Preparation method for synthesizing p-dinitrobenzene from wet material

A technology for p-dinitrosobenzene and nitrosophenol is applied in the field of preparation of chemical raw material p-dinitrosobenzene, and can solve the problems of reduced rubber material quality, difficulty in removing by-products, dangerous use of raw materials, etc. The effect of low cost of raw materials, simple operation process and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

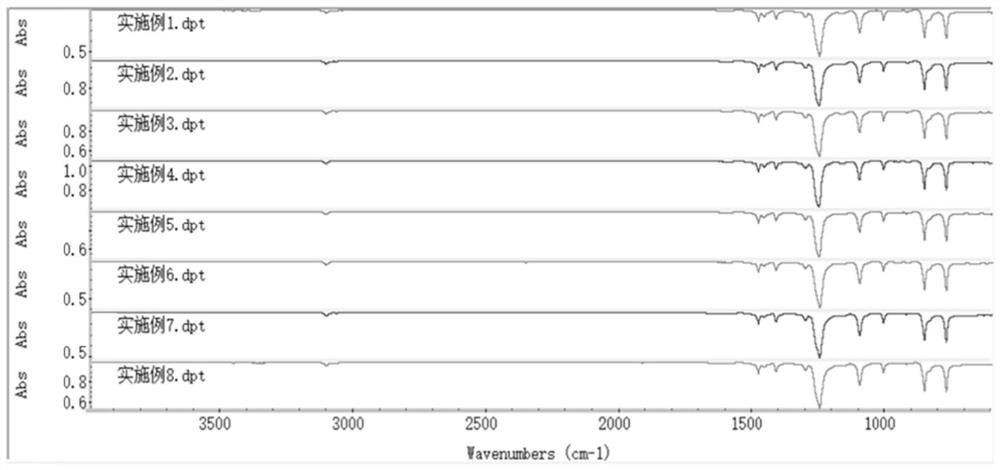

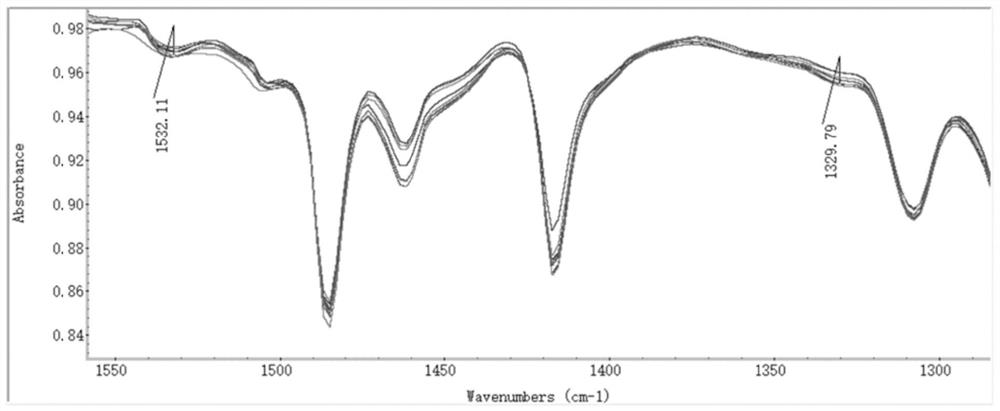

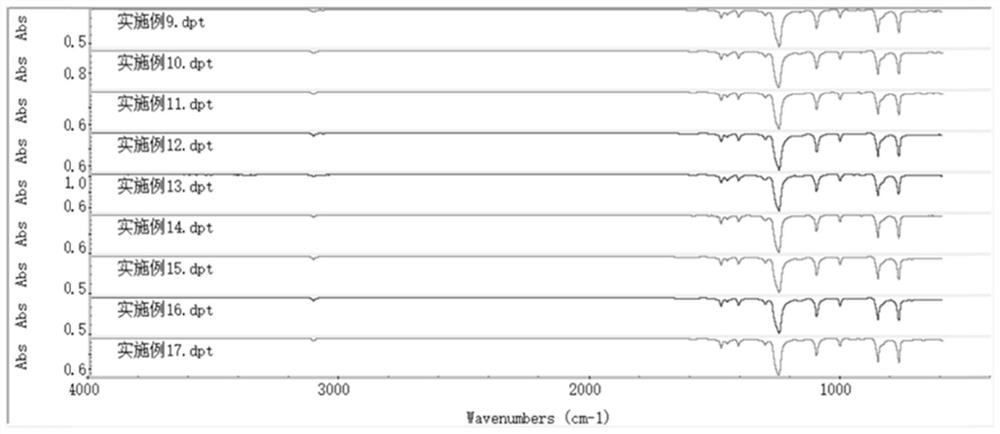

Examples

Embodiment 1

[0037] In the first step, add sodium nitrite (2.0mol, 137.99g) and sodium hydroxide (1.5mol, 60.12g) into 483mL of tap water, stir to dissolve them completely, then add phenol (1.0mol, 94.60g), and stir to dissolve Mixed solution 1 was obtained; concentrated sulfuric acid (3mol, 294.78g) was slowly added to 535mL ice water, stirred and diluted to obtain solution 2;

[0038] At an ambient temperature of 3°C, slowly (2 hours) drop solution 1 into solution 2, maintain the system temperature at 5°C, continue stirring for 2 hours after addition, filter and wash to obtain the intermediate p-nitrosophenol wet material;

[0039]In the second step, add hydroxylamine hydrochloride (2mol, 139.54g) into 109mL of tap water, stir and dissolve to obtain solution 3; at an ambient temperature of 42°C, add solution 3 (2 hours) dropwise to the intermediate p-nitrosophenol wet In the aqueous solution of the raw material, keep the temperature of the system at 40° C., continue to stir for 2 hours ...

Embodiment 2

[0044] In the first step, add sodium nitrite (1.0mol, 69.21g) and sodium hydroxide (1.5mol, 60.23g) into 483mL of tap water, stir to dissolve them completely, then add phenol (1.0mol, 94.52g), and stir to dissolve Mixed solution 1 was obtained; concentrated sulfuric acid (3mol, 294.03g) was slowly added to 535mL ice water, stirred and diluted to obtain solution 2;

