Method for synthesizing phenoxycycloposphazene

A technology of hexaphenoxycyclotriphosphazene and hexachlorocyclotriphosphazene, which is applied in the field of phosphazene compound synthesis, can solve the problems of unfavorable industrial transformation, difficult recovery of reaction solvent, and low reaction temperature, and achieve easy control and equipment The effect of small footprint and high synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

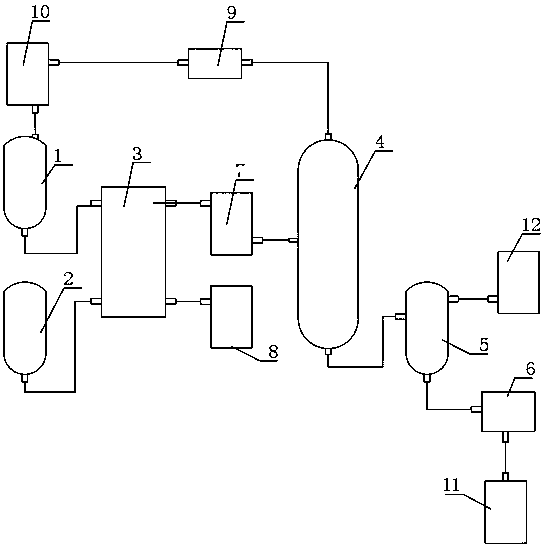

[0026] The synthetic method of hexaphenoxy cyclotriphosphazene comprises the following steps:

[0027] (1) Add chlorobenzene, hexachlorocyclotriphosphazene and tetrabutylammonium chloride into the organic phase raw material preparation kettle 1, stir and dissolve to obtain the organic phase raw material, and the content of hexachlorocyclotriphosphazene in the organic phase raw material is 225 g / L, the consumption of tetrabutylammonium chloride is 4% of hexachlorocyclotriphosphazene quality; Sodium hydroxide aqueous solution and phenol are added in the preparation kettle 2 of water phase raw material, react and generate sodium phenate, make water phase raw material, The sodium phenate content of the aqueous phase raw material is 450 g / L.

[0028] (2) Let the organic phase raw material in the organic phase raw material preparation kettle 1 flow into the centrifugal extractor 3 through the upper liquid inlet of the centrifugal extractor, and at the same time let the aqueous phase...

Embodiment 2

[0031] The synthetic method of hexaphenoxy cyclotriphosphazene comprises the following steps:

[0032] (1) Add o-dichlorobenzene, hexachlorocyclotriphosphazene and tetrabutylammonium bromide into the organic phase raw material preparation kettle 1, stir and dissolve to obtain the organic phase raw material, and the content of hexachlorocyclotriphosphazene in the organic phase raw material The amount of tetrabutylammonium bromide is 225 g / L, and the consumption of tetrabutylammonium bromide is 3% of the quality of hexachlorocyclotriphosphazene; sodium hydroxide aqueous solution and phenol are added in the water phase raw material preparation kettle 2, and the reaction generates sodium phenate, and the water phase Raw material, the sodium phenate content of aqueous phase raw material is 225 g / L.

[0033] (2) Let the organic phase raw material in the organic phase raw material preparation kettle 1 flow into the centrifugal extractor 3 through the upper liquid inlet of the centrifu...

Embodiment 3

[0036] The synthetic method of hexaphenoxy cyclotriphosphazene comprises the following steps:

[0037] (1) Add toluene, hexachlorocyclotriphosphazene and dodecyltrimethylammonium chloride into the organic phase raw material preparation kettle 1, stir and dissolve to obtain the organic phase raw material, the hexachlorocyclotriphosphazene of the organic phase raw material The content is 562.5 g / L, and the amount of dodecyltrimethylammonium chloride is 2% of the mass of hexachlorocyclotriphosphazene; sodium hydroxide aqueous solution and phenol are added to the water phase raw material preparation kettle 2, and the reaction generates sodium phenoxide , the aqueous phase raw material was obtained, and the sodium phenate content of the aqueous phase raw material was 225 g / L.

[0038] (2) Let the organic phase raw material in the organic phase raw material preparation kettle 1 flow into the centrifugal extractor 3 through the upper liquid inlet of the centrifugal extractor, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com