Super-hydrophobic digital micro-fluidic chip based on anodic oxidation method, manufacturing method thereof, and liquid drop control system

An anodic oxidation method and digital microfluidic technology, applied in fluid controllers, chemical instruments and methods, and laboratory containers, can solve problems such as high driving voltage, high cost, and complicated preparation methods, and reduce motion resistance , Simple preparation, and the effect of driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] Specific implementation mode one: the following combination figure 1 Describe this embodiment, a super-hydrophobic digital microfluidic chip based on the anodic oxidation method described in this embodiment, the super-hydrophobic digital microfluidic chip includes a first substrate 1, an electrode sheet 2, and a first dielectric layer 3 and the first hydrophobic layer 4;

[0039] The top surface of the first substrate 1 is covered with a plurality of electrode sheets 2, and the plurality of electrode sheets 2 are in an array covering the top surface of the first substrate 1, and the body of the first substrate 1 is provided with a plurality of through holes. The plurality of through holes correspond to the electrode sheets 2 one by one;

[0040] The bottom surface of the first substrate 1 is provided with a plurality of wires, and each wire is connected to a through hole; each wire is electrically connected to an electrode sheet 2 through a through hole process;

[00...

specific Embodiment approach 2

[0046] Specific embodiment 2. This embodiment describes a method for manufacturing a super-hydrophobic digital microfluidic chip based on the anodic oxidation method described in specific embodiment 1, including:

[0047] Step 1. The electrode sheet 2 and the wires are respectively arranged on both sides of the first substrate 1 by using the PCB preparation process, and the wires are connected to the electrode sheet 2 through the via hole process, and the via holes are sealed by the via hole capping oil process;

[0048] Step 2, covering the electrode sheet 2 with a dielectric layer by anodic oxidation;

[0049] Step 3: Soak the first substrate 1 covered with the dielectric layer in a hydrophobic reagent to prepare a hydrophobic layer, and complete the manufacture of a super-hydrophobic digital microfluidic chip.

[0050] Further, in this embodiment, in step 2, the specific method of covering the electrode sheet 2 with a dielectric layer by anodic oxidation is as follows:

[...

specific Embodiment approach 3

[0060] Embodiment 3: This embodiment is based on the drip control system based on the super-hydrophobic digital microfluidic chip described in Embodiment 1. It is divided into a single-layer drive mode and a double-layer drive mode. The single-layer drive mode is based on the bottom plate Chip implementation, also including a microprocessor and multiple relays;

[0061] A relay is connected between each wire connected to the bottom layer of the superhydrophobic digital microfluidic chip wiring and the power supply, and the switch control signal input end of each relay is connected to a switch control signal output end of the microcontroller;

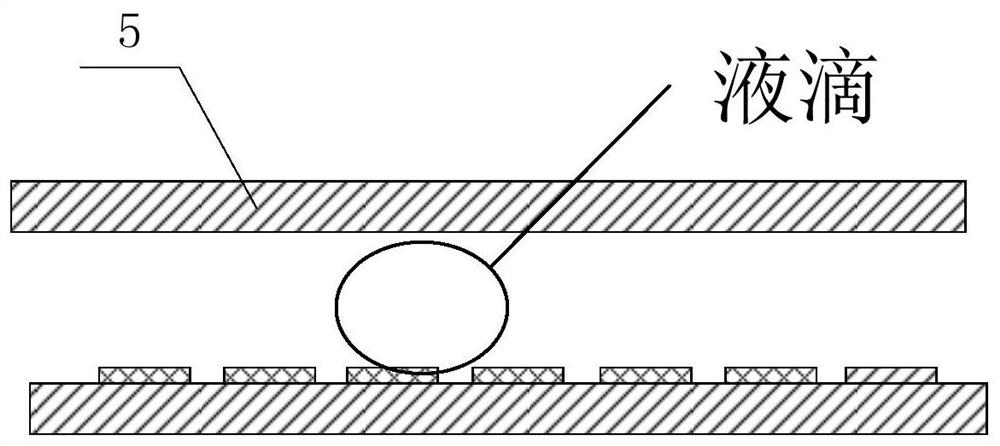

[0062] The double-layer driving mode is realized based on the bottom board chip, and also includes a microprocessor, top board chip 5 and multiple relays;

[0063] The top plate chip 5 includes a second substrate, a second electrode layer and a second hydrophobic layer;

[0064] The second electrode layer covers one side of the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com