Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

421 results about "Potassium hydrocarbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

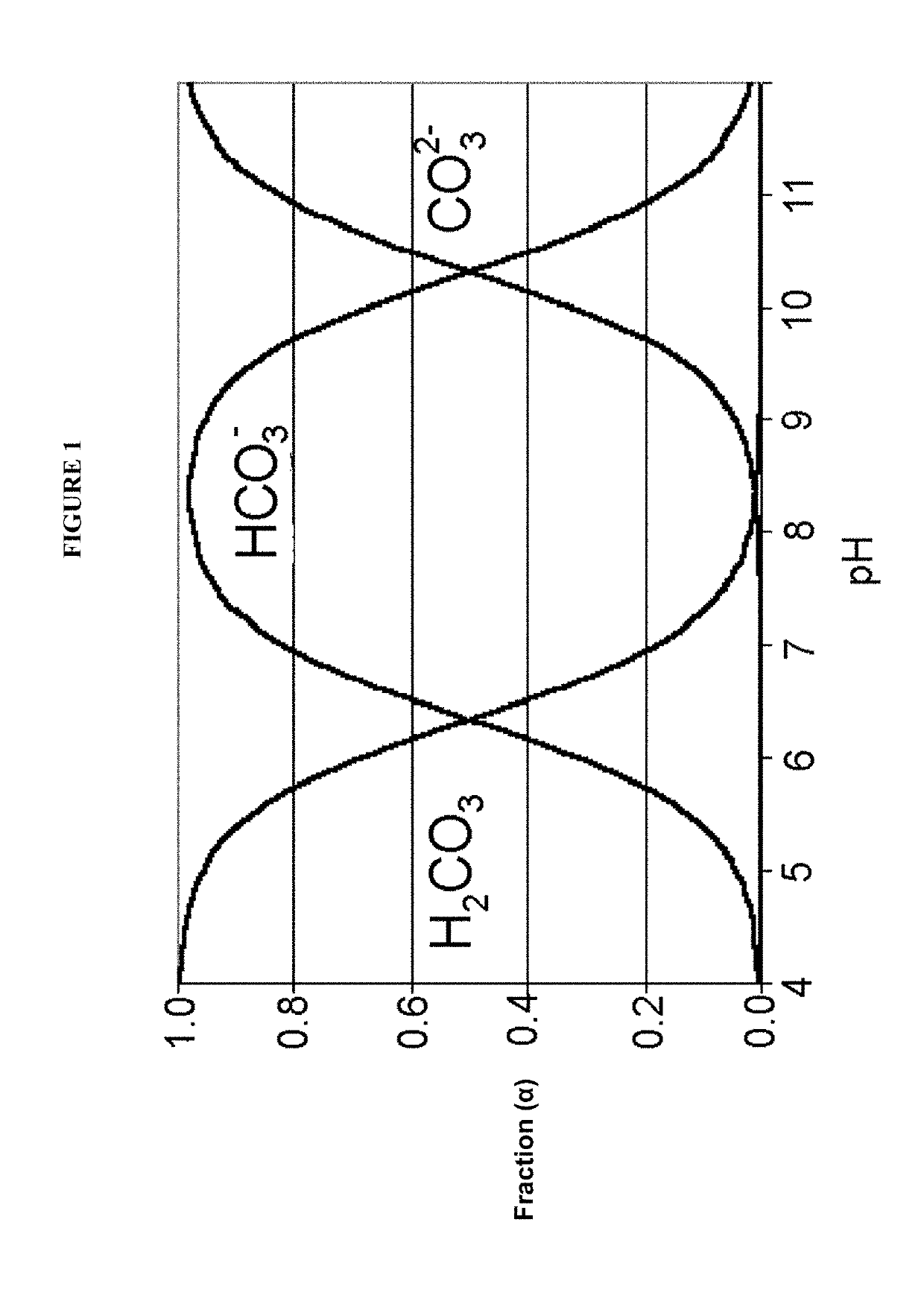

Potassium bicarbonate (also known as potassium hydrogen carbonate or potassium acid carbonate) is a colorless, odorless, slightly basic, salty substance. According to the U.S. Food and Drug Administration (FDA), potassium bicarbonate is generally recognized as safe.

Paddy hull burned gas and waste residue comprehensive utilization method

The invention discloses a comprehensive utilization method for rice hull combustion emissions and waste residue, in particular a method for preparing superfine silicon dioxide and active carbon with high specific surface area by using the emissions and waste residue generated by the pyrolysis and combustion of the rice hull, which comprises the following steps: the main raw material sodium carbonate (or potassium carbonate) is heated and hydrolyzed to be sodium bicarbonate (or potassium bicarbonate), OH<-> is released, the silicon dioxide in the rice hull ashes is dissolved, the sodium bicarbonate (or the potassium bicarbonate) is reduced to sodium carbonate (or potassium carbonate) after temperature reduction, and then the silicon dioxide precipitate is separated out. The method has the advantages that the silicon dioxide which only plays the role of catalyst in the process can be used circularly without consumption, the cost is reduced; the purified combusted tail gas can be used for preparing a precipitator of the silicon dioxide, thus avoiding the pollution brought by acid neutralization and precipitation in the traditional technology, reducing the cost, making full use of carbon dioxide and reducing green house gas emission; and the activating agent for preparing the active carbon can be recovered, which can be returned to the hydrolyzation process to be reused after adjusting the concentration of the sodium carbonate (or the potassium carbonate), thus reducing the cost.

