Continuous production process of sodium salicylate solution

A sodium salicylate and production process technology, which is applied in the field of continuous production process of sodium salicylate solution, can solve the problems of inability to continuously feed and discharge materials, long production cycle, insufficient production capacity, etc., and improve energy utilization rate , increase production capacity, and improve the reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through the following embodiments in conjunction with the accompanying drawings.

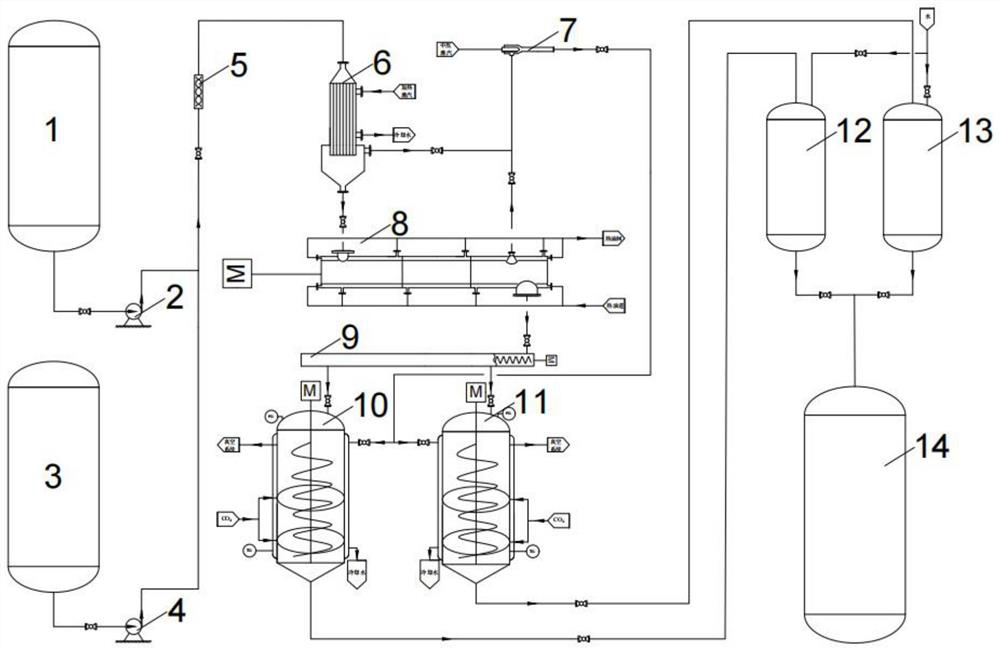

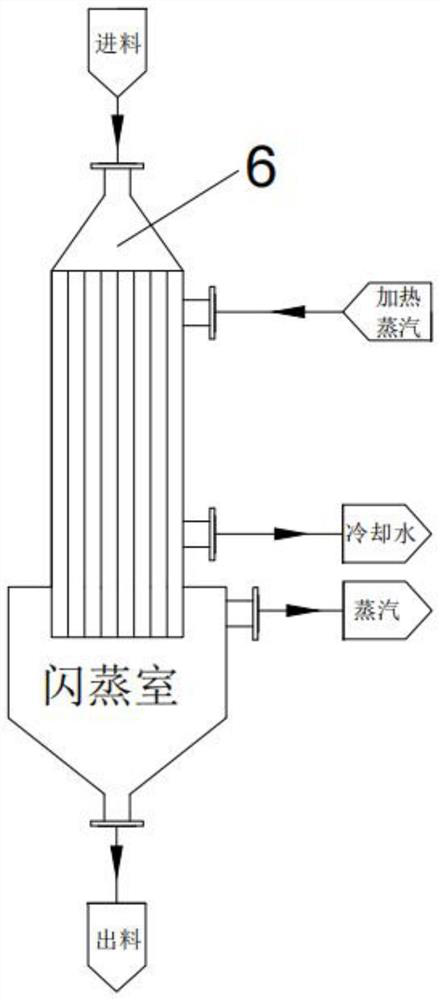

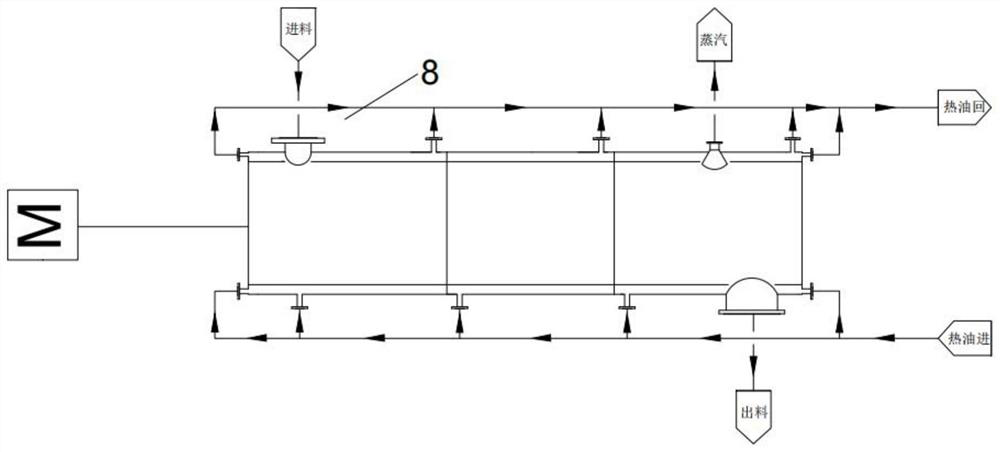

[0020] see Figure 1 to Figure 5 , a continuous production process for sodium salicylate solution, comprising a phenol solution storage tank 1, a centrifugal pump 2, a sodium hydroxide solution storage tank 3, a centrifugal pump 4, a static mixer 5, a falling film evaporator 6, a Venturi Ejector 7, horizontal thin film evaporator 8, screw feeder 9, reaction kettle 10, reaction kettle 11, sodium salicylate powder storage tank 12, sodium salicylate powder storage tank 13, sodium salicylate solution storage tank tank 14 and valves. Above-mentioned phenol solution storage tank 1 and sodium hydroxide solution storage tank 3 outlets are respectively connected to static mixer 5 through pipeline, manual ball valve and centrifugal pump 2 and centrifugal pump 4, and above-mentioned static mixer 5 passes through falling film evaporator 6, horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com