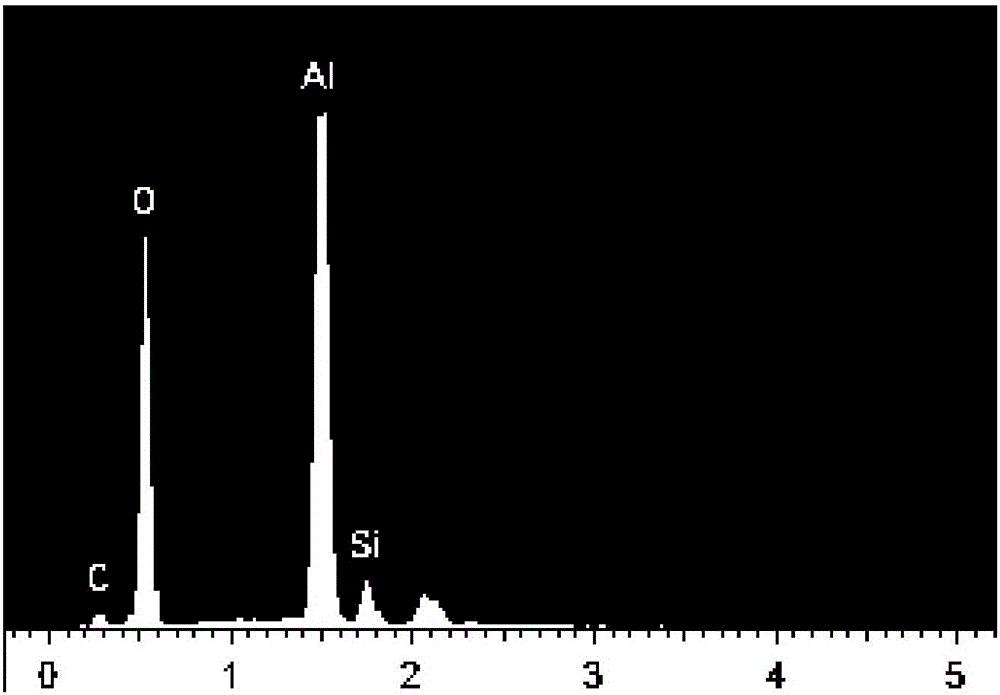

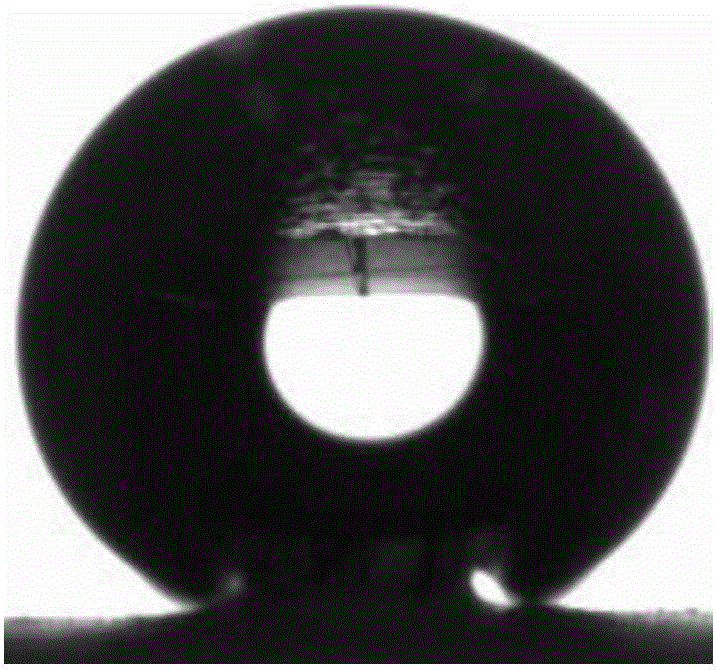

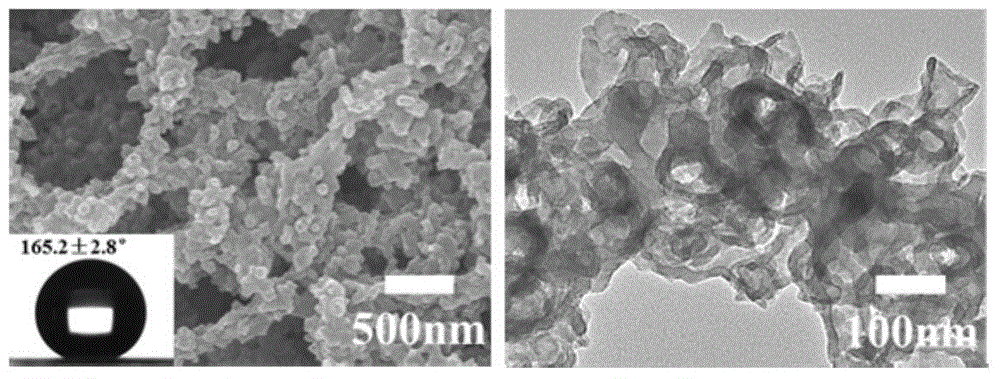

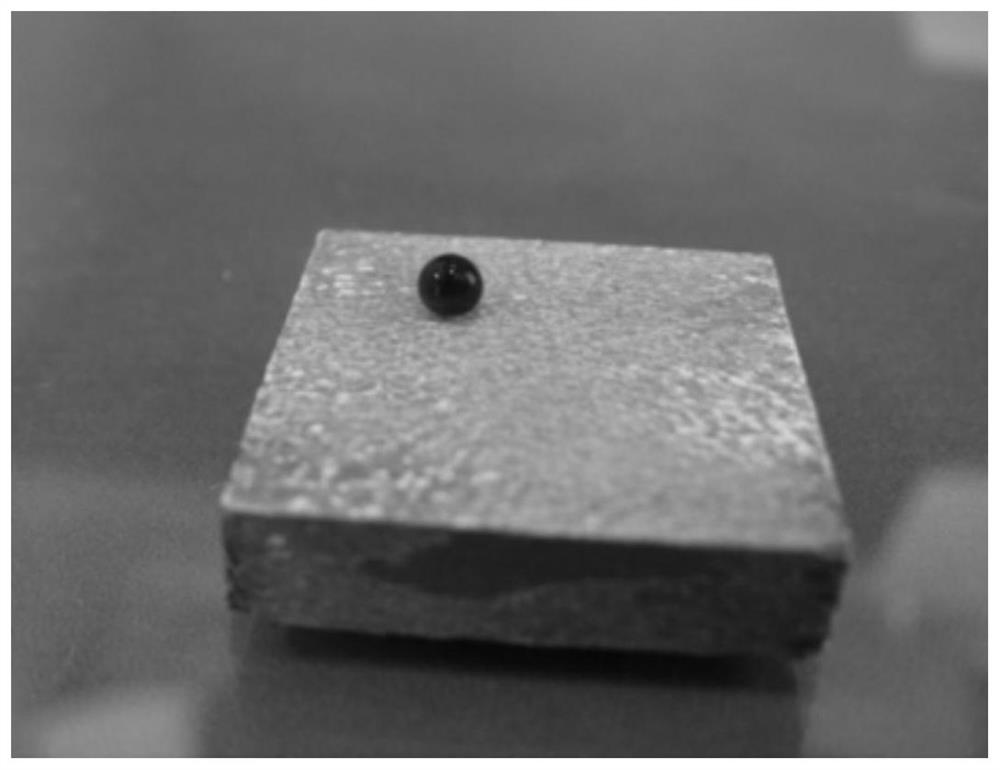

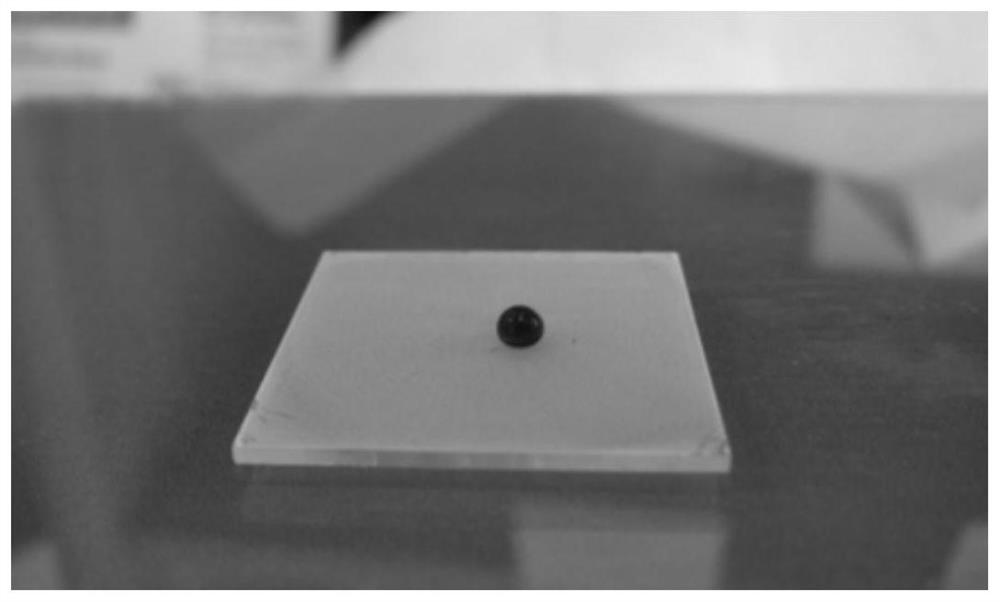

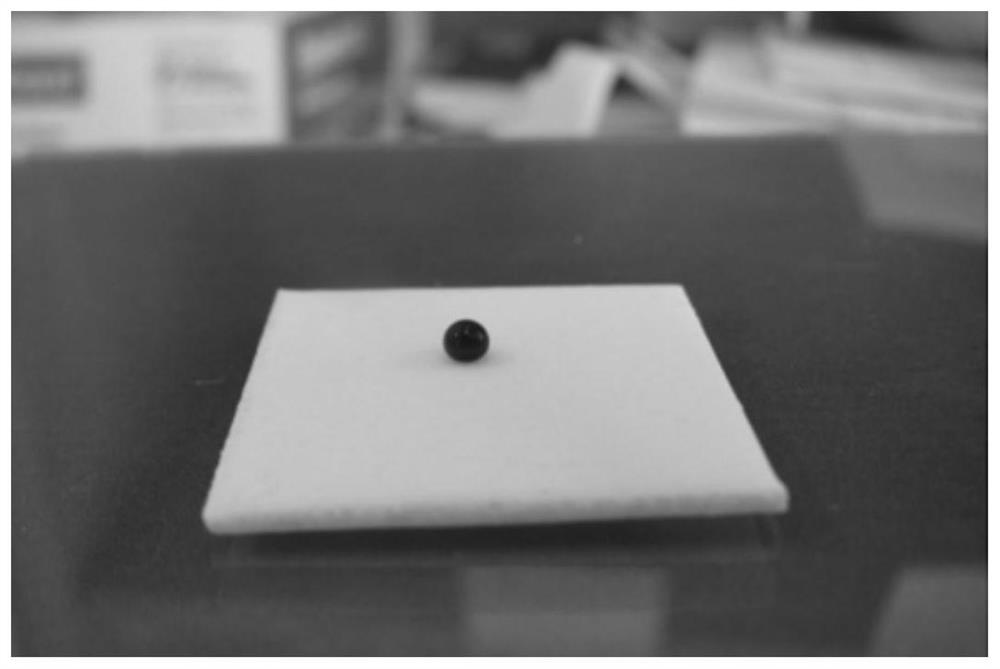

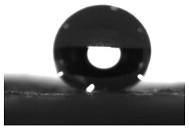

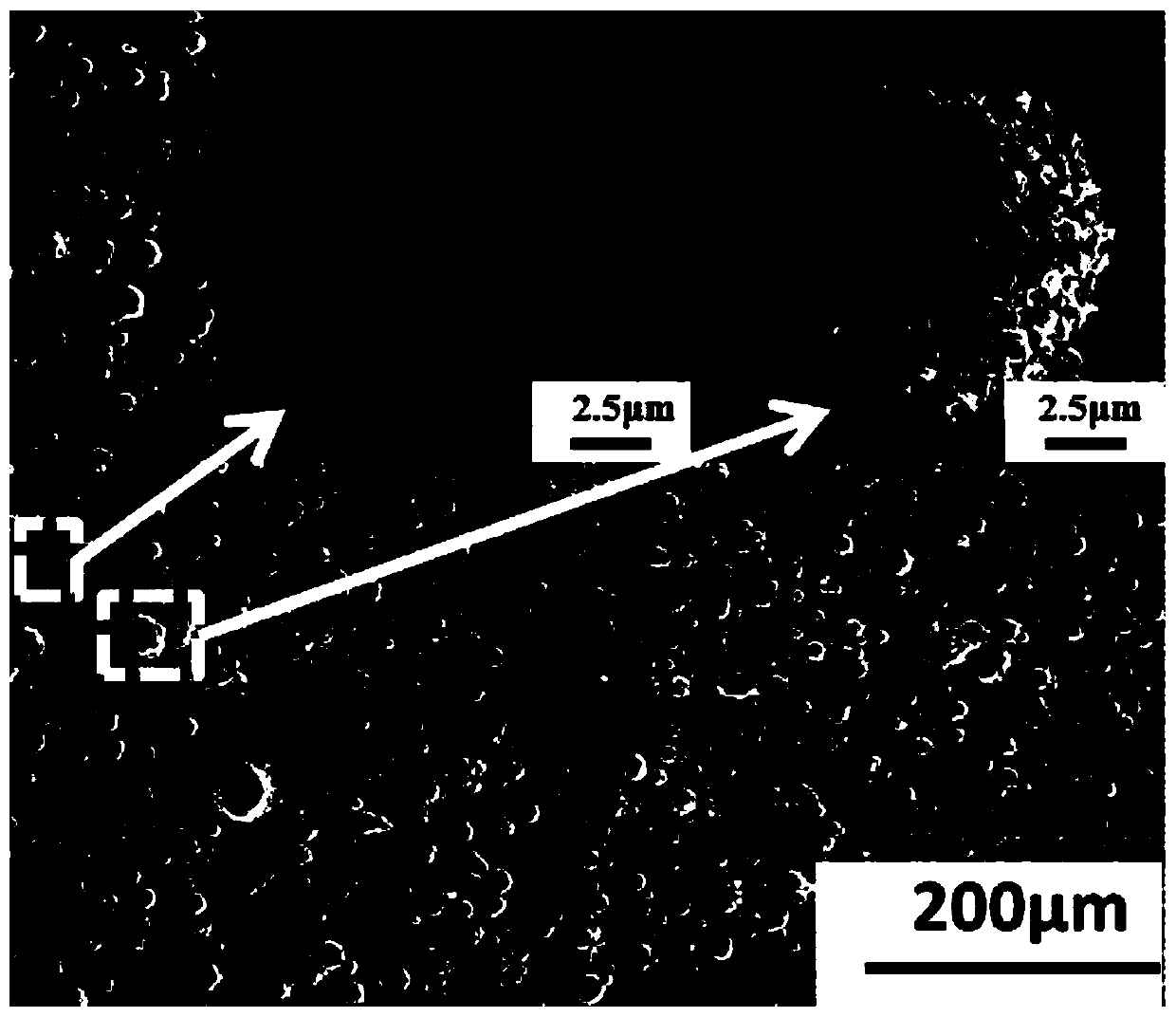

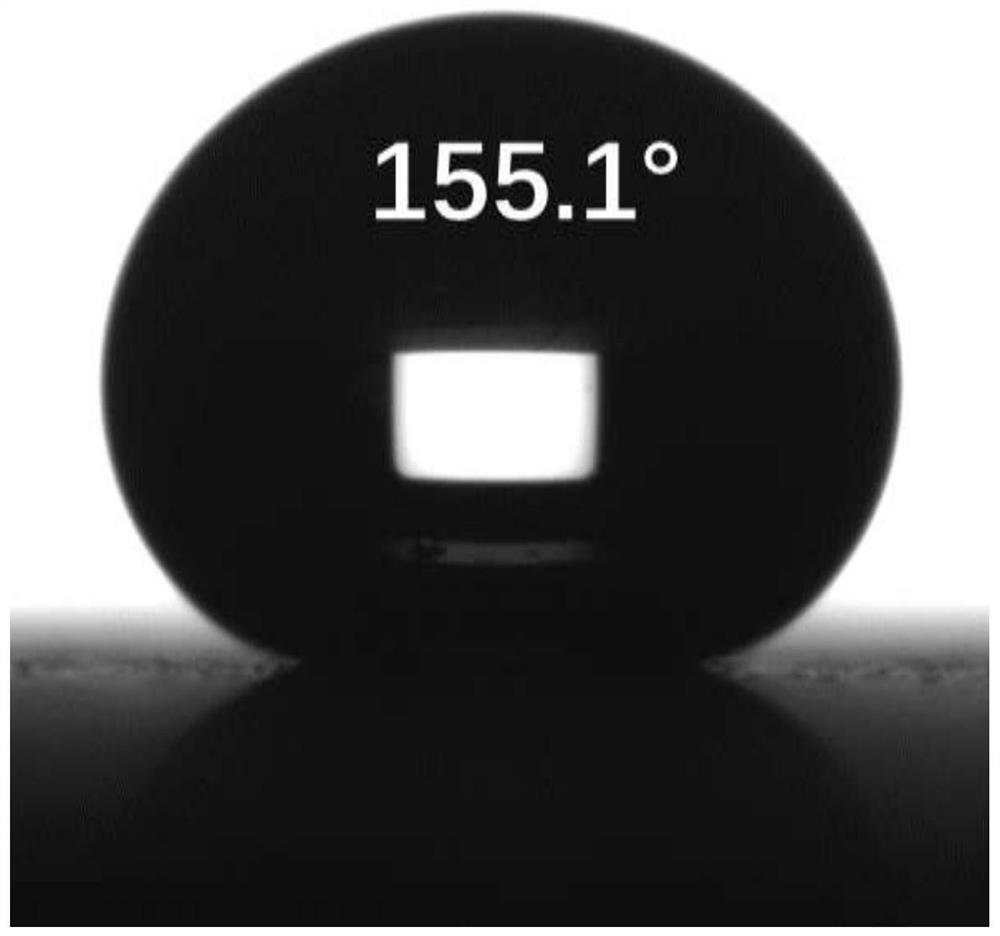

Preparation method for fluoride-free, non-toxic, economic and efficient aluminium-based superhydrophobic material

InactiveCN105921380AReduce resistanceImprove corrosion resistancePretreated surfacesCoatingsOrganic filmSuperhydrophobe

The invention discloses a preparation method for a fluoride-free, non-toxic, economic and efficient aluminium-based superhydrophobic material. The preparation method comprises the following steps: stably obtaining a micrometer-nanometer binary composite graded structure from aluminium and aluminium alloy through simple hydrochloric acid etching and water boiling sequentially; spin-coating a layer of fluoride-free, non-toxic and cheap polydimethylsiloxane solution on the micrometer-nanometer graded aluminium-based surface by virtue of a spin-coating method, curing and then forming an organic film layer, and thus achieving a superhydrophobic surface having a contact angle of 158 degrees with water and having a rolling angle of 2 degrees. The superhydrophobic surface is superhydrophobic with strong acid and strong base, and has high lasting stability due to the protection effect of the organic film layer. The superhydrophobic surface disclosed by the invention has the characteristics of being fluoride-free, non-toxic, simple and convenient to operate, economic and efficient.

Owner:SOUTH CHINA UNIV OF TECH

Room-temperature-curing super-hydrophobic coating specially used for electricity, and preparation and use methods of same

ActiveCN109554036AImprove performanceImprove insulation performanceAntifouling/underwater paintsPaints with biocidesElectricityOrganic solvent

The invention discloses a room-temperature-curing super-hydrophobic coating specially used for electricity, and preparation and use methods of same. The coating includes, by mass, 50%-63% of an organic solvent, 10%-20% of hydrophobic nanoparticles, 1%-2% of a silane coupling agent, 10%-25% of fluorocarbon resin, 7%-20% of acrylic resin, and 0.5-1% of an odor-covering agent. The components are stepwise stirred and mixed and then are ultrasonically dispersed uniformly to make the coating. The use method of the coating includes fill-packaging the coating and directly spray-coating surface of facilities therewith, wherein the thickness of the coating layer only need to avoid sagging phenomenon, and curing the coating for 30 min to 2 h according to the thickness at room temperature. The super-hydrophobic coating is simple in preparation method and low in cost, is convenient to use, has super-hydrophobicity and weather resistance, has insulation performance, and has wide application prospect.