Owner:JILIN UNIV

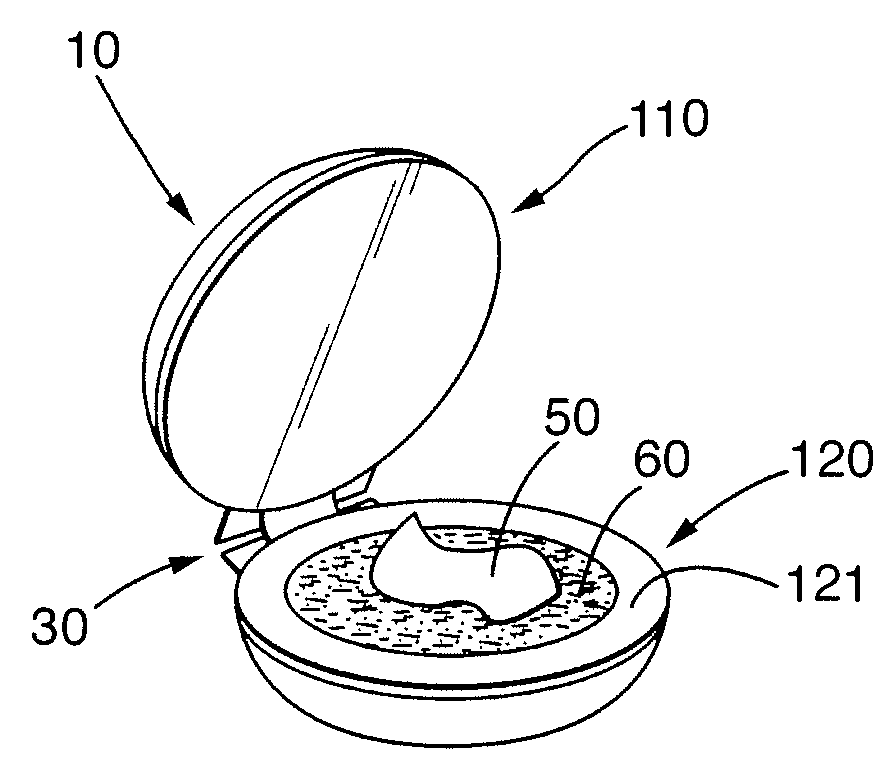

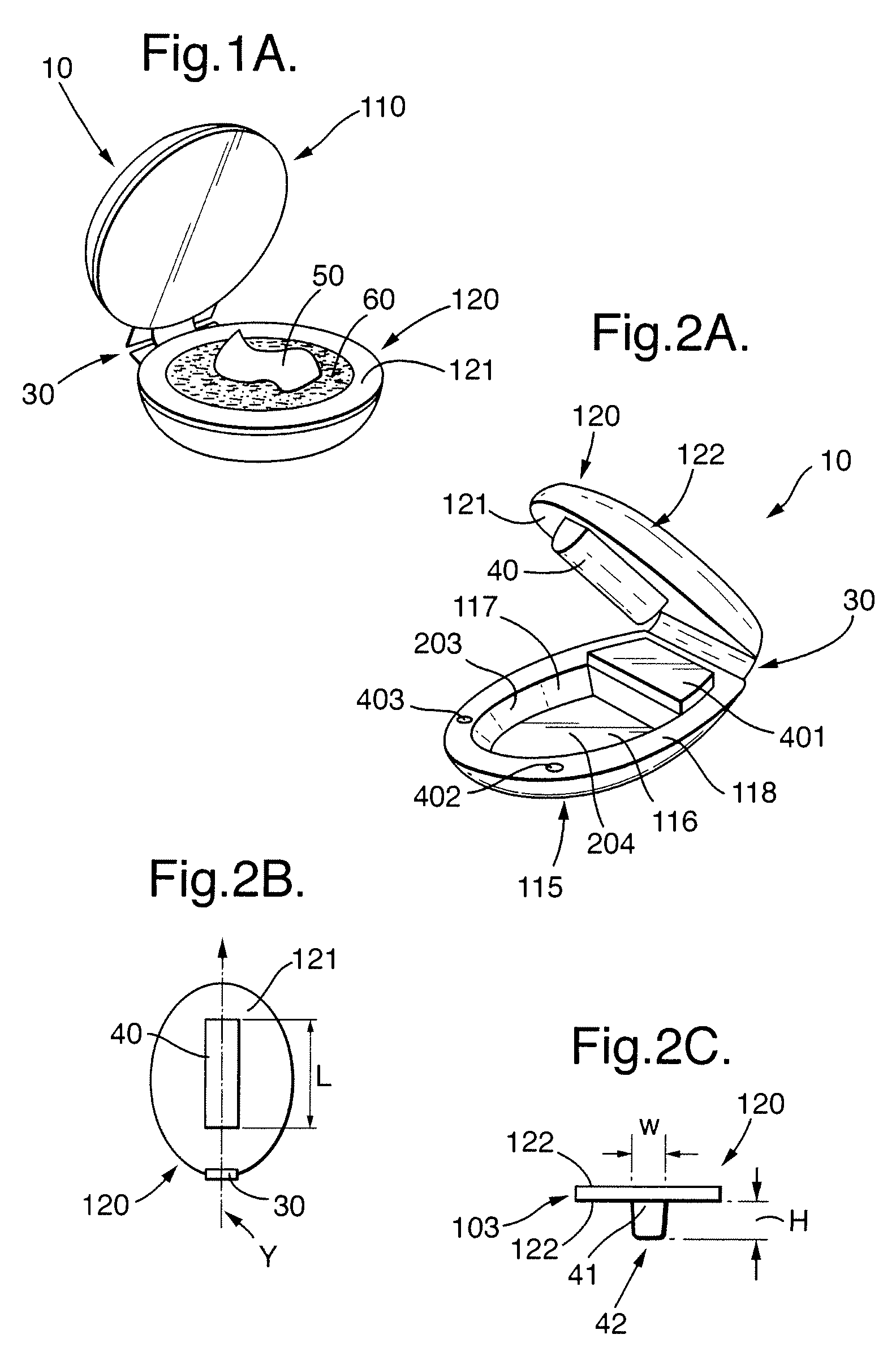

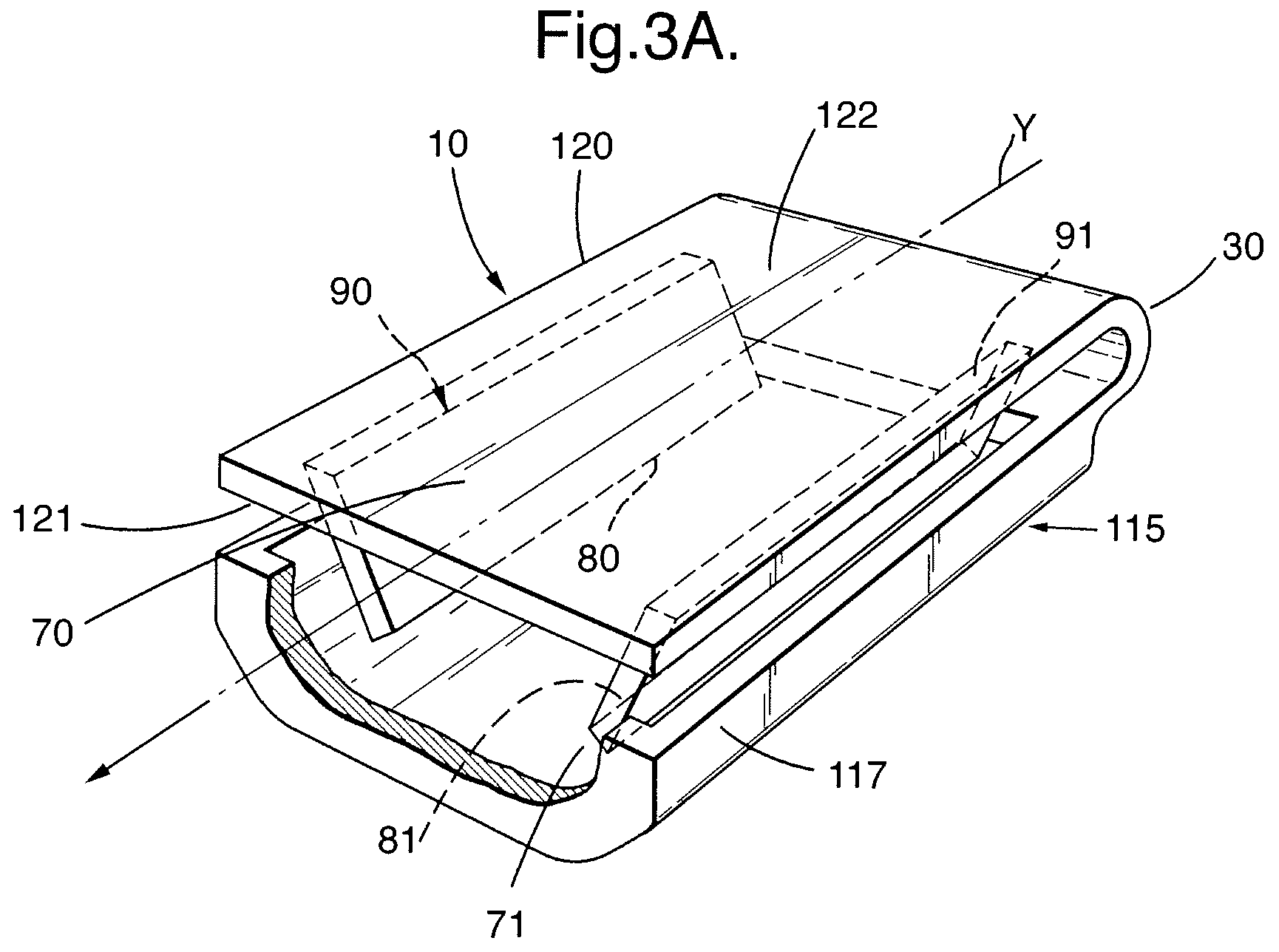

System for Highlighting Hair

The present invention relates to a system to highlight the hair. The system comprises a device (10) and a composition (50). Device (10) comprises a first portion movably joined to a second portion. Composition (50) comprises a percentage of hydrogen peroxide and a percentage of an alkalizer by weight of said composition (50). The weight percentages of hydrogen peroxide and of an alkalizer are defined by equation (I): X+1.5Y≧15 (I) wherein X is the percentage by weight of hydrogen peroxide by weight of the composition (50) and wherein Y is the percentage by weight of an alkalizer by weight of the composition (50). Said composition (50) comprises at least 2% of hydrogen peroxide by weight of said composition (50) and said alkalizer is an inorganic salt selected from the group consisting of sodium silicate, sodium metasilicate, potassium hydrogen carbonate, ammonium carbonate, ammonium hydrogen carbonate and sodium hydrogen carbonate and mixtures thereof. Said composition (50) allows to perform highlighting when applied with the device (10) as described herein.

Owner:WELLA OPERATIONS US LLC

Preparation method and product of multistage porous carbon material

The invention discloses a preparation method of a multistage porous carbon material. The preparation method comprises the following steps: blending a carbon source with an activator, and performing two-step carbonization and after treatment to obtain the multistage porous carbon material, wherein the two-step carbonization comprises low-temperature carbonization and high-temperature carbonization, the temperature of the low-temperature carbonization is 200-400 DEG C, and the temperature for the high-temperature carbonization is 800-1200 DEG C; the carbon source is a biomass, monosaccharide, disaccharide or polysaccharide of which the cellulose content is more than 20%; and the activator is selected from ammonium oxalate, potassium oxalate, potassium hydrogen oxalate, potassium tetroxalate, sodium oxalate, sodium hydrogen oxalate, sodium tetroxalate, sodium hydrogen carbonate or potassium hydrogen carbonate. The invention provides the preparation method of the multistage porous carbon material rich in macropore, and according to the preparation method, physical expansion and chemical activation are utilized, and a carbon source is used as a raw material to match with a specific activator in order to prepare the multistage porous carbon material rich in macropore; and the raw material is low in price and easy to obtain, the method is simple and strong in sustainability and has a potential for large-scale production.

Owner:ZHEJIANG UNIV

Method for producing o-chloroaniline

InactiveCN101333169AHigh yieldLow costOrganic compound preparationAmino compound preparationEthylenediamineO-nitrochlorobenzene

An o-chloroaniline production method takes o-nitrochlorobenzene as raw material and is characterized in that the o-nitrochlorobenzene is dissolved in alcohol solvent in the presence of catalyst and additive and reacted with hydrogen at 10-120 DEG C and under 0.3-4.0 MPa; the reaction process is continuous reaction; after the completion of the reaction, the o-chloroaniline is obtained through treatment, wherein, the catalyst can be selected from one of the following: Ni / Al2O3, Raney Ni, Pt / C and Pd / C; while the additive can be selected from one, or two, or three of the following compounds: cyclohexylamine, ethylenediamine, ethanolamine, diethanolamine, triethanolamine, pyridine, liquid ammonia, ammonium bicarbonate, ammonium carbonate, sodium carbonate, sodium bicarbonate, potassium bicarbonate, potassium carbonate, potassium hydrogen phosphate, potassium dihydrogen phosphate, sodium hydrogen phosphate and sodium dihydrogen phosphate; the dosage of the catalyst takes up 0.05% to 20% of the mass of the o-nitrochlorobenzene; the dosage of the additive takes up 0. 5% to 20% of the mass of the o-nitrochlorobenzene; the alcohol can be methanol or ethanol; the dosage of alcohol takes up 30% to 150% of the dosage of the o-nitrochlorobenzene; the continuous reaction is realized through 1 to 6 tank reactors which are connected in series.

Owner:淮安嘉诚高新化工股份有限公司

Enhanced light weight armor system with reactive properties

InactiveUS7322267B1Prevent penetrationDissipate energyReactive armourDynamic armourThin metalNanoparticle

A light-weight armor system for retrofitting onto light vehicles, such as HMMWVs, trucks, or helicopters, or incorporating into a vehicle to protect against HEAT or high explosive warheads. The armor system comprises multiple layers of a thin metal film. The front side of the thin metal sheet facing away from the vehicle is coated with a layer of zirconium nanoparticles and imprinted with a network of hollow packets filled with water and sealed. The back side of the thin metal sheet is coated with a layer of potassium bicarbonate powder. The multiple layers of metal film are imbedded in a matrix of composite foam to form a honeycomb structure that can be retrofitted onto light vehicles or used in new designs.

Owner:FOI GRP

Room-temperature efficient ozone decomposition catalyst and preparation method thereof

ActiveCN102513106AGuaranteed conditions that generate the desired valenceRich in channelsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater vaporDecomposition

The invention discloses a room-temperature efficient ozone decomposition catalyst and a preparation method thereof. The catalyst is prepared by the following steps of: preparing manganese nitrate, cerous nitrate and silver nitrate into a solution according to a mol ratio of 1: (0.3-0.5): (0.01-0.1); taking potassium carbonate and / or potassium bicarbonate as a precipitant, taking potassium chlorate as an oxidant, and precipitating to prepare active components; and then, adding N,N-diethyl ethylamine and crystallizing in a reaction kettle at a temperature in a range of 180-220 DEG C; after the crystallization, carrying out filter pressing to obtain sediments with the water content of 70-80 wt%; and then, adding a binding agent and a pore-forming agent and uniformly agitating; conveying the mixture into a banded extruder to be extruded and molded into cylindrical grains; drying the cylindrical grains at a temperature in a range of 80-100 DEG C and adding the dried cylindrical grains intoa muffle furnace to be roasted at a temperature in a range of 450-550 DEG C. The ozone decomposition catalyst provided by the invention has the advantages of capabilities of completely purifying thousands of ppm of ozone at the room temperature and resisting the violent fluctuation of the ozone concentration, good water vapor resistance and long service life.

