Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Sodium phenoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

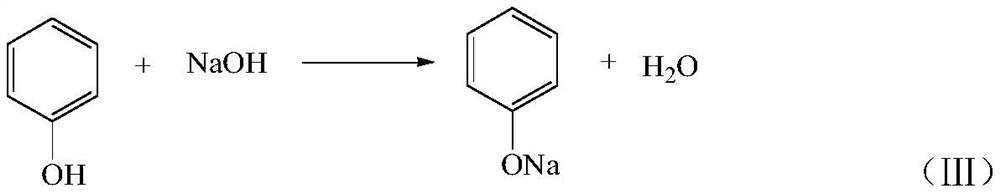

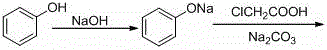

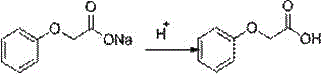

Sodium phenoxide (sodium phenolate) is an organic compound with the formula NaOC₆H₅. It is a white crystalline solid. Its anion, phenoxide, also known as phenolate, is the conjugate base of phenol. It is used as a precursor to many other organic compounds, such as aryl ethers.

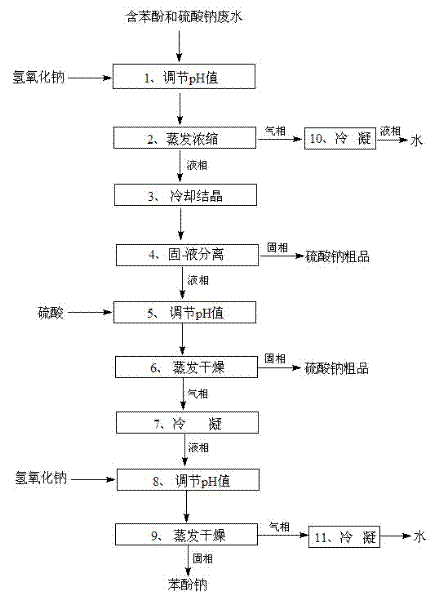

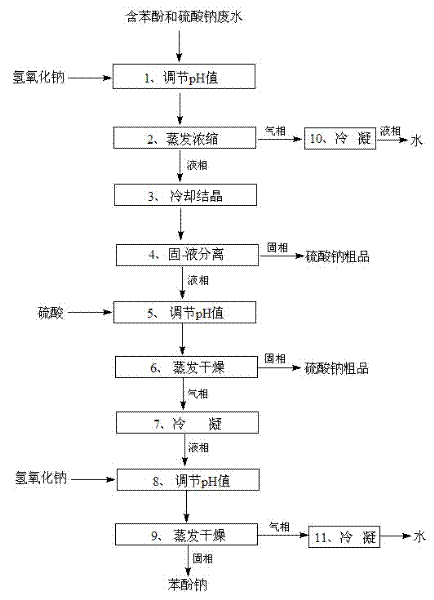

Resource utilization of waste water containing phenol and sodium sulfate and treating method

InactiveCN102351357AReasonable workmanshipSimple methodOrganic chemistryOrganic compound preparationSodium PhenolateWastewater

The invention relates to resource utilization of waste water containing phenol and sodium sulfate and a treating method, and especially to a method of treating waste water containing 0.1% to 2.0% of phenol and 5% to 30% of sodium sulfate and recycling phenol and sodium sulfate. The method comprises the following steps: (1) pH value adjusting; (2) evaporative concentration; (3) cooling and crystallization; (4) solid-liquid separation; (5) pH value adjusting; (6) evaporation and drying; (7) condensation; (8) pH value adjusting; (9) evaporation and drying. The method enables sodium phenolate and a byproduct of sodium sulfate to be obtained simultaneously. The invention has the advantages of a reasonable process, a simple method, environmental protection, energy consumption, low operational cost, good product quality and a high utilization rate of valuable components.

Owner:扬州大学江都高端装备工程技术研究所

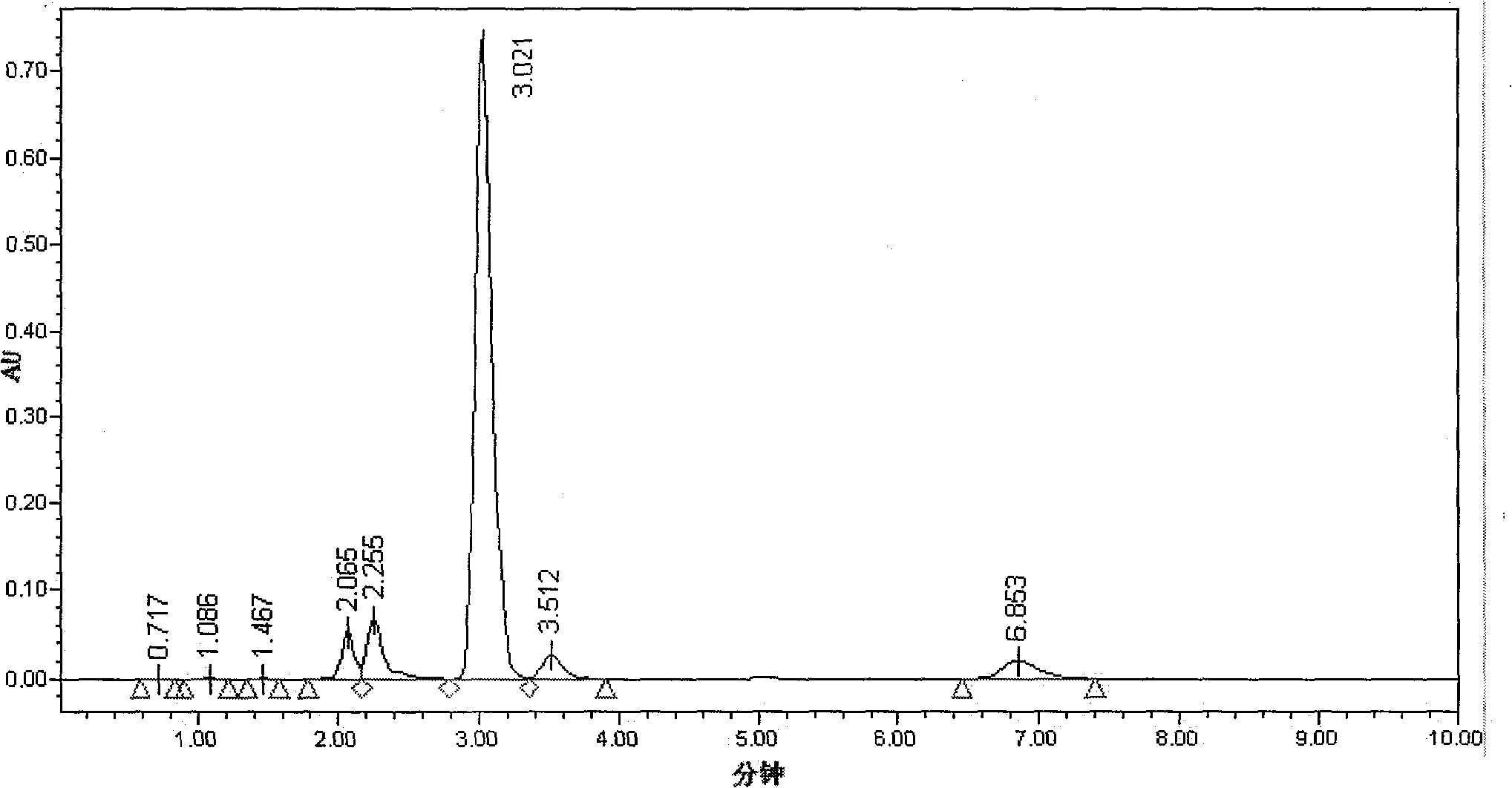

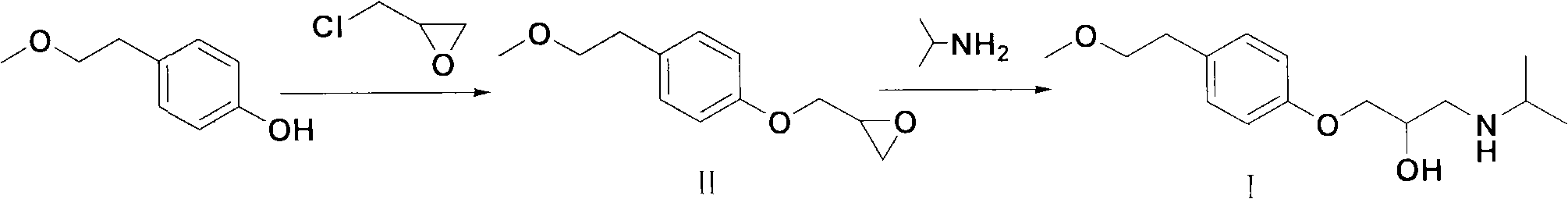

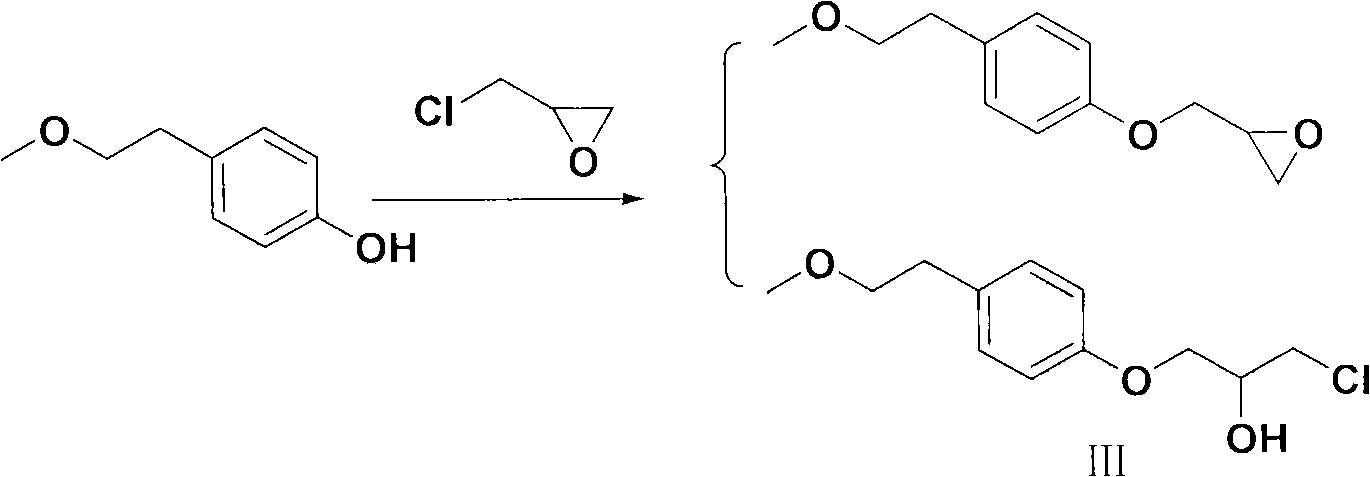

Preparation method of metoprolol

InactiveCN102381995AHigh purityShort reaction timeOrganic compound preparationAmino-hyroxy compound preparationIsopropyl alcoholMetoprolol

The invention relates to a preparation method of metoprolol. Reaction of methoxy ethyl phenol and sodium hydroxide liquor is carried out at the temperature ranging from 30 DEG C to 80 DEG C to generate methoxy sodium ethyl phenate. When the temperature is reduced to a range between 0 DEG C and 40 DEG C, epichlorohydrin is added for reaction to obtain compound II. Due to isopropyl alcohol, the compound II is reacted with isopropyl amine to obtain metoprolol. Compared with the prior art, fewer by-products are generated during preparation of the compound II, reaction time is short, and the obtained product can be reacted with the isopropyl amine to prepare the metoprolol without being purified.