Owner:昆明理工大电力工程技术有限公司

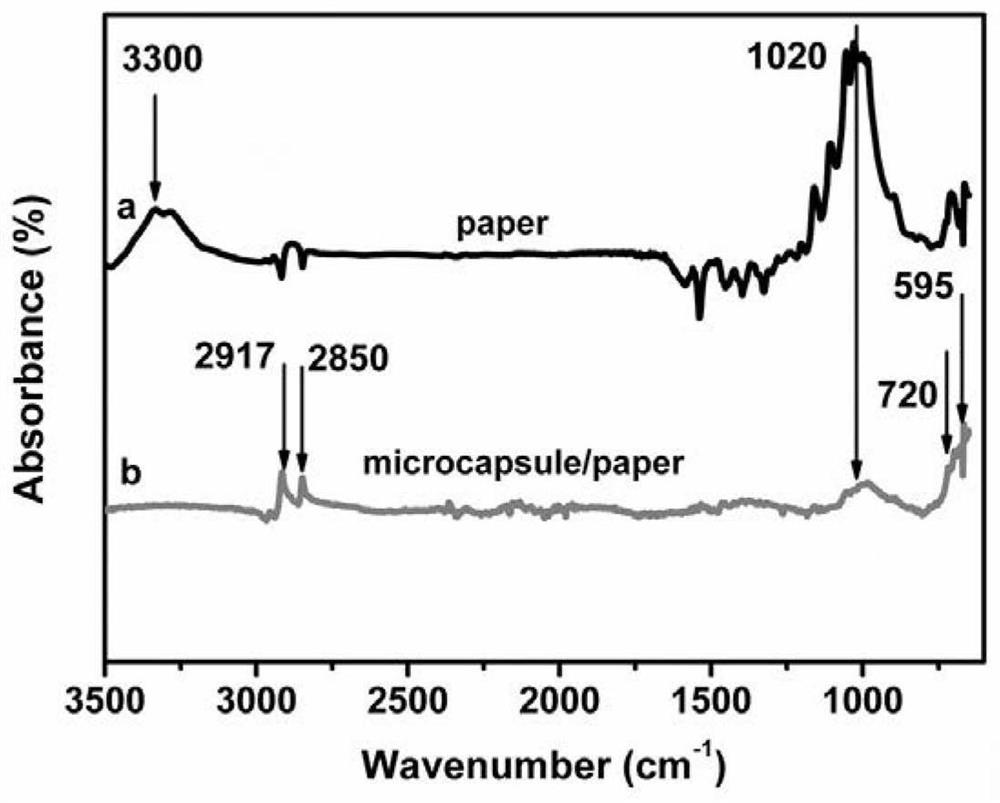

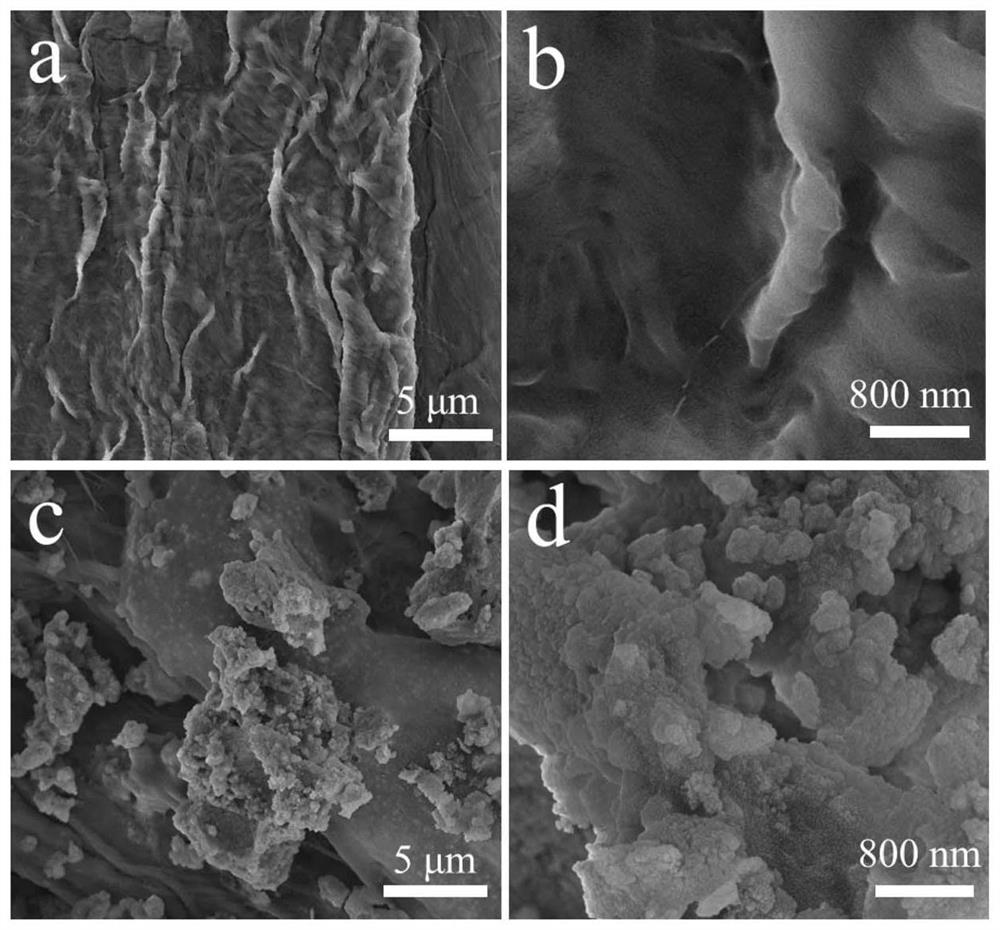

Preparation method of super-hydrophobic paper

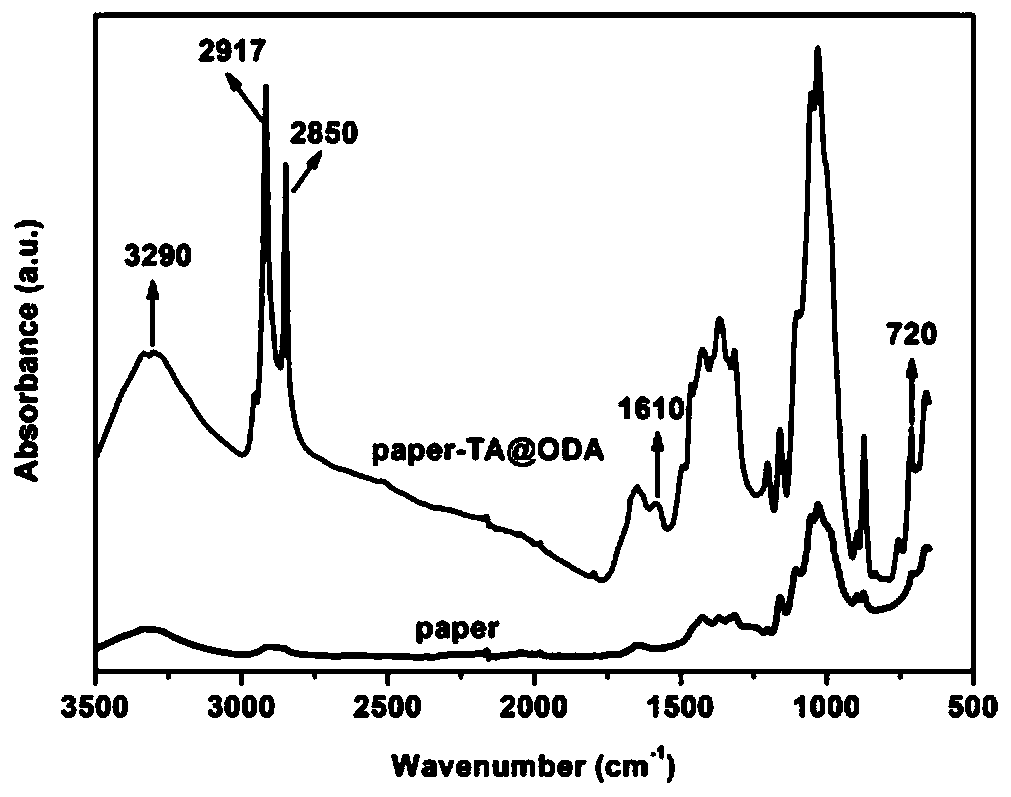

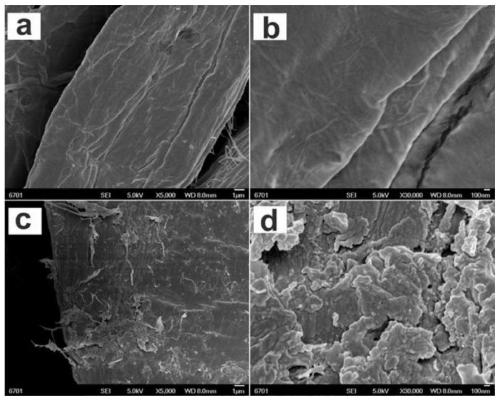

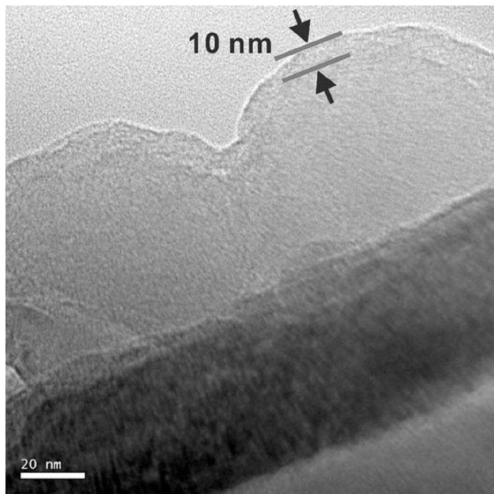

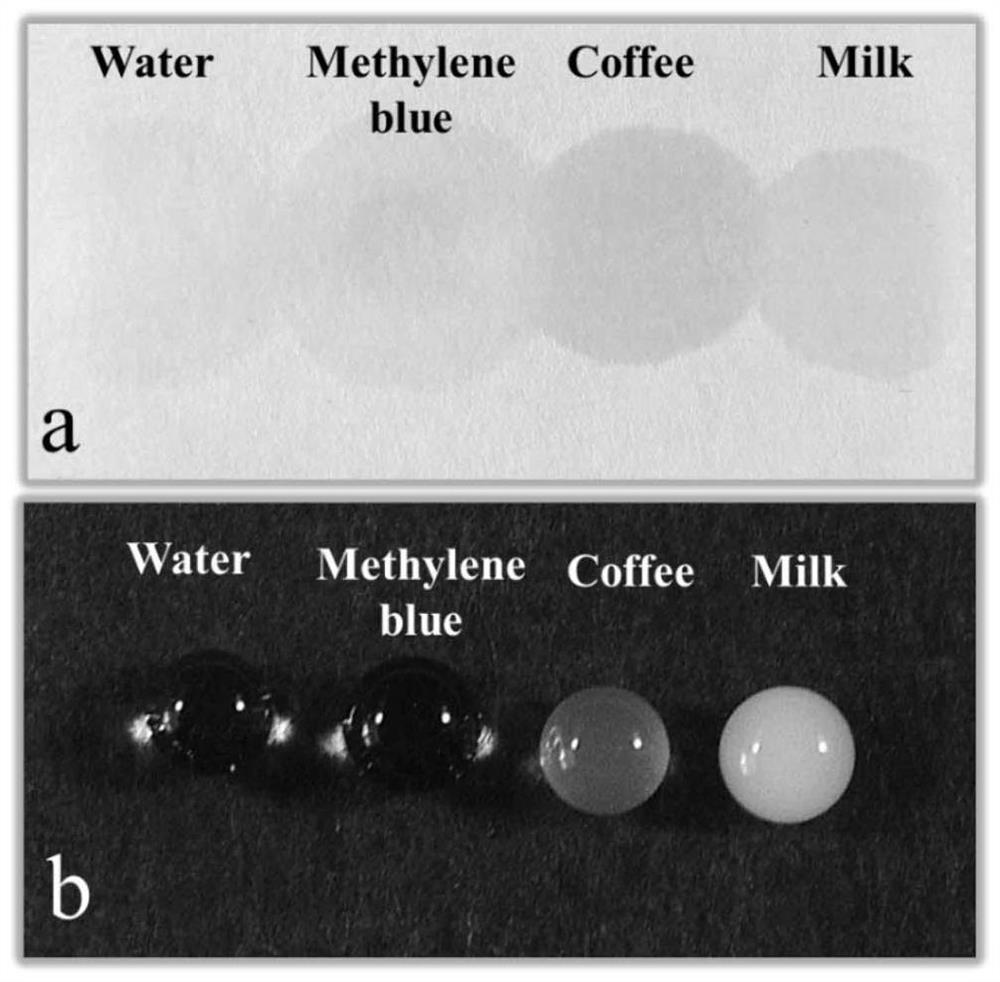

ActiveCN111549568AAchieving superhydrophobicityImproves UV resistanceWater-repelling agents additionNon-macromolecular organic additionAluminium chlorideFiber

The invention discloses a preparation method of super-hydrophobic paper, wherein the preparation method comprises the following steps: step 1, carrying out ultrasonic emulsification on octadecylamineto obtain an octadecylamine emulsion; step 2, uniformly mixing the octadecylamine emulsion with paper pulp in proportion to form an octadecylamine-paper pulp mixed solution; step 3, adding tannic acidand aluminum chloride hexahydrate into the octadecylamine-paper pulp mixed solution, adjusting the pH value, and carrying out a stirring reaction to form tannic acid@octadecylamine microcapsule (TA@ODA) modified paper fiber pulp; and step 4, centrifuging, flattening and drying the paper fiber pulp to obtain the super-hydrophobic paper. Compared with a traditional method, the preparation method ofthe super-hydrophobic paper provided by the invention does not need complex instruments and equipment, does not need a complex synthesis process, does not need too long time, and has the advantages of simple operation, convenience, environmental protection and the like, and the prepared super-hydrophobic paper has good super-hydrophobic performance, good durability and self-repairing performance.

Owner:LANZHOU JIAOTONG UNIV

Method for preparing super hydrophobic coating on copper or copper alloy net

InactiveCN102877047ASimple manufacturing processAvoid the process of groomingLiquid/solution decomposition chemical coatingChemical platingRepeatability

The invention discloses a method for preparing a super hydrophobic coating on copper or a copper alloy net without surface modification. A precious metal nanometer coating is plated on the copper or the copper alloy net by adopting a chemical plating method, the coating is not needed to be modified by substance with low surface energy, and the coating is converted into a super hydrophobic coating after being placed in air for a certain period of time. According to the method adopted by the invention, the technology is simple, the operation is easy, the repeatability is good, and the method is applicable to the large-scale production of the super hydrophobic coating.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

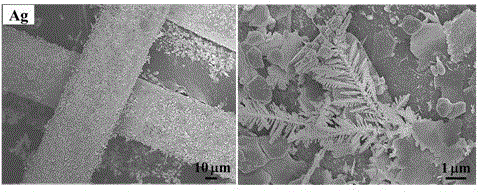

Preparation technology for super-hydrophobic surface of 7075 aluminum alloy

ActiveCN108857273ASmall grain sizeSuperhydrophobicLaser beam welding apparatusRoom temperatureMegasonic cleaning

The invention discloses a preparation technology for the super-hydrophobic surface of a 7075 aluminum alloy, and belongs to the field of electrodeposition application. The problems of super-hydrophobic structure preparing are solved. The preparation technology comprises the following steps that the surface of the aluminum alloy is ground through metallographic sandpaper to be smooth; the ground workpiece surface is polished through a metallographic sample polishing machine, and put into deionized water to be ultrasonically washed; a pit-shaped structure is constructed in the polished workpiecesurface through a laser marking machine, and the polished workpiece surface is placed in the deionized water to be ultrasonically washed and dried; a workpiece substrate subjected to laser treatmentis subjected to nickel ion electrodeposition, and placed in the deionized water to be ultrasonically washed, wherein the electrodeposition time of the workpiece is controlled at about 4 min, and the components of a plating solution comprise NiSO4.6H2O, ammonium citrate tribasic, ammonium hydroxide and ammonium acetate; and the deposited surface is placed in a dry box to be heated at the temperature of 150 DEG C, heat preservation is conducted for 2 hours, and the surface is cooled along with a furnace to the room temperature. The hydrophobicity of the surface reaches better, and the hydrophobic contact angle of the surface subjected to laser electrodeposition composite preparation reaches 152 degrees.

Owner:CHANGCHUN UNIV OF SCI & TECH

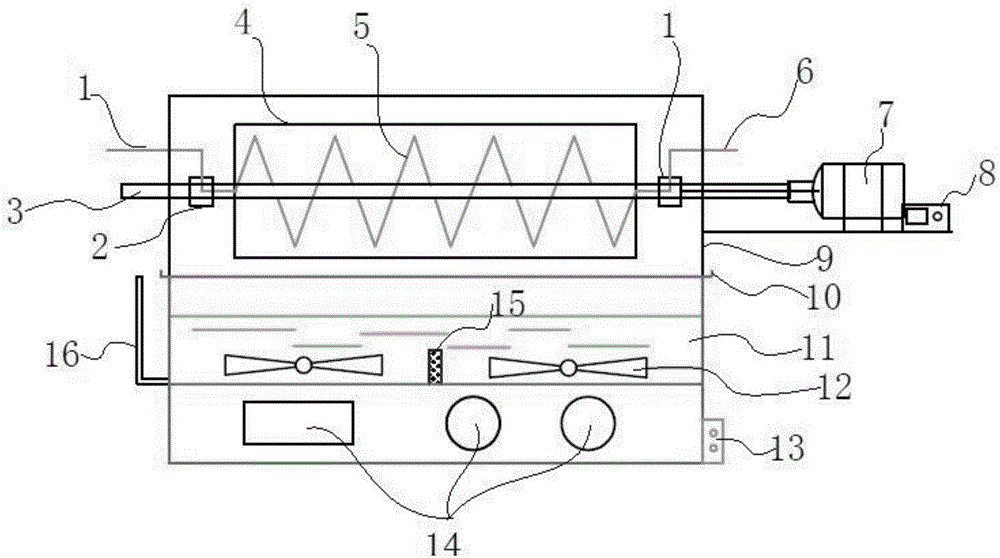

Preparing method for graphene oxide super-hydrophobic coating and coating evaporation device

InactiveCN106756786ANot easy to peel offExtended service lifeVacuum evaporation coatingSputtering coatingTime rangeCoated surface

The invention discloses a preparing method for a graphene oxide super-hydrophobic coating. The method comprises the steps that an evaporation method is utilized for evaporation of a graphene oxide solution to a metal base, and an inner coating is formed, wherein according to the evaporation conditions of the inner coating, the evaporation temperature ranges from 35 DEG C to 95 DEG C, and the non-vacuum evaporation time ranges from 0.5 h to 3 h; and organic matter with the low surface energy is subjected to evaporation to the inner coating through the evaporation method to become an outer coating, according to the evaporation conditions of the outer coating, the non-vacuum evaporation is conducted for 0.5-3 h at the temperature ranging from 100 DEG C to 150 DEG C, and then drying is conducted for 1-3 h at the temperature ranging from 140 DEG C to 160 DEG C. The invention further discloses a coating evaporation device. The coating evaporation device comprises an upper roller type device and a lower evaporation device. The surface contact angle of the prepared super-hydrophobic graphene oxide coating is 150 degrees or above, the super-hydrophobic graphene oxide coating can effectively restrain adhesion and corrosion of water vapor, oil dirt and the like through special structures between coating bodies, peeling is not likely to happen, the service life is long, large-scale production is convenient to achieve, and the super-hydrophobic graphene oxide coating can be widely applied to the fields of self cleaning, corrosion preventing and the like.

