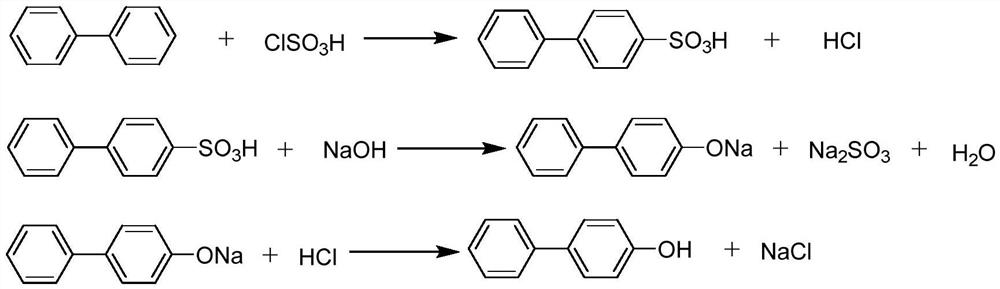

Production method and application of p-phenylphenol

A technology for the production of p-phenylphenol, which is applied in chemical instruments and methods, the preparation of organic compounds, and the preparation of sulfonic acid, etc., which can solve the problems of high catalyst requirements, unstable sources, and large equipment investment, and achieve high product quality , low industrial cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

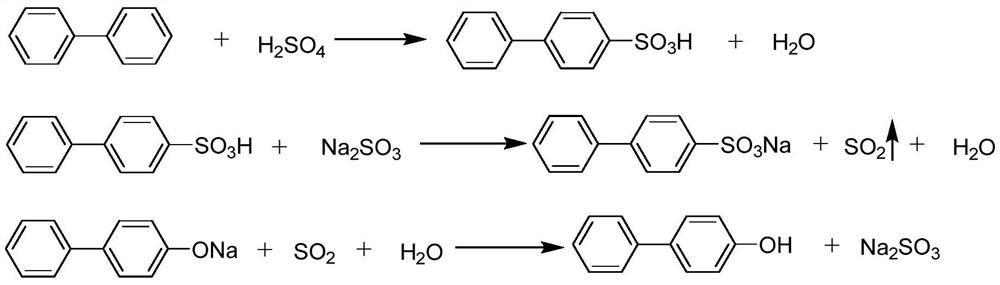

[0064] The production method of p-phenylphenol in the present embodiment is as follows:

[0065] 1. Sulfonation: Add 171.1kg of biphenyl (99%, 1.1kmol) to a 1000L enamel reaction kettle, raise the temperature to 100°C, and slowly drop 100kg (1.0kmol) of concentrated sulfuric acid with a content of 98% into the reaction kettle , the dropping time is 60 minutes, the temperature of the reaction material will rise during the dropping process, the reaction temperature is controlled at 110-120°C, and the temperature is raised to 130°C after the dropping is completed, and the temperature is kept for 2 hours to generate 4-phenylbenzenesulfonic acid; ℃, 0.001MPa, distill off the water and unreacted biphenyl formed by the reaction under reduced pressure.

[0066] 2, neutralization: the reaction liquid of step (1) is slowly added mass fraction and is in the sodium sulfite aqueous solution 529.2kg (with 1.05kmol) of 25%, neutralizes 4-phenylbenzenesulfonic acid, generates 4-phenylsulfonic...

Embodiment 2

[0072] The production method of p-phenylphenol in the present embodiment is as follows:

[0073] 1. Sulfonation: Add 186.7kg of biphenyl (99%, 1.2kmol) to a 1000L enamel reaction kettle, raise the temperature to 150°C, and slowly drop 100kg (1.0kmol) of concentrated sulfuric acid with a content of 98% into the reaction kettle , the dropping time is 60 minutes, the temperature of the reaction material will rise during the dropping process, and the reaction temperature is controlled at 135-150°C. After the dropping is completed, it is kept at 150°C for 1 hour to generate 4-phenylbenzenesulfonic acid; 0.005MPa, the water generated by the reaction and unreacted biphenyl were distilled off under reduced pressure.

[0074] 2. Neutralization: The reaction solution of step (1) is slowly added into 756 kg (with 1.2 kmol) of 20% sodium sulfite aqueous solution in mass fraction to neutralize 4-phenylbenzenesulfonic acid to generate sodium 4-phenylsulfonate and sulfur dioxide , collect t...

Embodiment 3

[0080] The production method of p-phenylphenol in the present embodiment is as follows:

[0081] 1. Sulfonation: Add 155.6kg of biphenyl (99%, 1.0kmol) to a 1000L enamel reaction kettle, raise the temperature to 120°C, and slowly drop 100kg (1.0kmol) of concentrated sulfuric acid with a content of 98% into the reaction kettle , the dropping time is 60 minutes, the temperature of the reaction material will rise during the dropping process, and the reaction temperature is controlled at 100-120°C. After the dropping is completed, it is kept at 90°C for 3 hours to generate 4-phenylbenzenesulfonic acid; 0.01MPa, the water and unreacted biphenyl produced by the reaction were distilled off under reduced pressure.

[0082] 2. Neutralization: the reaction solution of step (1) is slowly added into 924 kg (with 1.10 kmol) of 15% sodium sulfite aqueous solution in mass fraction to neutralize 4-phenylbenzenesulfonic acid to generate sodium 4-phenylsulfonate and sulfur dioxide , collect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com