Owner:YANGTZE RIVER PHARMA GRP BEIJING HAIYAN PHARMA +1

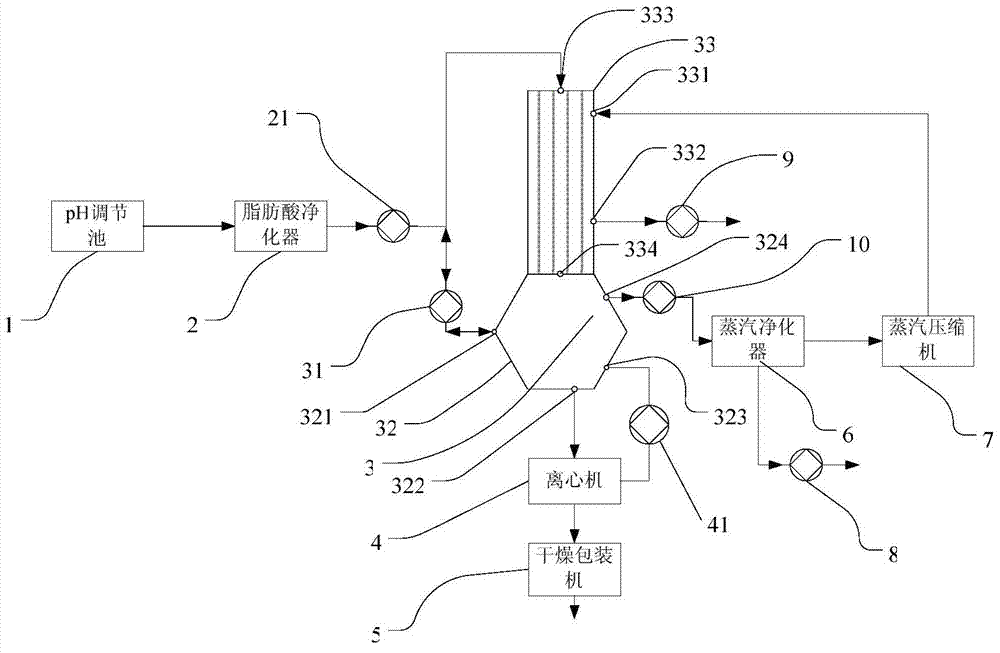

Process and device for recovering and treating wastewater generated by preparing sebacic acid with castor oil

ActiveCN103787542ARealize resource reuseAchieving zero emissionsMultistage water/sewage treatmentNature of treatment waterSebacic acidFatty acid

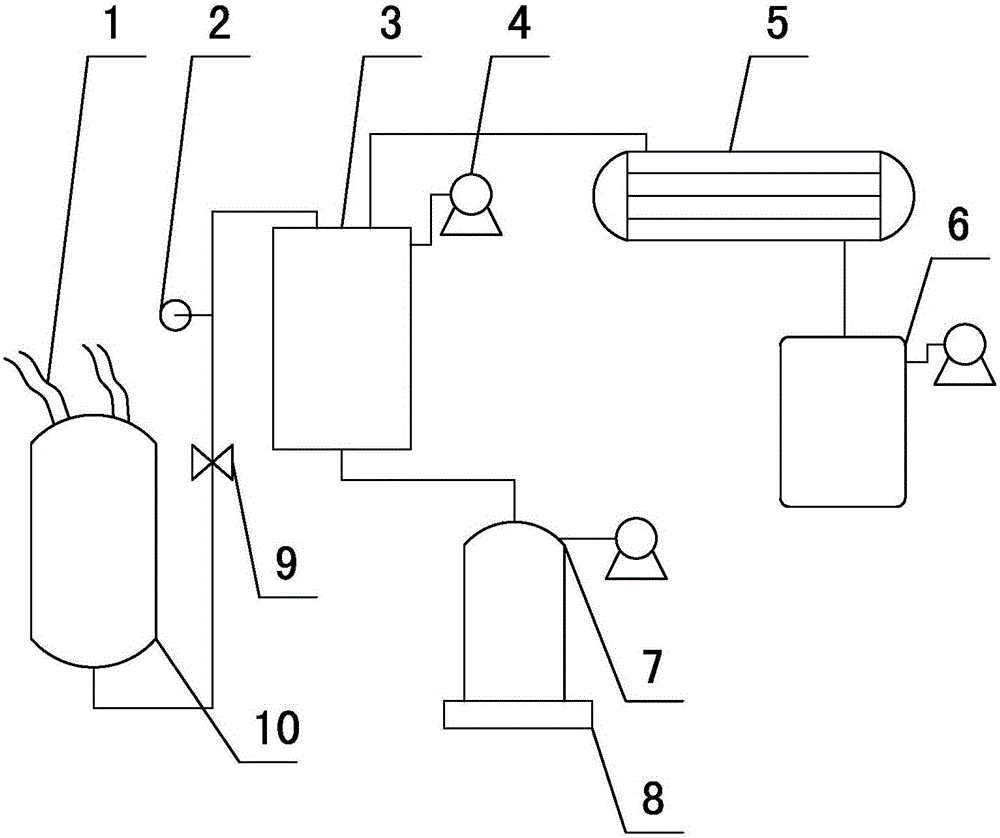

The invention relates to a process and a device for recovering and treating wastewater generated by preparing sebacic acid with castor oil. The process comprises the steps of a, adjusting the pH value, b, purifying a fatty acid, c, carrying out evaporative crystallization, d, carrying out solid-liquid separation of anhydrous sodium sulfate, e, purifying secondary steam by removing phenol, f, compressing the secondary steam, and g, repeating the steps c-f, and collecting a sodium phenate solution, condensate water and the separated solid obtained in the step d. The invention also relates to a device for recovering and treating wastewater generated by preparing sebacic acid with castor oil; the device comprises a pH regulating reservoir, a fatty acid purifier, a waste material delivery pump, a mechanical steam recompression / evaporative crystallization system, a dryer and the like. The recovery process is simple to operate and low in cost, and also capable of realizing zero emission of contaminants, and environment-friendly and energy-saving, and in the meantime, the recovery device is simple and easy to operate.

Owner:广州新普利节能环保科技有限公司

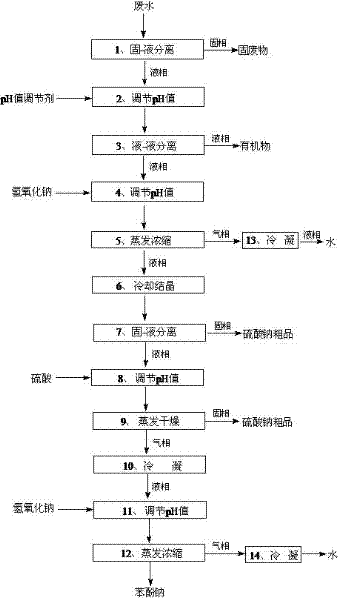

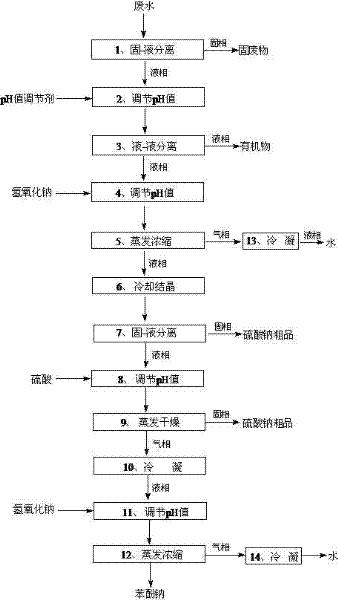

Recycling utilization and processing method for wastewater generated in sebacic acid production process

InactiveCN102311195AIncrease profitReduce heat transfer areaPreparation from carboxylic acid saltsOrganic compound preparationWastewaterProcess engineering

The invention releases to a recycling utilization and processing method for wastewater generated in a sebacic acid production process, in particular to a recycling utilization and processing method for wastewater containing phenol and sodium sulfate generated in the sebacic acid production process. The method comprises the following steps: (1) carrying out solid-liquid separation; (2) regulating a pH value; (3) carrying out liquid-liquid separation; (4) regulating the pH value; (5) evaporating and concentrating; (6) cooling and crystallizing; (7) carrying out solid-liquid separation; (8) regulating the pH value; (9) evaporating and drying; (10) condensing; (11) regulating the pH value; and (12) evaporating and condensing. With the technical method, the byproduct sodium sulfate can be obtained while sodium phenate is obtained. The recycling utilization and processing method has the advantages of reasonable technology, simple method, low operation cost, and high valuable ingredient use ratio, and is energy-saving and environmentally-friendly, and the generated products have high quality.

Owner:YANGZHOU UNIV

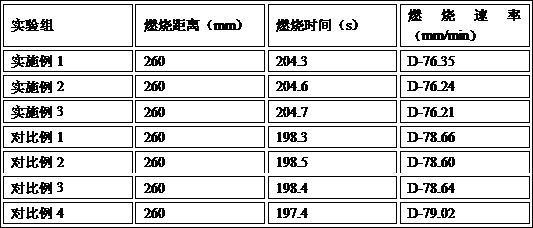

Epoxy resin curing agent and preparation method thereof

InactiveCN103641999ASimple preparation processLow costGroup 5/15 element organic compoundsEpoxyPhosphor

The invention relates an epoxy resin curing agent and a preparation method thereof, belonging to the technical field of auxiliary synthesis. A preparation process of the epoxy resin curing agent comprises synthesis of a first intermediate, synthesis of a second intermediate and synthesis of an end product. The preparation method specifically comprises the following steps: under protection of an inert atmosphere, dissolving phosphonitrilic chloride trimer in a solvent tetrahydrofuran, dropwise adding tetrahydrofuran liquor of sodium phenoxide, and reacting to obtain the first intermediate; dissolving aminophenol into the solvent tetrahydrofuran, dropwise adding tetrahydrofuran liquor of sodium hydride, and curing to obtain the second intermediate; and obtaining the product by reacting the first intermediate with the second intermediate. The curing agent obtained by adopting the technical scheme disclosed by the invention has characteristics of being simple to synthesize and prepare, high in thermal stability and high in high-temperature solid residual rate, contains a large number of nitrogen-phosphor elements, and has excellent halogen-free flame-retardant performance.

Owner:IND RES INST ZHIJIANG COLLEGE OF ZHEJIANG UNIV OF TECH

Salicylic acid preparation method

InactiveCN110143860AHigh purityHigh recovery rateOrganic compound preparationCarboxylic compound separation/purificationCross-linkDesorption

The invention provides a salicylic acid preparation method. The preparation method specifically comprises the following steps: step 1, preparing sodium phenoxide powder; step 2, preparing a sodium salicylate solution; step 3, preparing industrial salicylic acid; step 4, preparing salicylic acid; and step 5, recovering sodium salicylate. Salicylic acid and phenol are recovered from wastewater produced by salicylic acid preparation, and the recovery rate by using NDA-800 ultra-high cross-linked adsorption resin is high; purity of the recovered phenol and salicylic acid is high, the recovered phenol and salicylic acid can be directly produced and recycled, and the use is not influenced. The NDA-800 ultra-high cross-linked adsorption resin can be repeatedly used after desorption, and the recycled wastewater can reach the emission standard after simple treatment.