Owner:SUZHOU IND PARK ANZEWEN ENVIRONMENTAL PROTECTION TECH

Method for environment-friendly clean production of D,L-methionine

InactiveCN106432018AIncrease profitAvoid accumulationOrganic compound preparationChemical recyclingChromatographic separationAlkaline hydrolysis

A method for environment-friendly clean production of D,L-methionine includes: performing alkaline hydrolysis of 5-(2-methylmercaptoethyl)-hydantoin to obtain carbonate-containing methionine alkali metal saponified solution; then feeding carbon dioxide, crystallizing, and separating to respectively obtain methionine and hydrocarbonate water solution of methionine; subjecting the hydrocarbonate water solution of methionine to chromatographic separation. The method has advantages that loss of D,L-methionine due to pyrolysis can be reduced, simplicity in operation, low cost and high utilization rate of raw materials are realized, high efficiency in acquisition of high-purity methionine crystals is achieved, the purity of the obtained methionine is up to 99.4%, the methionine recovery rate reaches 97%, and the desalinization rate reaches 98% or above. In addition, accumulation of a great quantity of impurities of methionine-containing potassium bicarbonate mother liquor and emission of the potassium bicarbonate mother liquor are avoided, discharge of saline wastewater is avoided, and accordingly environment friendliness and clean production are realized. In a whole process, potassium carbonate serving as a hydrolysis agent is recycled without loss, and replenishment of alkaline potassium compounds is avoided.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

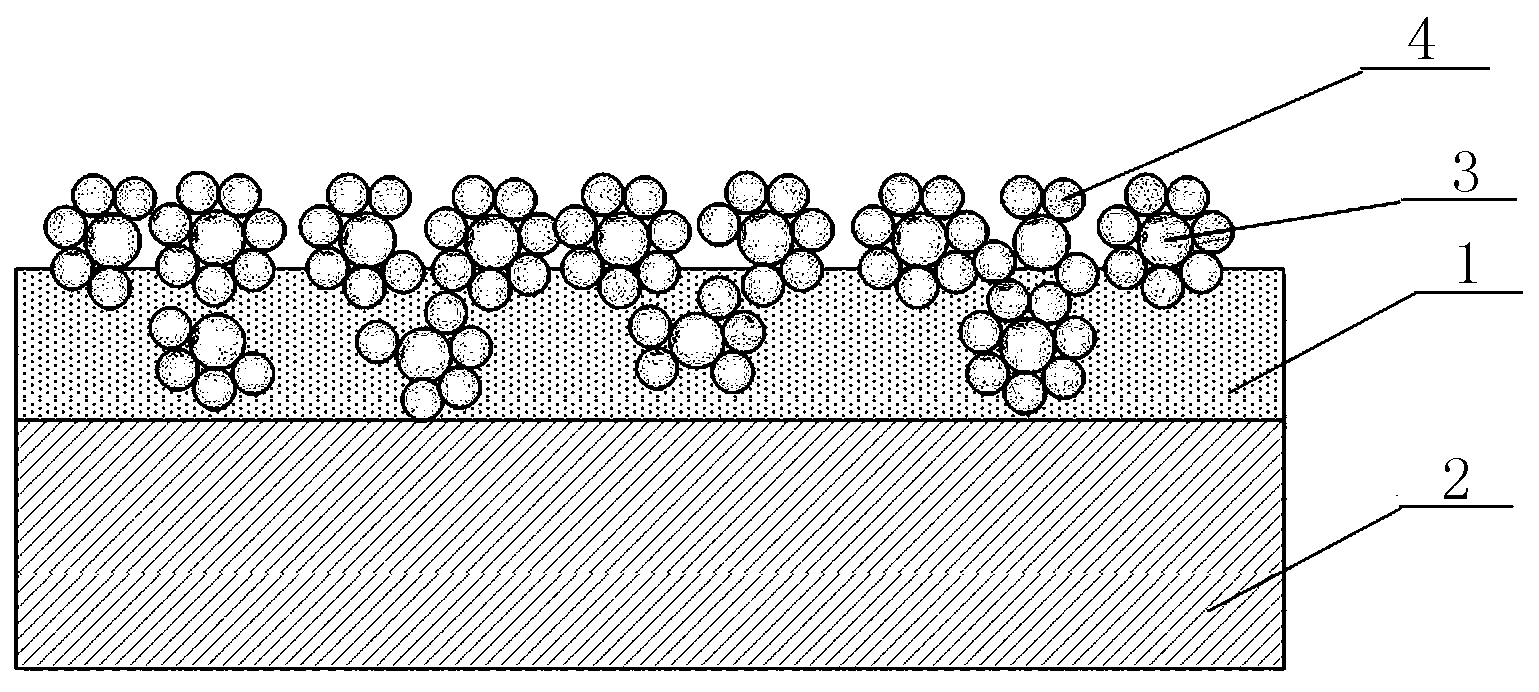

Method for preparing AuNPs-PDMS composite micro film biosensor

The invention discloses a method for preparing AuNPs (nanogold)-PDMS (polydimethylsiloxane) composite micro film surface stress biosensor. The method comprises the following steps: by taking a PDMS film as a substrate and using a chloroauric acid solution as a first-step reducing agent, reducing to generate a gold seed; by utilizing the gold seed generated on the film and taking glucose and potassium bicarbonate as auxiliary reducing agents, performing second-step reduction on the composite film by using the chloroauric acid; by utilizing an AuNPs-PDMS composite film as a sensitive element of the sensor and taking PDMS as a substrate, preparing a gold electrode of the sensor by adopting a sputtering technology, and finishing preparation of the sensor. The electric conductivity of the AuNPs-PDMS composite film generated by the method is obviously improved, so that the sensitivity of the sensor is improved. Moreover, the preparation method is simple, and possibility is provided for miniature, low-cost batch production.

Owner:TAIYUAN UNIV OF TECH

Agricultural composite manure and preparing method thereof

InactiveCN1583681AReduce use costReduce pollutionAmmonium salt fertilisersUrea compound fertilisersDicarbonateSodium phosphates

An agricultural nutritive composite fertilizer able to increase the resistance of agricultural crops to diseases is prepared from ammonium molybdate, borax, sodium phosphate, urea, potassium sulfate (or chloride), complex copper, complex zinc, potassium dicarbonate and auxiliary.

