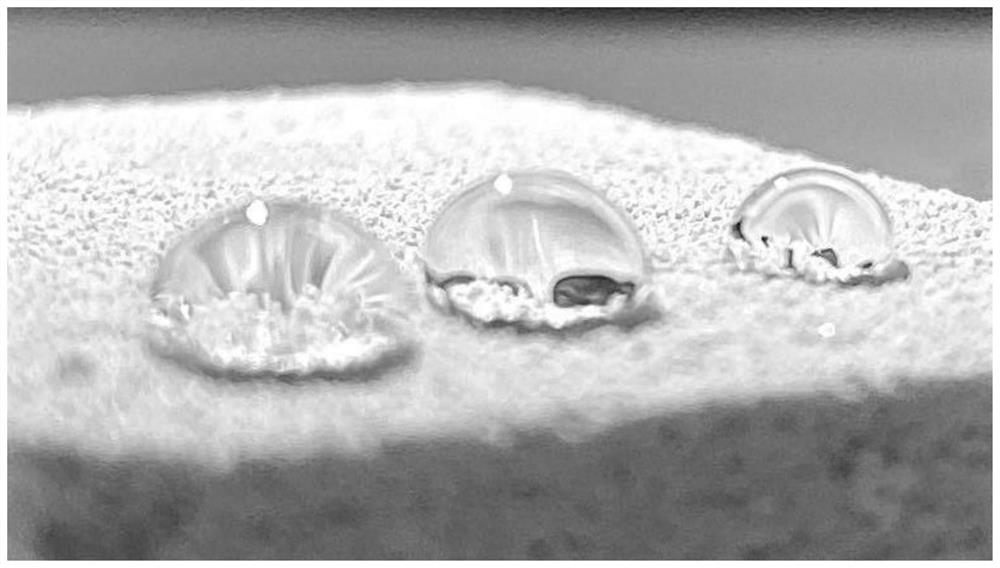

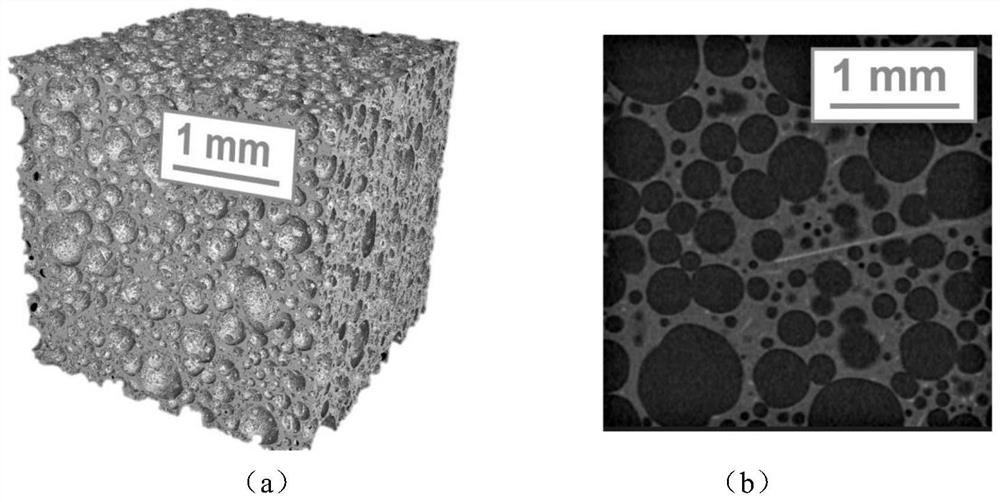

A kind of superhydrophobic geopolymer prepared by microcellular foaming and preparation method thereof

A technology of microporous foaming and geopolymers, applied in applications, ceramic products, cement production, etc., can solve problems such as difficulty in resisting mechanical damage, general hydrophobic effect, weak resistance to mechanical damage, etc., and achieve improvement of micron-level roughness Degree, avoid mechanical damage, improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

