Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84 results about "Potassium bitartrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium bitartrate, also known as potassium hydrogen tartrate, with formula KC₄H₅O₆, is a byproduct of winemaking. In cooking it is known as cream of tartar. It is processed from the potassium acid salt of tartaric acid (a carboxylic acid). The resulting powdery acid can be used in baking or as a cleaning solution (when mixed with an acidic solution such as lemon juice or white vinegar).

Handwork-dough-modeling and plasticine dual-purpose material

ActiveCN103651654AGood moisturizing effectImprove toughnessDough treatmentOrnamental structuresBiotechnologyKaolin clay

The invention relates to a handwork-dough-modeling and plasticine dual-purpose material. The handwork-dough-modeling and plasticine dual-purpose material comprises, by weight, 8 parts of wheat flour, 5 parts of glutinous rice flour, 1 part of malt sugar, 0.5 part of refined salt, 0.5 part of condensed milk, 2 parts of fresh milk, 0.8 part of honey, 2 parts of diatom soil, 2 parts of modified starch, 1 part of waxiness corn starch, 1.5 parts of kaolin, 0.5 part of bone glue, 1 part of calcium carbonate, 0.8 part of glycerin, 0.2 part of sodium diacetate, 0.5 part of potassium hydrogen tartrate, 0.5 part of food colorant, 1.5 parts of aloe gel, 0.1 part of olive oil, 0.2 part of sun screen and 5 parts of water. When children make handwork artware, the handwork-dough-modeling and plasticine dual-purpose material can be used as a dough modeling material so that dough modeling handwork artware can be made, and can also be used as a plasticine material for playing, multiple kinds of modeling can be made in a pinched mode, and the handwork-dough-modeling and plasticine dual-purpose material has the advantages of being green, nontoxic, harmless, free of cracking, antibacterial, long in retention time, good in modeling and proper in rigidity.

Owner:启东市清源环境检测技术有限公司

Health care cake

InactiveCN102960403AAdd new flavorsCan relax muscles and unblock collateralsDough treatmentBakery productsYolkLycopodium clavatum

The invention relates to a health care cake, in particular to a health care cake which can prevent and treat hyperlipidemia. The health care cake adopts the technical scheme that the health care cake comprises the following raw materials in parts by weight: 15-60 parts of traditional Chinese medicine micropowder, 110-130 parts of low-gluten flour, 70-90 parts of milk, 2-4 parts of baking powder, 160-200 parts of protein, 60-80 parts of yolk, 20-50 parts of berry sugar and 0.03-0.05 parts of potassium bitartrate, wherein the traditional Chinese medicine micropowder comprises the following traditional Chinese medicine in parts by weight: 10-20 parts of lycopodium clavatum, 8-20 parts of frangipani and 3-10 parts of radix glycyrrhizae. The particle diameter of the traditional Chinese medicine micropowder is 0.1-10 micrometers. The health care cake has the functions of conditioning balance of a liver, a spleen and a kidney through frangipani, cuscuta chinensis, poria cocos and ophiopogon roots, quenching thirst, dispersing blood stasis, cleaning the bowels, relaxing muscles and tendons and promoting blood circulation by the lycopodium clavatum, tonifying qi and smoothing collaterals, so that the anti-hyperlipidemia purpose is achieved.

Owner:仲珉

Food composite leavening agent, as well as preparation method and application thereof

InactiveCN102613261AImprove applicabilityPromote resultsDough treatmentCalcium biphosphateSodium bicarbonate

The invention discloses a food composite leavening agent, as well as a preparation method and application thereof. The leavening agent comprises the following components in percentage by weight: 25%-55% of sodium bicarbonate, 4%-30% of gluconic acid-Delta-lactone, 4%-20% of calcium biphosphate, 3%-15% of potassium bitartrate and 15%-64% of corn starch. The prepared product does not contain components harmful to human health, and has better subjective appreciation and larger specific volume than the traditional formula. The texture analysis shows that: the hardness, elasticity, cohesion, chewiness, resilience and other indexes reach the standards of the similar products in the market. The leavening agent can be used to make cakes, fried bread sticks, steamed bread and other flour food.

Owner:SOUTH CHINA UNIV OF TECH +1

Composite food raising agent and applications thereof

InactiveCN103564273AQuality improvementImprove qualityFood ingredient as raising agentFood shapingSodium bicarbonateFood additive

The invention discloses a composite food raising agent. The raising agent comprises, by weight, a first component and a second component accounting for 40% of the first component, wherein the first component comprises 10% of sodium bicarbonate, 15% of calcium hydrogen phosphate, 35% of potassium bitartrate, 25% of sodium lactate, and 15% of citric acid, and the second component selects corn starch. The composite food raising agent can be used as a food additive replacing alum and used in food processing, especially in starch product (such as dry vermicelli, vermicelli and sheet jelly) processing. The composite food raising agent improves the quality and the grade of the products, thus achieving an objective of replacing the alum innocuously and harmlessly and improving the comprehensive quality and grade of the products. In addition, the invention also discloses applications of the composite food raising agent.