Owner:ZHENJIANG GAOPENG PHARMA

Dehydration technology and device for salicylic acid intermediate sodium phenoxide

InactiveCN104998429ASimplify the dehydration processReduce processing timeOrganic chemistryOrganic compound preparationSodium PhenolateSalicylic acid

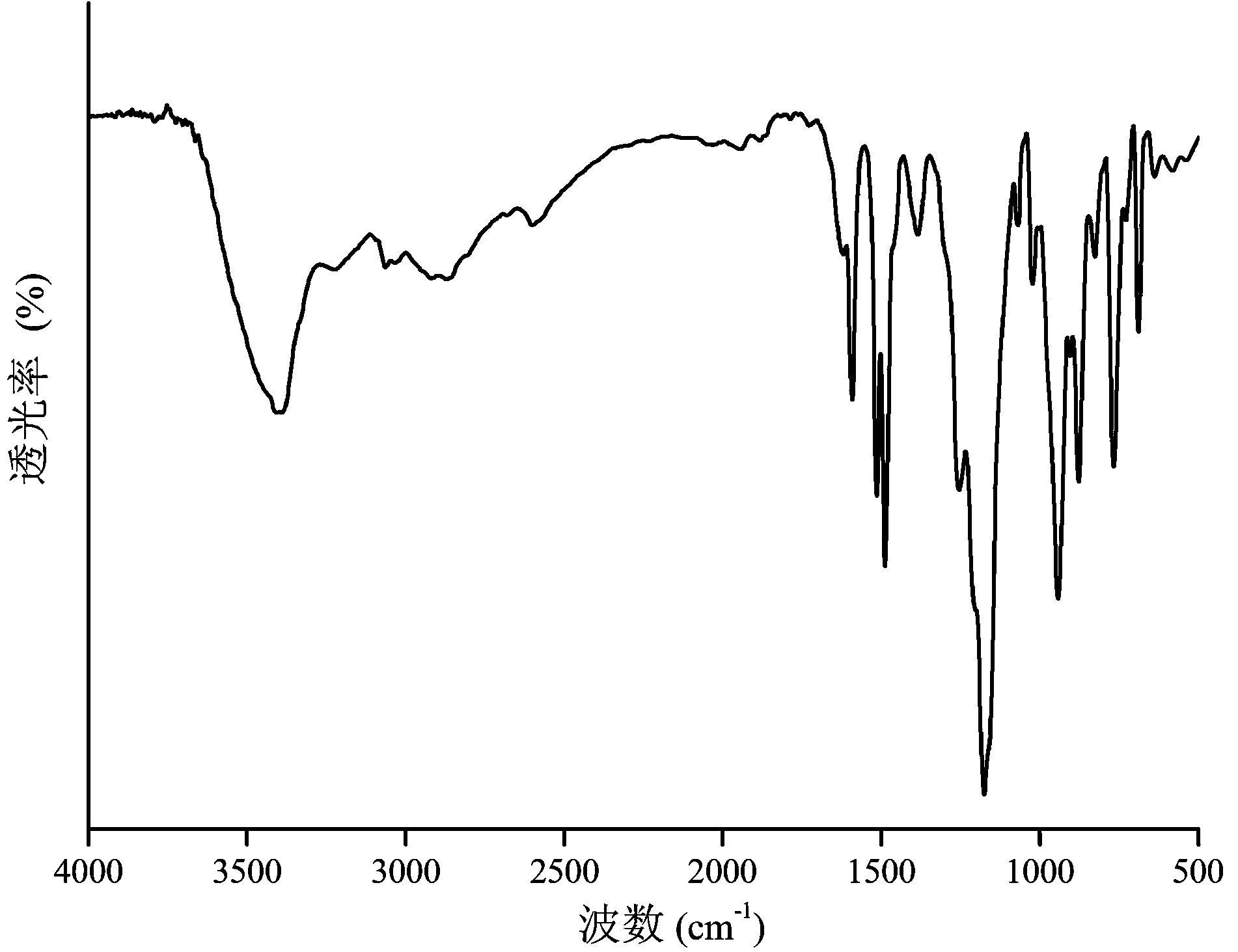

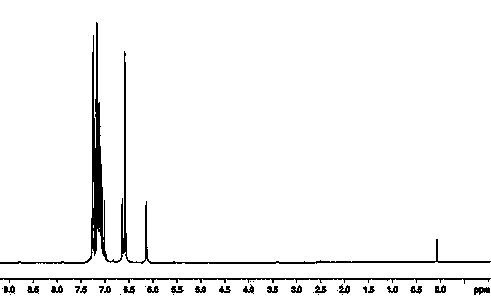

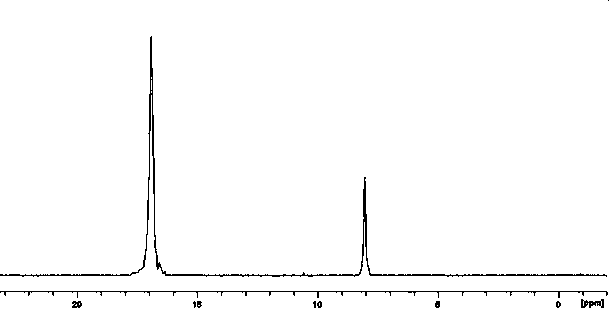

The invention relates to a dehydration technology and device for salicylic acid intermediate sodium phenoxide and belongs to the technical field of dehydration of sodium phenoxide. According to the dehydration technology for the salicylic acid intermediate sodium phenoxide, a prepared sodium phenoxide solution is heated, then a vacuum feeding manner is adopted, the sodium phenoxide solution is delivered to a membrane evaporator for evaporation dehydration, and steam in the membrane evaporator is collected after being condensed. With the adoption of the dehydration technology for the salicylic acid intermediate sodium phenoxide, the technology time is shortened and the heat utilization efficiency is improved; the dehydration device for the salicylic acid intermediate sodium phenoxide is simple to design, scientific and reasonable.

Owner:SHANDONG XINHUA PHARMA CO LTD

Method for preparing 2,5-dihydroxy p-benzene dicarboxylic acid

InactiveCN101508642AHigh yieldHigh purityOrganic compound preparationCarboxylic compound preparationPtru catalystN octane

A method for the carboxylation preparation of 2,5-dihydroxyterephthalic acid by taking n-octane as solvent to Pd(II) / C-catalyze the hydroquinone is disclosed, specifically comprising the steps of: in a high-pressure reaction kettle, taking sodium phenolate, potassium hydroxide and carbon dioxide as reactants, performing Pd(II) / C-catalysis to prepare 2,5-dihydroxyterephthalic acid sylvite, and obtaining the 2,5-dihydroxyterephthalic acid by means of recrystallization and acidification. The inventive catalyst is simply prepared, the solvent is easy for recovery and the product is high in purity.

Owner:JIANGSU UNIV

Preparation method of 4-chlorine-3-fluorine benzene ether

InactiveCN107721832AHigh yieldHigh purityOrganic compound preparationEther preparation by ester reactionsN dimethylformamideOil phase

The invention discloses a preparation method of 4-chlorine-3-fluorine benzene ether. The preparation method comprises the following steps: firstly, by taking o-fluoronitrobenzene as a raw material, preparing 4-amino-3-fluorophenol; taking N,N-dimethylformamide as a reaction medium, carrying out acylating chlorination reaction between the 4-amino-3-fluorophenol and an acyl chloride reagent, thus preparing 4-chlorine-3-fluorophenol, mixing sodium phenoxide with a sodium hydroxide aqueous solution, then adding the 4-chlorine-3-fluorophenol, and uniformly stirring and mixing, thus preparing a mixed solution; adding the prepared mixed solution into a reactor, then adding diethyl sulfate, stirring for 3 min, and heating to 80 to 120 DEG C for reaction; at the end of reaction, adjusting the pH ofa reaction system to 2 to 5, allowing the reaction system to stand still for layering, collecting an oil phase, washing the oil phase with the sodium hydroxide aqueous solution, and collecting the oil phase, namely the 4-chlorine-3-fluorine benzene ether. The method disclosed by the invention is easy to operate, low in cost, high in target product purity and high in yield.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Continuous synthetic method of phenoxy acetic acid

ActiveCN104829447AControl reaction temperatureLess side effectsPreparation from carboxylic acid saltsOrganic compound preparationSodium acetateSodium chloroacetate

The invention provides a continuous synthetic method of phenoxy acetic acid and belongs to the technical field of preparation of a herbicide 2,4-D intermediate. The method comprises the following steps: simultaneously adding a sodium phenoxide aqueous solution and a sodium chloroacetate aqueous solution into a constant-pressure funnel provided with a heating sleeve to perform mixed reaction, and retaining the mixture in the constant-pressure funnel for 10-15min; overflowing reaction liquid into a 3-mouth flask containing dilute hydrochloric acid or dilute sulfuric acid at 15-20 DEG C; adjusting the pH value to 5-6 by using the dilute hydrochloric acid or dilute sulfuric acid; stirring for 0.8-1.2 hours at room temperature; and performing suction filtration to obtain white crystalline powder namely phenoxy acetic acid. According to the method provided by the invention, the sodium phenoxide aqueous solution and the sodium chloroacetate aqueous solution are simultaneously added into the constant-pressure funnel provided with the heating sleeve to perform reaction, so that the internal pressure can be kept unchanged, inverse suction can be prevented and the liquid in the funnel can flow downwards smoothly to improve the reaction efficiency; and moreover, during the preparation of the sodium chloroacetate solution, a Na2CO3 solution is dropwise added into chloroacetic acid slowly, and the chloroacetic acid is excessive, so that the reaction temperature can be beneficially controlled, and side reactions are reduced.

Owner:邳州市润宏实业有限公司

Application of phenolic compounds as nematicides

The invention belongs to the field of pesticides, and particularly relates to an application of phenol compounds as nematicides. The invention further discloses the application of one or more of the phenolic compounds represented by the general formula I or salts thereof in serving as the nematicides. The general formula I is shown in the specification. The compounds are suitable for being used asthe nematicides, especially sodium phenolate with good activity is commonly used as a preservative, and 3-hydroxybenzoic acid and 4-hydroxybenzoic acid are antioxidants which are widely applied at present, and the compounds are low in toxicity, low in price and easy to obtain.

Owner:沈阳恩柽研究院有限公司

Synthetic method of methyl salicylate

PendingCN112341335AReduce pollutionReduce corrosionOrganic compound preparationCarboxylic acid esters preparationPtru catalystStrong acids

The invention discloses a synthesis method of methyl salicylate. The method comprises the following steps: preparing sodium phenolate by using caustic soda flakes and phenol as raw materials, carryingout carboxylation reaction on the obtained sodium phenolate and carbon dioxide gas to obtain sodium salicylate, reacting the obtained sodium salicylate with chloromethane gas under the action of a phase transfer catalyst to obtain a crude methyl salicylate product containing a toluene solvent, neutralizing and washing the crude methyl salicylate product, recovering the toluene solvent at normal pressure, and carrying out vacuum distillation to obtain a finished methyl salicylate product. According to the method, a strong acid catalyst is not used, so that the wastewater amount is greatly reduced, and the corrosion to equipment and the pollution to the environment are reduced. According to the method, equipment is not seriously corroded, the wastewater amount is small, and the process is more environmentally friendly.