Owner:SHANGHAI UNIV

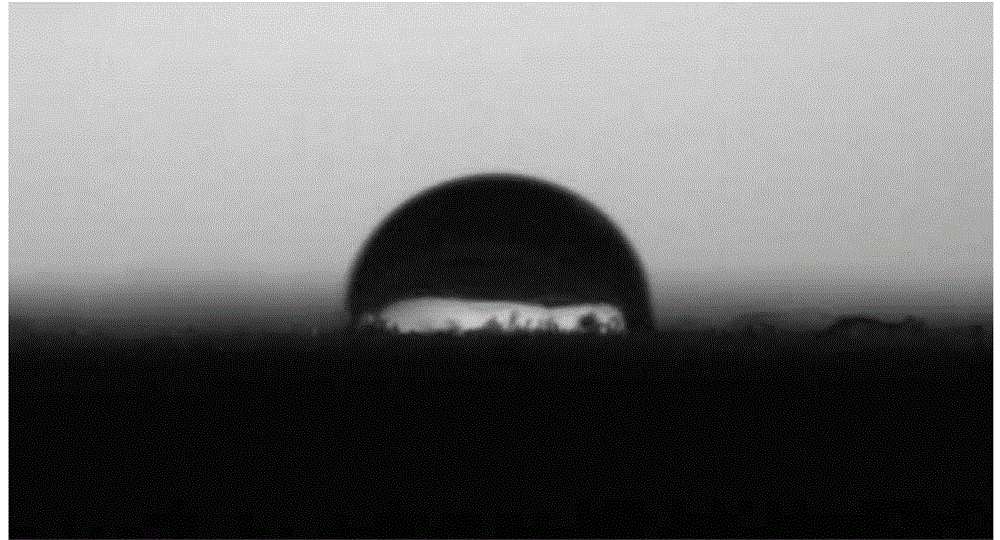

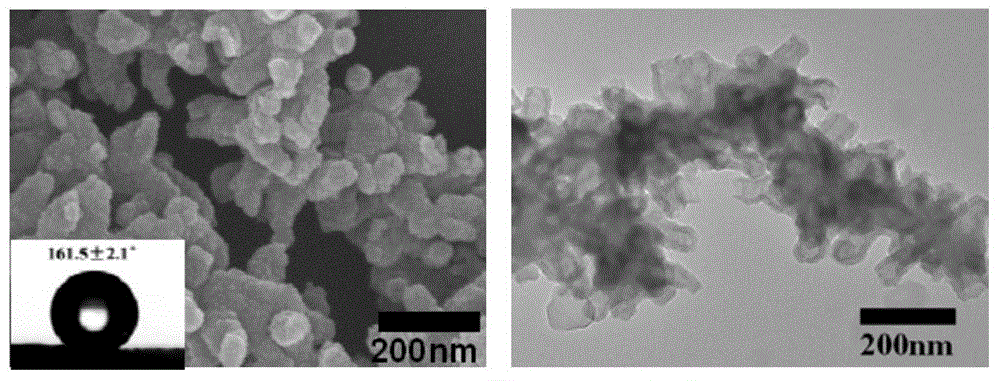

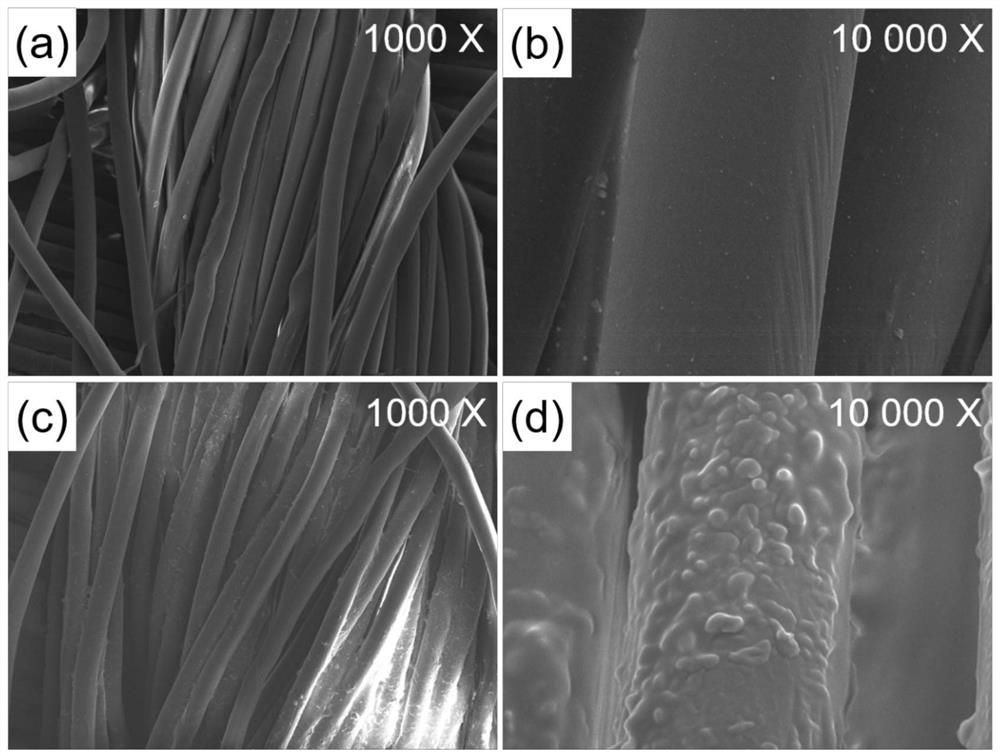

Preparation method and application of super-hydrophobic nanofibers of coral structure

InactiveCN104695035ASimple manufacturing methodUniversalMonocomponent synthetic polymer artificial filamentMicrometerNanofiber

The invention provides nanofibers of a coral structure. The nanofibers are characterized in that the diameters of the nanofibers are 10-500 nm, and the lengths of the nanofibers are over 1 micrometer. Protrusions evenly distributed are formed on the surfaces of the nanofibers, the diameters of the protrusions are 1-200 nm, and the lengths of the protrusions are 1-500 nm. The invention further provides a super-hydrophobic material which is characterized by comprising the nanofibers of the coral structure. The contact angle of the surface of the hydrophobic material is larger than 150 degrees, and the rolling angle is smaller than 5 degrees.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Super-hydrophobic coating as well as preparation method and application thereof

ActiveCN113292876AEasy constructionAchieving superhydrophobicityCoatingsCoatings without pigmentsCoating

The invention provides a super-hydrophobic coating as well as a preparation method and application thereof. The coating can be smeared on the surfaces of flexible or rigid materials, can also be smeared on flat or rough substrates made of plastics, metals and the like, can realize the functions of self-cleaning, water resistance, freezing resistance, fog resistance, fluid resistance reduction and corrosion resistance, and can be widely applied to the fields of buildings, household appliances, traffic transportation, clothing, electronic devices, liquid transportation and the like.

Owner:GUANGZHOU UNIVERSITY

Superhydrophobic coating containing hollow glass beads and preparation method thereof

InactiveCN109294426AAchieving superhydrophobicityLow densityPolyurea/polyurethane coatingsRoom temperaturePolyvinylidene difluoride

The invention discloses a superhydrophobic coating containing hollow glass beads and a preparation method thereof. The method is characterized by comprising the steps of: (1) modifying hollow glass beads with a silane coupling agent to realize the hydrophobic performance of the hollow glass beads; (2) preparing a polyurethane solution and a polyvinylidene fluoride solution of different concentrations, and stirring the polyvinylidene fluoride solution and the polyurethane solution uniformly according to certain mass ratio to obtain a polymer solution A; (3) adding the modified hollow glass beads into the polymer solution A according to a proper mass ratio, adding a defoamer and performing stirring for 1-2h at room temperature to obtain a superhydrophobic coating solution; and (4) conductingbrush coating of the superhydrophobic coating solution on a substrate surface, and performing drying at 50-70DEG C to obtain the hollow glass bead superhydrophobic coating. The method provided by theinvention has the characteristics of simple preparation process and low cost, and can achieve large-scale application.

Owner:SOUTHWEST PETROLEUM UNIV

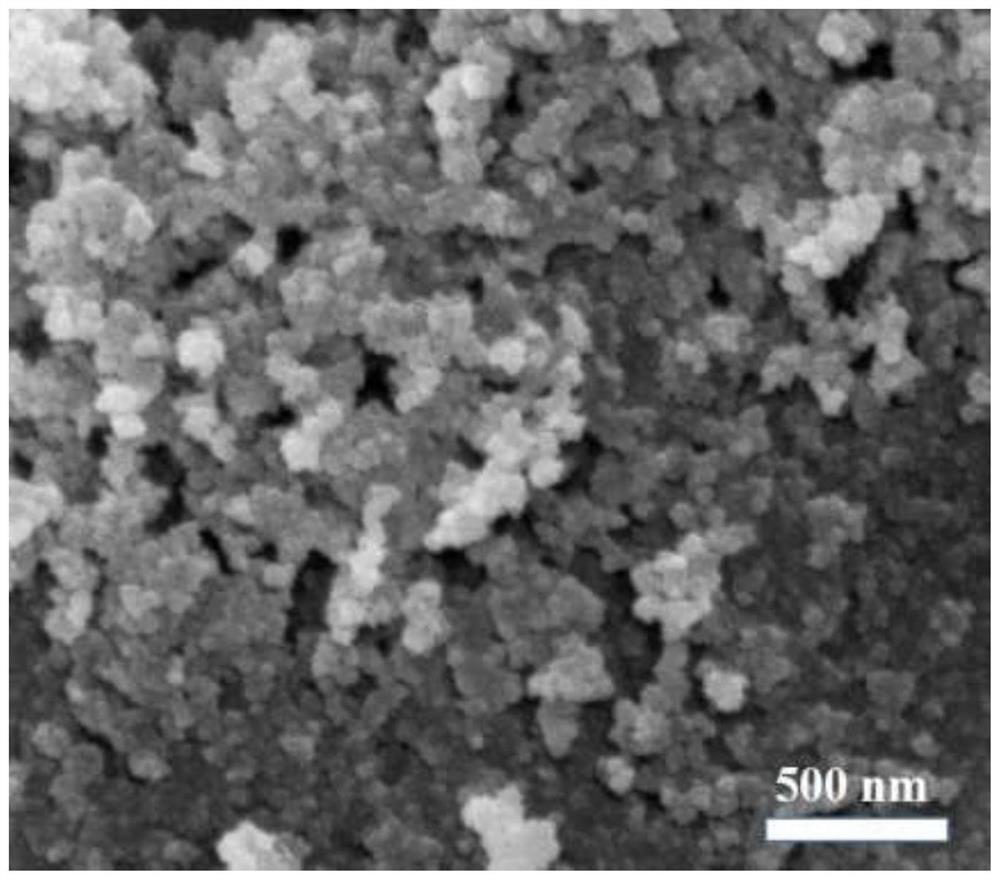

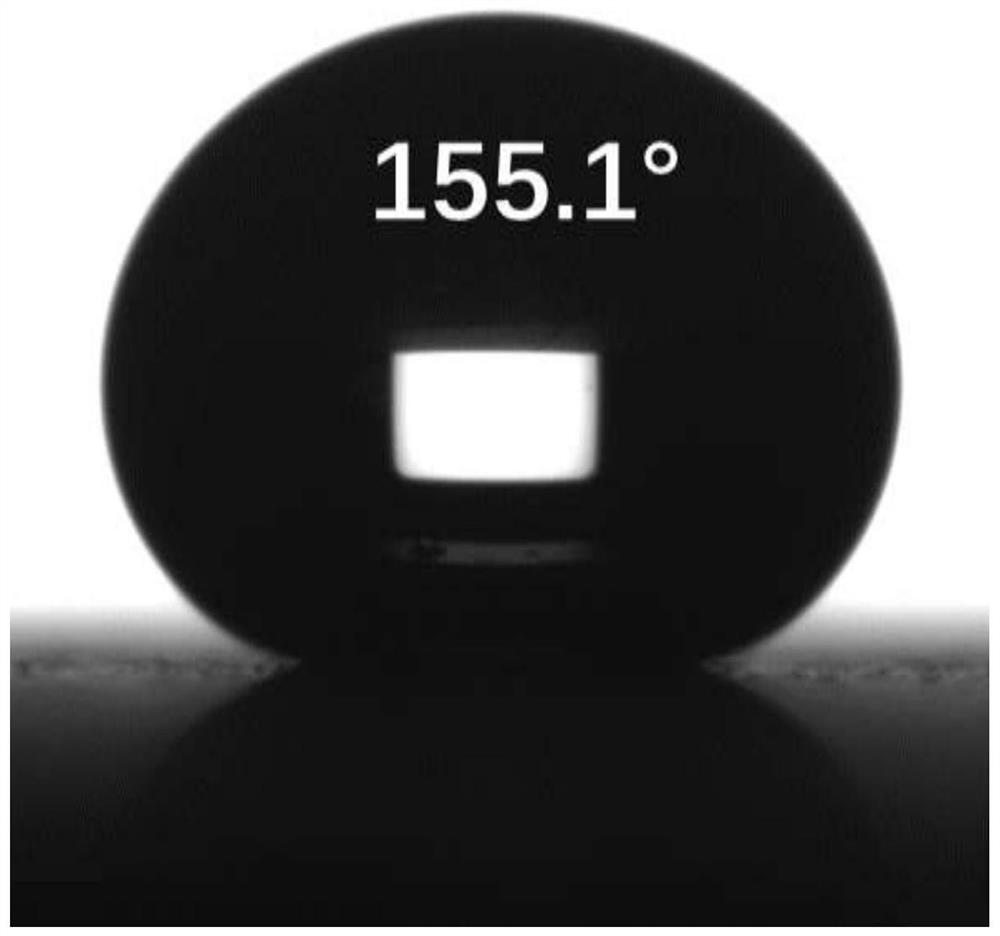

Preparation method of super-hydrophobic stainless steel mesh nano-aluminum thin film