Owner:陈天骏

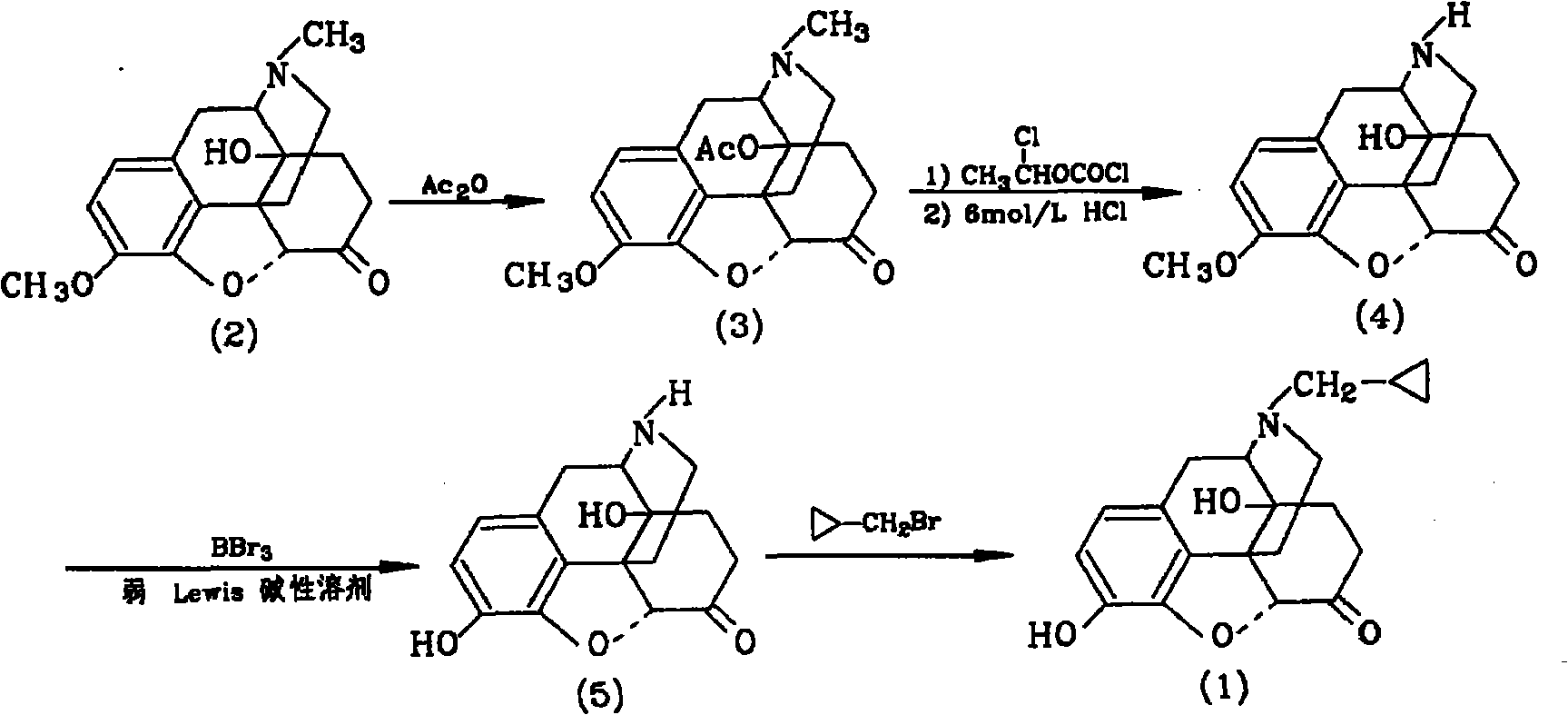

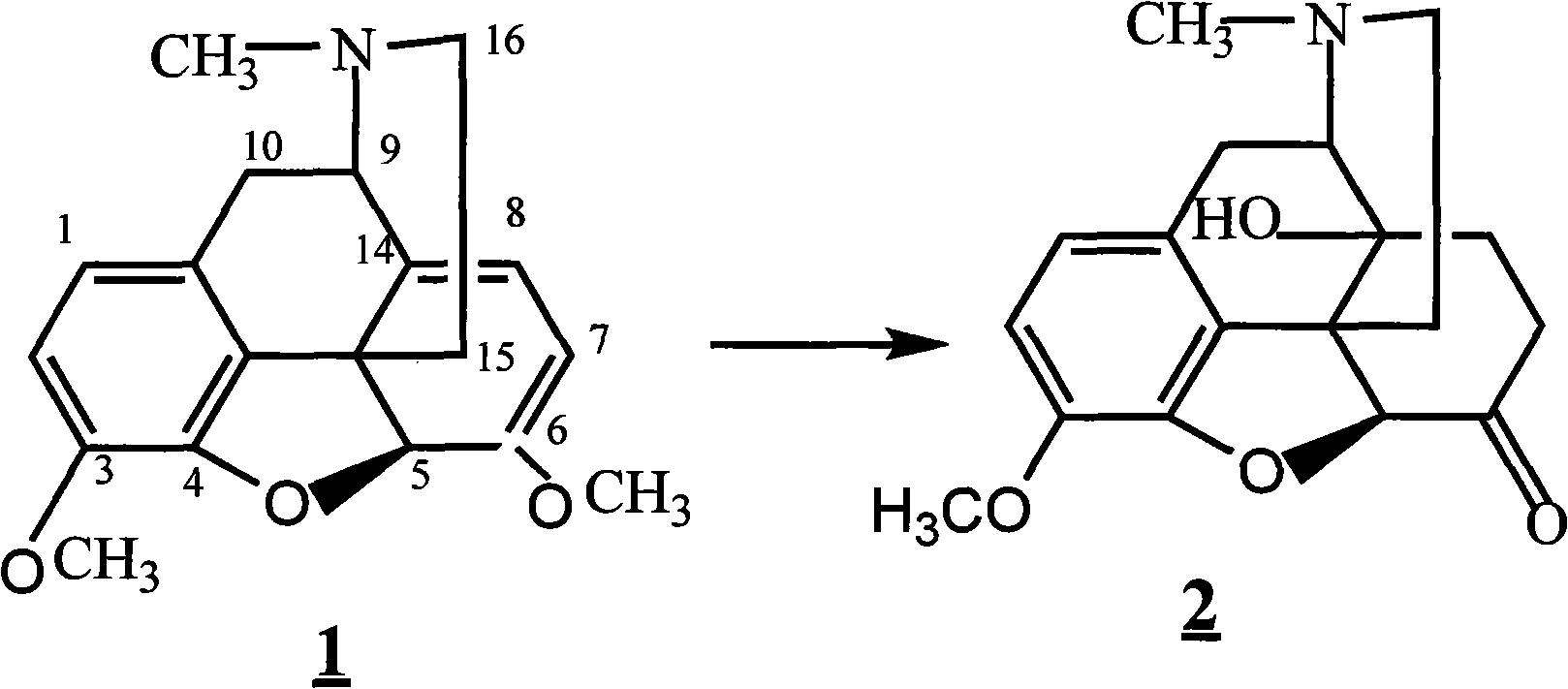

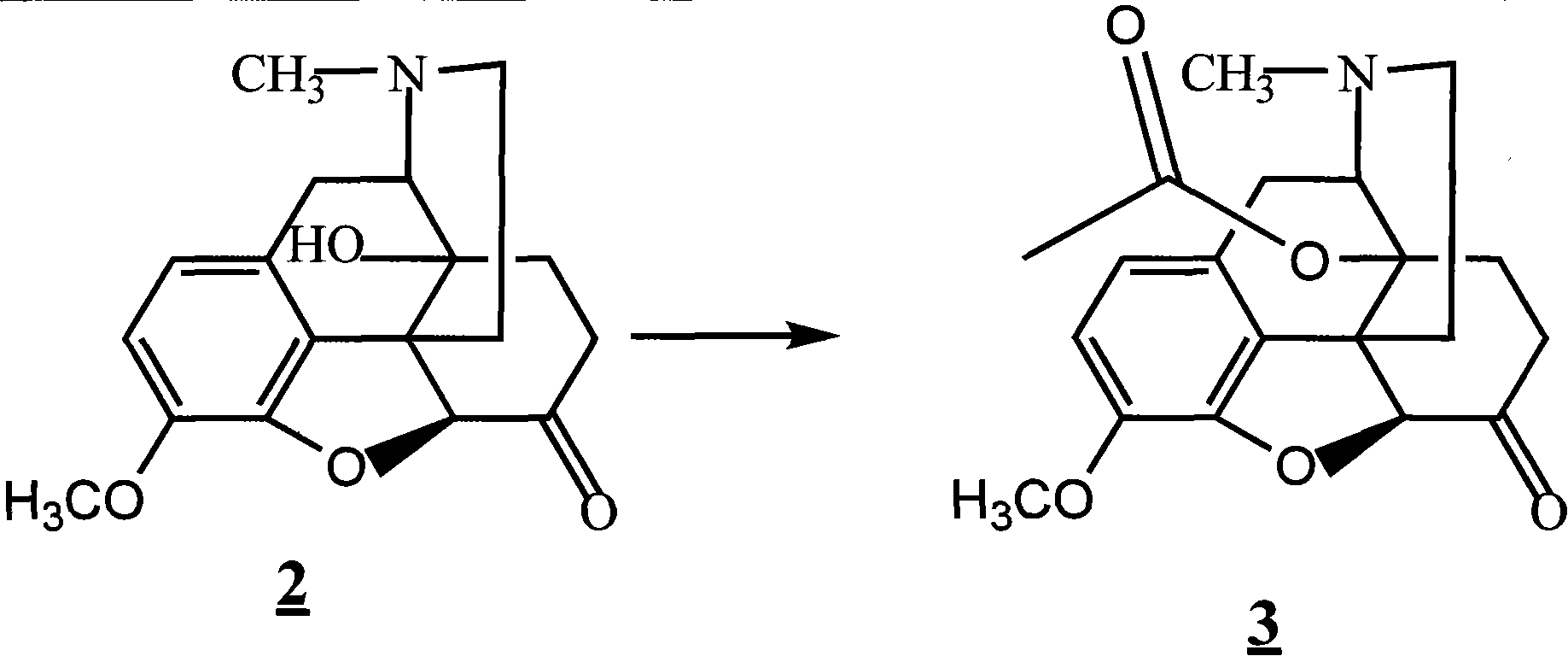

Method for synthesizing naloxone or naltrexone

The invention provides a method for synthesizing naloxone or naltrexone, which comprises the following steps of: dissolving thebaine in formic acid, uniformly stirring, dripping an oxidant, keeping the temperature of between 20 and 40 DEG C for 3 to 7 hours, displacing gas in a reaction vessel by inert gas serving as protective gas for 3 to 5 times, adding a metallic framework catalyst, displacing the gas by hydrogen for 3 to 5 times, keeping the temperature of between 25 and 45 DEG C and stabilizing a system for 7 to 13 hours to obtain a compound 2; reacting the compound 2 with acetic anhydride at the temperature of between 60 and 100 DEG C for 1 to 2 hours to obtain a compound 3; taking the inert gas as the protective gas, adding toluene, chloroformic acid-1-chloroethyl ester and potassium bicarbonate into the compound 3, heating to the temperature of between 75 and 100 DEG C and reacting for 20 to 40 hours, concentrating under reduced pressure until the system is fully dry, adding 10 percent hydrochloric acid, and heating and refluxing for 2 to 6 hours to obtain a compound 4; dissolving the compound 4 and at least one alkylation reagent in an organic solvent 1 and reacting with alkali at the temperature of between 50 and 100 DEG C to obtain a compound 5; and reacting the compound 5 with boron tribromide in an organic solvent 2 at the temperature of between -10 and 40 DEG C for 2 to 4 hours to obtain a compound 6, namely the naloxone or naltrexone.

Owner:甘肃普安制药股份有限公司

Chemical process

This invention provides a process for preparing sodium ferric gluconate complex in sucrose using the following steps: a) combining a ferric salt solution with a weak alkali chosen from the group consisting of alkaline earth metal and ammonium salts, such as sodium carbonate, sodium bicarbonate, lithium carbonate, potassium carbonate, potassium bicarbonate, ammonium carbonate, ammonium bicarbonate and mixtures thereof, to form the ferric oxyhydroxide; b) combining ferric oxyhydroxide and sodium gluconate in solution to yield the sodium ferric gluconate complex; c) isolating the sodium ferric gluconate complex; and d) combining the sodium ferric gluconate with sucrose in solution to yield the desired sodium ferric gluconate complex in sucrose.

Owner:GENEVA PHARMA INC

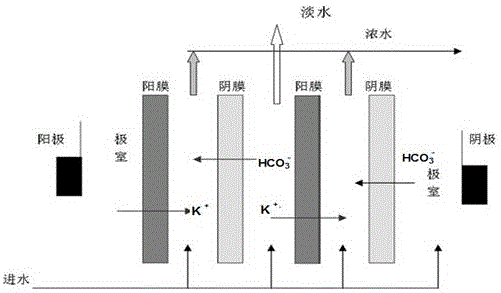

Separation and purification method of D,L-methionine

ActiveCN106432020AHigh purityAvoid generatingOrganic compound preparationOrganic chemistry methodsPurification methodsWastewater

The invention provides a separation and purification method of D,L-methionine. The separation and purification method is realized through the following steps: hydrolyzing 5-(2-methylthio-ethyl)-hydantoin through an alkaline potassium compound to obtain a potassium methionine saponified solution containing potassium carbonate, introducing carbon dioxide into the saponified solution, crystalizing and separating to obtain methionine and a potassium bicarbonate water solution containing less methionine respectively, carrying out homogeneous membrane electroosmosis, heterogeneous membrane electroosmosis and the like on the potassium bicarbonate water solution respectively. By adopting the method provided by the invention, energy consumption needed by subsequent purification and concentration can be reduced and the operation is simple; the purity of the obtained methionine reaches up to 99.4 percent, the retention rate of the methionine reaches 98.8 percent, and the salt removing rate reaches 99.5 percent; the method can avoid a condition that the methionine is decomposed after being heated for a long time to generate malodorous gas; the method is low in cost, a condition that a lot of acidic and odorous wastewater is discharged is avoided, the method is green and environment-friendly, and the separated potassium bicarbonate can be completely circulated to the step of hydrolyzing the 5-(2-methylthioethyl)-hydantoin; fresh potassium carbonate, potassium bicarbonate or potassium hydroxide does not need to be supplemented.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Preparation methods of 2,5-furandicarboxylic acid and 2,5-furanyl polyester

InactiveCN108997278ALow costLow priceOrganic chemistryBulk chemical productionSodium bicarbonatePolyester

The invention provides a preparation method of 2,5-furandicarboxylic acid. The preparation method comprises the following steps: A), with non-grain biomass as a raw material, preparing furfural; B), oxidizing the furfural to obtain furoic acid; C), performing an addition reaction on the furoic acid and carbon dioxide under the action of a catalyst to obtain the 2,5-furandicarboxylic acid, whereinthe catalyst is one or more of potassium carbonate, sodium oxalate, sodium nitrate, potassium nitrate, sodium nitrite, potassium nitrite, potassium acetate, sodium acetate, potassium formate, sodium formate, sodium hydrogen carbonate, potassium hydrogen carbonate, sodium hydroxide and potassium hydroxide. The furfural is prepared from the non-grain biomass as the raw material, so that the raw material cost is low; the furoic acid reacts with the carbon dioxide under the action of the specific catalyst to obtain the 2,5-furandicarboxylic acid; the catalyst is low in price; the used carbon dioxide is environment-friendly; by the preparation method, the yield is high.