Owner:江苏宏邦化工科技有限公司

Technology for preparing salicylic acid through micro-channel continuous-flow reactor

InactiveCN110041189AEfficient conductionEnlarge the mass transfer interfacePreparation from carboxylic acid saltsCarboxylic acid salt preparationSalicylic acidContinuous flow

The invention discloses a technology for preparing salicylic acid through a micro-channel continuous-flow reactor. The technology comprises the following steps: (1) mixing a preheated sodium phenoxidesolution and preheated carbon dioxide in the micro-channel continuous-flow reactor, reacting, cooling and discharging after reaction, performing gas-liquid separation on material liquid and collecting a liquid solution; (2) utilizing water to extract the liquid solution prepared in the step (1) and acidifying an obtained water solution to prepare a salicylic acid crude product. The preparation technology disclosed by the invention can greatly improve the gas-liquid contact area in a reaction process, and the production efficiency is improved; meanwhile, the fine pipe diameter and the large specific surface area of the micro-channel reactor are favorable for mass and heat transfer of a reaction system, and occurrence of side reaction in the reaction process is reduced; in addition, the continuous reaction characteristic can effectively improve stability of product quality; by means of the reaction device, the sodium phenoxide conversion rate can reach 93% or above, and the salicylic acid yield can reach 91% or above; thus, the preparation technology is very suitable for industrial production.

Owner:SOUTHEAST UNIV

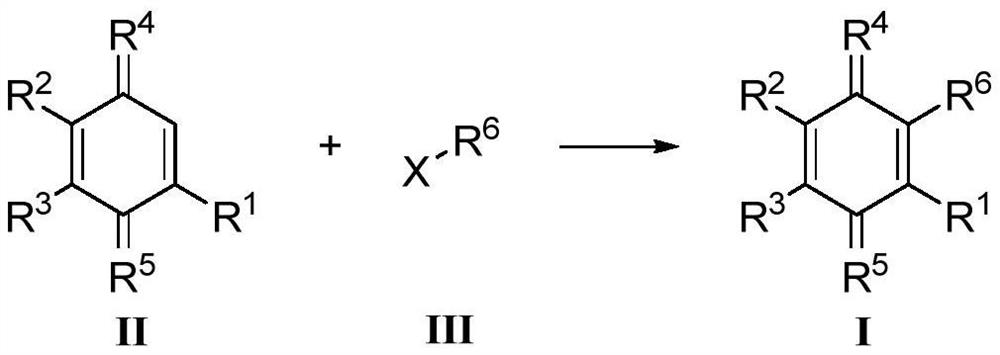

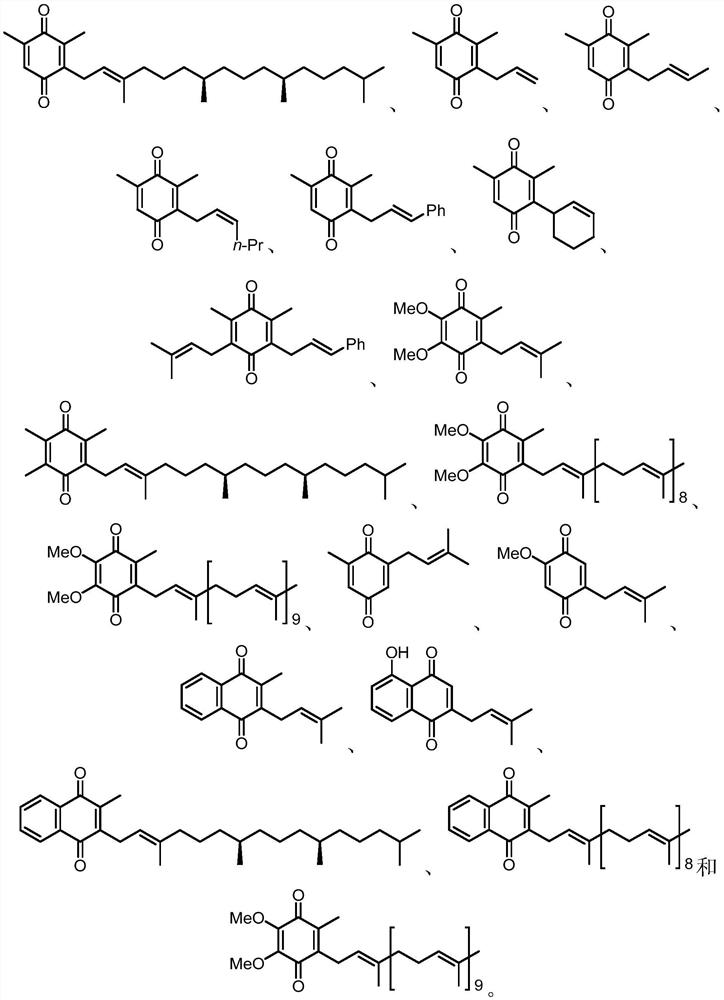

Preparation method of quinone compound

ActiveCN113735696ANo residueHigh selectivityOrganic compound preparationQuinone preparationCombinatorial chemistryQuinone Compound

The invention discloses a preparation method of a quinone compound. The invention provides the preparation method of the quinone compound, the preparation method comprises the following step: in the presence of alkali, carrying out condensation reaction on a compound as shown in a formula II and a compound as shown in a formula III to obtain the quinone compound as shown in a formula I, the alkalinity of the alkali is stronger than that of sodium phenate. The method is easy to operate and suitable for industrial production.

Owner:SHANGHAI TECH UNIV

Anti-cracking polyethylene photovoltaic cable material and preparation method thereof

InactiveCN112266525AImprove crack resistanceAvoid hydrolysisPlastic/resin/waxes insulatorsCellulosePolymer science

The invention discloses an anti-cracking polyethylene photovoltaic cable material and a preparation method thereof, and the anti-cracking polyethylene photovoltaic cable material comprises the following raw materials by weight: 10-15 parts of crosslinked polyethylene, 5-7 parts of polyvinyl chloride, 5-7 parts of a heat stabilizer, 2-4 parts of a plasticizer, 2-4 parts of a hardener, 2-3 parts ofa colorant, 2-4 parts of a lubricant, 2-4 parts of a flame retardant, and 2-4 parts of zirconium dioxide. The heat stabilizer is composed of phenol, a methyltin heat stabilizer and a barium-zinc heatstabilizer, the lubricant is composed of sodium stearate and magnesium stearate, the hardener is composed of cellulose and glass fibers, the plasticizer is composed of cyclic fatty acid methyl ester and methyl phosphate, and the flame retardant is composed of triphenyl phosphate, melamine cyanurate and parachlorophenol. According to the invention, the overall tear resistance of the product is improved by adopting a cross-linked polyethylene polyvinyl chloride doping mode, phenol and sodium hydroxide are combined to generate sodium phenolate to absorb phosgene, and the effect of improving the safety of the product in the preparation and use processes can be achieved.

Owner:吴春明

Efficient synthesis method of salicylic acid

PendingCN113336638AReduce production efficiencySimple process principlePreparation from carboxylic acid saltsOrganic compound preparationSalicylic acid synthesisMedicinal chemistry

An efficient synthesis method of salicylic acid belongs to the technical field of salicylic acid synthesis. The dehydration method adopted by the invention comprises the following steps: vacuumizing a sodium phenate solution for primary dehydration, adding phenol into the sodium phenate solution when the water content of the sodium phenate solution reaches about 45% such that a part of the phenol and water form a binary azeotrope, and separating the binary azeotrope under negative pressure condiction to achieve the purpose of taking out water by the phenol. The residual phenol and the sodium phenate form the bulky compound under the vacuum condition, and the bulky compound has the large specific surface area, such that the reaction rate is accelerated, the reaction time is substantially shortened, and the production efficiency is improved when the CO2 is introduced to perform the carboxylation reaction; meanwhile, the binary azeotrope and phenol separated in the process can be recycled, so that resources are saved, and the cost is reduced.

Owner:宁夏万香源生物科技有限公司

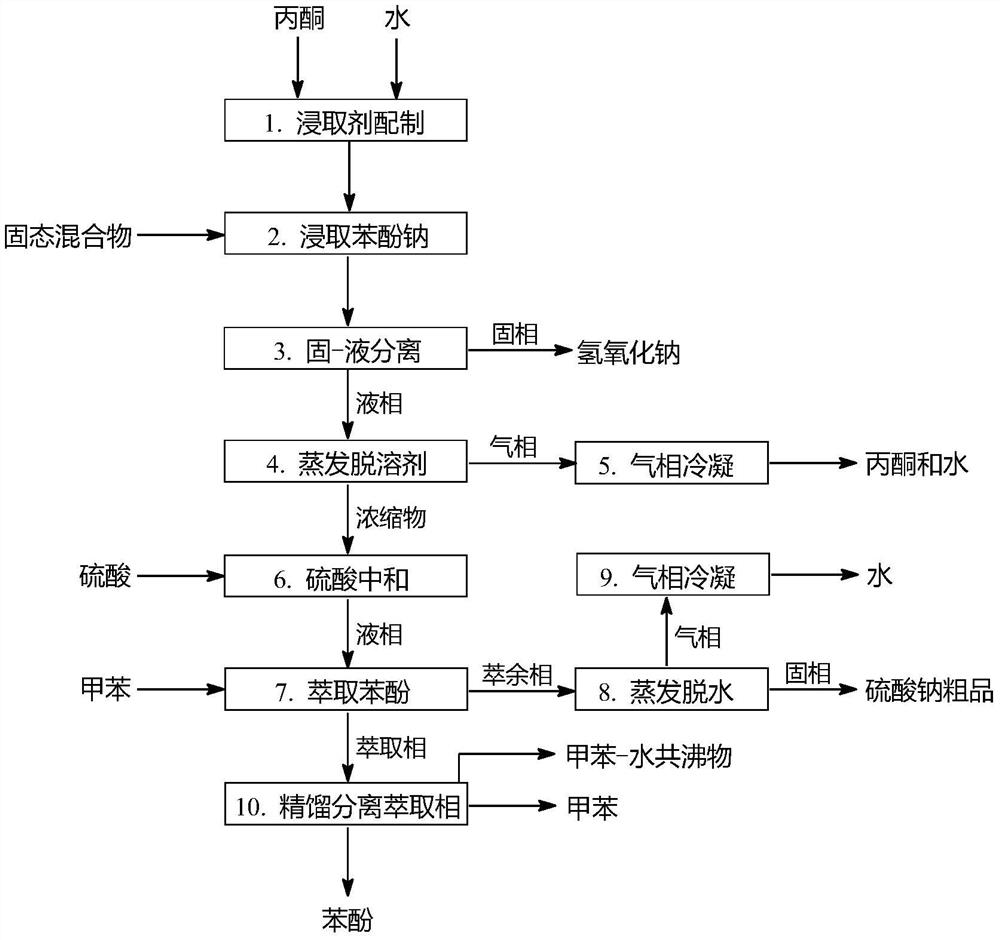

Method for separating sodium phenolate and sodium hydroxide solid mixture and recovering phenol by toluene extraction separation

ActiveCN111777495ANo lossEmission reductionOrganic chemistryOrganic compound preparationChemical industrySodium Phenolate

The invention relates to a method for separating a sodium phenolate and sodium hydroxide solid mixture and recovering phenol by toluene extraction separation. Particularly, an acetone-water mixed solvent is used as a leaching agent, methyl benzene is used as an extracting agent, a leaching-extraction-rectification coupled technology is adopted for separating and recovering phenol, and cyclic utilization of sodium hydroxide, the leaching agent and the extracting agent is achieved while phenol is obtained through separation. The separation method fully utilizes the characteristics of a separatedmaterial system and the characteristics of the separation process, is simple and feasible in separation operation, low in operation cost, high in material utilization rate, clean and environment-friendly, and is a clean production method meeting the development requirements of green chemical industry.