InactiveCN107641832AImprove efficiencyAvoid precious metalsMaterial nanotechnologyElectrolytic coatingsAlcoholStrong acids

The invention discloses a preparation method of a super-hydrophobic stainless steel mesh nano-aluminum thin film. The preparation method comprises the following steps: a, grinding a stainless steel mesh by using abrasive paper so as to remove an oxide layer on the surface, subsequently feeding the stainless steel mesh into acetone, absolute ethyl alcohol and deionized water in sequence, carrying out ultrasonic oscillation cleaning to remove impurities on the surface, and then carrying out air drying for later use; b, preparing stable suspension; (the intermediate steps are omitted); f, takingout the stainless steel mesh treated in the step e, then leaching with the absolute ethyl alcohol, and putting the stainless steel mesh into a drying oven for drying to obtain the super-hydrophobic stainless steel mesh nano-aluminum thin film. According to the preparation method of the super-hydrophobic stainless steel mesh nano-aluminum thin film, disclosed by the invention, a contact angle of the obtained super-hydrophobic stainless steel mesh nano-aluminum thin film is as high as 155 to 165 degrees, and a rolling angle is smaller than 10 degrees. In addition, in the preparation process of the super-hydrophobic stainless steel mesh nano-aluminum thin film, simple required equipment, efficient deposition, low cost and uniform film layer are realized; a large amount of precious metals, strong acid and strong base are avoided, so that the cost and the risk of preparation are reduced.

Owner:CHONGQING UNIV

Super-hydrophobic microcapsule polymer cement-based anticorrosive coating as well as preparation method and application thereof

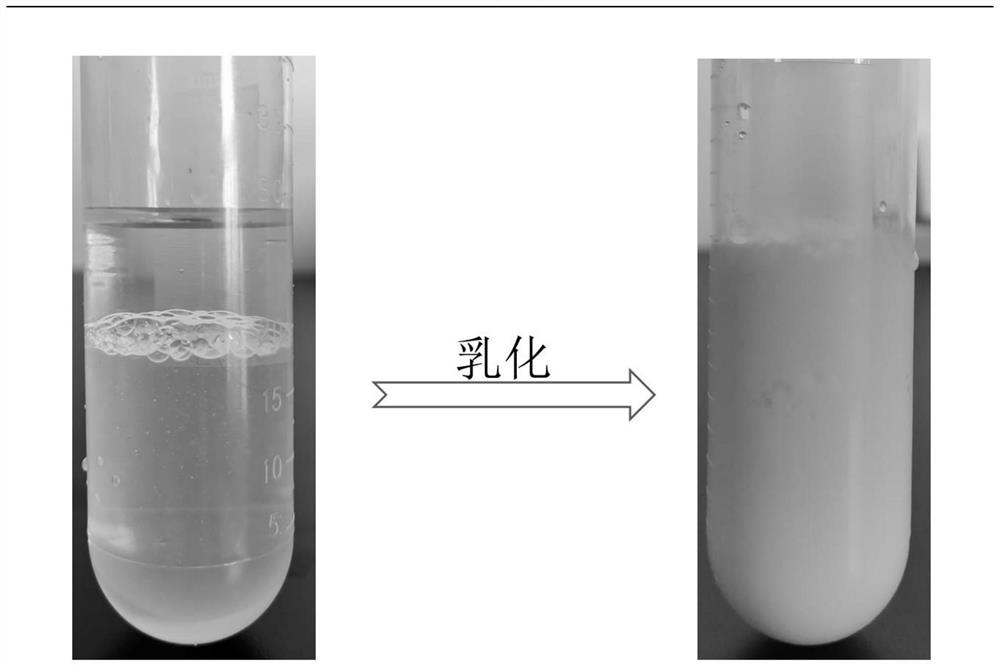

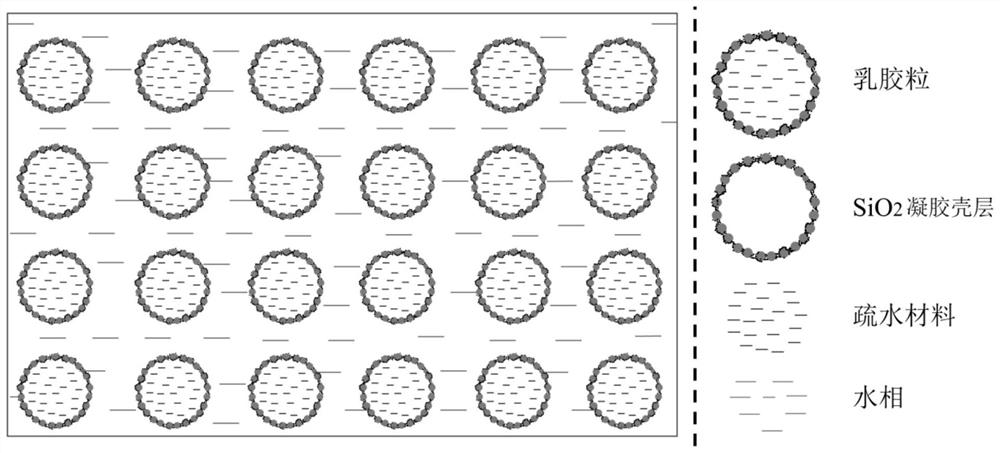

The invention relates to the field of cement anticorrosive coatings, in particular to a super-hydrophobic microcapsule polymer cement-based anticorrosive coating as well as a preparation method and application thereof. The coating is prepared from the following raw materials in parts by weight: 65-85 parts of cement, 65-70 parts of quartz sand, 0.5-1.0 part of a reinforcing agent, 0.17-0.32 part of a retarder, 45-55 parts of emulsion, 15-18 parts of water, 1.1-1.8 parts of a coalescing agent, 0.47-1.4 parts of a light stabilizer, 0.2-0.6 part of a preservative, 0.05-0.3 part of hydrophobic modified graphene oxide and 6-8 parts of a water-based microcapsule emulsion, wherein the water-based microcapsule emulsion is of a core-shell structure formed by taking a hydrophobic material as a coreand SiO2 gel as a shell layer. The anticorrosive paint provided by the invention avoids adverse effects on a cement hydration hardening process and a polymer film forming process, and effectively solves the problem of compatibility between a hydrophobic agent and emulsion as well as between the hydrophobic agent and cement.

Owner:UNIV OF JINAN

Bio-based super-hydrophobic coating as well as preparation method and application method thereof

ActiveCN110964390AAchieving superhydrophobicityGood compatibilityPriming paintsSuperhydrophobeOrganic chemistry

The invention relates to a bio-based super-hydrophobic coating and a preparation method and an application method thereof, the bio-based super-hydrophobic coating comprises a primer and a top coating,and the top coating is prepared from resin B, lotus leaf particles, a pigment, a thickener, an acid-base regulator and the like. According to the bio-based super-hydrophobic coating as well as the preparation method and the application method thereof, the resin B is used as a matrix, the lotus leaf particles belonging to pure organisms are crushed and ground through a specific process, a nano-micron dual structure of lotus leaves is reserved, and the lotus leaf particles are added into an environment-friendly coating matched with the the lotus leaf particles. The primer is firstly coated or sprayed on a surface to be hydrophobic to ensure adhesion, reduction of surface energy and adhesion of the coating due to addition of e thlotus leaf particles is avoided, then the top coating is coatedor sprayed on the surface to be hydrophobic, the water contact angle after coating is larger than 150 degrees, the synthesis process is simple, the cost is low, and the coating is green, environmentally friendly, safe and pollution-free and can be produced in batches. The super-hydrophobic self-cleaning coating can be widely applied to the surfaces of wall surfaces, cement, metal, glass and the like to realize super-hydrophobicity and self-cleaning.

Owner:SUZHOU WHOLENANO NEW MATERIAL TECH CO LTD

Super-hydrophobic anti-pollution flashover coating with hydrophobic mobility and preparation method thereof

ActiveCN111574925AGuaranteed long-term effectivenessExtended service lifeFireproof paintsAntifouling/underwater paintsOrganosolvFirming agent

The application provides a super-hydrophobic anti-pollution flashover coating with hydrophobic mobility. The super-hydrophobic anti-pollution flashover coating is prepared from the following raw materials: organic silicon resin, an organic solvent, silicon oxide, a flame retardant, a cross-linking agent, a coupling agent, a dispersing agent, an antifoaming agent, a leveling agent and an organic silicon resin curing agent. The invention also provides a preparation method of the super-hydrophobic anti-pollution flashover coating with hydrophobic mobility. The anti-pollution flashover coating provided by the invention has super-hydrophobicity and hydrophobic mobility at the same time; the surface hydrophobicity of the anti-pollution flashover coating is improved, the long-term effectiveness of the anti-pollution flashover coating is ensured, the service life of the anti-pollution flashover coating is prolonged, and the occurrence probability of pollution flashover accidents is reduced, sothat problems of low hydrophobicity and easy deposition of dirt on the surface of the existing anti-pollution flashover coating are solved, and the occurrence probability of pollution flashover accidents is reduced.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Super-hydrophobic perovskite/silicon dioxide composite light-emitting film and preparation method and application thereof

ActiveCN112457841AAchieving superhydrophobicityImprove stabilityLuminescent compositionsSemiconductor devicesFluorescenceSilicon oxide

A preparation method of the super-hydrophobic perovskite / silicon dioxide composite light-emitting film comprises the following steps: firstly, uniformly dispersing PbBr2 and alkali liquor in an alcohol solvent to obtain a Pb-based dispersion liquid, uniformly dissolving Cs2CO3 and TEOS in the alcohol solvent to obtain a CsSi-based dispersion liquid, dropwise adding the Cs-Si-based dispersion liquid into the Pb-based dispersion liquid under a stirring condition, and after sufficient reaction for a certain period of time, adding hexamethyldisilazane for modification reaction, coating the obtained dispersion liquid with a film and dried, so that the super-hydrophobic perovskite / silicon dioxide composite light-emitting film with high efficiency and high stability is obtained. The preparation method provided by the invention is simple and easy to implement, mild in reaction condition and low in cost, macro preparation can be realized, and the obtained perovskite / silicon dioxide composite material can show good super-hydrophobic function and stability, and has a wide application prospect in the fields of self-cleaning, efficient and high-stability LEDs or fluorescent solar light collectors and the like.

