Micro-injection molding mould with super-hydrophobic surface of micro-nano composite structure and micro-injection molding method

A technology of micro-nano composite structure and super-hydrophobic surface, which can be applied in cleaning methods, cleaning methods and utensils using liquids, chemical instruments and methods, etc. problems such as poor core tolerance, to facilitate research and mass production, reduce the requirements of experimental protection, and achieve the effect of good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

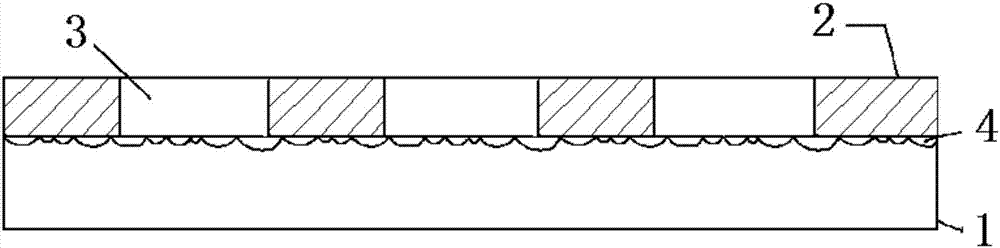

Image

Examples

Embodiment 1

[0051] The nano-structured surface of the nano-aluminum alloy plate 1 is obtained through an electrochemical corrosion anodic coating process, such as Figure 7 Shown; The preparation method of nano-aluminum alloy plate 1, specifically carries out according to the following steps:

[0052] Step (1), put a 5052 aluminum alloy plate with a size of 10cm in length x 10cm in width x 300μm in thickness for ultrasonic cleaning in acetone to remove the oil on the surface, and then ultrasonically clean it with distilled water for 8 minutes;

[0053] Step (2), put the aluminum alloy plate cleaned in step (1) into a sodium hydroxide solution with a concentration of 30g / L, place it ultrasonically at 57°C for 1min, remove the oxide layer on the surface, and then ultrasonically clean it with distilled water for 8min;

[0054] In step (3), place the aluminum alloy plate cleaned in step (2) in a 300g / L nitric acid solution to neutralize the residual sodium hydroxide solution on the surface of...

Embodiment 2

[0059] The preparation method of the nano-aluminum alloy plate 1 is specifically carried out according to the following steps:

[0060] Step (1), put a 5052 aluminum alloy plate with a size of 10cm in length x 10cm in width x 250μm in thickness for ultrasonic cleaning in acetone to remove the oil on the surface, and then ultrasonically clean it with distilled water for 5 minutes;

[0061] Step (2), put the aluminum alloy plate cleaned in step (1) into a sodium hydroxide solution with a concentration of 25g / L, place it ultrasonically at 53°C for 2min, remove the oxide layer on the surface, and then ultrasonically clean it with distilled water for 5min;

[0062] In step (3), place the aluminum alloy plate cleaned in step (2) in a 350g / L nitric acid solution to neutralize the residual sodium hydroxide solution on the surface of the aluminum alloy plate for 3 minutes, and then put the aluminum alloy plate in distilled water Ultrasonic cleaning for 8 minutes;

[0063] Step (4), th...

Embodiment 3

[0067] The preparation method of the nano-aluminum alloy plate 1 is specifically carried out according to the following steps:

[0068] Step (1), put a 5052 aluminum alloy plate with a size of 10cm in length x 10cm in width x 270μm in thickness for ultrasonic cleaning in acetone to remove the oil on the surface, and then ultrasonically clean it with distilled water for 6 minutes;

[0069] Step (2), put the aluminum alloy plate cleaned in step (1) into a sodium hydroxide solution with a concentration of 28g / L, place it ultrasonically at 55°C for 1.5min, remove the oxide layer on the surface, and then ultrasonically clean it with distilled water for 6min ;

[0070] In step (3), place the aluminum alloy plate cleaned in step (2) in a 320g / L nitric acid solution to neutralize the residual sodium hydroxide solution on the surface of the aluminum alloy plate for 3.5 minutes, and then put the aluminum alloy plate in distilled water Medium ultrasonic cleaning for 9 minutes;

[0071]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com