Owner:QINGJIAN COUNTY JIUTIAN POTATO IND

Selective extraction of potassium chloride employing tartaric acid as safe, benign and recyclable extractant

ActiveUS9540248B2Eliminate needImprove recycling efficiencyAlkali metal chloridesCarbonateNuclear chemistry

Owner:COUNCIL OF SCI & IND RES

High-efficiency slow-release compound fertilizer containing Crotalaria pallida

InactiveCN104098378AImprove the phenomenon of single fixationImprove adsorption capacityFertilizer mixturesCrotalaria pallidaEcological environment

The invention relates to the field of compound fertilizers, in particular to a high-efficiency slow-release compound fertilizer containing Crotalaria pallid. The fertilizer is prepared from the following raw materials by weight part: 10-15 of 1250-2000 mesh diatomite, 10-12 of calcium carbonate, 6-8 of borax, 2-3 of magnesium ascorbyl phosphate, 8-10 of disodium hydrogen phosphate, 5-6 of pyracetic acid, 10-12 of potassium bitartrate, 20-22 of urea, 25-28 of diammonium phosphate, 12-15 of crop leftover, 3-5 of plasma protein powder, 1-3 of Crotalaria pallid fine powder, 4-5 of potassium alginate, 2-4 of stearic acid, 10-12 of gelatin, 1-3 of Vaseline, 1-2 of Tween 80, 2-4 of medical stone powder, 6-8 of polymeric ferric silicate sulfate, and 4-5 of an assistant. The compound fertilizer provided by the invention utilizes diatomite and a coating agent with good slow release ability to form dual cladding on the multielement nutrients, so that the nutrients are difficult to lose, and the fertilizer efficiency can be more lasting. The Crotalaria pallid fine powder in the coating agent has certain insecticidal and antibacterial ability, provides good growing environment for crop roots, and does not destroy the soil ecological environment. The fertilizer provided by the invention can significantly improve the crop yield and quality and enhance economic benefits.

Owner:安徽红三星磷复肥有限责任公司

Oil-gas transmission pipeline cleaning agent and preparation method thereof

InactiveCN104130882AStable in natureEasy to cleanSurface-active detergent compositionsDetergent compounding agentsCelluloseAlkylphenol

The invention relates to an oil-gas transmission pipeline cleaning agent and a preparation method thereof. The oil-gas transmission pipeline cleaning agent comprises the following components by weight: 28-36 parts of a Gleditsia Sinensis Lam extracted solution, 5-7 parts of polydimethylsiloxane, 6-9 parts of sodium carboxymethylcellulose, 10-16 parts of alkylphenol polyoxyethylene, 8-12 parts of ethylene glycol monobutyl ether, 15-20 parts of sodium chloride, 5-10 parts of citric acid, 4-8 parts of polyepoxysuccinic acid, 2-6 parts of potassium bitartrate, 5-12 parts of cetanol, 30-45 parts of ethanol, and 48-50 parts of water. The cleaning agent and the preparation method provided by the invention have the advantages that: 1. the cleaning agent provided by the invention has an excellent cleaning effect on pipelines, and can reach a clearance rate of 95% on dust and dirt in pipelines; 2. the raw materials involved in the invention are environment friendly and non-toxic, and have wide sources and low price; and 3. the preparation method provided by the invention is simple and feasible, and is convenient to implement, and the cleaning agent prepared by the method have stable properties and can be stored for a long time.

Owner:青岛蓬勃石油技术服务有限公司

Plating solution for carrier copper foil stripping layer and preparation method of stripping layer

The invention relates to a plating solution for a carrier copper foil stripping layer and a preparation method of the stripping layer. The plating solution is prepared from components as follows: potassium bitartrate with the concentration of 20-60 g / L, zinc sulfate with the concentration of 8-16 g / L and an additive A with the concentration of 5-20 g / L and the pH of 3.0-5.0, wherein the additive Ais a mixture formed by mixing at least one of 3-(2,3-epoxy propoxy)propyl trimethoxy silane, 3-(2,3-epoxy propoxy)propyltriethoxysilane, 3-(2,3-epoxy propoxy)propyl methoxy dimethyldiethoxylsilane or3-(methylacryloyl oxy)propyl trimethoxy silane with at least one of potassium thiocyanate, monopotassium phosphate, sodium acetate or ammonium sulfate. The carrier copper foil stripping layer obtained with the adoption of the plating solution for the carrier copper foil stripping layer and the preparation method of the stripping layer is a novel nano composite zinc plating layer, is very thin anduniform and can completely and stably strip carrier foil off the pressed very thin copper foil.

Owner:胡旭日

Vermicelli and its production process

InactiveCN1387785AImproved performance of the finished productNo side effectsFood preservationFood preparationParaffin waxCorn starch

The present invention provides alumless vermicelli agglutinant which includes high effective composite emulsifier, sodium carboxymethyl cellulose, sodium tripolyphosphate, tartaric acid, potassium hydrogen tartarate, sodium bicarbonate, paraffin wax, edible salt, acid denatured potato starch. The present invention also discloses alumless vermicelli including sweet potato starch, potato starch, corn starch etc. The present invention also discloses the production method of alumless vermicelli, said method can shorten ageing time, raise product performance, improve manufacturing efficiency etc.