Owner:WUHAN UNIV OF TECH

A kind of superhydrophobic geopolymer prepared by microcellular foaming and preparation method thereof

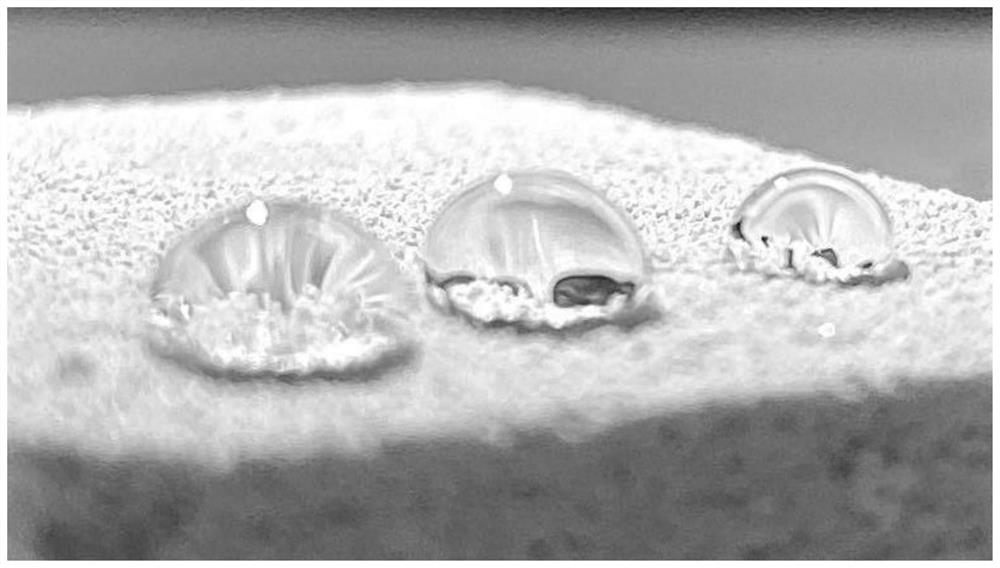

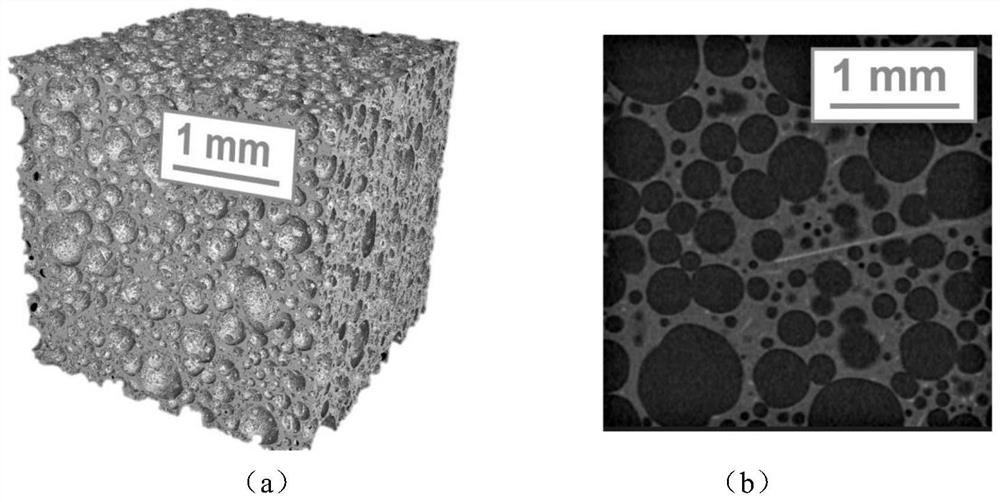

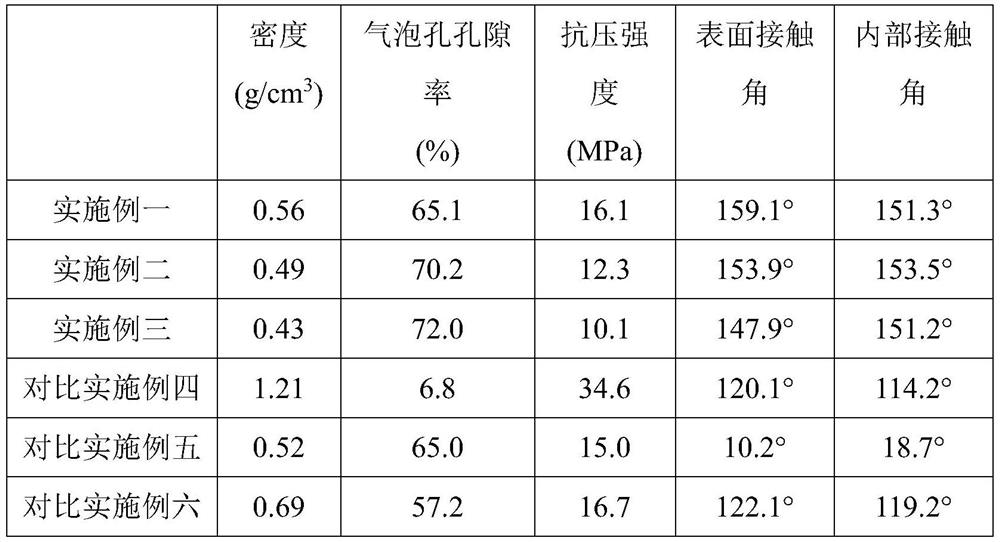

ActiveCN112079585BReduced pore distributionHigh densitySolid waste managementCement productionFiberThermal insulation

The invention discloses a superhydrophobic geopolymer prepared by microporous foaming, which comprises the following raw materials in parts by weight: 30-45 parts of silicon-aluminum mineral raw materials, 35-50 parts of alkali activator, polydimethylsilane 0.5-1.5 parts of oxane, 0.05-0.15 parts of silane coupling agent, 2-5 parts of silicon carbide powder, 2-4 parts of short fiber, 1-3 parts of alkyl glycoside, and 1-3 parts of hydrogen peroxide. The invention also discloses a preparation method of the superhydrophobic geopolymer prepared by microcellular foaming. The present invention utilizes the blocking effect of short fibers on air bubbles, and the properties of silicon carbide powder and its inherent impurities silicon element and carbon element reacting in a strong alkali environment to generate gas to realize a large number of uniform microbubble pore structures with adjustable pore diameters; Superhydrophobic modification is carried out from the internal structure of the material to avoid the performance being affected by mechanical damage, so that the material has a durable hydrophobic ability; to prepare low-density, high-strength, corrosion-resistant and high-temperature foamed materials, while hydrophobic and impermeable, can be used To filter adsorption, thermal insulation, foundation treatment, structure filling.

Owner:ZHEJIANG UNIV +2

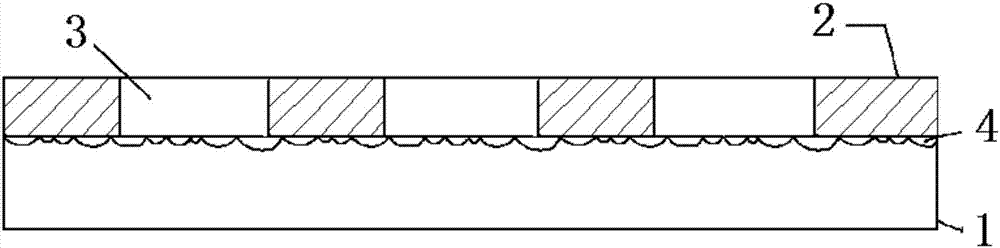

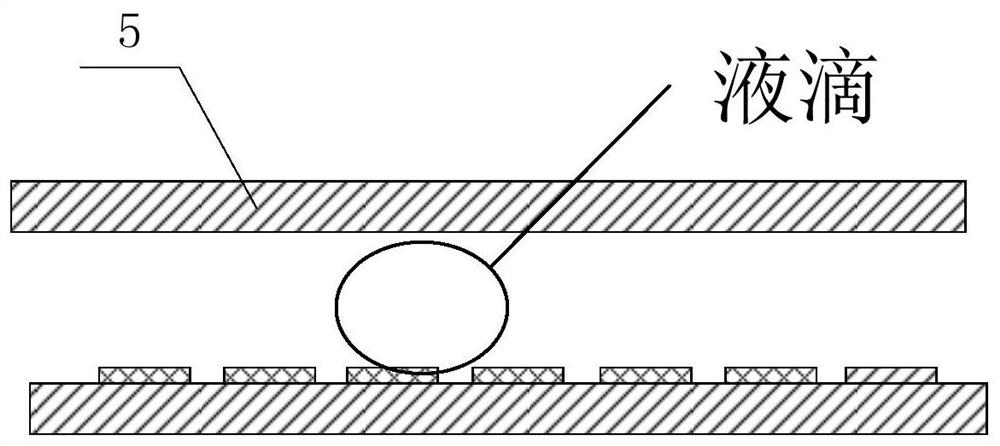

Super-hydrophobic digital micro-fluidic chip based on anodic oxidation method, manufacturing method thereof, and liquid drop control system

ActiveCN113996358ALow movement resistanceLow costLaboratory glasswaresFluid controllersControl systemEngineering

The invention discloses a super-hydrophobic digital micro-fluidic chip based on an anodic oxidation method, a manufacturing method thereof, and a liquid drop control system, and relates to the field of biochemical detection micro-fluidic chips. The problems that an existing hydrophobic digital micro-fluidic chip is complex in preparation mode and high in manufacturing cost, and liquid drops can be controlled to move only by high driving voltage are solved. The top surface of a first substrate of the super-hydrophobic digital micro-fluidic chip is covered with a plurality of electrode plates, the plurality of electrode plates are distributed on the top surface of the first substrate in an array manner, the plate body of the first substrate is provided with a plurality of through holes, and the plurality of through holes are in one-to-one correspondence with the electrode slices; a plurality of wires are distributed on the bottom surface of the first substrate, and each wire is connected with one through hole; each lead is electrically connected with one electrode plate through a via hole process; and the outer side of each electrode plate is covered with a first dielectric layer, the upper surfaces of the first dielectric layers and the upper surface of the first substrate are both covered with hydrophobic layers, and the first dielectric layers are prepared by anodizing the electrode plates in an alkaline solution. The chip is suitable for biochemical detection microfluidics.

Owner:HARBIN INST OF TECH

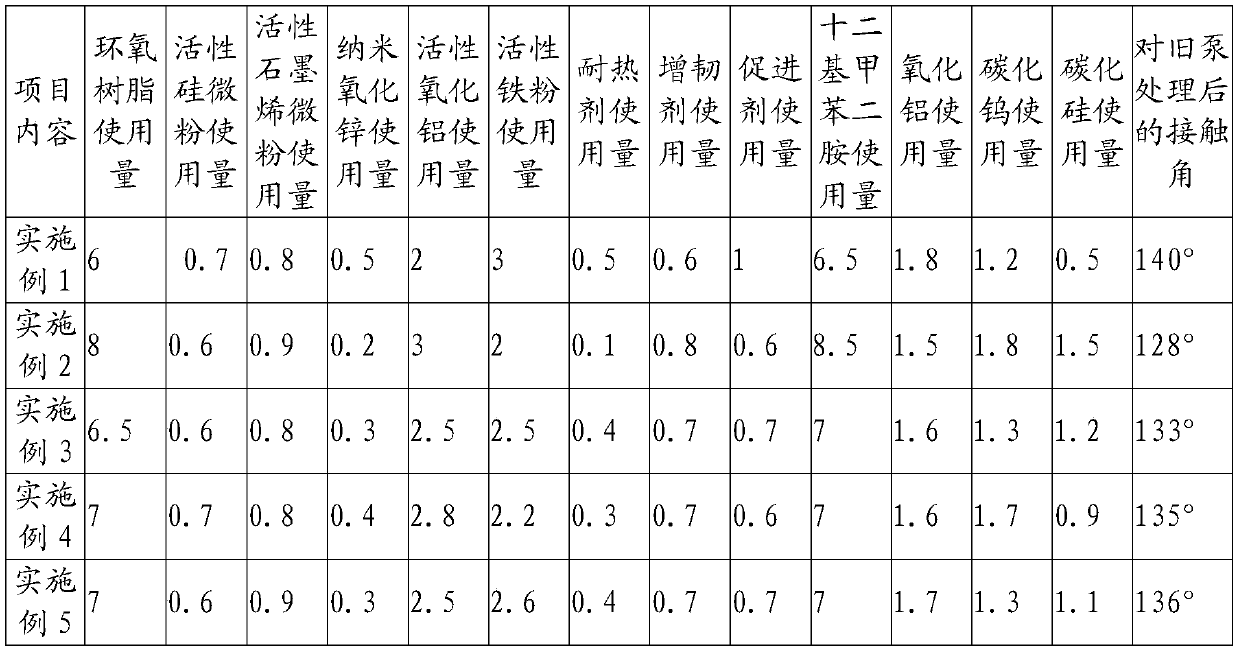

Super-hydrophobic paint for old pump transformation and preparation method and application of paint

ActiveCN109943200AAchieving superhydrophobicitySuperhydrophobicity hasChemical industryEpoxy resin coatingsEpoxyCavitation

The invention discloses a super-hydrophobic paint for old pump transformation and preparation method of the paint and belongs to the field of super-hydrophobic paints. The paint comprises a componentA and a component B. The component A is a modified resin composition and comprises 6-8 parts of epoxy resin, 0.6-0.7 part of active silica micro-powder, 0.8-0.9 part of active graphene micro-powder, 0.2-0.5 part of nano-zinc oxide, 2-3 parts of active aluminium oxide, 2-3 parts of active iron powder, 0.1-0.5 part of a heat-resisting agent, 0.6-0.8 part of a toughening agent and 0.6-1 part of an accelerant; the component B is a modified curing agent composition and comprises 6.5-8.5 parts of lauryl toluenediamine, 1.5-1.8 parts of aluminium oxide, 1.2-1.8 parts of tungsten carbide and 0.5-1.5 parts of silicon carbide. The surface of an old pump is coated with the super-hydrophobic paint to form a super-hydrophobic coating, so that the super-hydrophobic paint has a super-hydrophobic function, the friction resistance is lowered, the influence of the cavitation phenomenon on the pump body is reduced, and the energy-saving efficiency of the pump body is greatly improved.

Owner:青岛环普节能科技有限公司

Method for preparing super-hydrophobic paper through laser printing

ActiveCN112522991AAchieving superhydrophobicityFreedom can be realizedMaterial nanotechnologyCoatings with pigmentsFree energiesEngineering

The invention discloses a method for preparing super-hydrophobic paper, which realizes the super-hydrophobic property of the surface of the paper, and the static contact angle of the prepared super-hydrophobic surface can reach 153.0 degrees. The prepared super-hydrophobic paper has good moisture resistance and ultraviolet resistance, after hydrophobicity is lost under the action of external force, octadecylamine packaged by polydopamine can be melted, released and migrated to the surface of a polydopamine capsule under the action of temperature, the free energy of the surface is reduced, andself-repairing of the super-hydrophobic performance of the surface of the paper is achieved. According to the preparation method disclosed by the invention, complex instruments and equipment are not needed, a complex synthesis process is not needed, complex steps are not needed, too long time is not needed, the laser printing technology has the advantages of being rapid, efficient and the like, and the preparation method of the super-hydrophobic paper has the characteristics of being simple and environmentally friendly.

