Technology for preparing salicylic acid through micro-channel continuous-flow reactor

A technology of reactor and microchannel, which is applied in carboxylate preparation, carboxylate preparation, organic chemistry, etc., can solve the problems of low production efficiency and raw material conversion rate, affecting reaction selectivity, and prone to side reactions, etc., to achieve Improve production efficiency, improve stability, and facilitate the effect of mass and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

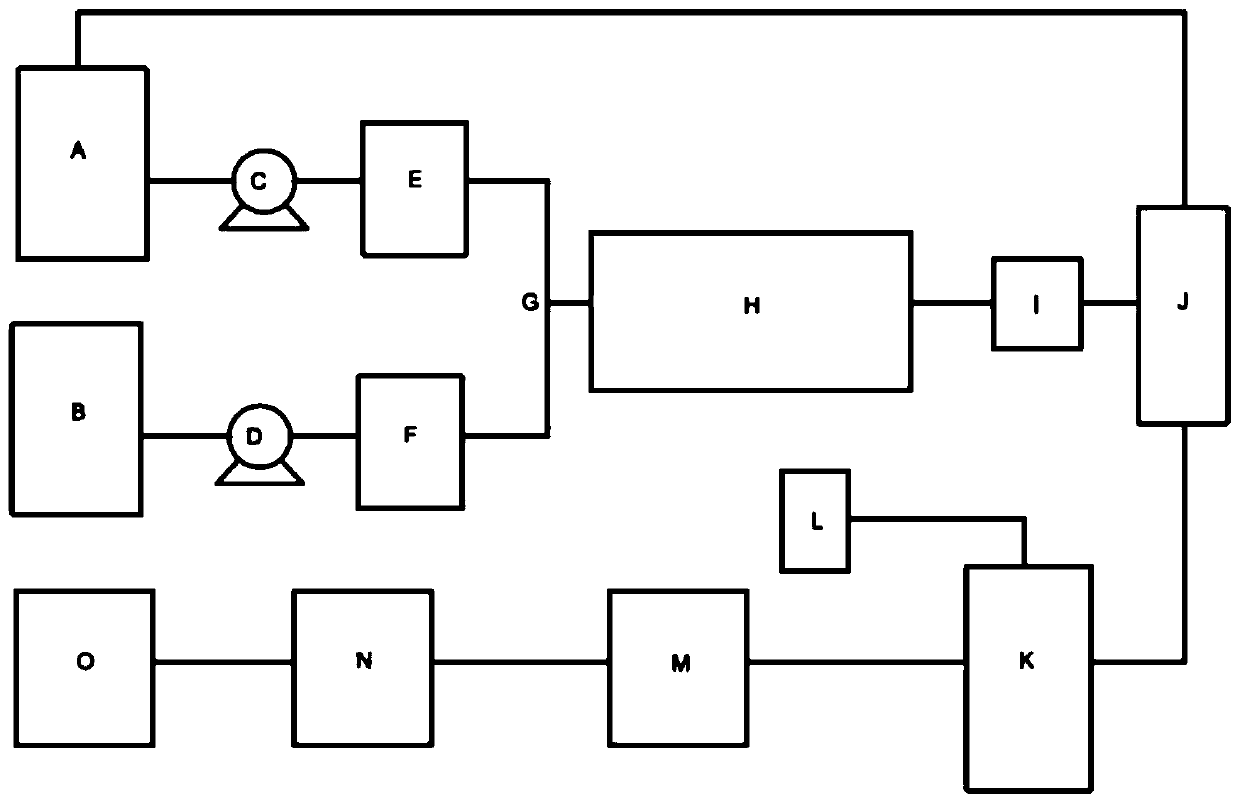

Image

Examples

Embodiment 1

[0021] The n-hexyl alcohol solution of sodium phenate and carbon dioxide are pumped into the preheating module of microchannel continuous flow reactor respectively, after preheating finishes, enter mixing module and reaction module and react, the mol ratio of the sodium phenate entering reaction module and carbon dioxide is 1: 3. The temperature of the preheating module, the mixing module and the reaction module is set to 160°C, the pressure of the reaction module is controlled by the back pressure valve control system at the outlet of the reaction module to 1.0MPa, and the retention time of the reaction is 300s. After the reaction is completed, the reactant After the cooling module, it enters the separation module to complete the gas-liquid separation, the carbon dioxide in the gas phase is recovered and recycled, and the liquid phase enters the sodium salicylate storage tank.

[0022] Extract the sodium salicylate in the sodium salicylate solution with water. After the extrac...

Embodiment 2

[0024] The n-octanol solution of sodium phenate and carbon dioxide are pumped into the preheating module of microchannel continuous flow reactor respectively, after preheating finishes, enter mixing module and reaction module and react, the mol ratio of the sodium phenate entering reaction module and carbon dioxide is 1: 1. The temperature of the preheating module, the mixing module and the reaction module is set to 110°C, the pressure of the reaction module is controlled by the back pressure valve control system at the outlet of the reaction module to 2.0MPa, and the retention time of the reaction is 900s. After the reaction is completed, the reactant After the cooling module, it enters the separation module to complete the gas-liquid separation, the carbon dioxide in the gas phase is recovered and recycled, and the liquid phase enters the sodium salicylate storage tank.

[0025] The sodium salicylate in the sodium salicylate solution is extracted with water. After the extract...

Embodiment 3

[0027] The n-hexyl alcohol solution of sodium phenate and carbon dioxide are pumped into the preheating module of microchannel continuous flow reactor respectively, after preheating finishes, enter mixing module and reaction module and react, the mol ratio of the sodium phenate entering reaction module and carbon dioxide is 1: 10. The temperature of the preheating module, the mixing module and the reaction module is set to 200°C, the pressure of the reaction module is controlled by the back pressure valve control system at the outlet of the reaction module to 0.1MPa, and the retention time of the reaction is 100s. After the reaction is completed, the reactant After the cooling module, it enters the separation module to complete the gas-liquid separation, the carbon dioxide in the gas phase is recovered and recycled, and the liquid phase enters the sodium salicylate storage tank.

[0028] Extract the sodium salicylate in the sodium salicylate solution with water. After the extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com