Owner:陈朝晖

Household water pipeline cleaning agent and preparation method thereof

InactiveCN105838527AEasy to cleanWash thoroughlyCationic surface-active compoundsNon-ionic surface-active compoundsSodium bicarbonateBetaine

The invention discloses a household water pipe cleaning agent and a preparation method thereof. The raw materials of the household water pipe cleaning agent include saponin extract, sodium lauryl sulfate, p-aminobenzoic acid, ammonia water, sodium bicarbonate, and potassium hydrogen tartrate , polyepoxysuccinic acid, sodium sulfite phosphine carboxylic acid, polycarboxylate superplasticizer, phosphonocarboxylic acid polymer, Belsperse 164 dispersant, dimethyl methanol, amino ether betaine, urotropine, stannous octoate, surface Active agent, mineral spirits D, aluminum naphthenate, sodium chloride, lipase, tetradecyldimethylbenzyl ammonium chloride, triethanolamine oleate soap, ferric citrate, polyether and water. The raw materials of the invention are environmentally friendly and non-toxic, have a wide range of sources and low prices, and can be stored for a long time. Well, the biological slime, breeding fungus, and bacteria caused by it should be cleaned thoroughly and cleanly.

Owner:王维娜

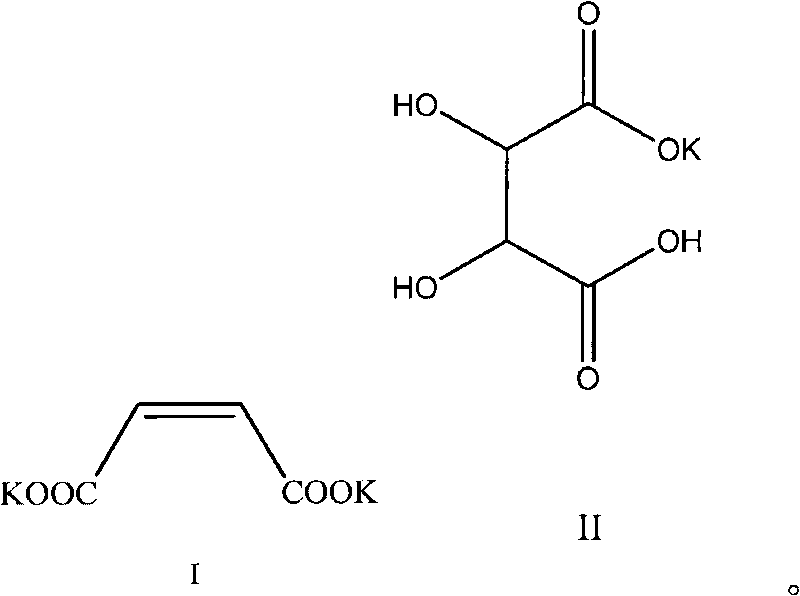

Method for preparing L (+) potassium hydrogen tartrate

ActiveCN101736040ALow costEmission reductionMicroorganism based processesOn/in organic carrierHydrogenNocardia

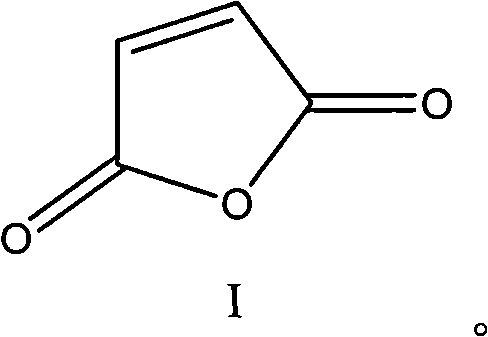

The invention discloses a method for preparing L (+) potassium hydrogen tartrate. The method is as follows: dissolving epoxy potassium succinate shown as formula II in water, using immobilized cellgranules prepared by fermented thalli obtained by Nocardia strain fermentation as a biocatalyst, carrying out conversion reaction at 35-37 DEG C for 18 hours to form potassium tartrate shown as formula III, dissolving the potassium tartrate in water and reacting with L (+) tartaric acid shown as formula IV until the pH value of reaction liquid ranges from 3.5 to 3.7, thereby preparing the L (+) potassium hydrogen tartrate. The method has the advantages that solid waste is not generated in the process of production, and the added amount of the tartaric acid is half of the added amount of the prior art when equal quality potassium hydrogen tartrate is prepared, thereby saving the energy cost and reducing the discharge of waste water and rubbish by half.