Owner:YANGZHOU UNIV

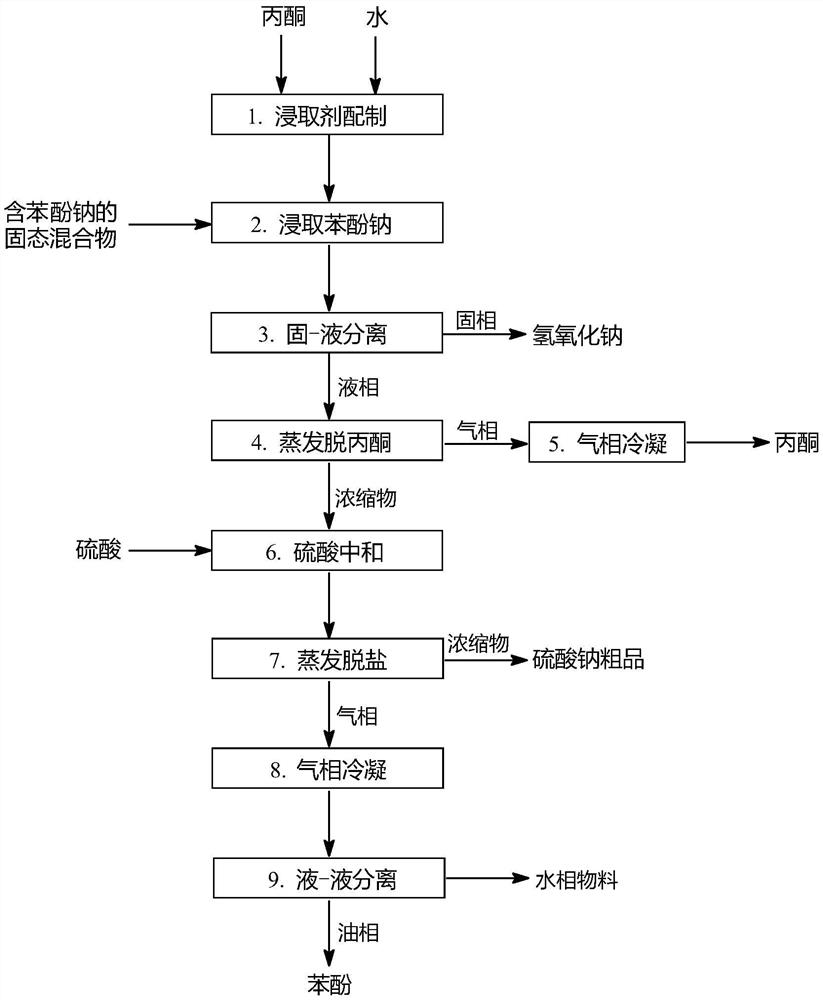

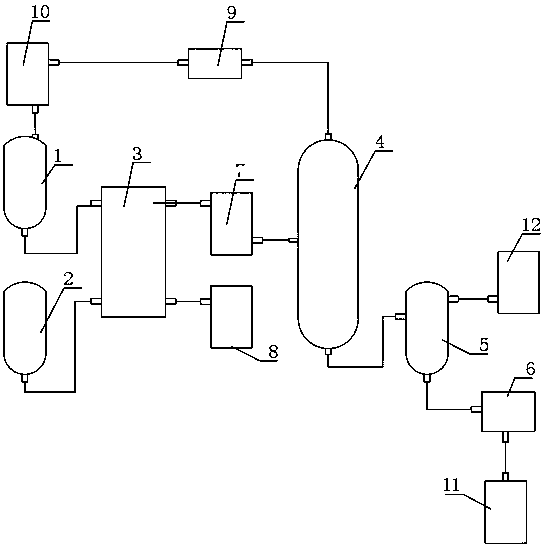

A method of leaching-evaporation-phase separation coupled separation and recovery of phenol

ActiveCN111635296BImprove solubilitySeparation is feasibleOrganic chemistryOrganic compound preparationSocial benefitsSodium Phenolate

The invention relates to a method for leaching-evaporation-phase separation coupled separation and recovery of phenol, in particular using acetone-water mixed solvent as the leaching agent to leaching and separating the solid mixture of sodium phenate and sodium hydroxide, and then evaporating, liquid-liquid Phase separation to obtain phenol, while sodium hydroxide, acetone, and water can be recycled. The separation method of the present invention makes full use of the characteristics of the separated species and the characteristics of the separation process. Not only is the separation operation simple and easy, and the operation cost is low, but also other materials can be recovered and utilized as resources while separating and obtaining phenol. The process technology not only has industrial application value, but also has significant economic and social benefits.

Owner:YANGZHOU UNIV

Method for synthesizing phenoxycycloposphazene

InactiveCN110759947AContinuous operationHigh degree of automationGroup 5/15 element organic compoundsOrganic solventPtru catalyst

The invention discloses a method for synthesizing phenoxycycloposphazene. The method comprises the following steps: dissolving hexachlorocyclotriphosphazene and a phase transfer catalyst into an organic solvent so as to obtain an organic-phase raw material; by taking a sodium phenate aqueous solution as a water-phase raw material, simultaneously feeding the organic-phase raw material and the water-phase raw material into a multi-stage centrifugal extractor with a heating function, performing a multi-stage countercurrent reaction, dissolving generated phenoxycycloposphazene into an organic solvent to form an organic-phase reaction liquid, and dissolving generated sodium chloride into water to form a water-phase reaction liquid; and distilling the organic-phase reaction liquid supporting thephenoxycycloposphazene to remove the solvent, washing hot residues obtained after the solvent is removed by using a low-molecule alcohol, and performing solid-liquid separation after washing, so as to obtain the phenoxycycloposphazene. The method is possible in continuous production, simple in process and easy to control, and the product is high in yield and purity.

Owner:山东省海洋化工科学研究院

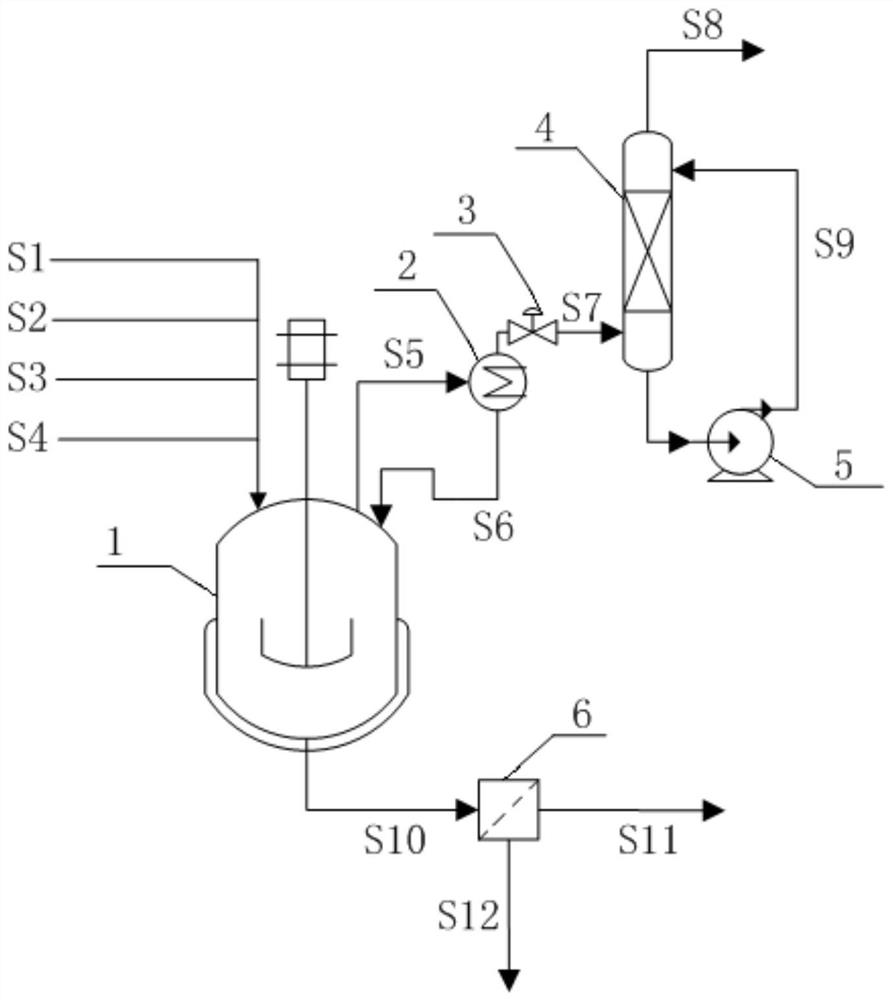

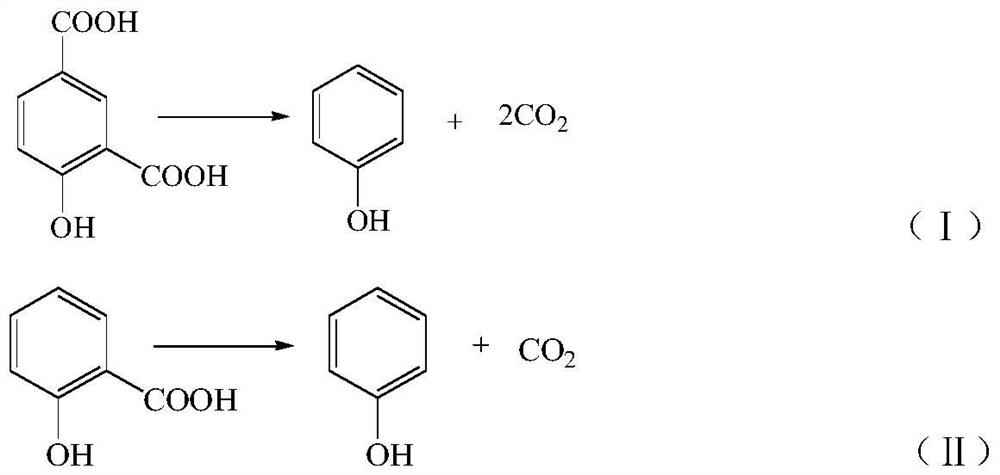

A kind of method that utilizes salicylic acid residue to decompose and recover sodium phenolate

ActiveCN109503332BMild reaction conditionsOrganic chemistryOrganic compound preparationActivated carbonWash water

The invention discloses a method for decomposing and recovering sodium phenolate by utilizing salicylic acid residue, comprising the following steps: adding water into a reaction kettle, starting stirring, and then adding solid salicylic acid residue; controlling the pressure in the reaction kettle, heating the reaction kettle When the material reaches 160-220°C, the reaction exhaust gas enters the condenser for condensation, and the phenol and water in it are condensed and refluxed into the reactor. Use water; after the reaction is completed, the pressure is released and cooled, and sodium hydroxide is added to the reaction kettle to control the pH value to be 12-13; finally, activated carbon is added to the reaction kettle, adsorbed and decolorized, and filtered to obtain a sodium phenolate solution. The method disclosed in the invention enables the salicylic acid residue to be recycled, only generates a small amount of activated carbon solid waste, has little impact on the environment, and belongs to an environment-friendly treatment process.

