Method for separating sodium phenolate and sodium hydroxide solid mixture and recovering phenol by toluene extraction separation

A sodium hydroxide, separation and recovery technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of low sodium salt use value, difficult solid waste treatment, difficult resource utilization, etc., to achieve Simple operation, easy separation operation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The main process equipment is leaching equipment, solid-liquid separation equipment, evaporation equipment, extraction equipment, rectification equipment, etc.

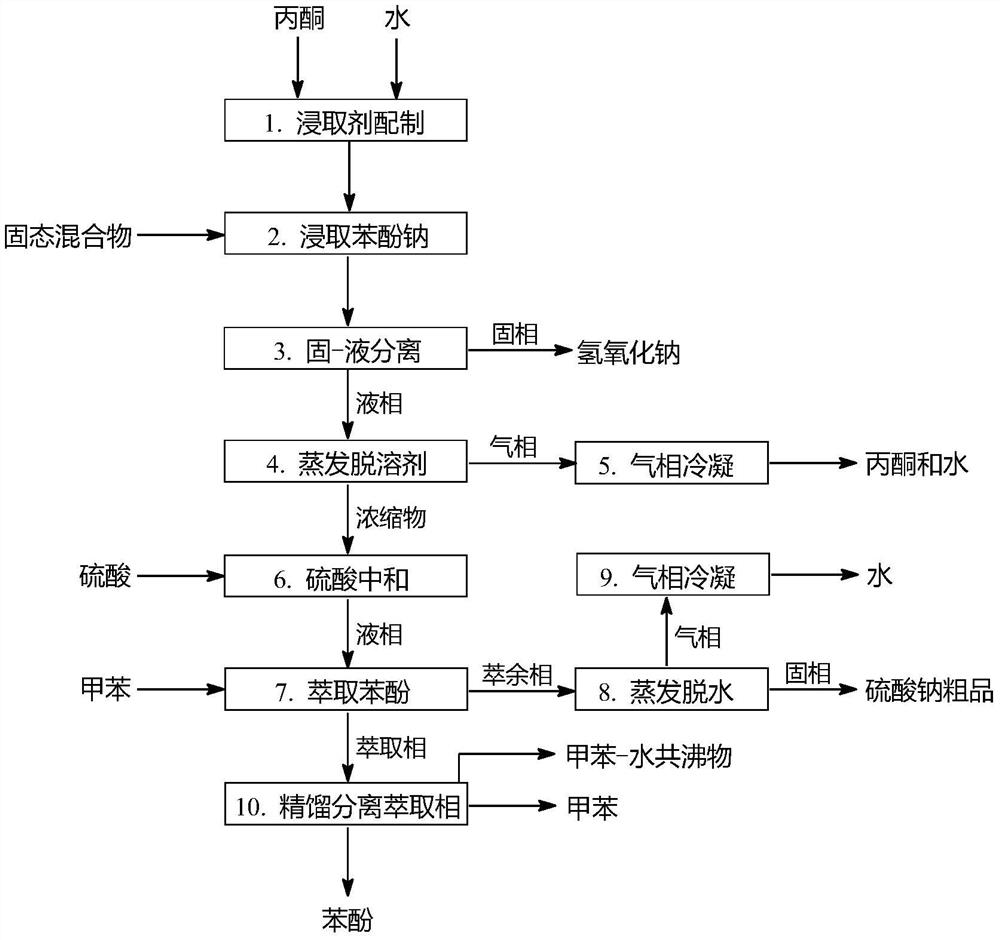

[0053] A method for separating the solid mixture of sodium phenate and sodium hydroxide and extracting and recovering phenol with toluene, especially using acetone-water mixed solvent as the leaching agent and toluene as the extraction agent, and adopting leaching-extraction-rectification coupling technology for separation and recovery The method for phenol, while separating and obtaining phenol, realizes the recycling of sodium hydroxide, lixiviating agent, extraction agent, is characterized in that described method step is as follows:

[0054] (1) preparation of leaching agent: mixing acetone and water, the volume ratio of water and acetone in the obtained leaching agent is 10.0:100, and this solvent enters the next step as leaching agent;

[0055] (2) Sodium phenate leaching: In the leaching equipment, the a...

Embodiment 2

[0065] The main process equipment is leaching equipment, solid-liquid separation equipment, evaporation equipment, extraction equipment, rectification equipment, etc.

[0066] A method for separating the solid mixture of sodium phenate and sodium hydroxide and extracting and recovering phenol with toluene, especially using acetone-water mixed solvent as the leaching agent and toluene as the extraction agent, and adopting leaching-extraction-rectification coupling technology for separation and recovery The method for phenol, while separating and obtaining phenol, realizes the recycling of sodium hydroxide, lixiviating agent, extraction agent, is characterized in that described method step is as follows:

[0067] (1) preparation of leaching agent: mixing acetone and water, the volume ratio of water and acetone in the obtained leaching agent is 1.0:100, and this solvent enters the next step as leaching agent;

[0068] (2) Sodium phenate leaching: In the leaching equipment, the ac...

Embodiment 3

[0078] The main process equipment is leaching equipment, solid-liquid separation equipment, evaporation equipment, extraction equipment, rectification equipment, etc.

[0079] A method for separating the solid mixture of sodium phenate and sodium hydroxide and extracting and recovering phenol with toluene, especially using acetone-water mixed solvent as the leaching agent and toluene as the extraction agent, and adopting leaching-extraction-rectification coupling technology for separation and recovery The method for phenol, while separating and obtaining phenol, realizes the recycling of sodium hydroxide, lixiviating agent, extraction agent, is characterized in that described method step is as follows:

[0080] (1) preparation of leaching agent: acetone and water are mixed, and the volume ratio of water and acetone in the obtained leaching agent is 5.0:100, and this solvent enters the next step as leaching agent;

[0081] (2) Sodium phenate leaching: In the leaching equipment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com