Owner:杭州瑞晶生物科技有限公司

Preparation method for cleaning agent for industrial crude oil pipelines

InactiveCN105400606AWith anti-rust protectionStrong ability to remove industrial crude oilInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEnvironmental resistanceSulfite salt

The invention discloses a preparation method for cleaning agent for industrial crude oil pipelines. The cleaning agent prepared according to the method is composed of the following components in parts by weight: 5-8 parts of active silicon micro powder, 2-6 parts of anhydrous sodium sulfite, 4-8 parts of sodium citrate, 2-5 parts of sodium dodecyl sulfate, 1-3 parts of potassium bitartrate, 12-22 parts of methylal, 5-10 parts of ethanol, 3-9 parts of p-hydroxybenzoic acid, 3-5 parts of an anti-oxidant, 4-9 parts of a surfactant, 3-7 parts of an antirust agent, and 50-60 parts of deionized water. The cleaning agent for crude oil pipelines is strong in industrial crude oil removal capability, free of toxicity, good in cleaning effect, safe and environment-friendly, possesses antirust protective effect on crude oil pipelines, and prolongs the service life of equipment.

Owner:WUXI JIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

Steamed buns swelling agent

The invention discloses a steamed buns swelling agent. The steamed buns swelling agent comprises the following components by weight percent: 30 to 60 percent of sodium bicarbonate, 4 to 30 percent of gluconic acid-theta-lactone, 4 to 20 percent of monoglyceride, 3 to 15 percent of sucrose ester, 20 to 50 percent of corn starch and 3 to 15 percent of potassium bitartrate. The steamed buns swelling agent is reasonable in formula, good in application effect and low in production cost.

Owner:扬州润园投资发展有限公司

Method for treating and utilizing potassium hydrogen tartrate mother liquor

ActiveCN101759554AReduce COD contentImprove resource utilizationOrganic compound preparationCarboxylic compound preparationResource utilizationPotassium

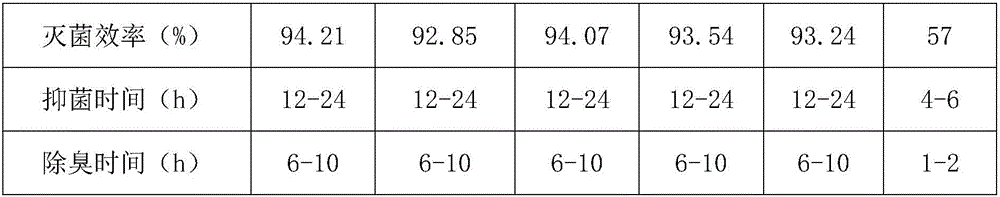

The invention discloses a method for treating and utilizing potassium hydrogen tartrate mother liquor. The potassium hydrogen tartrate mother liquor takes maleic anhydride as raw material which is oxidized by hydrogen peroxide, alkali is added and the pH value is adjusted at 3.5-3.7, and the mother liquor containing the residual potassium maleic acid as shown in formula I after centrifugally preparing DL-potassium hydrogen tartrate is prepared. The method comprises the following steps: the potassium hydrogen tartrate mother liquor and the hydrogen peroxide are in oxidation reaction under the action of catalyst sodium tungstate, and the DL-potassium hydrogen tartrate as shown in formula II is prepared. The method has the benefits that through recycling the process wastewater, the COD content of the process wastewater is greatly reduced, the waste material is changed into useful material, the DL-potassium hydrogen tartrate is prepared by using the useful components in the process wastewater, and the resource utilization ratio is improved.

Owner:杭州瑞晶生物科技有限公司

Method of synchronously preparing DL-tartaric acid and DL-potassium hydrogen tartrate

ActiveCN103012114AGuaranteed uptimeImprove conversion rateOrganic compound preparationCarboxylic acid salt preparationFiltrationHeteropoly acid

The invention discloses a method of synchronously preparing DL-tartaric acid and DL-potassium hydrogen tartrate. The method comprises the following steps: 1) sequentially adding deionized water, maleic anhydride and hydrogen peroxide in a reactor, heating and raising temperature to take reaction; 2) adding phosphorus-molybdenum heteropoly acid as a catalyst into the product obtained in the step 1), and slowly raising the temperature; 3) preserving heat at 70-74 DEG C and taking reaction for 18-22 hours; raising the temperature to 105-115 DEC C, taking hydrolysis reaction for 3-4 hours to obtain a solution comprising 2,3-epoxysuccinic acid; reducing the temperature of the solution comprising 2,3-epoxysuccinic acid to 6-8 DEG C, and naturally crystallizing; and then, performing suction filtration, wherein the obtained filtrate is primary mother solution, and the obtained crystal is dried to obtain DL-tartaric acid; and 4) regulating the pH value of the primary mother solution to 3.5-3.8 by a potassium hydroxide solution with the mass concentration of 45-55%; reducing the temperature to room temperature, and naturally crystallizing, and then performing suction filtration, wherein the obtained filtrate is secondary mother solution, and the obtained crystal is dried to obtain DL-potassium hydrogen tartrate.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Process for separating and recovering potash element form Eichhornic crassipes plant

InactiveCN1560017ACarboxylic acid salt preparationCarboxylic compound separation/purificationWater HyacinthsPotassium carbonate

