Anti-freezing pumping concrete and preparation method thereof

A technology for pumping concrete and concrete, applied in the field of concrete, can solve the problems of reducing the antifreeze performance of pumped concrete and reducing the air content of pumped concrete, and achieve the effects of low thermal expansion coefficient, improved antifreeze performance and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A preparation method for antifreeze pumped concrete, comprising the following steps:

[0051] Step 1, pretreatment: Weigh 50kg fly ash, 0.005kg sodium phenate, 0.01kg p-toluenesulfonate and 0.015kg sodium stearate, add 10% water in 150kg water and mix and stir to make a solution, place the solution in In the ultrasonic oscillator, set the temperature at 30°C-40°C, preferably 35°C, and the ultrasonic reaction time is 3min;

[0052]Step 2: Weigh 220kg of cement, 60kg of mineral powder, 870kg of sand, and 840kg of stones into the mixer, set the stirring speed to 35r / min, fully stir and mix until uniform, and obtain a dry mixture;

[0053] Step 3. Weigh the remaining water, 8.5kg pumping agent, 7.4kg antifreeze, 0.1kg triterpene saponin concrete air-entraining agent, 30kg nano-ceramic powder and 4kg natural rubber latex into the mixer, pretreat in step 1 The final solution is also put into the blender, set the stirring speed to 35r / min, and fully stir and mix with the dry ...

Embodiment 2- Embodiment 6

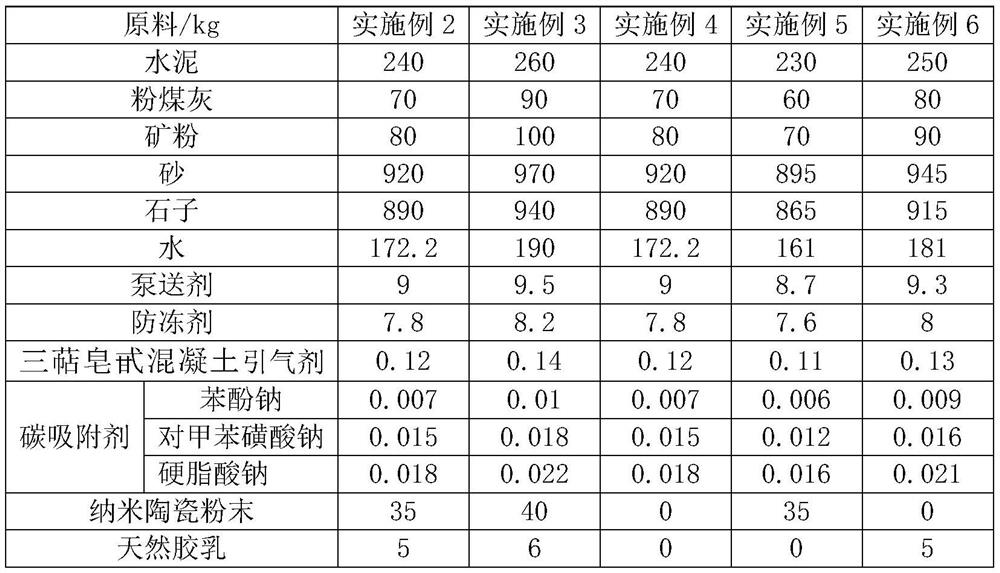

[0055] The difference between the following examples and Example 1 is that the weight of each raw material is different, see Table 1 for details:

[0056] Table 1

[0057]

Embodiment 4

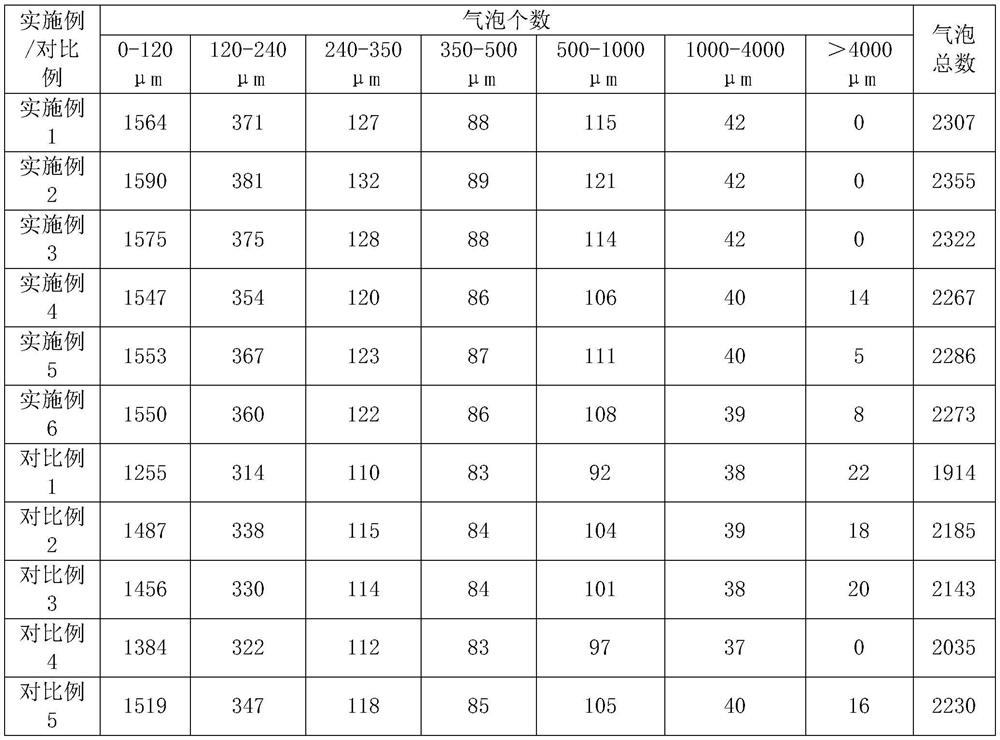

[0092] Embodiment 4, comparative example 2, comparative example 3 are compared with comparative example 1 respectively, embodiment 4 has added sodium phenate, sodium p-toluenesulfonate and sodium stearate as carbon adsorbent, comparative example 2 has only added sodium phenate, Sodium p-toluenesulfonate was used as the carbon adsorbent, and in Comparative Example 3, only sodium stearate was added as the carbon adsorbent. From the test results, the total number of bubbles and the gas content of Example 4, Comparative Example 2 and Comparative Example 3 are all improved compared to the total number of bubbles and the gas content of Comparative Example 1, but the degree of improvement of Comparative Example 2 and Comparative Example 3 is higher than that of the embodiment. The degree of improvement in Example 4 is much smaller, reflecting the synergistic effect of sodium phenate, sodium p-toluenesulfonate and sodium stearate to reduce the inhibitory effect of fly ash on the air-en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com