Superhydrophobic coating containing hollow glass beads and preparation method thereof

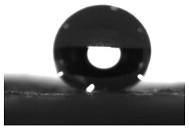

A technology of hollow glass microspheres and super-hydrophobic coating, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of cumbersome preparation process of super-hydrophobic coating and inability to achieve large-scale application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Modification of hollow glass microspheres: 1.8 g of n-octyltriethoxysilane was dissolved in a mixed solution of ethanol-deionized water (the mass fraction of ethanol was 95%), and the temperature was raised to 60° C. after stirring evenly. Add 18.0 g of hollow glass microspheres and continue to stir and react for 4 hours, then dry to obtain surface hydrophobized hollow glass microspheres.

[0020] (2) Preparation of brushing solution: 1. Prepare polyurethane solution according to the mass ratio of polyurethane elastomer and organic solvent 1:6; 2. Prepare polyvinylidene fluoride according to the mass ratio of polyvinylidene fluoride and N-methylpyrrolidone 1:20 Vinyl fluoride solution; 3. Weigh the polyurethane solution and polyvinylidene fluoride solution according to the mass ratio of polyurethane elastomer and polyvinylidene fluoride 6:3 and magnetically stir to obtain a polymer mixed solution A; 4. According to the modified hollow glass micro The mass ratio of t...

Embodiment 2

[0023] (1) Modification of hollow glass microspheres: Dissolve 1.5 g of n-octyltriethoxysilane in a mixed solution of ethanol-deionized water (ethanol mass fraction is 85%), stir evenly and heat up to 60°C. Add 15.0 g of hollow glass microspheres and continue to stir and react for 4 hours, then dry to obtain surface hydrophobized hollow glass microspheres.

[0024] (2) Preparation of brushing solution: 1. Prepare polyurethane solution according to the mass ratio of polyurethane elastomer and organic solvent 1:5; 2. Prepare polyvinylidene fluoride according to the mass ratio of polyvinylidene fluoride and N-methylpyrrolidone 1:20 Vinyl fluoride solution; 3. Weigh the polyurethane solution and polyvinylidene fluoride solution according to the mass ratio of polyurethane elastomer and polyvinylidene fluoride 6:1 and magnetically stir to obtain a polymer mixed solution A; 4. According to the modified hollow glass micro The mass ratio of the solute (polyurethane elastomer + polyviny...

Embodiment 3

[0027] (1) Modification of hollow glass microspheres: Dissolve 2.0 g of perfluorodecyltriethoxysilane in a mixed solution of ethanol-deionized water (the mass fraction of ethanol is 90%), stir evenly and heat up to 70°C . Add 20.0 g of hollow glass microspheres and continue to stir and react for 3 hours, then dry to obtain surface hydrophobized hollow glass microspheres.

[0028] (2) Preparation of brushing solution: 1. Prepare polyurethane solution according to the mass ratio of polyurethane elastomer and organic solvent 1:7; 2. Prepare polyvinylidene fluoride according to the mass ratio of polyvinylidene fluoride and N-methylpyrrolidone 1:18 Vinyl fluoride solution; 3. Weigh the polyurethane solution and polyvinylidene fluoride solution according to the mass ratio of polyurethane elastomer and polyvinylidene fluoride 6:2 and magnetically stir to obtain a polymer mixed solution A; 4. According to the modified hollow glass micro The mass ratio of the beads to the obtained pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com