Owner:LANZHOU JIAOTONG UNIV

Method for preparing hydrophobic porous oil-water separation material

InactiveCN107638874AImprove surface roughnessGood hydrophobicityOther chemical processesAlkali metal oxides/hydroxidesParaffin waxPerlite

The invention relates to a method for preparing a hydrophobic porous oil-water separation material and belongs to the technical field of material processing. The method comprises the following steps:stirring and mixing sliced paraffin with liquid paraffin, performing water bath heating so as to obtain molten paraffin, weighing obsidian, pitchstone and perlite, performing ball-milling, screening so as to obtain ball-milling powder, putting the ball-milling powder and molybdenum disulfide into a quartz pipeline, sealing the quartz pipeline, vacuuming, performing heating, introducing argon intoa quartz tube, controlling a flowing speed, performing heat-preservation heating, leaving to stand, cooling to the room temperature, collecting modified granules, mixing the modified granules with molten paraffin, performing heating stirring, and performing vacuum freeze-drying, and performing crushing screening so as to obtain modified packing; putting polyether polyol, deionized water, a foam stabilizer, modified packing and diphenylmethane diisocyanate into a flask, performing stirring mixing so as to obtain a mixed liquid, casting into a mold, performing foaming treatment, performing heat-preservation heating, leaving to stand, and cooling to the room temperature, thereby obtaining a hydrophobic porous oil-water separation material.

Owner:常州蓝旗亚纺织品有限公司

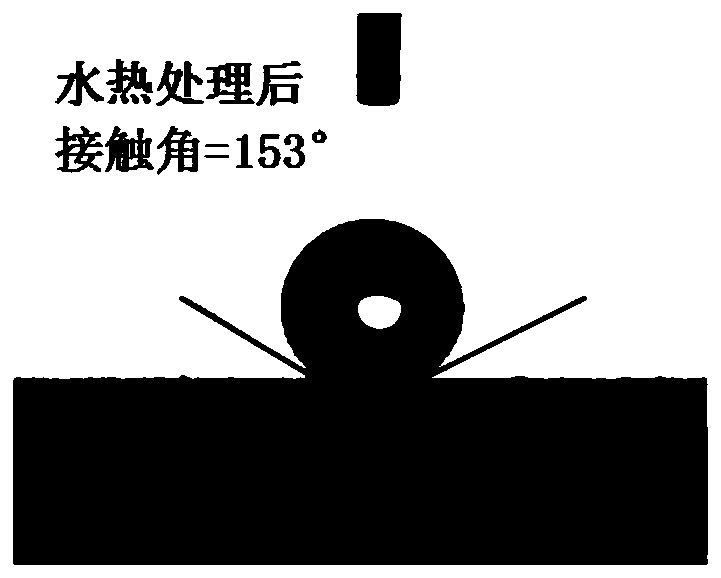

Method for constructing super-hydrophobic corrosion-resistant conversion film on surface of magnesium-lithium alloy and magnesium-lithium alloy with super-hydrophobic corrosion resistance

ActiveCN110592569AReduce contact areaImprove corrosion resistanceMetallic material coating processesCorrosion resistantAlloy surface

The invention relates to the technical field of magnesium-lithium alloy surface corrosion resistance, in particular to a method for constructing a super-hydrophobic corrosion-resistant conversion filmon the surface of magnesium-lithium alloy and the magnesium-lithium alloy with super-hydrophobic corrosion resistance. The method for constructing the super-hydrophobic corrosion-resistant conversionfilm on the surface of the magnesium-lithium alloy comprises the following steps that a mixed solution comprising stearic acid, ethanol and water is mixed with the magnesium-lithium alloy, and afterhydrothermal reaction, the super-hydrophobic corrosion-resistant conversion film is formed on the surface of the magnesium-lithium alloy. Compared with existing films commonly prepared through a sol-gel method, an etching method and a soaking method, the super-hydrophobic corrosion-resistant film constructed through a hydrothermal method has the advantages of being simple and environmentally friendly. The super-hydrophobic film can reduce the contact area of corrosion liquid and a matrix, so that the corrosion resistance of the magnesium-lithium alloy can be effectively improved while the surface of the magnesium-lithium alloy is super-hydrophobic.

Owner:HOHAI UNIV +1

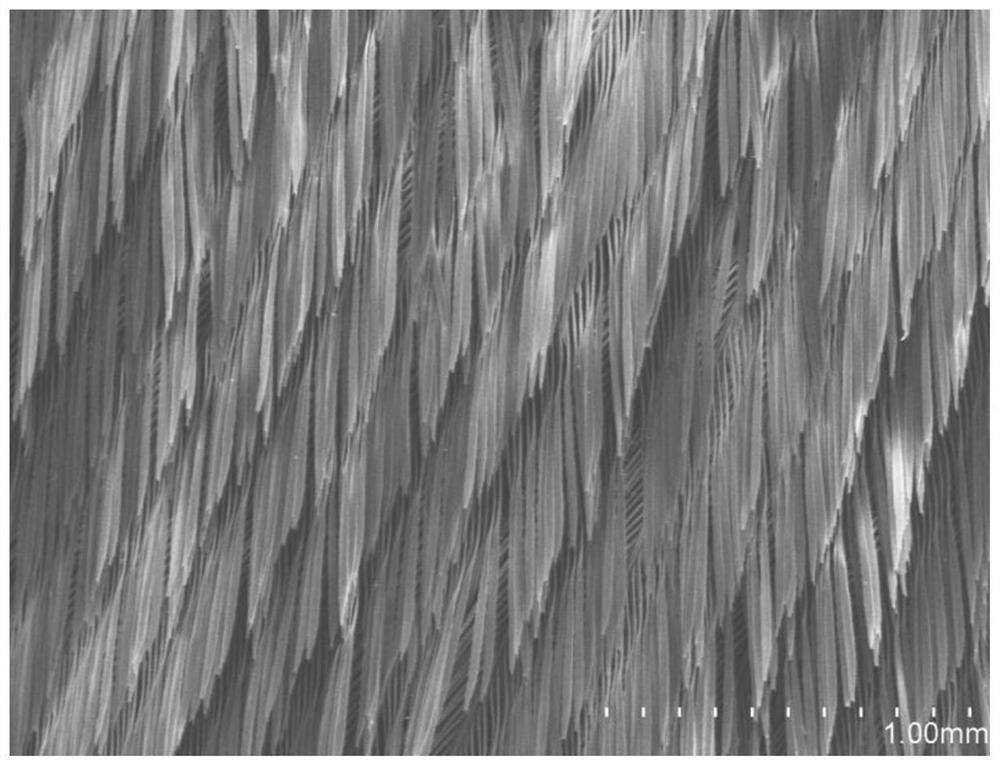

Sodium alginate modified amphiphilic feather as well as preparation method and application thereof

The invention discloses sodium alginate modified amphiphilic feather. One surface of the feather is uniformly covered with a layer of sodium alginate. The invention also discloses a preparation method of the sodium alginate modified amphiphilic feather. The method comprises the following steps of (1) dispersing sodium alginate powder into a solvent, performing oscillating and uniform mixing, and carrying out ultrasonic treatment to obtain a high-dispersity sodium alginate solution; (2) dispersing absolute ethyl alcohol into the sodium alginate solution, performing oscillating and uniform mixing, and performing ultrasonic treatment to obtain a high-dispersity mixed solution; and (3) spraying the mixed solution on one side of the feather, and carrying out vacuum heat drying to obtain the final product. The amphiphilic feather can accelerate water delivery and reduce heat loss; both the sodium alginate and the feather are biodegradable materials, which are environment-friendly and non-toxic, and are cheap and easy to obtain; and the preparation process is simple, the operation is carried out at room temperature, the cost is relatively low, the feather is environment-friendly and non-toxic, and the obtained amphipathic feather has excellent photothermal conversion efficiency and salt resistance and has a wide development prospect in the field of seawater desalination.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Preparation method of super-hydrophobic fabric

PendingCN112376273ADo not change the original colorAchieving superhydrophobicityLight resistant fibresLiquid repellent fibresPolymer scienceOrganic chemistry

The invention relates to the technical field of super-hydrophobic materials, in particular to a preparation method of a super-hydrophobic fabric. The preparation method comprises the following steps:(1) by using octadecylamine as a raw material, preparing a nano octadecylamine finishing agent by using an ultrasonic dispersion method; (2) performing suction filtration on the nano octadecylamine finishing agent obtained in the step (1) by using a vacuum suction filtration method, and depositing the nano octadecylamine finishing agent on the surface of the fabric; and (3) heating the fabric obtained in the step (2) to obtain the super-hydrophobic fabric. According to the preparation method of the super-hydrophobic fabric, the super-hydrophobic property of the surface of the fabric is achieved, the static contact angle of the surface of the prepared super-hydrophobic fabric can reach 152 degrees, the super-hydrophobic fabric has good friction resistance, washing resistance and ultravioletresistance, meanwhile, less instruments and equipment are used, the steps are simple, the time is short, the original color of the fabric is not changed, operation is simple and convenient, the preparation process is carried out in a water system, and the preparation method is simple and friendly to the environment.

