Dehydration technology and device for salicylic acid intermediate sodium phenoxide

A technology of sodium phenolate and dehydration device, which is applied in the chemical industry, preparation of organic compounds, sustainable manufacturing/processing, etc. The effect of environmental improvement, simple dehydration process, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

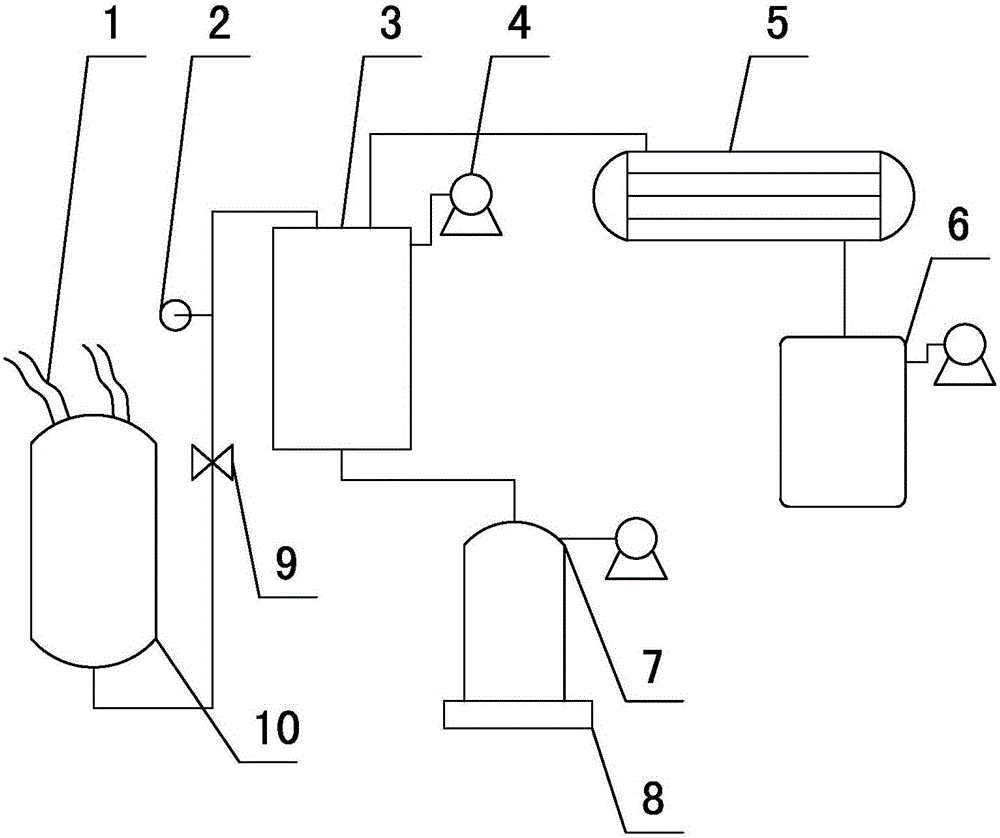

Method used

Image

Examples

Embodiment 1

[0027] 3530L of phenol aqueous solution with a concentration of 66.04g / mL and 1480L of 73.3g / mL sodium hydroxide aqueous solution are formulated into a sodium phenoxide solution with a concentration of 59.50g / mL and a volume of 5000L, and the sodium phenoxide preparation tank is heated to 90 by steam ℃; when the vacuum degree of the membrane evaporator, condensed water recoverer, and concentrated sodium phenate collector reaches 0.05Mpa, open the regulating valve and turn on the rotameter to control the feed rate of each membrane evaporator at 1000L / h, Four film evaporators are used to operate in parallel; the vapor pressure of the film evaporator is controlled at 0.3Mpa; the content of concentrated sodium phenate is 80.07wt%.

Embodiment 2

[0029] 21950L of phenol aqueous solution with a concentration of 60.24g / mL and 8080L of 70.31g / mL sodium hydroxide aqueous solution are formulated to form a sodium phenate solution with a concentration of 54.47g / mL and a volume of 30030L, and the sodium phenate preparation tank is heated to 93 by steam ℃; when the vacuum degree of the film evaporator, outlet water receiver, and concentrated sodium phenate receiver system reaches 0.078Mpa, turn on the feeding cock and the flow meter cock, so that the feeding speed of each film evaporator is controlled at 1500L / h, open four units at the same time; the vapor pressure of the film evaporator is controlled at 0.4Mpa; the content of concentrated sodium phenate is 90.27wt%.

Embodiment 3

[0031] 35000L of phenol aqueous solution with a concentration of 64.24g / mL and 13520L of 71.5g / mL sodium hydroxide aqueous solution are formulated into a sodium phenoxide solution with a concentration of 57.18g / mL and a volume of 48500L, and the sodium phenoxide preparation tank is heated to 95 by steam. ℃; when the vacuum degree of the film evaporator, outlet water receiver, and concentrated sodium phenate receiver system reaches 0.095Mpa, turn on the feeding cock and the flow meter cock, so that the feeding speed of each film evaporator is controlled at 2000L / h, open four sets at the same time; the vapor pressure of the film evaporator is controlled at 0.5Mpa; the content of concentrated sodium phenate is 94.87wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com