Owner:QINGDAO UNIV OF SCI & TECH +2

Preparation method for synthesizing p-dinitrobenzene from wet material

PendingCN114213253ALow costExcellent adhesive bonding performanceNon-macromolecular adhesive additivesOrganic compound preparationNitrosoHydroxylamine

The preparation method comprises the following steps: adding phenol into an aqueous solution of sodium nitrite and sodium hydroxide to prepare a mixed solution of sodium phenolate and sodium nitrite, dropwise adding the mixed solution into a sulfuric acid solution at a preset temperature, and carrying out stirring reaction, filtering and washing to prepare an intermediate p-nitrosophenol wet material; dropwise adding a hydroxylamine hydrochloride aqueous solution into the intermediate p-nitrosophenol wet material, stirring for reaction, filtering and washing to obtain a p-benzoquinone dioxime wet material; the preparation method comprises the following steps: dissolving a p-benzoquinone dioxime wet material in an aqueous solution of sodium hydroxide to obtain an alkaline p-benzoquinone dioxime solution, dropwise adding a dilute NaClO solution into the alkaline p-benzoquinone dioxime solution, stirring, reacting, filtering and washing to obtain a p-dinitrobenzene product. According to the method, the raw material cost is low, only water is involved as a reaction solvent in the whole process, the operation process is simple, a wet material intermediate does not need to be dried in the process, and the finally prepared p-dinitrosobenzene has excellent adhesive performance.

Owner:天元(杭州)新材料科技有限公司 +1

Phenol-containing wastewater treatment method

InactiveCN113149261AEfficient enrichmentReduced phenolic contentOrganic chemistryFatty/oily/floating substances removal devicesOil phaseSodium hydroxide

The invention relates to a phenol-containing wastewater treatment method, which adopts liquid membrane extraction to treat phenol-containing wastewater, and comprises the following steps: 1, measuring the phenol content in the phenol-containing wastewater, adding a liquid membrane extract according to the measured phenol content, and fully mixing the liquid membrane extract and the phenol-containing wastewater at a stirring speed of 60r / min, reacting phenol in the phenol-containing wastewater with sodium hydroxide in the liquid membrane extraction liquid for 10 min; 2, performing standing for 10 min after the reaction is completed, layering a water phase and an emulsion phase, and separating the water phase from the emulsion phase to obtain an emulsion containing sodium phenate; and 3, stirring the emulsion containing sodium phenate obtained in the step 2 at a stirring speed of 1500r / min for 3-10min for demulsification, performing standing for 20min after demulsification is completed, layering a water phase and an oil phase, separating the oil phase from the phase, and continuing to use the oil phase as a preparation raw material of the liquid membrane extraction liquid. According to the method, phenolic compounds in the wastewater can be effectively enriched into the emulsion, the extraction liquid can be repeatedly used, the extraction efficiency is high, the energy consumption is low, and resources can be effectively saved while wastewater treatment reaches the standard.

Owner:禹城京都新材料科技有限公司

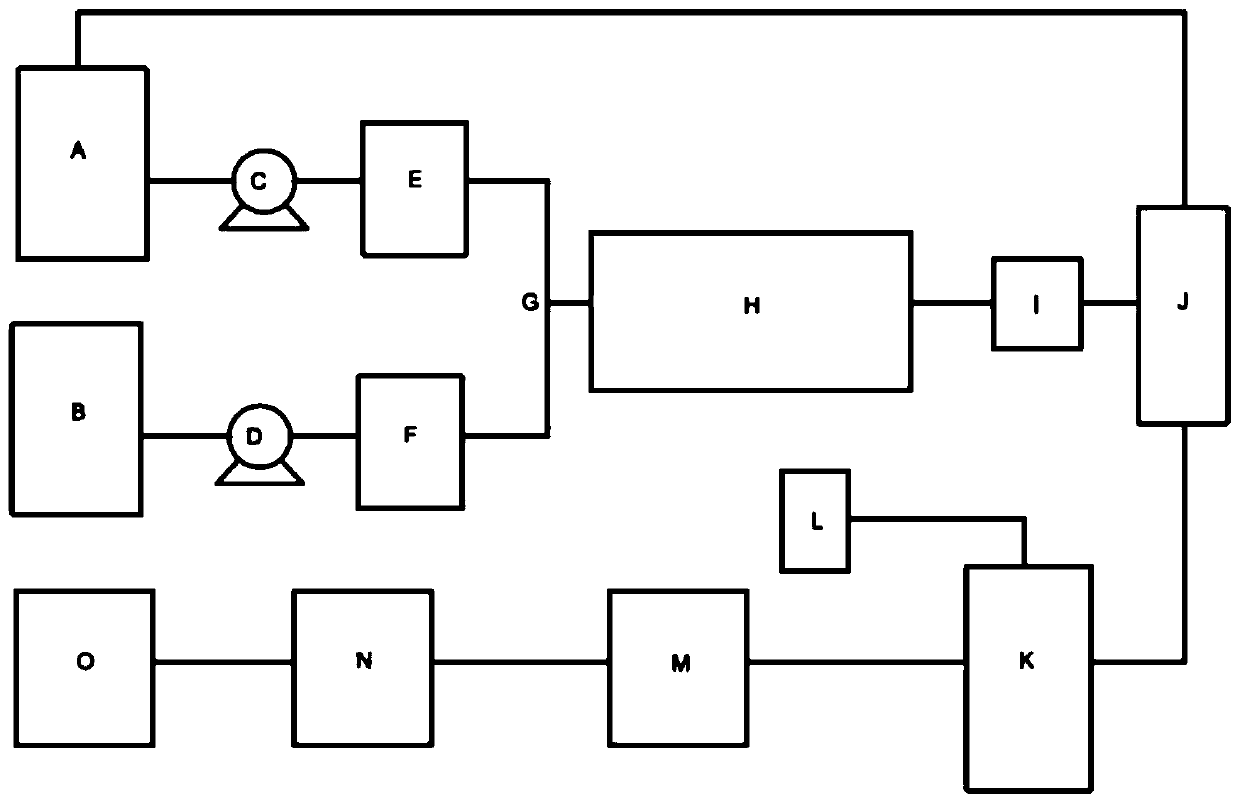

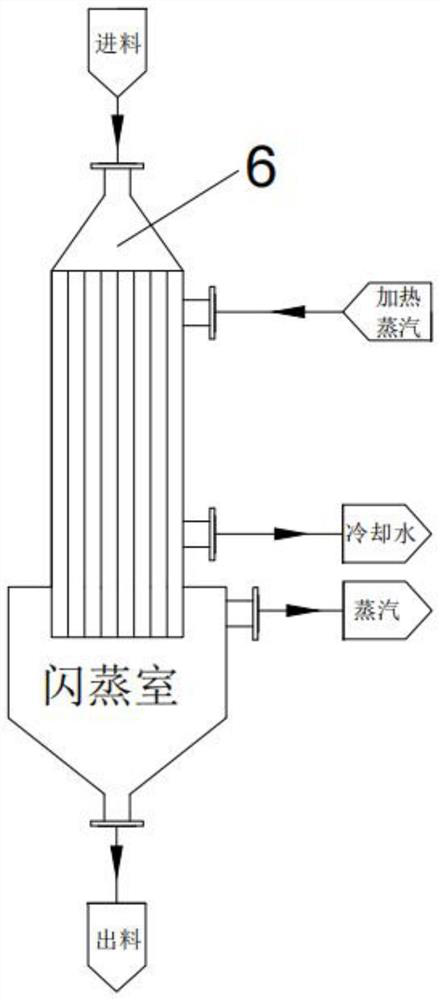

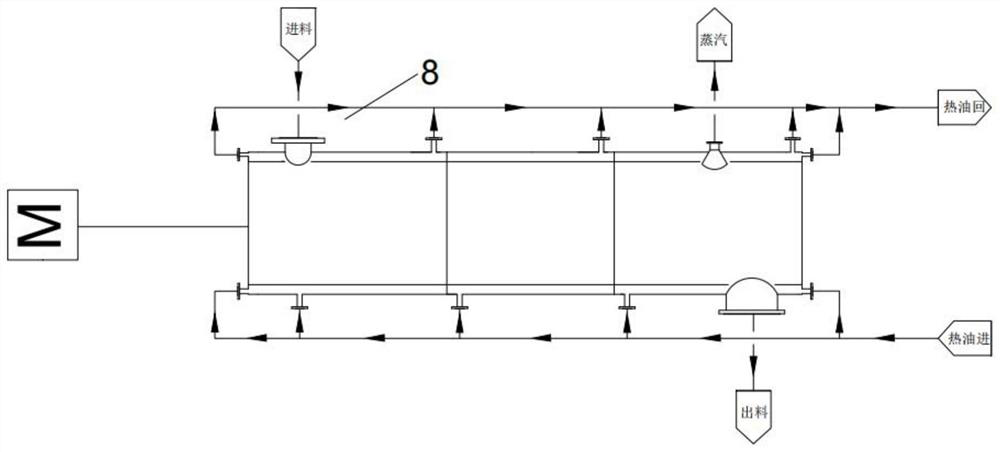

Continuous production process of sodium salicylate solution

PendingCN114345285ARealize continuous controllableIncrease production capacityPreparation from carboxylic acid saltsEvaporationHigh energySodium salicylate

The invention discloses a continuous production process of a sodium salicylate solution. The continuous production process comprises a sodium phenate solution storage tank, a sodium hydroxide solution storage tank, a centrifugal pump, a static mixer, a falling film evaporator, a horizontal film evaporator, a spiral feeder, a reaction kettle, a pressure gauge, a thermometer, a sodium salicylate powder storage tank, a sodium salicylate solution storage tank, a valve and the like. Outlets of the phenol solution storage tank and the sodium hydroxide solution storage tank are respectively connected to a static mixer through a pipeline, a manual ball valve and a centrifugal pump, the static mixer is connected to a reaction kettle through a falling film evaporator, a horizontal film evaporator and a spiral feeder, and the reaction kettle comprises a gas distribution pipe, a jacket, a motor, a thermometer and a pressure gauge. And the reaction kettle is connected to a sodium salicylate solution storage tank through a sodium salicylate powder storage tank. According to the invention, the continuous preparation of the sodium salicylate solution can be realized, and the problems of long production period, incapability of continuous feeding and discharging, high energy consumption and insufficient productivity in the existing intermittent production are solved.