Owner:芜湖万隆新材料有限公司

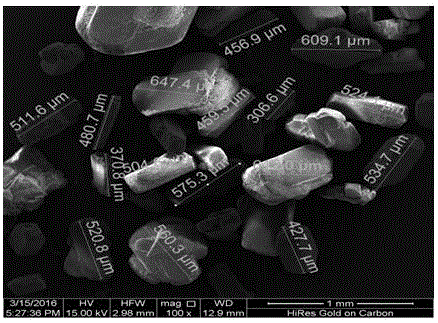

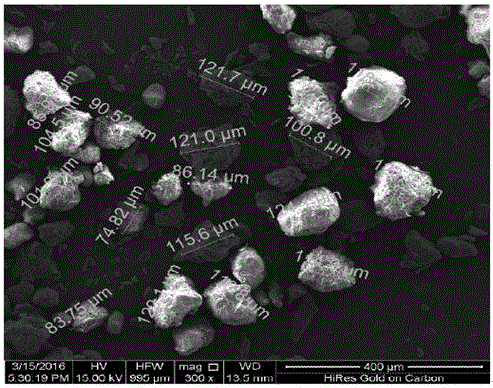

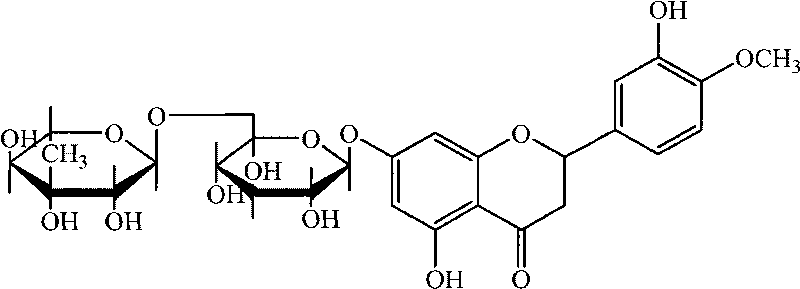

Method for extracting hesperidin from tangerine peel

ActiveCN101747394AReduce the impactGood choiceSugar derivativesSugar derivatives preparationDipotassium hydrogen phosphateSodium bicarbonate

The invention discloses a method for extracting hesperidin from tangerine peel. The method comprises: mixing tangerine peel with a solid-phase alkali reagent, wherein the tangerine peel is tangerine peel powder which is ground to have a powder particle size analysis result D90 between 10 and 200 mu m; adding water, stirring, centrifuging and taking supernatant; adding acid to regulate pH between 2.0 and 6.0; standing and then filtering the obtained product; drying a filter cake; and obtaining hesperidin. The solid-phase alkali reagent is one or arbitrary mixture of more than two of sodium hydroxide, aluminum hydroxide, calcium hydroxide, potassium hydroxide, sodium bicarbonate, potassium bicarbonate, sodium carbonate, potassium carbonate, calcium carbonate, sodium silicate, disodium hydrogen phosphate or dipotassium hydrogen phosphate. By adopting a mechanochemical technique to extract and separate the hesperidin, the method has the advantages of high extraction rate, high product purity, simple process, environment-friendly property, low cost and short production cycle, and is an extraction-separation route with broad industrialization prospects.

Owner:ZHEJIANG UNIV OF TECH

Water-based foam fire extinguisher

InactiveUS6379578B1Improve alcohol resistanceFireproof paintsAntifouling/underwater paintsWater basedDepressant

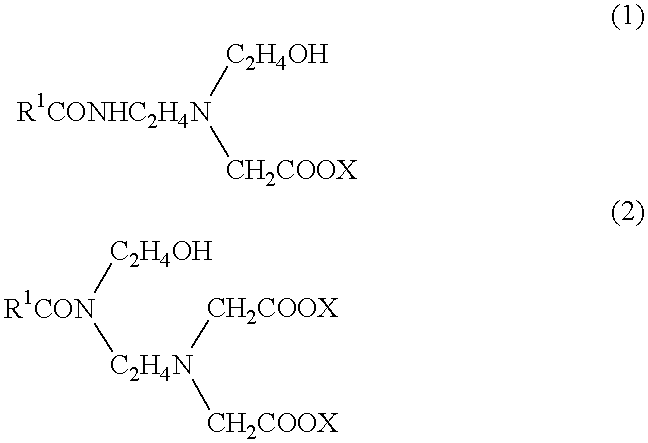

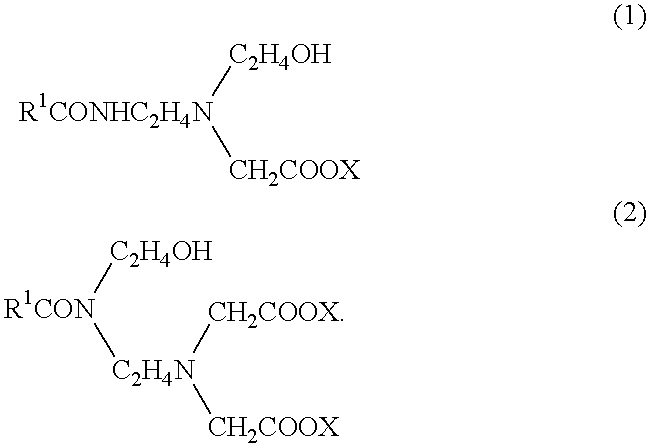

A water-based foam fire extinguisher excellent in foaming properties and film-forming properties in a low temperature region which includes an aqueous solution of at least one member selected among potassium hydrogen carbonate, ammonium phosphate, ammonium sulfate, ammonium bromide, boron oxide, and potassium tetraborate and, incorporated in the solution, a freezing point depressant so as to have a freezing point of -20.degree. C. or below, characterized by containing a perfluoroalkylbetaine as a fluorochemical surfactant and one or more amide-amino acid type surfactants represented by general formula (1) and / or (2) ##STR1## (wherein R.sup.1 represents C.sub.7-23 alkyl, hydroxyalkyl, aralkyl, or alkenyl; and X represents an alkali metal or hydrogen) as hydrocarbon surfactants.

Owner:TERAYAMA RIYAKO +2

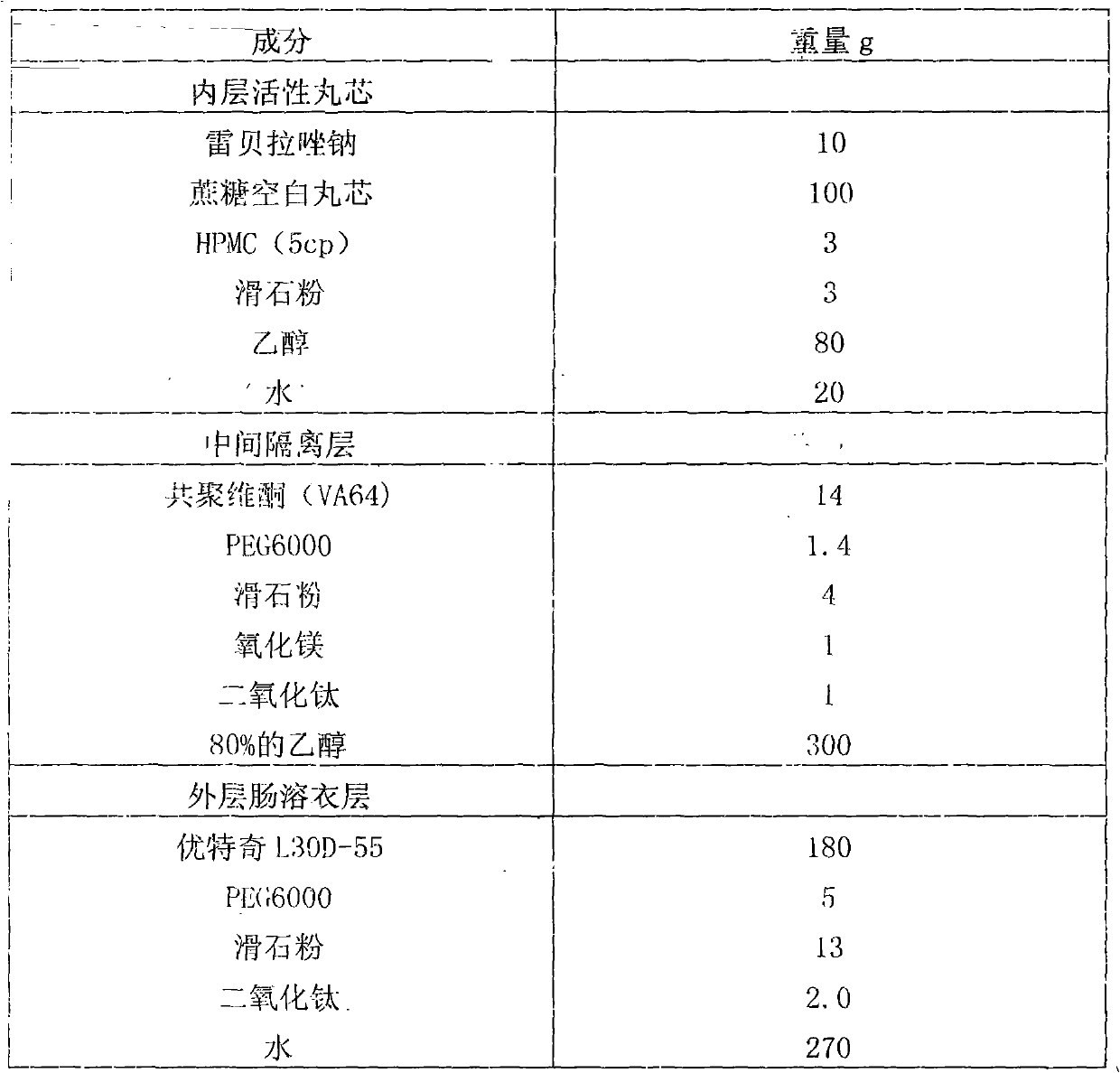

Rabeprazole sodium enteric-coated micro-pellet and preparation method thereof

ActiveCN102552159AImprove stabilityQuick releaseOrganic active ingredientsDigestive systemSodium bicarbonateSolubility

The invention belongs to the field of medicament preparations, and relates to a rabeprazole sodium enteric-coated preparation and a preparation method thereof. A rabeprazole sodium enteric-coated micro-pellet disclosed by the invention comprises a blank pellet core, a medicament carrying layer, an isolating layer and an enteric-coated layer from inside to outside, wherein the weight increment of the medicament carrying layer is 10-20 percent; the weight increment of the isolating layer is 5-10 percent; the weight increment of the enteric-coated layer is 30-50 percent; the medicament carrying layer consists of rabeprazole sodium, hydroxypropyl methyl cellulose and talc powder; the isolating layer consists of copovidone, a plasticizing agent, talc powder, titanium dioxide and a stabilizing agent; the stabilizing agent is one or more of magnesium oxide, calcium oxide, sodium carbonate, sodium bicarbonate, potassium carbonate and potassium bicarbonate; and the enteric-coated layer consists of an enteric-coated material, a plasticizing agent, talc powder and titanium dioxide. The rabeprazole sodium enteric-coated micro-pellet disclosed by the invention has the effects of high solubility and high stability.