Owner:LANZHOU JIAOTONG UNIV

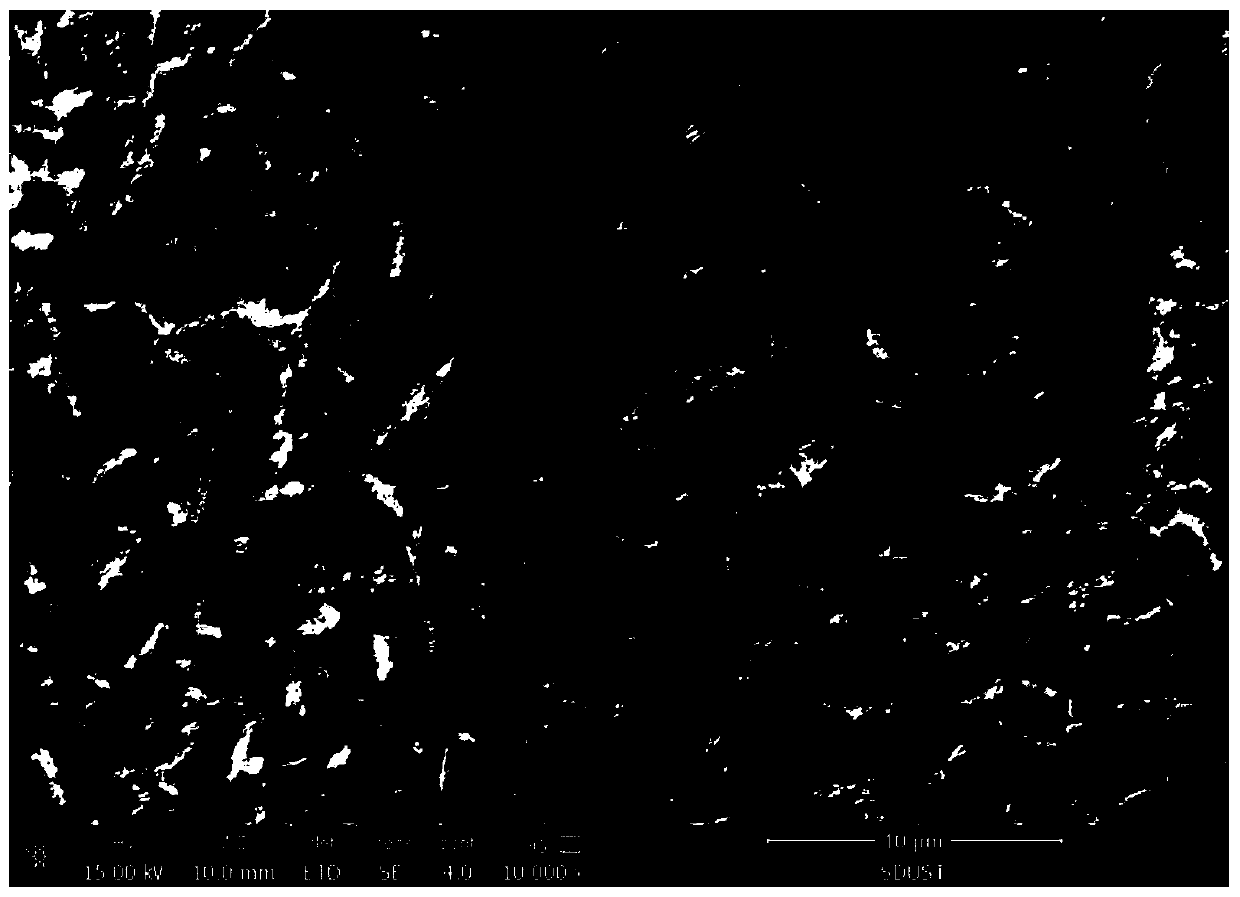

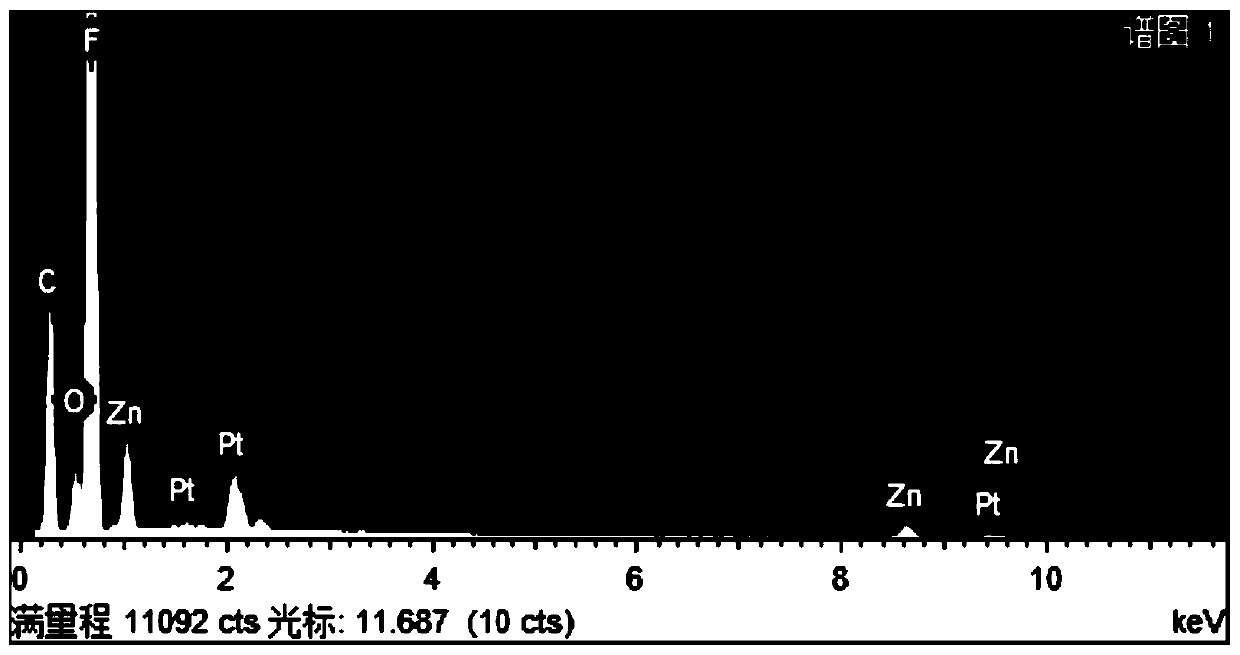

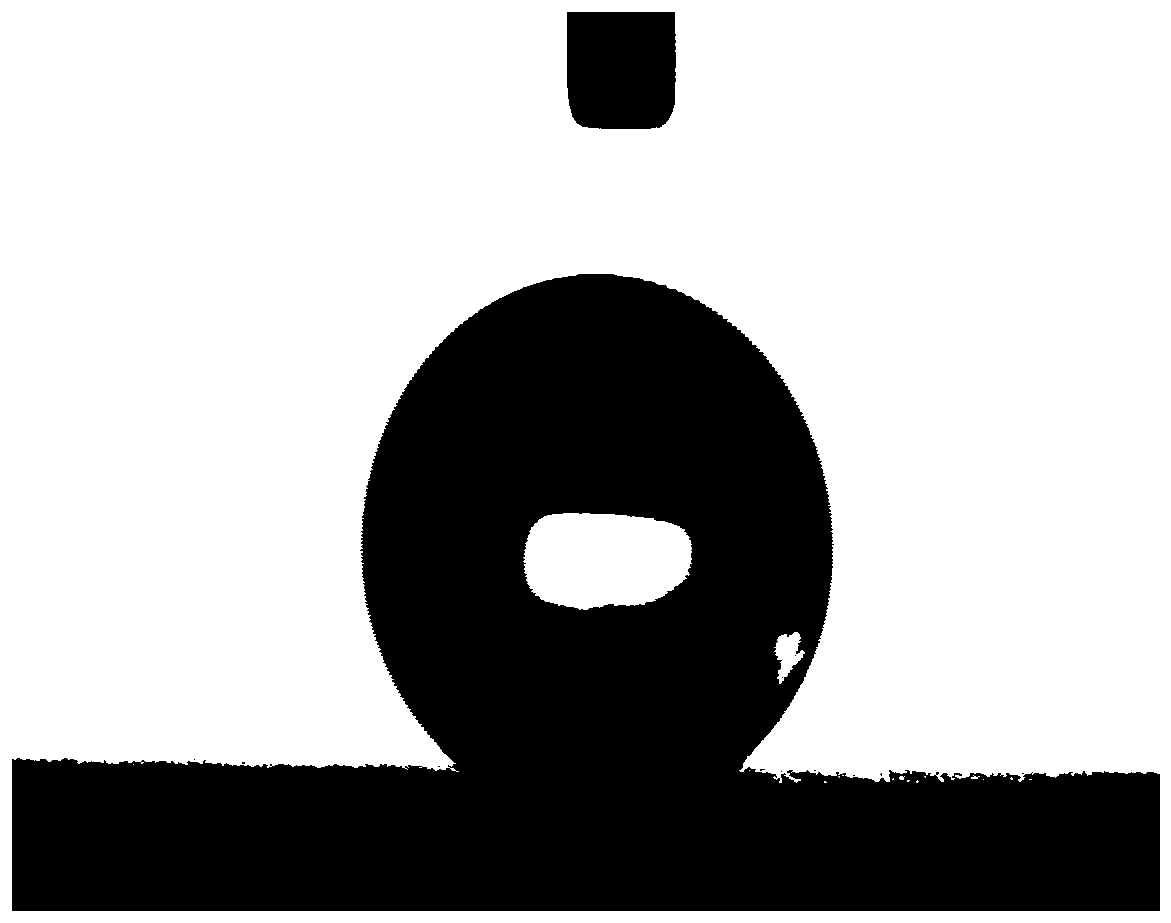

Super-hydrophobic Zn-poly tetra fluoro ethylene (PTFE) composite electrodeposition layer and preparation method thereof

The invention provides a super-hydrophobic Zn-poly tetra fluoro ethylene (PTFE) composite electrodeposition layer and a preparation method thereof. The preparation method includes the steps that a steel matrix is activated by adopting a sulfuric acid aqueous solution, the activated steel matrix is used as a negative pole, zinc metal is used as a positive pole, and electrodeposition is conducted inan electrodeposition solution; and the electrodeposition solution contains a zinc salt, boric acid, PTFE powder and a surfactant, and the concentration of the PTFE powder is 10-40 g / L. In the prepared super-hydrophobic Zn-PTFE composite electrodeposition layer, sheet PTFE microstructures are evenly distributed on the surface of the electrodeposition layer, network structures are formed, most sheet PTFE microstructures are basically perpendicular to the matrix surface, the structural characteristics and low surface energy of PTFE itself make the obtained Zn-PTFE composite electrodeposition layer realize super-hydrophobicity, and at the same time, the electrodeposition layer further has the characteristics of strong adhesion and high stability.

Owner:SHANDONG UNIV OF SCI & TECH

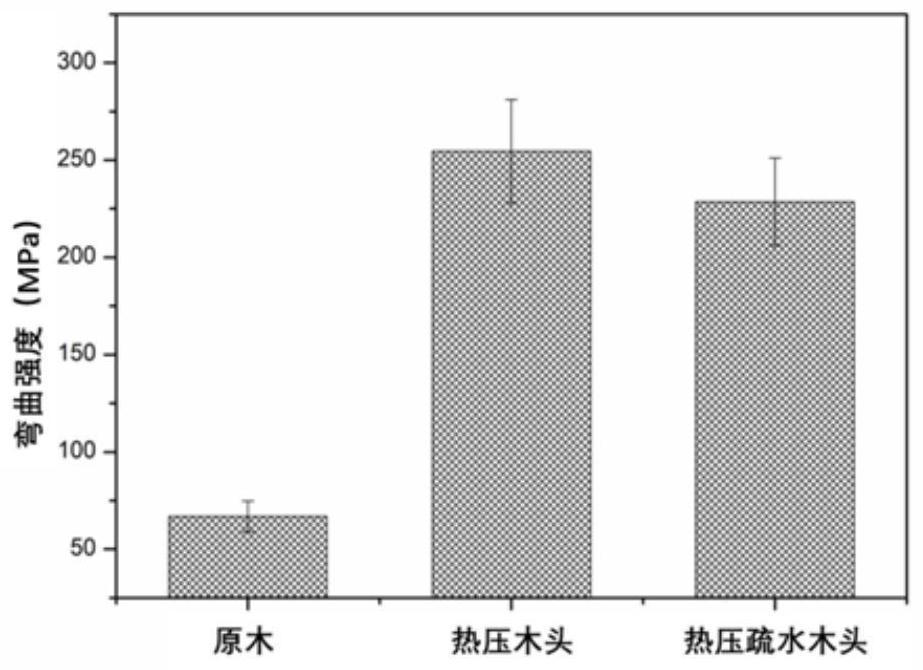

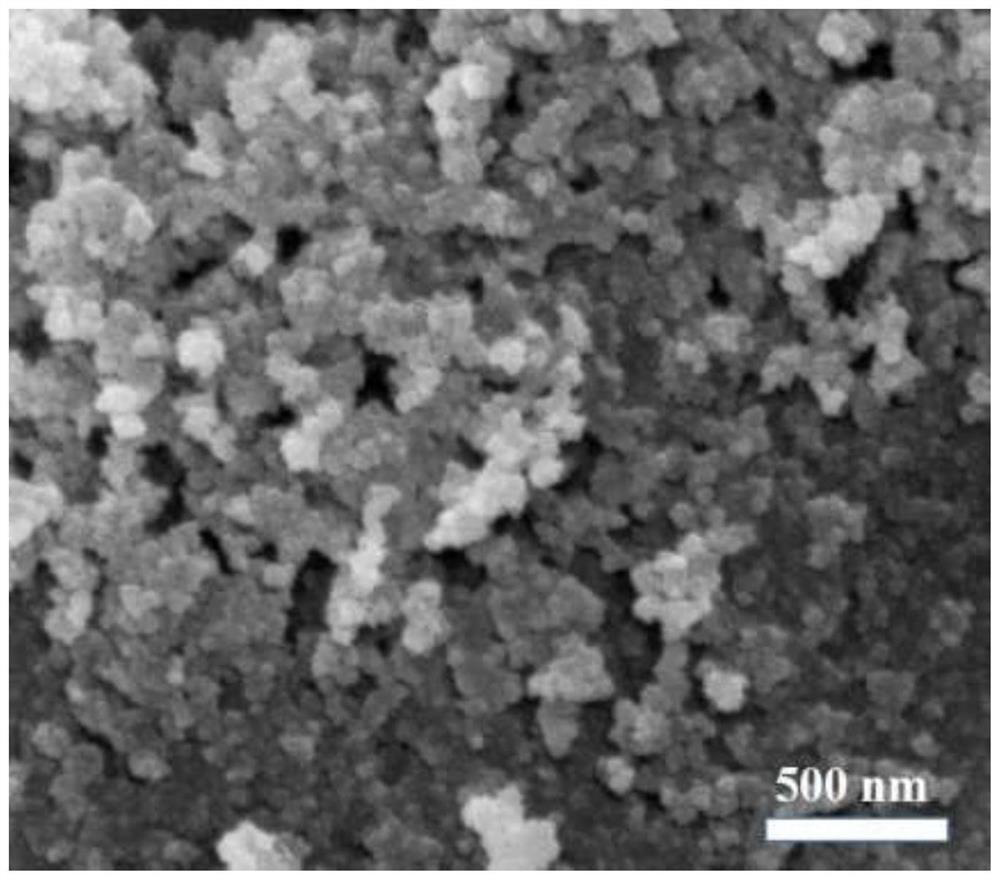

A full-surface super-hydrophobic antifreeze high-strength wood and its manufacturing method

ActiveCN111015857BImprove frost resistanceExcellent high strengthWood treatment detailsPretreatment apparatusPolymer scienceHemicellulose

Owner:DONGHUA UNIV

A kind of superhydrophobic perovskite/silicon dioxide composite luminescent film and its preparation method and application

ActiveCN112457841BAchieving superhydrophobicityImprove stabilityLuminescent compositionsSemiconductor devicesAlkaneAlcohol

The invention discloses a superhydrophobic perovskite / silicon dioxide composite luminescent film, the preparation method of which comprises the following steps: firstly, PbBr 2 and lye are uniformly dispersed in alcohol solvent to obtain Pb-based dispersion, Cs 2 CO 3 , TEOS is uniformly dissolved in an alcohol solvent to obtain a Cs-Si-based dispersion, and then the Cs-Si-based dispersion is added dropwise to the Pb-based dispersion under stirring conditions, and after a sufficient reaction for a certain period of time, hexamethyldisilamine is added Alkanes are used for modification reaction, and then the resulting dispersion is coated and dried to obtain a superhydrophobic perovskite / silicon dioxide composite luminescent film with high efficiency and high stability. The preparation method involved in the present invention is simple and easy, the reaction conditions are mild, the cost is low, and macro-scale preparation can be realized. The obtained perovskite / silicon dioxide composite material can exhibit good superhydrophobic function and stability, and is self-cleaning, Efficient and stable LEDs or fluorescent solar concentrators have broad application prospects.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com