Method for preparing super hydrophobic coating on copper or copper alloy net

A technology of super-hydrophobic coating and copper alloy mesh, which is applied in the field of functional materials, can solve the problems of increasing process complexity, production cost, and environmental impact, and achieve the effects of easy operation, simplified preparation process, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of embodiment 1 superhydrophobic nano-gold-brass net, comprises the steps:

[0021] Clean the 300-mesh brass mesh with ultrasonic ethanol solvent, dry it, and then immerse it in 20mM HAuCl 4 In the aqueous solution, react at room temperature for 60 minutes, take it out, rinse the surface with distilled water, put it in an oven at 80 ° C for 5 hours, and finally place it in the air for 7 days to obtain a superhydrophobic coating.

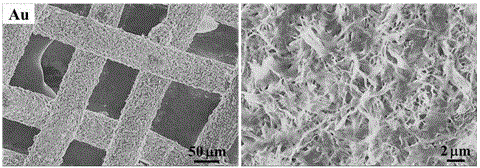

[0022] attached figure 1 It is the surface topography of nano-gold-brass network observed by Hitachi S224800 scanning electron microscope (SEM). It can be seen from the figure that a layer of micron-scale coating is tightly covered on the brass mesh fiber, and from figure 1 As can be seen in the enlarged picture on the right, these micron-scale coatings are composed of many nanoribbons, thereby constructing a micro-nano double microstructure on the surface.

Embodiment 2

[0023] The preparation method of embodiment 2 superhydrophobic nano-silver-copper mesh, comprises the steps:

[0024] Clean the 100-mesh red copper mesh with ultrasonic ethanol solvent, dry it, and then immerse it in 10mM AgNO 3 In the aqueous solution, react at room temperature for 30 minutes, take it out, rinse the surface with distilled water, put it in a 60°C oven for 3 hours, and finally place it in the air for 5 days to obtain a superhydrophobic coating.

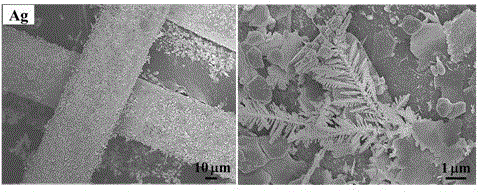

[0025] attached figure 2 It is the SEM picture of the observed nano-silver-copper network. It can be seen from the figure that nanosheets and dendritic micro-nano structures are piled up on the copper mesh fibers. The length of the branches is 3-5 μm, and the bifurcations on the branches are composed of many nano-scale rods. Therefore, in Micro-nano double microstructures are also constructed on the surface.

Embodiment 3

[0026] The preparation method of embodiment 3 superhydrophobic nano-platinum-bronze mesh, comprises the following steps:

[0027] After the 500-mesh bronze mesh was cleaned by ultrasonic ethanol solvent, it was dried in the air, and then immersed in 50mM H 2 PtCl 6 ·6H 2 O aqueous solution, reacted at room temperature for 720min, took it out, rinsed the surface with distilled water, put it in a 120°C oven to dry for 9h, and finally left it in the air for 15 days to obtain a superhydrophobic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com