Owner:NANJING CHANGAO PHARMA SCI & TECH CO LTD +1

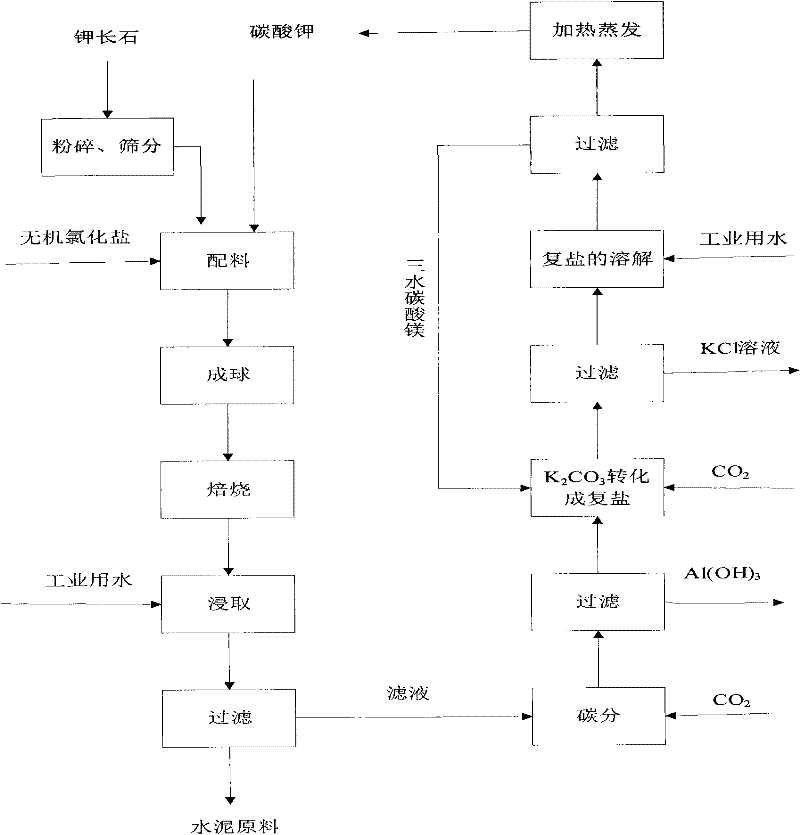

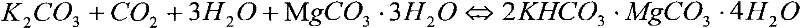

Method for producing potassium fertilizer and aluminum oxide by comprehensively using potassium feldspar

InactiveCN102531710ARealize comprehensive utilizationImprove utilizationAluminium compoundsPotassium fertilisersAluminium hydroxideChloride

The invention relates to a method for producing a potassium fertilizer and aluminum oxide by comprehensively using potassium feldspar. The method comprises the following steps of: (1) smashing potassium feldspar and inorganic chlorate, and burdening potassium feldspar, inorganic chlorate and potassium carbonate in the mass ratio of 1:(1-2):(1-10); (2) pelletizing the prepared material, and sintering at the temperature of 500-1,200 DEG C for 1-5 hours to obtain a sintered material and generate CO2 gas simultaneously; (3) soaking the material obtained in the step (2) into water and filtering; (4) introducing a filtrate obtained in the step (3) into the CO2 gas obtained in the step (2) to obtain an aluminum hydroxide precipitate, and filtering; (5) adding a filtrate obtained in the step (4) into nesquehonite, introducing CO2 gas to obtain a complex salt precipitate, filtering and crystalizing a filtrate to obtain a potassium chloride chemical fertilizer; and (6) adding water for dissolving a complex salt obtained in the step (5) to obtain a solid of nesquehonite, circularly using, heating a potassium bicarbonate solution for decomposing to obtain a potassium carbonate solution for circularly using, and repeating the step (1) to the step (6).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing sodium metavanadate/potassium metavanadate

The invention discloses a method for preparing sodium metavanadate / potassium metavanadate, which comprises the following steps: heating sodium modified vanadium extraction leach liquor to 80-90 DEG C, adding calcium chloride saturated solution into the sodium modified vanadium extraction leach liquor with the mass ratio of Ca: V= 1.5: 2, stirring the mixture uniformly while the temperature of 80-90 DEG C is kept, and filtering the mixture after reaction for 30-40 minutes to obtain vanadic acid solid; washing and filtering the obtained vanadic acid solid; putting the washed vanadic acid solid in a container, adding sodium bicarbonate solution or potassium bicarbonate solution with the mass concentration of 20-30% by a molar ratio of CO3<2-> to Ca<2+> in the range of 1 to 1.2 into the container, fully stirring the mixture at temperature of 60-70 DEG C, , filtering the mixture after reaction for 30-40 minutes to obtain calcium carbonate solid and sodium metavanadate or potassium metavanadate solution, evaporating, concentrating, crystallizing, and finally, separating the obtained crystal and dring at a temperature below 40 DEG C to obtain the sodium metavanadate or potassium metavanadate solid.

Owner:PANZHIHUA IRON AND STEEL +1

Fertilizer and plant growth promoter to increase plant yield and method of increasing plant yield

ActiveUS20190185390A1Increase productionImprove efficiencySuperphosphatesAlkali orthophosphate fertiliserSodium bicarbonateAmmonium nitrate

A slow release carbohydrate / bicarbonate / nitrogen fertilizer which includes: a nitrogen component selected from the group consisting of a urea compound, ammonium bicarbonate, ammonium sulfate and ammonium nitrate; a bicarbonate component selected from the group consisting of ammonium bicarbonate, potassium bicarbonate and sodium bicarbonate; and a soluble carbohydrate component selected from the group consisting of a starch and a sugar, wherein the fertilizer is applied to increase crop yield and increase protein levels in plant products by placing the aforesaid fertilizer beneath the surface of soil on which is growing cultivated plants.

Owner:INNOVATIONS FOR WORLD NUTRITION LLC

Cyanide-free gold electroplating solution and electroplating process using same

The invention relates to a cyanide-free gold electroplating solution and an electroplating process using the same. The solution contains 180-200 g / L of a main coordination agent, 5-8 g / L of an auxiliary coordination agent, 20-30 g / L of potassium bicarbonate, 0.5-0.8 g / L of potassium gold chloride and 0.5-5 mL / L of a combined additive. The cyanide-free gold electroplating system solution is good in stability, dispersing capacity and covering capacity and high in current efficiency, a plating layer is flat and compact in crystallization and golden yellow and bright in appearance, the applied current density range is wide, the temperature requirement range is wide, the system can meet the requirement of long-term thick gold electroplating, and problems that the plating layer turns red, floating dust exists and the like are solved with the increase of the thickness of the plating layer during electroplating.

Owner:朱忠良

Yttrium zirconium composite nano-ceramic powder

The invention relates to an yttrium zirconium composite nano-ceramic powder in the field of ultrafine ceramic and preparation method thereof. The components and molar percentage contents of the composite nano-ceramic powder are as follows: 5% to 8% of yttrium oxide and 92% to 95% of zirconium oxide; the preparation method includes the following steps: zirconium oxychloride is dissolved in ethanol, and then yttrium oxide is added at the temperature of 60 DEG C to 80 DEG C; cooling, sodium bicarbonate or potassium bicarbonate solution is added, acrylic ester is then added, ultrasonic washing is carried out for 20 to 30 minutes, and reaction is carried out after putting in a high pressure reaction pot; the power is taken out after the reaction is finished, and then washed, so that the yttrium zirconium composite nano-ceramic powder is obtained. The invention has simple preparation method and low cost, and industrialization production is easily realized; the yttrium zirconium composite nano-ceramic powder in the invention has the characteristics of good toughness and easy sintering; and the yttrium zirconium composite nano-ceramic powder in the invention rarely has crystal imperfection.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of special solid base catalyst for biodiesel preparation

InactiveCN107029695AAvoid easy cloggingEffective penetrationMetal/metal-oxides/metal-hydroxide catalystsSodium bicarbonateBiodiesel

The invention belongs to the technical field of new energy resources and discloses a preparation method of a special solid base catalyst for biodiesel preparation. The method includes: taking sodium dodecyl benzene sulfonate as a surfactant to obtain saturated sodium bicarbonate solution at a high temperature, performing polymerization reaction in a same vessel to obtain polystyrene emulsion, adopting emulsion microspheres for adsorbing the saturated sodium bicarbonate solution, then dropwise adding tetraethyl orthosilicate to realize hydrolysis and coating of surfaces of the emulsion microspheres, decomposing potassium bicarbonate at a lower temperature to generate gas and form a porous structure, and calcining at a higher temperature to remove an polystyrene inner core, so that the special solid base catalyst for biodiesel preparation is obtained. By adoption of the polymer emulsion for adsorption of sodium bicarbonate to form the spongy porous solid base catalyst through two-step calcination, a carrier and an effective component are both in porous structures, and the problem that catalysts prepared according to a traditional impregnation method are prone to causing pore passage blockage and influences on catalysis efficiency is effectively solved.

Owner:陈毅忠

Method for preparing high-performance porous carbon material from organic solid wastes through nitrogen-doping hydrothermal operation and activation

ActiveCN110342512AAbundant nitrogen-containing functional groupsHighly developed pore structureCarbon compoundsPorous carbonPotassium hydroxide

The embodiment of the invention provides a method for preparing a high-performance porous carbon material from organic solid wastes through nitrogen-doping hydrothermal operation and activation. The method comprises the following steps: by taking coconut shells, orange peel, cigarette ends and saw dust as organic solid wastes, organic nitrogen sources such as melamine, urea and dicyandiamide as hydrothermal nitrogen doping agents, preparing nitrogen-doping hydrothermal charcoal by using an organic solid waste hydrothermal process nitrogen source synchronous doping method; further by taking thenitrogen-doping hydrothermal charcoal as a precursor, performing solid-phase mixing on the precursor with an activator of potassium carbonate, potassium bicarbonate or potassium hydroxide, further performing activation treatment so as to obtain a porous carbon material which is rich in micropore and mesoporous structure and has a specific surface area as high as 1526-3365m<2> / g. Meanwhile, the carbon material has an excellent methylbenzene adsorption and iodine adsorption capability. The method is simple in process, easy in condition control and good in practicability, has considerable application prospects in the field of pollutant adsorption treatment and has good economic benefits and social benefits.