The invention discloses a method of separating and recovering potassium element from Eichhornia crassipes Solm, namely water hyacinth. Its characteristic: extracting the fresh Eichhornia crassipes Solm by proper-concentration hydrochloric acid, extruding and separating resiudes to obtain extract; adding in potassium carbonate solution, filtering out the deposit, passing the filtrate through a filling tower; passing the clear liquor through an cation exchange resin to exchang most potassium on a column; washing the potassium on the colum by lower-concentration hydrochloric acid, adding in solid potassium carbonate, neutralizing the effluent liquid, finally adding in a precipitator tartaric acid solution, depositing potassium in the effulent liquid, dehydrating the deposit and drying to obtain the finised potassium hydrogen tartrate, which is a raw material needed by food industry and pharmaceutical industry. The invention is a new way of controlling environmental pollution and resources recovery.

Owner:HUAZHONG AGRI UNIV

Early strength agent used for concrete hollow bricks

The invention discloses an early strength agent for concrete hollow bricks, which comprises at least the following raw materials: rosin, phenol, magnesium trisilicate, potassium bitartrate, triethanolamine, shale ash, methylmethacrylate, urea and trehalose. The early strength agent for the concrete hollow bricks can achieve the synergistic complementary effect of the raw materials. In 1d time, thecompressive strength ratio can reach 200% or above, and thereby demoulding requirements of the concrete hollow bricks can be satisfied. The early strength agent reduces the slump amount of the concrete hollow brick during demoulding, shortens the demoulding time, and improves work efficiency.

Owner:兰新良

Handwork-dough-modeling and plasticine dual-purpose material

ActiveCN103651654BGood moisturizing effectImprove toughnessDough treatmentOrnamental structuresBiotechnologyKaolin clay

The invention relates to a handwork-dough-modeling and plasticine dual-purpose material. The handwork-dough-modeling and plasticine dual-purpose material comprises, by weight, 8 parts of wheat flour, 5 parts of glutinous rice flour, 1 part of malt sugar, 0.5 part of refined salt, 0.5 part of condensed milk, 2 parts of fresh milk, 0.8 part of honey, 2 parts of diatom soil, 2 parts of modified starch, 1 part of waxiness corn starch, 1.5 parts of kaolin, 0.5 part of bone glue, 1 part of calcium carbonate, 0.8 part of glycerin, 0.2 part of sodium diacetate, 0.5 part of potassium hydrogen tartrate, 0.5 part of food colorant, 1.5 parts of aloe gel, 0.1 part of olive oil, 0.2 part of sun screen and 5 parts of water. When children make handwork artware, the handwork-dough-modeling and plasticine dual-purpose material can be used as a dough modeling material so that dough modeling handwork artware can be made, and can also be used as a plasticine material for playing, multiple kinds of modeling can be made in a pinched mode, and the handwork-dough-modeling and plasticine dual-purpose material has the advantages of being green, nontoxic, harmless, free of cracking, antibacterial, long in retention time, good in modeling and proper in rigidity.

Owner:启东市清源环境检测技术有限公司

Alloy electroplating liquid

The invention discloses an alloy electroplating liquid. The alloy electroplating liquid consists of the following raw material components in parts by weight: 80 to 100 parts of nickel sulfate, 10 to 20 parts of ferrous sulfate, 15 to 20 parts of stannous chloride, 10 to 20 parts of ammonium molybdate, 30 to 35 parts of potassium sulfate, 25 to 30 parts of iron chloride, 8 to 10 parts of aluminum chloride, 8 to 15 parts of ferrous hydroxide, 5 to 8 parts of calcium hydroxide, 6 to 8 parts of sodium citrate, 5 to 10 parts of oxalic acid, 5 to 8 parts of potassium bitartrate, 8 to 10 parts of sodium bicarbonate, 6 to 10 parts of choline bitartrate and 150 to 200 parts of deionized water. The alloy electroplating liquid can completely substitute an AG electroplating liquid, after a plated part has electroplating treatment of the alloy electroplating liquid, a decorative bright plating layer with exquisite and good crystallization can be obtained, and the electroplating cost by utilizing the AG precious metal electroplating liquid can be reduced.