[0045] At an ambient temperature of 3°C, slowly (2 hours) drop solution 1 into solution 2, maintain the system temperature at 5°C, continue stirring for 2 hours after addition, filter and wash to obtain the intermediate p-nitrosophenol wet material;

[0046] In the second step, add hydroxylamine hydrochloride (2mol, 139.02g) into 109mL tap water, stir and dissolve to obtain solution 3; at an ambient temperature of 42°C, add solution 3 (2 hours) dropwise to the intermediate p-nitrosophenol wet In the aqueous solution of the raw material, keep the system temperature at 40° C., continue to stir for 2 hours after the ...

Embodiment 3

[0052] In the first step, add sodium nitrite (2.0mol, 138.11g) and sodium hydroxide (1.0mol, 40.34g) into 483mL of tap water, stir to dissolve them completely, then add phenol (1.0mol, 94.42g), and stir to dissolve Mixed solution 1 was obtained; concentrated sulfuric acid (3mol, 294.12g) was slowly added to 535mL ice water, stirred and diluted to obtain solution 2;

[0053] At an ambient temperature of 3°C, slowly (2 hours) drop solution 1 into solution 2, maintain the system temperature at 5°C, continue stirring for 2 hours after addition, filter and wash to obtain the intermediate p-nitrosophenol wet material;

[0054] In the second step, add hydroxylamine hydrochloride (2mol, 139.24g) into 109mL of tap water, stir and dissolve to obtain solution 3; at an ambient temperature of 42°C, add solution 3 (2 hours) dropwise to the intermediate p-nitrosophenol wet In the aqueous solution of the raw material, keep the system temperature at 40° C., continue to stir for 2 hours after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com