Owner:HUAZHONG UNIV OF SCI & TECH

Technique for preparing potassium sodium dehydroandroandrographolide succinate

ActiveCN101260098ASolve the problem of unstable pHFully combinedOrganic chemistryAntipyreticSodium bicarbonateWater baths

The invention discloses a process of preparing Dehydroandrographolide Succinate Sodium and Potassium salts. The process includes: heating and dissolving Dehydroandrographolide Succinate with 3 to 6 times of absolute ethyl alcohol; adding mole KHCO3 and NaHCO3 in equal weight into water and dissolving in a water bath; dripping slowly while mixing in the temperature of between 50 and 80 DEG C until solution defecates, filtering and putting on a 0.22 mu m filter membrane, adding 7 to 11 times of absolute ethyl alcohol while mixing until the solution is even, standing in room temperature until natural crystallization seeds out, filtering and washing 2 to 3 times with absolute ethyl alcohol, fitering and drying with less pressure to obtain a canary solid. The invention provides a process route of preparing potassium sodium dehydroandroan drographolide succinate for injection with high purity, which uses Dehydroandrographolide Succinate as the raw material, is added with potassium bicarbonate and sodium bicarbonate directly to compose Potassium Sodium Dehydroandroan drographolide Succinate, which is high in process yields, high in product purity, good in solubility, less in impurity and complete in combination of Potassium and Sodium; the product is high in purity and good in solubility without obvious toxic and side effect in clinic application, the preparation is more stable compared with the similar and can be prepared into various preparations.

Owner:CHANGCHUN MAILING BIOLOGICAL ENG CO LTD

Preparations to support maintenance of acid-alkaline balance in the human body and methods directed to using same

InactiveUS20070003613A1Reduce ambient pHImprove efficiencyBiocideDispersion deliveryHuman bodyGlycerol

The present invention provides novel compositions in the form of a powder, capsule, liquid or lozenge, and methods for administering said novel compositions to assist the body in its ability to maintain a reasonable homeostatic mechanism for compensating for chronic internal acidity. The composition may contain several active ingredients, such as potassium bicarbonate, citric acid, calcium citrate, magnesium citrate, glycine, and licorice. The composition may also contain other inactive excipients, such as hypoallergenic rice, flour, glycerine, tangerine oil and gelatin. Following oral administration, the composition is rapidly broken down and absorbed into the systemic circulation. Upon absorption, the individual components are able to assist the physiological acid-alkaline buffer systems, promote anti-anxiety effects, and decrease inflammation in the digestive system.

Owner:TRIMEDICA INT

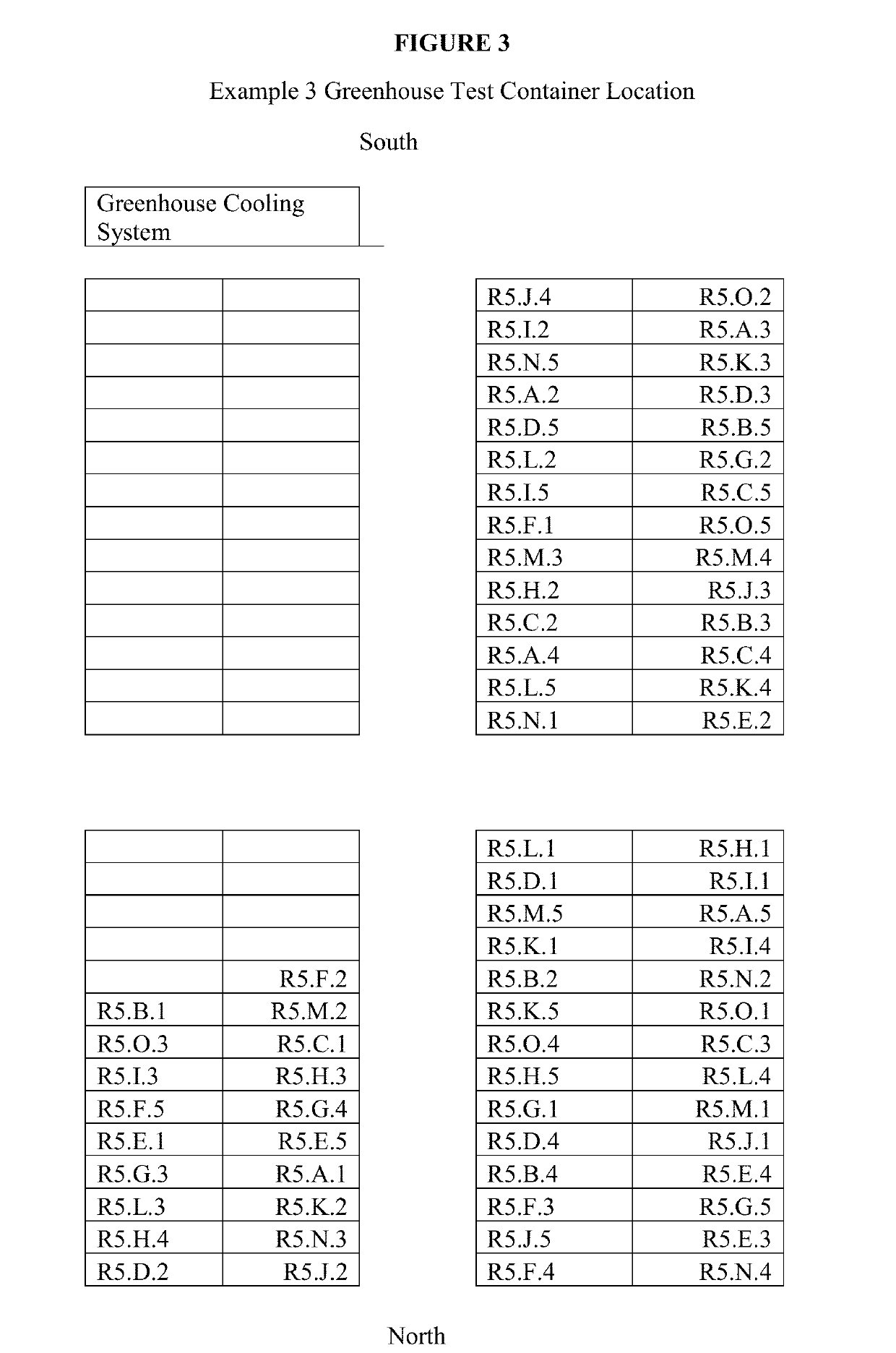

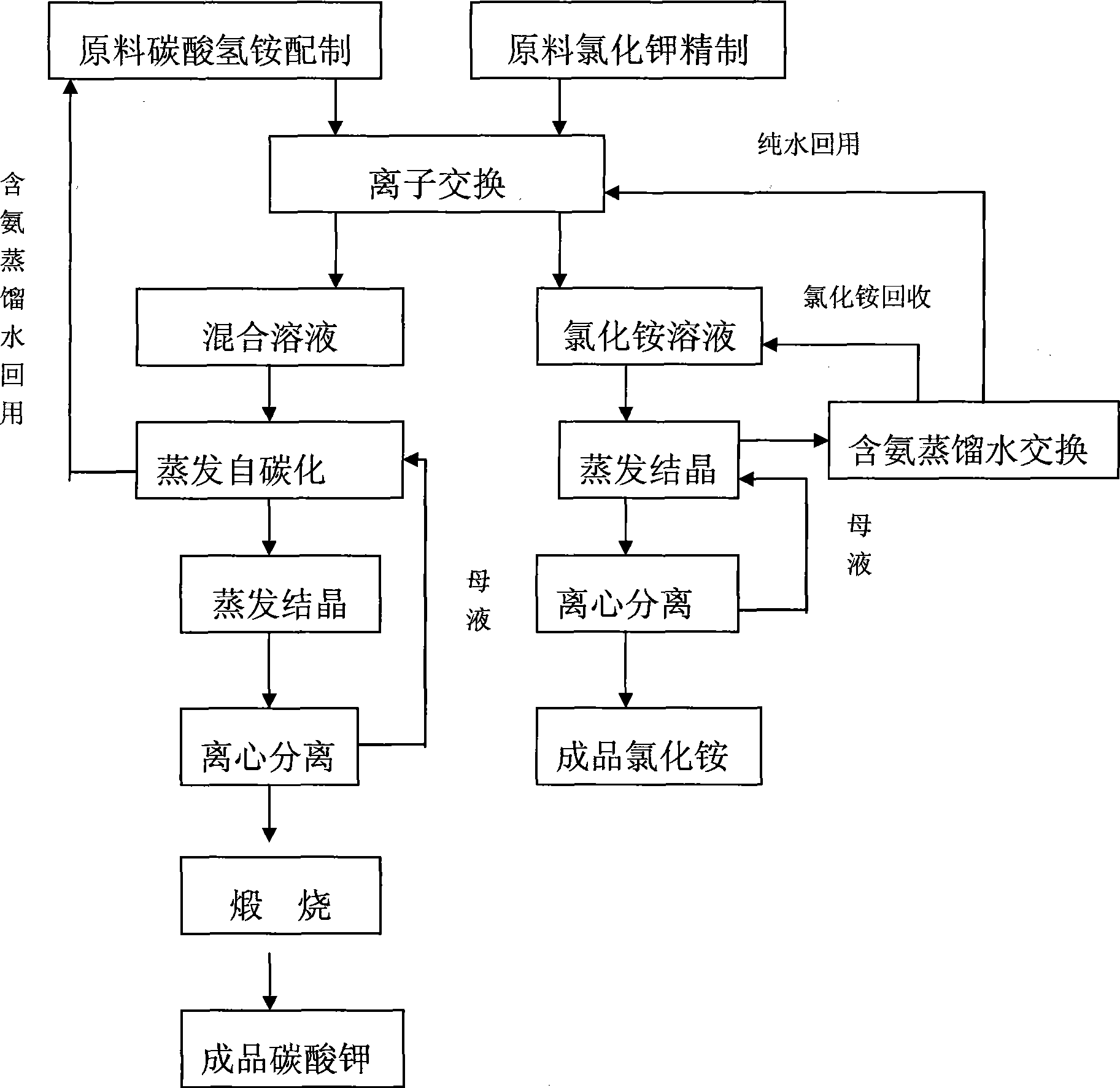

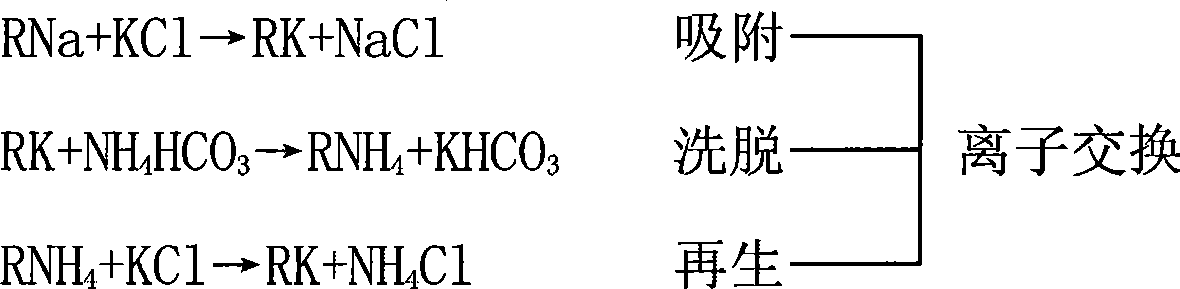

Production process of potassium carbonate

InactiveCN101481124AThe process steps are simpleReduce the temperatureCarbonate preparationSodium bicarbonateCarbonization