Owner:司徒建辉

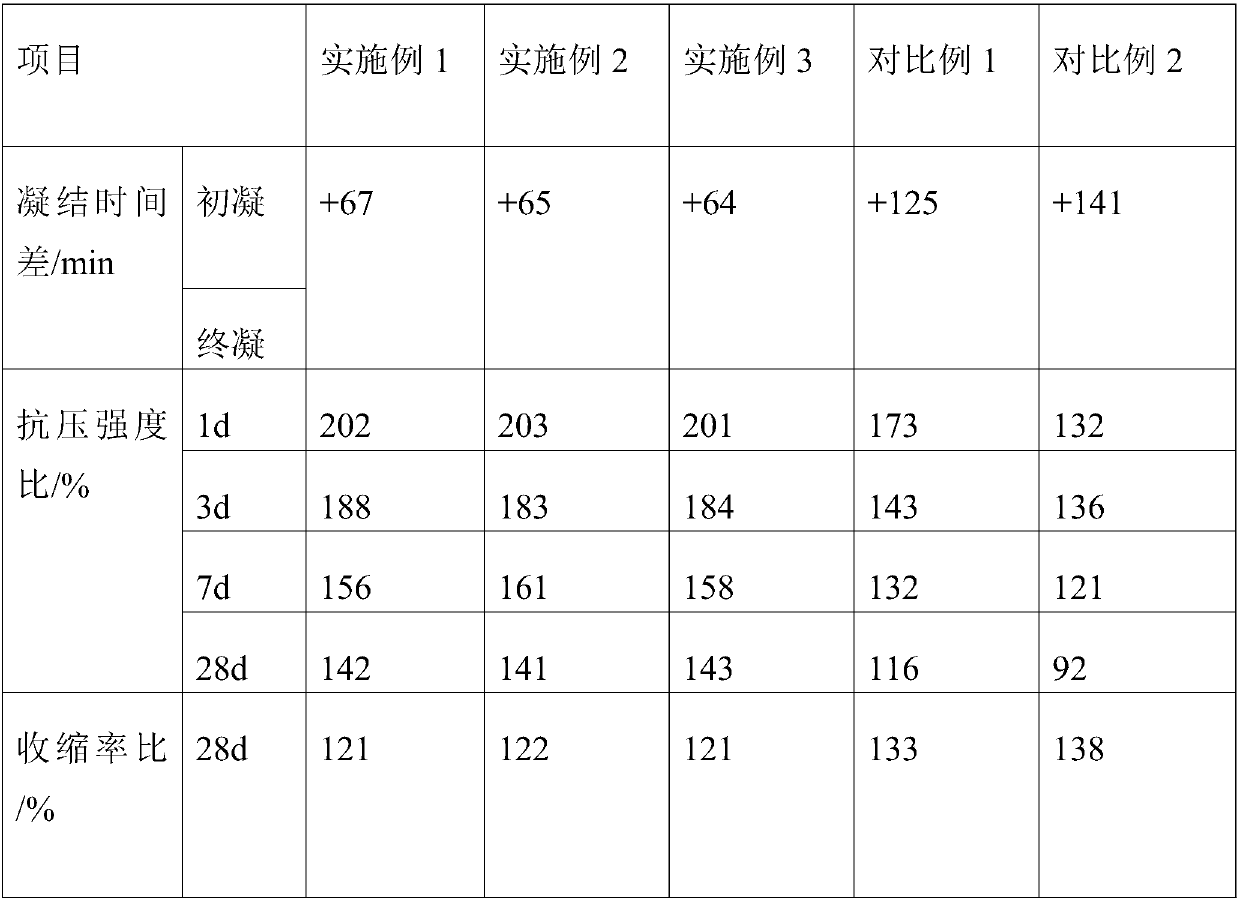

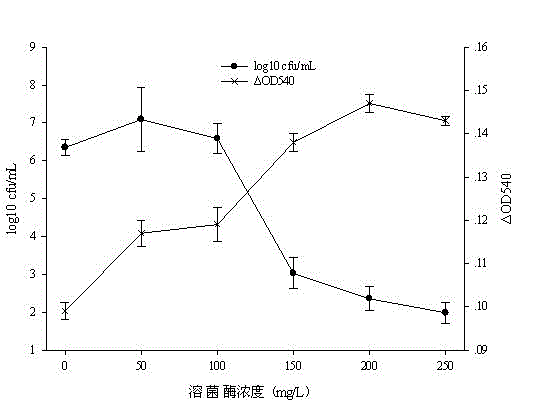

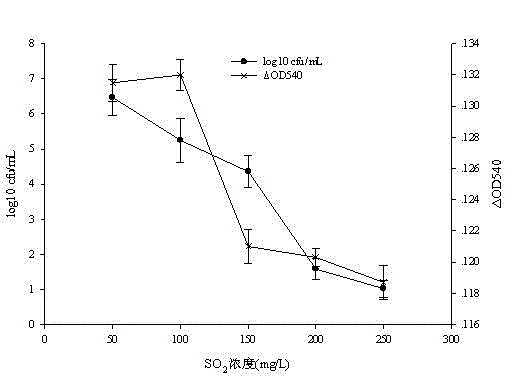

Method for enhancing biological and protein stability of iced white wine

ActiveCN104017709AAffect protein stabilityFree radical scavengingAlcoholic beverage preparationBiotechnologyGrape seed

The invention relates to a method for enhancing biological and protein stability of iced white wine, which comprises the following steps: (1) filtering Italian Riesling iced white wine subjected to alcohol fermentation through a 0.45 mu m filter membrane to obtain the filtered Italian Riesling iced white wine; (2) preparing an iced wine solution containing lysozyme and an iced wine solution containing sodium metabisulfite; and (3) sequentially adding the iced wine solution containing lysozyme, iced wine solution containing sodium metabisulfite and a grape seed proanthocyanidin concentrated solution into 1L of filtered Italian Riesling iced white wine, and regulating the pH value to 3.5-4.5 with a saturated potassium bitartrate solution, wherein the lysozyme concentration is 150-250 mg / L, the total SO2 concentration is 150-200 mg / L, and the total polyphenol concentration of the wine is 0.5-0.7 g / L. The method can prevent the iced white wine from the pollution of putrefactive microorganisms in the iced wine storage period without influencing the protein stability of the Italian Riesling iced white wine, and has the characteristics of no pollution, high safety and no residue as compared with antibiotics and chemical preservatives.