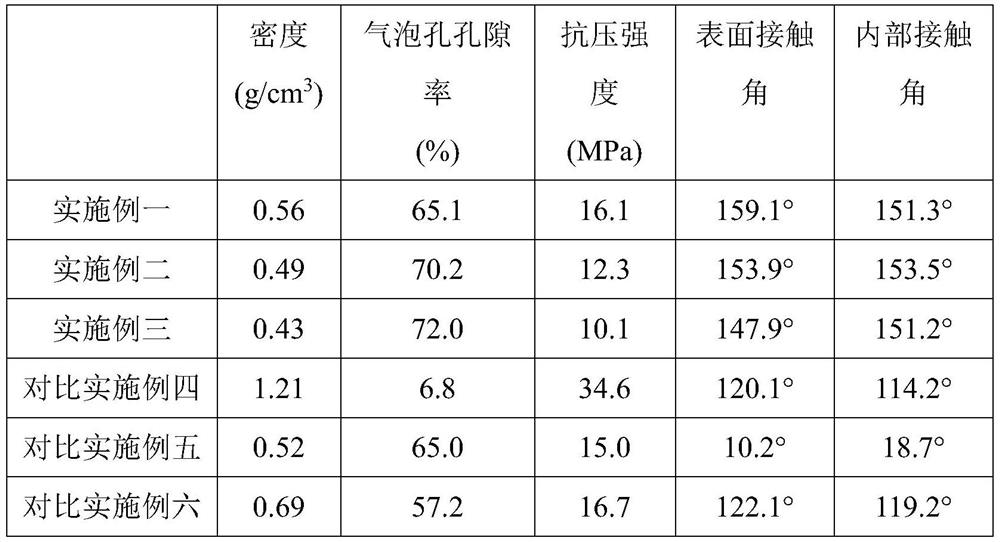

Embodiment 1

[0030] A superhydrophobic geopolymer prepared by microporous foaming, comprising 20 parts of metakaolin, 10 parts of fly ash, 10 parts of silica fume, 40 parts of alkali activator, 1.5 parts of polydimethylsiloxane, silane coupling 0.15 parts of joint agent, 3 parts of silicon carbide powder, 2 parts of basalt fiber, 1 part of alkyl glycoside, 2 parts of hydrogen peroxide.

[0031] The alkali activator is a composite material, which includes 10 parts of fixed sodium hydroxide, 20 parts of sodium silicate solution, and 10 parts of deionized water. When preparing the alkali activator, use a stirring rod to stir until it is uniform and clear, and then pour it into a plastic container and keep it sealed for 12 hours.

[0032] The viscosity of polydimethylsiloxane is 100 Stokes; the particle size of silicon carbide powder is 50-100 nanometers; the diameter of basalt fiber is 20-25 microns, and the average length is 5 mm; the concentration of hydrogen peroxide is 35% .

[0033] A ...

Embodiment 2

[0040] A superhydrophobic geopolymer prepared by microcellular foaming, comprising 15 parts of metakaolin, 5 parts of fly ash, 15 parts of silica fume, 45 parts of alkali activator, 1.5 parts of polydimethylsiloxane, silane 0.15 parts of joint agent, 2 parts of silicon carbide powder, 2 parts of silicon nitride fiber, 2 parts of alkyl glycoside, 2 parts of hydrogen peroxide.

[0041] The alkali activator is a compound material, which includes 10 parts of fixed sodium hydroxide, 25 parts of sodium silicate solution, and 10 parts of deionized water. When preparing the alkali activator, use a stirring rod to stir until it is uniform and clear, and then pour it into a plastic container and keep it sealed for 12 hours.

[0042] The viscosity of polydimethylsiloxane is 100 Stokes; the particle size of silicon carbide powder is 100-200 nanometers; the diameter of silicon nitride fiber is 10-15 microns, and the average length is 2 mm; the concentration of hydrogen peroxide is 30%.

[...

Embodiment 3

[0050] A superhydrophobic geopolymer prepared by microcellular foaming, comprising 20 parts of metakaolin, 10 parts of fly ash, 10 parts of silica fume, 45 parts of alkali activator, 1 part of polydimethylsiloxane, silane 0.1 part of joint agent, 3 parts of silicon carbide powder, 2 parts of basalt fiber, 1 part of alkyl glycoside, 3 parts of hydrogen peroxide.

[0051] The alkali activator is a compound material, which includes 8 parts of fixed sodium hydroxide, 25 parts of sodium silicate solution, and 12 parts of deionized water. When preparing the alkali activator, use a stirring rod to stir until it is uniform and clear, and then pour it into a plastic container and keep it sealed for 12 hours.

[0052] The viscosity of polydimethylsiloxane is 50 Stokes; the particle size of silicon carbide powder is 100-200 nanometers; the diameter of basalt fiber is 20-25 microns, and the average length is 5 mm; the concentration of hydrogen peroxide is 30% .

[0053] A method for pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com