The invention relates to a potassic carbonate, in particular to a technique for producing potassium carbonate. The method comprises the following steps: evaporating a mixed solution at a low temperature and pressure after the ion exchange process is performed to ammonium hydrogen carbonate and potassium chloride so that only a small amount of potassium bicarbonate is converted to potassium carbonate. Therefore, CO2 given out by decomposing ammonium hydrogen carbonate in the pressure reducing and evaporating process can realize the carbonization of the potassium carbonate, thereby the carbonization process is saved, the low temperature self-carbonizing production technique is realized, the energy consumption is reduced, the coal consumption is reduced to 1.3 tons from 1.8 tons in the traditional technique, the electricity consumption is reduced to 270KW / h from 450KW / h, the consumption of the main materials of the potassium chloride and the ammonium hydrogen carbonate per ton are reduced to 1.153 and 1.335 tons from 1.25 and 1.60 tons respectively, and the corrosion of the equipment is reduced.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

Compound noni fruit wine and preparation method thereof

ActiveCN105505680AOvercome the disadvantage of not being able to start the fermentation programBeautiful colorMicroorganism based processesAlcoholic beverage preparationPectinaseYeast

The invention discloses a preparation method of compound noni fruit wine. The preparation method includes the following steps that 1, noni fruits are cleaned and placed for after-ripening and are crushed and pulped; pectinase is added for enzymolysis, and filtration is performed to obtain noni fruit juice; 2, the other fruits are cleaned, chopped and juiced, and then the supernate is obtained so as to obtain other fruit juice; 3, the noni fruit juice and other fruit juice are mixed by the volume ratio of (3-11) to 1, cane sugar, citric acid and potassium bicarbonate are added to adjust the pH value and the the sugar degree which are 6.0-7.5 and 16-22oBx respectively, and high-temperature sterilization and enzyme deactivation are performed; 4, 40-120 mg / L SO2 solution is added into the product obtained in the step 3; 5, fermentation is performed: active dry yeast is activated, then the product obtained in step 4 serves as a fermentation substrate, and the activated active dry yeast is added to perform fermentation; 6, fermentation broth is filtered, a sterilized fermentation tank is filled with the product, and after fermentation is performed; 7, the compound noni fruit wine is obtained through aging, filtration, sterilization and filling. The invention further discloses the fruit wine prepared by means of the method.

Owner:YUNNAN INST OF TROPICAL CROPS

Production of high-purity medicine with lamp-dish flower acetic as raw material

ActiveCN1778808AAvoid instabilityThe process steps are simpleSugar derivativesSugar derivatives preparationSodium bicarbonatePotassium hydroxide

Process of high-purity breviscapine medicinal material includes laying breviscapine in container, adding into 2 time water, adding into alkaline solution, regulating pH 4-8, dissolving to obtain the alkaline solution which is one or several of sodium carbonate, potassium carbonate, sodium bicarbonate, potassium acid carbonate, sodium hydrate and potassium hydrate, adding into 3 time solvent, depositing at 18-35íÒC, laying aside, filtering, washing the deposit by solvent, transferring the deposit to solution with 10-60wt% solvent, acidizing to pH 1-2, depositing, filtering, washing to neutral, and drying to obtain the final product.

Owner:KUNMING LONGJIN PHARMA

Synthetic method for aliphatic alpha-calcium picrolonate

A synthetic method for aliphatic alpha-calcium picrolonate comprises the following steps: 1. adding carbonyl group reactant in glycolylurea in the presence of catalytic accessory and water and heating, wherein the mol ration of the glycolylurea and the carbonyl group reactant is 1:1.2-1.4; the carbonyl group reactant is aldehyde compound or ketone compound; when aldehyde compound is adopted the catalytic accessory is potassium bicarbonate, and when ketone compound is adopted the catalytic accessory is ethanolamine; 2. cooling to the room temperature, regulating the pH valve to 7 and separating out the intermediate product; 3. filtering and washing the intermediate product; 4. stirring and refluxing the intermediate product and sodium hydroxide solution, wherein the mol ratio of the intermediate product and sodium hydroxide is 1:3-5; 5. regulating the pH value to 4-5, antiregulating the pH value to 7 with the sodium hydroxide solution, and evaporating to remove the moisture; 6. adding absolute methyl alcohol to extract for several times and filtering; 7. distilling to remove the methyl alcohol; and 8. adding de-ionized water and aqueous calcium chloride solution of equivalent amount and separating out alpha-calcium picrolonate. As massive subsidiary products are removed in the method, the calcium content in the prepared product can achieve the standard.

Owner:NANJING CHEM REAGENT

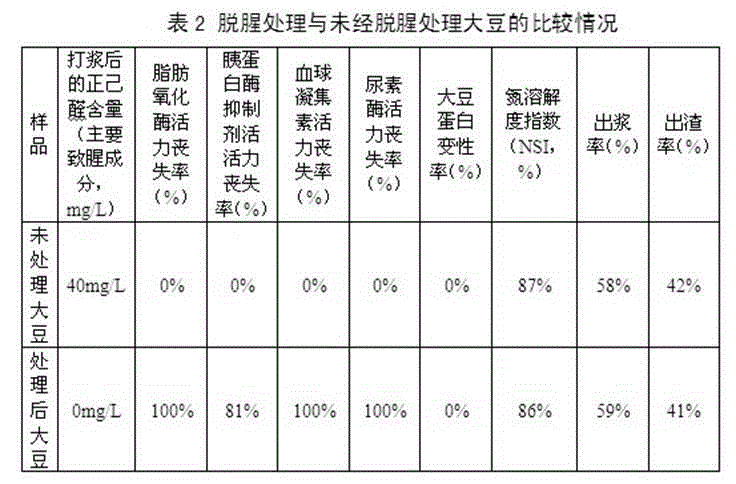

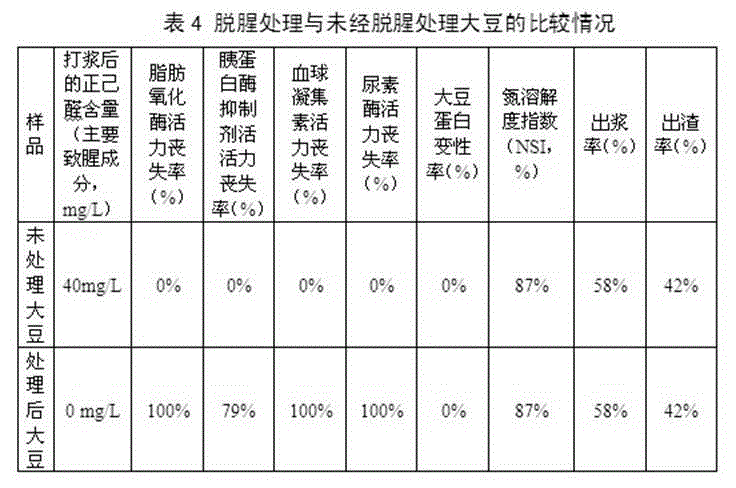

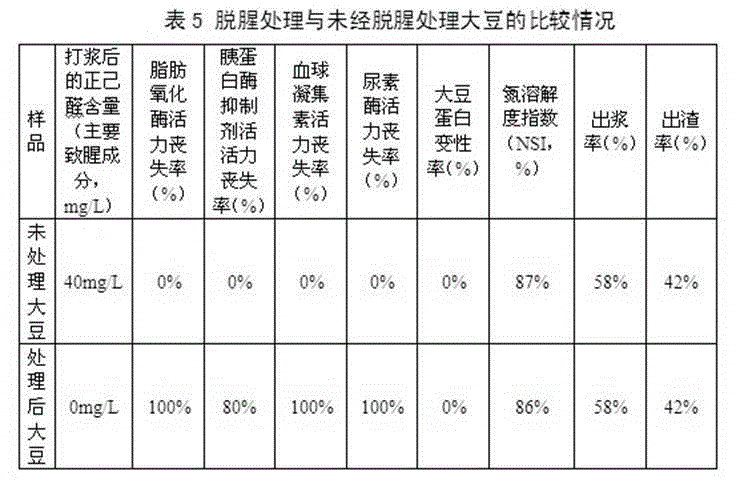

Preparation technique and application of non-odor soybean

InactiveCN102907627ANo beany smellEliminate anti-nutritional factorsFood preparationBiotechnologySodium bicarbonate

The invention relates to preparation technique and application of non-odor soybean. The preparation technique of non-odor soybean comprises cleaning, alkali treatment, microwave treatment, drainage and drying treatment and package, wherein the aqueous alkali comprises one or mixture of a plurality of sodium carbonate, sodium bicarbonate, potassium carbonate, potassium bicarbonate, sodium hydroxide and potassium hydroxide. The preparation technique combines the chemical treatment mode with the physical treatment mode to remove the beany flavor, the activity of the lipoxidase of the treated soybean is completely lost, and bean products prepared by the non-odor soybean do not generate n-hexylaldehyde or any beany flavor; besides, the preparation technique provided by the invention can eliminate the antinutritional factors in the soybean, the activity of the hemagglutinin and the urease of the treated soybean is completely lost, and the activity loss rate of the trypsin inhibitor is larger than 75%; and meanwhile, the nutritive value of the soybean is not being damaged at all.

Owner:桂仕林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com