Owner:QINGDAO UNIV OF SCI & TECH

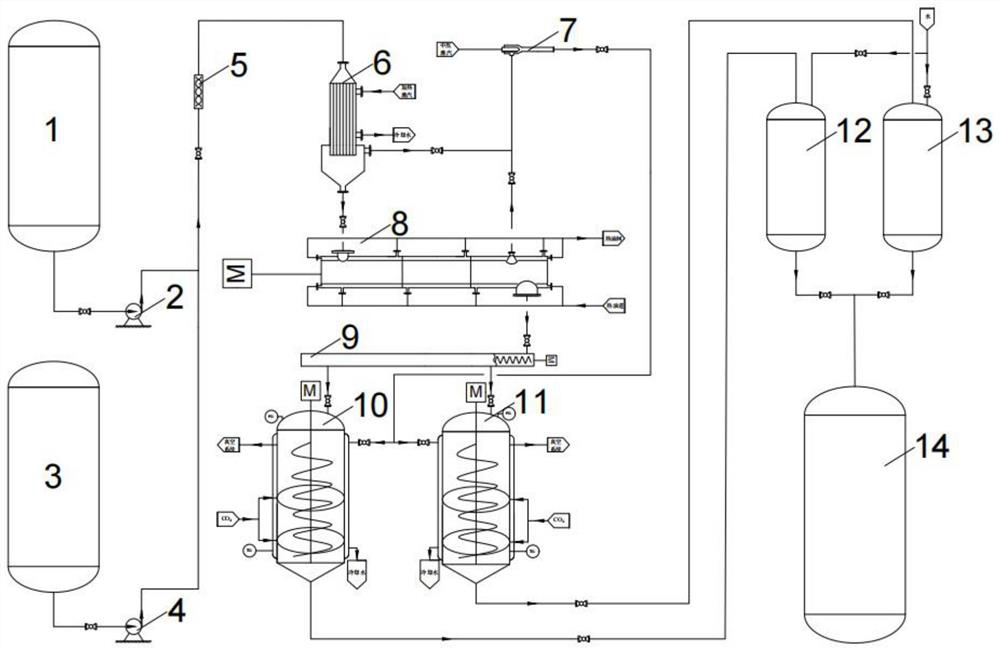

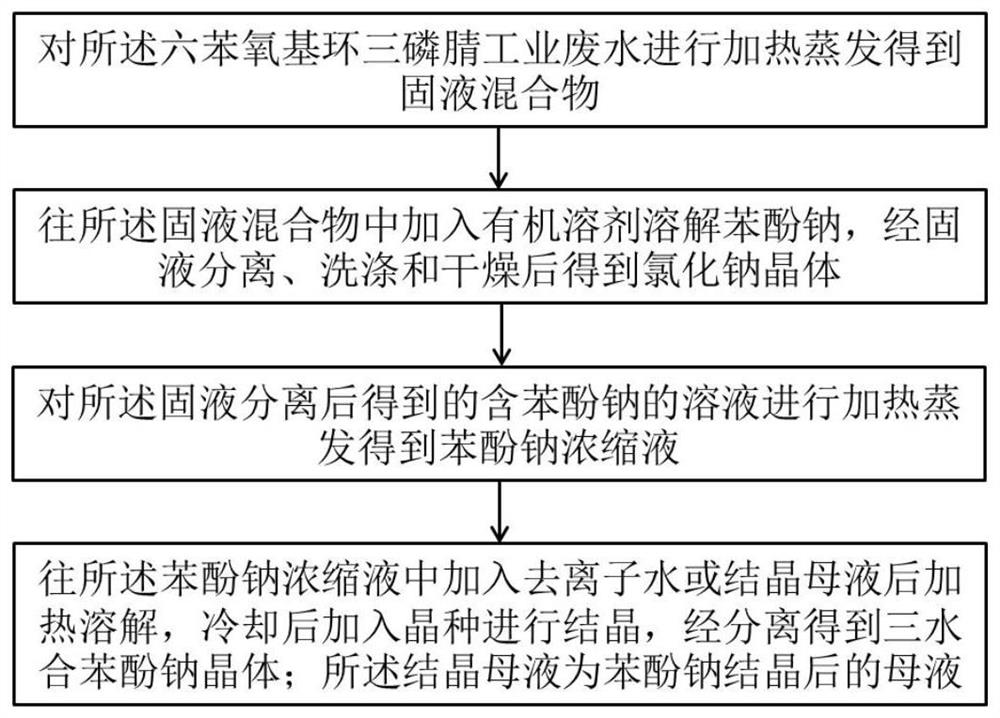

A kind of treatment method of hexaphenoxycyclotriphosphazene industrial waste water

ActiveCN108484369BReduce COD valueEfficient recyclingOrganic chemistryOrganic compound preparationIndustrial waste waterSodium Phenolate

A method for treating hexaphenoxycyclotriphosphazene industrial wastewater, comprising the following steps: heating and evaporating the hexaphenoxycyclotriphosphazene industrial wastewater to obtain a solid-liquid mixture; adding organic Sodium phenate is dissolved in a solvent, and sodium chloride crystals are obtained after solid-liquid separation, washing and drying; the solution containing sodium phenate obtained after the solid-liquid separation is heated and evaporated to obtain a sodium phenoxide concentrate; After adding deionized water or crystallization mother liquor, heating and dissolving, after cooling, crystal seeds are added for crystallization, and sodium phenoxide trihydrate crystals are obtained through separation; the crystallization mother liquor is the mother liquor after sodium phenoxide crystallization. The present invention can effectively recover sodium phenate and sodium chloride in waste water, and the obtained sodium phenate and sodium chloride have relatively high purity, can be recycled and utilized, can also significantly reduce the COD value of waste water, and have significant economic and environmental benefits .

Owner:MIANYANG TEACHERS COLLEGE

A kind of continuous synthesis method of phenoxyacetic acid

ActiveCN104829447BControl reaction temperatureLess side effectsPreparation from carboxylic acid saltsOrganic compound preparationSodium chloroacetateFiltration

Owner:邳州市润宏实业有限公司

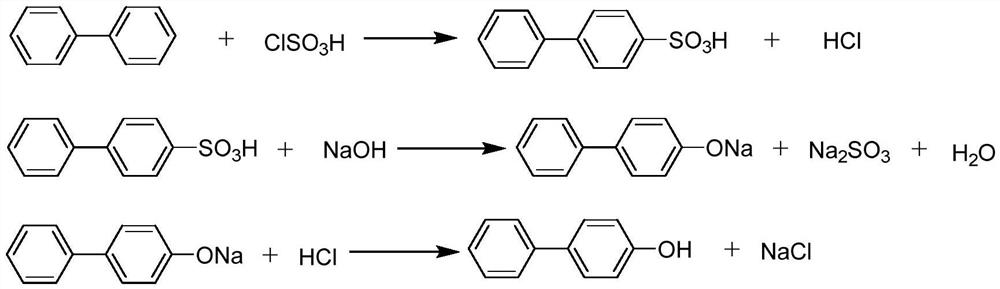

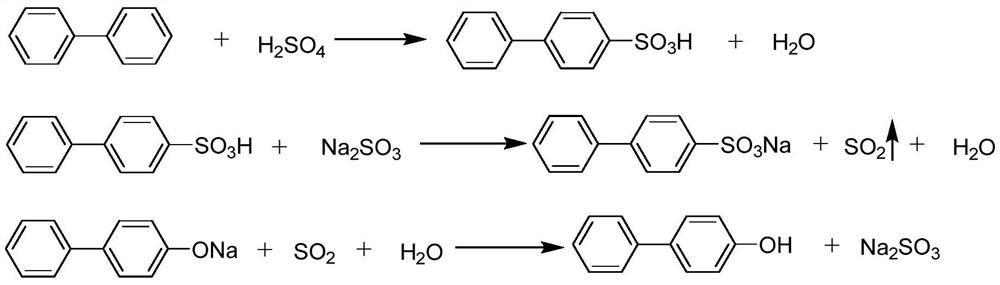

Production method and application of p-phenylphenol

PendingCN114213217AImprove economyRaw materials are easy to obtainOrganic compound preparationSulfonic acids salts preparationSulfite saltSodium hydroxide

The invention discloses a production method and application of p-phenylphenol, and the production method comprises the following steps: heating biphenyl and sulfuric acid to carry out sulfonation reaction, then neutralizing 4-phenylbenzenesulfonic acid in sulfonation reaction products by using sodium sulfite to generate sodium 4-phenylsulfonate and sulfur dioxide, collecting sulfur dioxide gas, cooling after the neutralization is finished, filtering, washing and drying to obtain p-phenylphenol. Filtering to obtain a sodium 4-phenylbenzenesulfonate solid; carrying out alkali fusion reaction on the sodium 4-phenylbenzenesulfonate solid and molten solid sodium hydroxide to generate sodium p-phenylphenolate and sodium sulfite; diluting the alkali fusion material with water, introducing collected sulfur dioxide for acidification reaction to generate p-phenylphenol and sodium sulfite, standing and separating to obtain crude p-phenylphenol and mother liquor, and finally rectifying to obtain p-phenylphenol. The method provided by the invention has the advantages of simple and easily available raw materials, good reaction atom economy, high yield, high product quality and low industrial cost, and is a feasible industrial production method of p-phenylphenol.

Owner:合肥欧腾测控技术有限公司

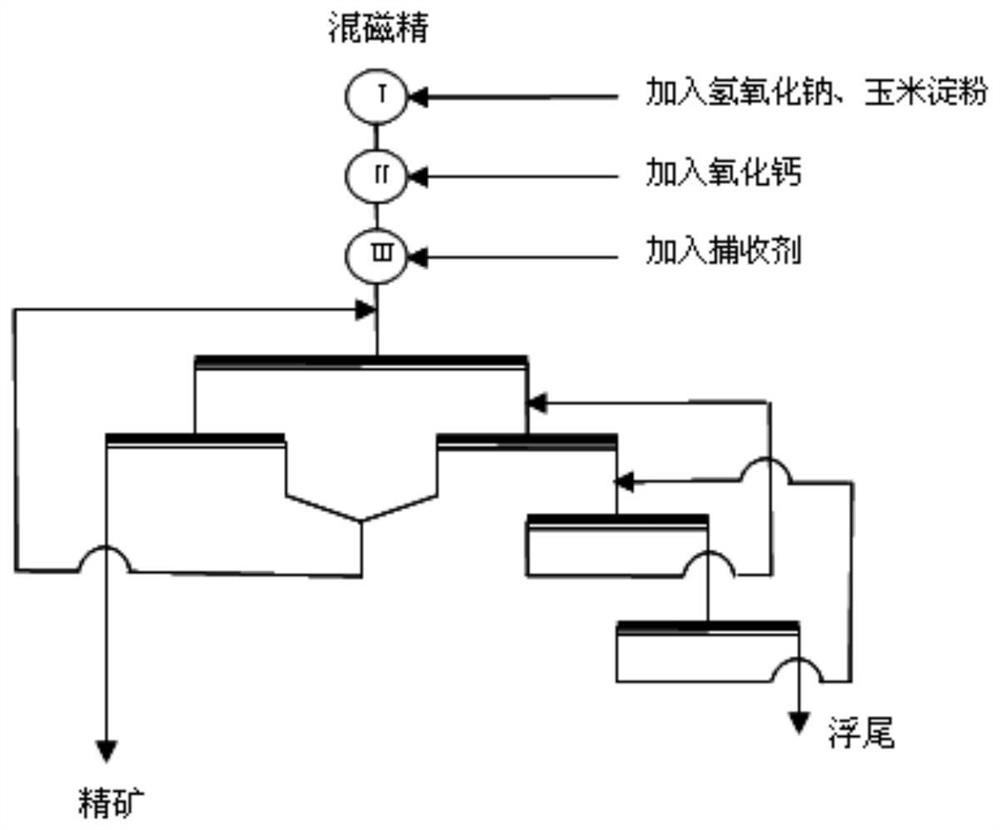

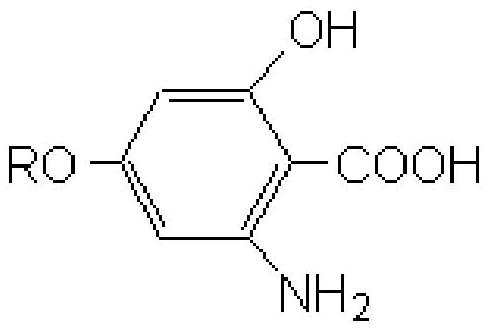

A kind of chelating amphoteric collector, its preparation method and its composition with fatty acid

The invention discloses a chelating amphoteric collector and a preparation method thereof. The collector contains alkyl, ether, phenyl, hydroxyl, amine and carboxyl, the length of the alkyl is C 5 ~C 16 . The preparation method is that p-aminophenol reacts with sodium ethylate to generate p-aminophenol sodium, and then reacts with 1-chloroalkane to generate p-alkoxyaniline; under the action of nitric acid and sulfuric acid, it generates 2,6-dinitro-4 ‑Alkoxyphenylacetamide; diazotization, diazo group replaced by cyano group under copper powder and potassium cyanide, acidic hydrolysis to 2,6‑dinitro‑4‑alkoxybenzoic acid; with sodium sulfide Selective reduction of a nitro group with ammonium chloride, diazotization reaction, acidic hydrolysis to generate 2-hydroxy-6-nitro-4-alkoxybenzoic acid; reduction to generate the target product 2-hydroxy-6-amine ‑4‑Alkoxybenzoic acid. The chelating amphoteric collector has good collecting ability, selectivity and low temperature resistance, and can be combined with various fatty acids to form a composite collector.

