Recycling utilization and processing method for wastewater generated in sebacic acid production process

A technology of production process and treatment method, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem that valuable components cannot be fully utilized, increase treatment costs, high Dealing with cost and other issues to achieve low cost, reduced processing costs, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

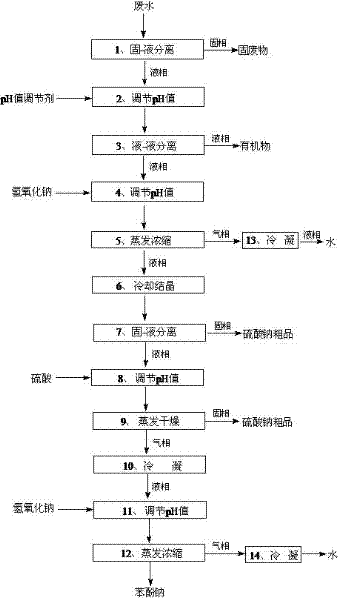

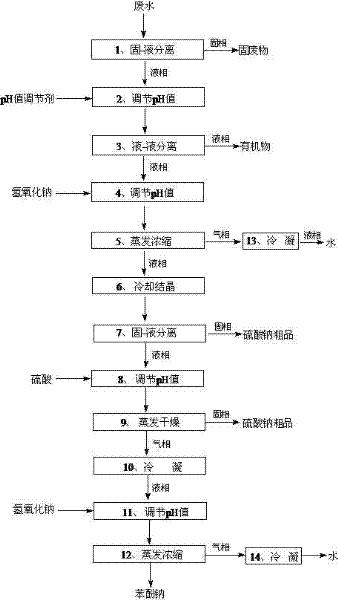

Image

Examples

Embodiment 1

[0046] The main process equipment is subsidence solid-liquid separation device, subsidence type liquid-liquid separation equipment, heat pump evaporation and concentration equipment, cooling crystallization equipment and evaporation concentration and drying equipment, etc.

[0047] A method for resource utilization and treatment of waste water in the production process of sebacic acid is a method for resource utilization and treatment of waste water containing phenol and sodium sulfate produced in the process of sebacic acid production. % phenol and the waste water of 5%~20% sodium sulfate, and recycle the method for sodium phenate and sodium sulfate, described method step is as follows:

[0048] (1) Solid-liquid separation: 1m 3 Wastewater containing 2kg of phenol and 50kg of sodium sulfate is subjected to solid-liquid separation in a sedimentation type solid-liquid separation device, the solid phase waste residue is removed, and the liquid phase enters the next step;

[004...

Embodiment 2

[0061] The main process equipment is filter type solid-liquid separation device, centrifugal liquid-liquid separation device, heat pump evaporation and concentration equipment, cooling crystallization equipment and evaporation concentration and drying equipment, etc.

[0062] A method for resource utilization and treatment of waste water in the production process of sebacic acid is a method for resource utilization and treatment of waste water containing phenol and sodium sulfate produced in the process of sebacic acid production. The waste water of 5%~20% sodium sulfate, and recycle the method for sodium phenate and sodium sulfate, described method step is as follows:

[0063] (1) Solid-liquid separation: 1m 3 Wastewater containing 10kg of phenol and 200kg of sodium sulfate is subjected to solid-liquid separation in a filter-type solid-liquid separation device, solid-phase waste residue is removed, and the liquid phase of the hydrochloric acid pickling wastewater after deslag...

Embodiment 3

[0076] The main process equipment is centrifugal solid-liquid separation device, high-efficiency oil-water separator, heat pump evaporation and concentration equipment, cooling crystallization equipment, evaporation concentration and drying equipment, etc.

[0077] A method for resource utilization and treatment of waste water in the production process of sebacic acid is a method for resource utilization and treatment of waste water containing phenol and sodium sulfate produced in the process of sebacic acid production. The waste water of 5%~20% sodium sulfate, and recycle the method for sodium phenate and sodium sulfate, described method step is as follows:

[0078] (1) Solid-liquid separation: 1m 3 Wastewater containing 5kg of phenol and 100kg of sodium sulfate is subjected to solid-liquid separation in a centrifugal solid-liquid separation device, solid phase waste residue is removed, and the liquid phase of the hydrochloric acid pickling wastewater after deslagging enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com