Owner:GANSU AGRI UNIV

Wine making method with effect of improvement of wine color stability

InactiveCN110846166AImprove stabilityImproved color stabilityMicroorganism based processesWine preparationFrozen storageGrape wine

The invention relates to the technical field of wine making and discloses a wine making method with an effect of improvement of wine color stability. The method includes: picking fresh green grapes, cleaning, and keeping for standby application; storing the grapes for 2-3h at a temperature ranging from -15 DEG C to -20 DEG C, subjecting to cell wall breaking in a cell wall breaking machine under the pressure of 100-100WPa, adding an appropriate amount of water after cell wall breaking, adding 50-200mg / L of yeast mannose to obtain grape mash, and storing for 6-8h at a temperature of 0.5-1 DEG C; adding wine into a freezing tank, subjecting to freeze storage for 1-2 days at a temperature of 0.5-1 DEG C, enabling the wine to flow vanes of a filter, and finally filling to obtain a finished wine product, wherein the vanes are uniformly pre-coated with diatomite and potassium bitartrate crystals. The method has advantages that wine stability is improved, the wine color stability can be improved substantially, and the wine is bright, glossy, full in taste and high in structural hierarchy.

Owner:宁夏贺兰山东麓庄园酒业有限公司

Preparation method of fried dough stick bulking agent

InactiveCN108651570AImprove organizational structureMuscle strengtheningDough treatmentPre-baking dough treatmentFood additiveSodium bicarbonate

The invention relates to the technical field of food additives, in particular to a preparation method of a fried dough stick bulking agent. The preparation method provided by the invention comprises the following steps: inoculating a liquid culture medium with aspergillus niger strains to be subjected to culture to obtain culture liquid, dipping the culture liquid with a sterilized inoculation needle, then performing streaking in a solid nutrient medium, performing culture, and picking a single colony with the sterilized inoculation needle; inoculating a fermentation medium with the single colony, carrying out shaking culture in a shaker, carrying out filtration with a four-layer gauze to obtain filter liquor, carrying out centrifugation on the filter liquor and then taking the obtained supernatant; mixing the supernatant, citric acid, potassium bitartrate, sodium chloride, and monocalcium phosphate, performing even stirring to obtain a stirred mixture, placing a chitosan solution intoa container, adding polysorbate 80 and polyvinyl alcohol, and performing stirring to obtain a stirred material; mixing the supernatant with sodium polyphosphate, performing even stirring to obtain astirred mixture liquid, adding dropwise the stirred mixture liquid to the stirred material with a dropping funnel, performing stirring, adding sodium bicarbonate, and then performing even stirring toobtain the fried dough stick bulking agent.

Owner:胡果青

A process of production of potassium ammonium sulfate compound fertilizer in cost-effective manner directly from concentrated sea bittern

InactiveUS20180230065A1High yieldMinimize residual tartaric acid contentChemical industrySulfate/bisulfate preparationProcess integrationPotassium

The present invention provides process for production of potassium ammonium sulfate compound fertilizer through the reaction of Epsom salt, obtained in course of chilling of concentrated sea bittern (32-33° Be), with potassium bitartrate, precipitated from such bittern, and ammonium hydroxide. While process integration was achieved through utilisation of Epsom salt; partial desulphatation of bittern, through crystallization of Epsom salt, resulted in about 17% improvement in K+ precipitation efficiency.

Owner:COUNCIL OF SCI & IND RES

High-temperature-resistant belt material composition, and high-temperature-resistant belt and preparation method thereof

InactiveCN107603098AImprove high temperature resistanceShorten aging timeEthylene-propylene-diene-monomerSulfur

The invention discloses a high-temperature-resistant belt material composition, and a high-temperature-resistant belt and a preparation method thereof. The composition comprises acrylate rubber, ethylene propylene diene monomer rubber, magnesium nitrate, zinc nitrate, potassium bitartrate, sulfur and nano zinc oxide. Relative to 100 parts by weight of the acrylate rubber, the content of the ethylene propylene diene monomer rubber is 30-80 parts by weight, the content of the magnesium nitrate is 10-20 parts by weight, the content of the zinc nitrate is 10-20 parts by weight, the content of thepotassium bitartrate is 0.1-5 parts by weight, the content of the sulfur is 1-5 parts by weight, and the content of the nano zinc oxide is 1-5 parts by weight. Through the design, the effects of effectively prolonging the service life, greatly lowering the use cost and enhancing the production efficiency are realized.

