Preparing method for graphene oxide super-hydrophobic coating and coating evaporation device

A super-hydrophobic coating, graphene technology, applied in coating, vacuum evaporation coating, metal material coating process and other directions, can solve the problems of difficult to achieve large-scale industrial production, short service life, easy to peel, etc. It is convenient for large-scale industrial production, low cost, and not easy to peel off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

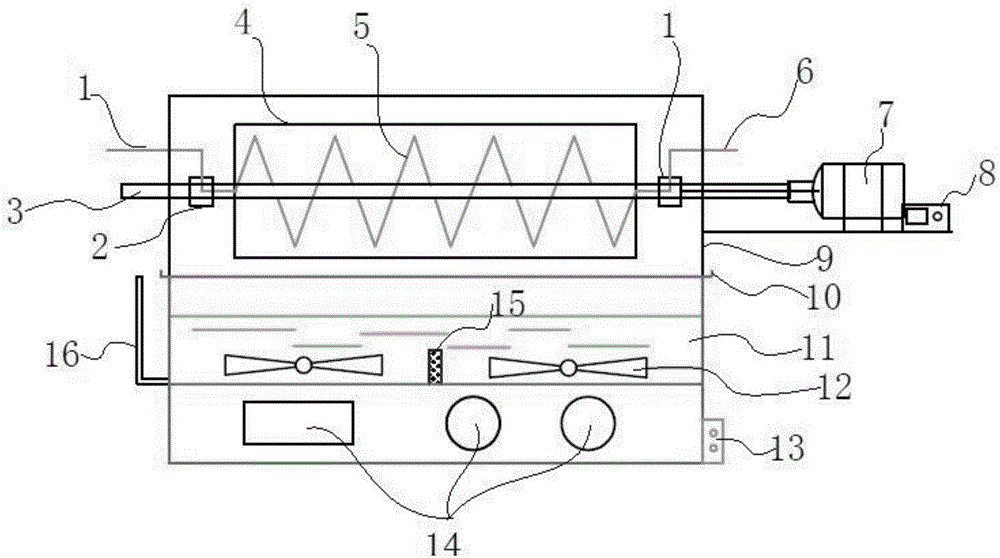

[0030] In this example, see figure 1 and figure 2 , an evaporation device for self-assembled superhydrophobic graphene oxide coating, including two parts of an upper drum type device and a lower evaporation device, the upper drum type device mainly includes a drum 4 arranged inside the upper cover 9, and two parts of the drum 4 The ends are fixedly connected to the rotating shaft 3 to form a rotating body. The rotating shaft 3 is set in the shaft hole on the upper cover 9 through the rotary joint 2. The outer surface of the drum 4 is used to coat and fix the vapor-deposited metal aluminum foil. The upper cover 9 is formed inside. In the drum chamber of the drum 4, the rotating shaft 3 is driven by the motor 7 combined with the rotating speed and the power control module 8, so that the rotating shaft 3 drives the drum 4 to rotate, thereby making the rotating speed of the drum 4 controllable, providing a stable rotating speed, and through temperature control The device makes t...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

[0045] In the present embodiment, a method for preparing a graphene oxide superhydrophobic coating is carried out using an evaporation device for a self-assembled superhydrophobic graphene oxide coating, including the following steps:

[0046] a. Inner coating preparation process: this step is the same as in Example 1;

[0047] b. Outer coating preparation process:

[0048] Using the non-vacuum evaporation method, at 100°C, using an alcohol solution of tridecafluorooctyltriethoxysilane with a mass percent concentration of 1wt%, for 3 hours, the low surface energy organic compound tridecafluorooctyltriethoxysilane Ethoxysilane is vapor-deposited on the inner coating prepared in step a to form an outer coating. After the process of preparing the outer coating by evaporation is completed, the coating is dried in an oven at 140°C for 3 hours to evaporate excess The unreacted organic solution comp...

Embodiment 3

[0050] This embodiment is the same as the previous embodiment, and the special features are:

[0051] In the present embodiment, a method for preparing a graphene oxide superhydrophobic coating is carried out using an evaporation device for a self-assembled superhydrophobic graphene oxide coating, including the following steps:

[0052] a. Inner coating preparation process: this step is the same as in Example 1;

[0053] b. Outer coating preparation process:

[0054] Using a non-vacuum evaporation method, at 150°C, using an alcohol solution of tridecafluorooctyltriethoxysilane with a mass percent concentration of 1wt%, evaporation for 0.5h, the low surface energy organic substance tridecafluorooctyl Triethoxysilane is vapor-deposited on the inner coating prepared in step a to form an outer coating. After the process of preparing the outer coating by evaporation is completed, the coating is dried in an oven at 160°C for 1 hour to evaporate The redundant unreacted organic solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com