Owner:鞍山市津翔工业有限公司

A kind of separation method of acetone, toluene, sodium phenate and water quaternary mixture

ActiveCN113024366BHigh purityEnable recyclingOrganic compound preparationDistillation purification/separationSodium PhenolateToluene

The invention relates to a method for separating a quaternary mixture of acetone, toluene, sodium phenate and water, especially a separation mass percentage concentration of 20% to 40% acetone, 10% to 30% toluene, 5% to 20% sodium phenate, The rest is a mixed material composed of water. The quaternary mixture is separated by distillation to remove acetone, azeotropic distillation to remove toluene and water, solid-liquid separation, condensation and drying. The method of the invention realizes the resourceful separation and recovery of the mixture of acetone, toluene, sodium phenate and water, the separation process is reasonable and the process is simple. It not only reduces the separation steps and energy consumption, but also has a high utilization rate of valuable components, is easy to realize continuous operation, and the separated products can realize resource utilization. Effective resource separation and recovery technology.

Owner:YANGZHOU UNIV

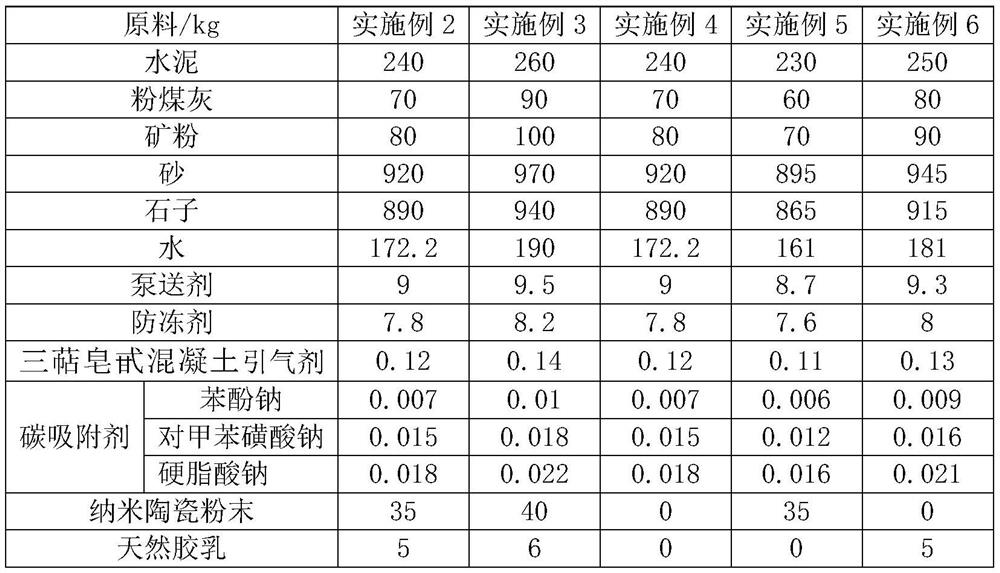

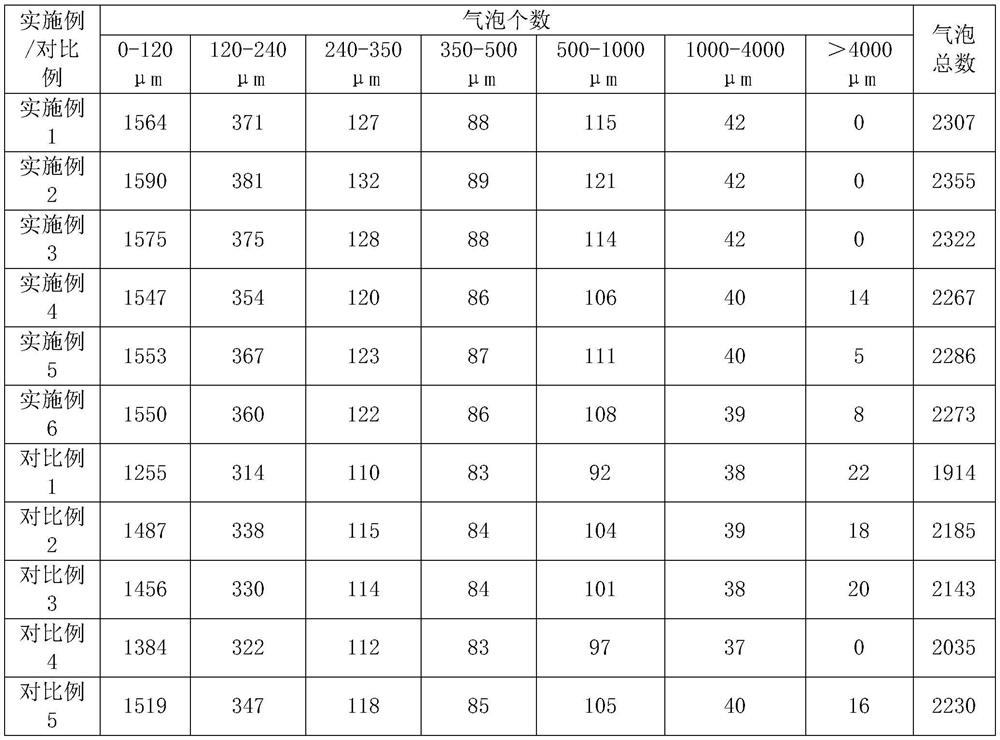

Anti-freezing pumping concrete and preparation method thereof

The invention discloses anti-freezing pumping concrete and a preparation method thereof. The anti-freezing pumping concrete comprises the following raw materials by weight: 220-260 parts of cement; 50-90 parts of fly ash; 60-100 parts of mineral powder; 870-970 parts of sand; 840-940 parts of stone; 150-190 parts of water; 8.5-9.5 parts of a pumping agent; 7.4-8.2 parts of an anti-freezing agent;0.1-0.14 part of an air entraining agent; and 0.03-0.05 part of a carbon adsorbent, which comprises 0.005-0.01 part of sodium phenolate, 0.01-0.018 part of sodium p-toluenesulfonate and 0.015-0.022 part of sodium stearate; the preparation method comprises the following steps of: conducting pretreatment: weighing the fly ash, the carbon adsorbent and 10% of water according to a stoichiometric ratio, performing mixing and stirring to prepare a solution, putting the solution into an ultrasonic oscillator, and setting the temperature at 30DEG C-40DEG C and controlling the ultrasonic reaction timeat 3min; weighing the raw materials according to the stoichiometric ratio, putting the raw materials into a stirrer, putting the pretreated solution into the stirrer, and fully stirring and mixing thesubstances uniformly. The anti-freezing pumping concrete can be used in the technical field of concrete, and has the advantages of reducing the inhibition effect of fly ash on the air entraining agent and improving the anti-freezing performance of the pumping concrete.

Owner:山东华爵混凝土有限公司

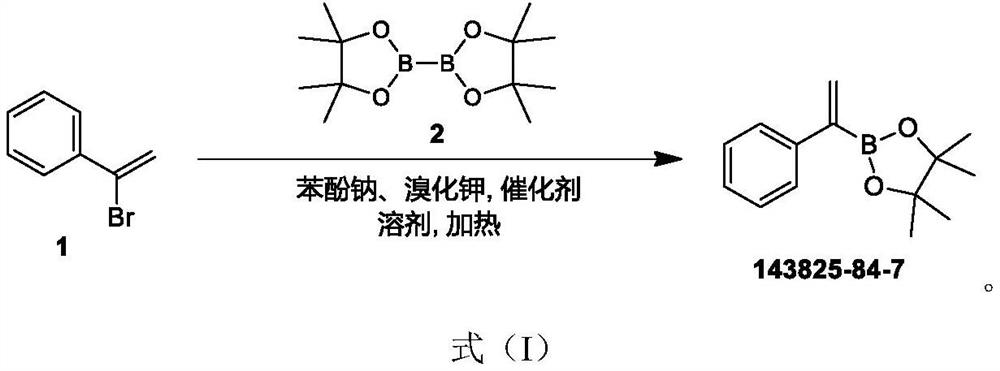

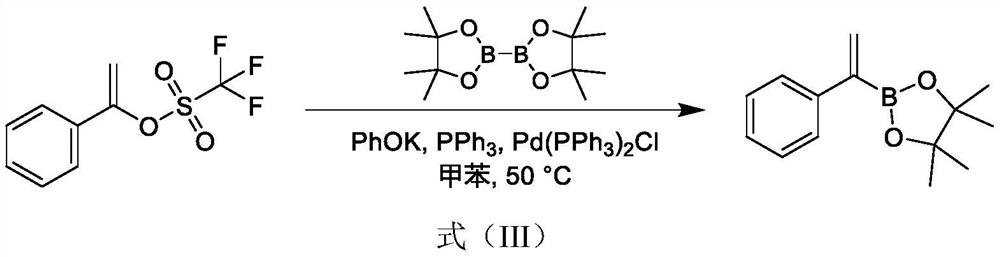

Synthesis method of 1-phenylvinyl borate

ActiveCN112574244ALow costEasy to solveGroup 3/13 element organic compoundsBromoethylenePhenyl group

The invention discloses a synthetic method of 1-phenylvinyl borate The preparation method comprises the following steps: by taking (1-bromovinyl)benzene 1 and diborate 2 as raw materials and sodium phenolate and potassium bromide as reaction reagents, heating the raw materials in methylbenzene to finish reaction, extracting, washing and concentrating the reaction solution to obtain a crude product, and performing pulping, low-temperature recrystallization and other operations which are easy for pilot scale-up to obtain the final product 1-phenylvinyl borate. The method replaces the raw material potassium phenate in the prior art, and the reagent cost is reduced. The invention solves the problems that in an existing route, raw materials are not easy to obtain, boric acid ester substituted products at different positions are easily generated, post-treatment needs column separation and the like and are not suitable for pilot scale-up. The invention provides a synthesis process which has the advantages of economical and easily available raw materials, good reaction selectivity and economical and easily operated post-treatment.

Owner:南通药明康德医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com