Owner:WUHU KANGDAOER TEXTILE SCI

Cold treatment technology for grape wine

InactiveCN107586688AIncrease cold stabilityImproved cold stabilityAlcoholic beverage preparationFlavorCold treatment

The invention discloses a cold treatment technology for grape wine. The cold treatment technology comprises the steps of freezing, extracting, mixing and dissolving, suction filtering, cold storing and filling. The cold treatment technology disclosed by the invention is characterized in that in a cold treatment process, mannose protein extracted from wine lees yeast is added into the grape wine; thus, a separating-out rate of potassium bitartrate and calcium tartrate crystalline is reduced, the potassium bitartrate and calcium tartrate crystalline can be slowly separated out, and cold stability of the grape wine is improved. The mannose protein not only can improve a lateral stability effect of the grape wine, but also can make the grape wine keep a style and a feature of a natural productand reduce a later chemical and physical treatment frequency and a later chemical and physical treatment degree. By means of performing cold treatment on the grape wine by the method disclosed by theinvention, not only is ageing of new wine is accelerated, but also raw color and acor taste of the wine are reduced, the taste is coordinated and palatable, and wine quality is improved; furthermore,stability of the grape wine is improved, and original taste and flavor of the wine are kept.

Owner:贵州神授酒业有限公司

High-strength ganged brick and preparation method thereof

The invention discloses a high-strength ganged brick. The high-strength ganged brick is mainly prepared from raw materials in percentage by weight as follows: 5%-20% of cement, 50%-90% of stone powder, 0.01%-0.1% of colored blanks, 5%-20% of fly ash, 0.01%-0.1% of a water reducing agent and 0.1%-1% of a modifier, wherein the modifier is prepared from following raw materials: triisopropanolamine, ferrous sulfate, calcium lignosulphonate, sodium metaaluminate, rosin, sodium fatty acid methyl ester sulfonate, sodium fluosilicate, mirabilite, acrylamide and potassium bitartrate. According to the high-strength ganged brick, the ganged brick has clean and smooth surfaces and is attractive, high in breaking strength and not prone to damage; the product has the advantages of being high in strength, moisture-absorbing, air-permeable, good in thermal insulation performance and the like, and is excellent in overall performance and durable in use. Besides, the preparation method is simple, has lowrequirement for equipment and facilitates production.

Owner:兰茂密

Ammonia-oxidizing bacteria immobilized glass plate and production method thereof

InactiveCN108164000AHigh strain activityEfficient degradationWater contaminantsBiological water/sewage treatmentPotassium tert-butoxideAmmonia-oxidizing bacteria

The invention discloses an ammonia-oxidizing bacteria immobilized glass plate. A production method of the ammonia-oxidizing bacteria immobilized glass plate comprises the following steps: cleaning a glass plate, and modifying the cleaned glass plate with a mixed solution formed by potassium bitartrate, potassium tert-butoxide, agarose and potassium hydrogen phthalate in order to obtain a substanceA; modifying the substance A with a mixed solution formed by 2-chloro-3-cyanopyrazine, 2-bromo-5-nitropyridine and 4-bromotetrahydropyran in order to obtain a substance B; modifying the substance B with a mixed solution formed by tetrahydrothiopyran-4-one and 1-aminoanthraquinone in order to obtain a substance C; and immobilizing the ammonia-oxidizing bacteria on the substance C to obtain a substance which is the ammonia-oxidizing bacteria immobilized glass plate. The ammonia-oxidizing bacteria immobilized glass plate has the advantages of high strain activity, and efficient degradation of ammonia nitrogen in wastewater.

Owner:光合强化(北京)生物科技有限公司

Modified forsterite-containing aluminum-based composite heat-dispersing material

ActiveCN104141071ACompact structureHigh surface finishHeat-exchange elementsMixed materialsForsterite

The invention relates to a lamp heat-dispersing material, and particularly relates to a modified forsterite-containing aluminum-based composite heat-dispersing material and a production method thereof. The heat-dispersing material is prepared from the following raw materials in parts by weight: 80-82 parts of aluminum, 15-18 parts of aluminum nitride, 16-20 parts of forsterite, 3-4 parts of tetraethyl orthosilicate, 2-3 parts of maleic anhydride, 5-8 parts of sodium lignin sulfonate, 1-2 parts of tartaric acid, 4-6 parts of potassium bitartrate and 4-5 parts of auxiliaries. The heat-dispersing material integrates the advantages of aluminum, aluminum nitride, forsterite and the like and also has the good heat-conductivity and insulating properties; after the forsterite is soaked and modified by the mixed solution of maleic anhydride, tartaric acid and potassium bitartrate, the heat-conductivity property can be improved and the modified forsterite is more easily compatible with metal powder; and through the added auxiliaries, the sintering performance of the mixed material can be improved; and the prepared heat-dispersing material is compact in structure, high in surface finishing degree, strong in waterproof and antirust capabilities, efficient and fast in heat-dispersing property, and capable of fast transmitting heat, so that the service life of a lamp can be prolonged.

Owner:江苏南通海之升电子商务有限公司

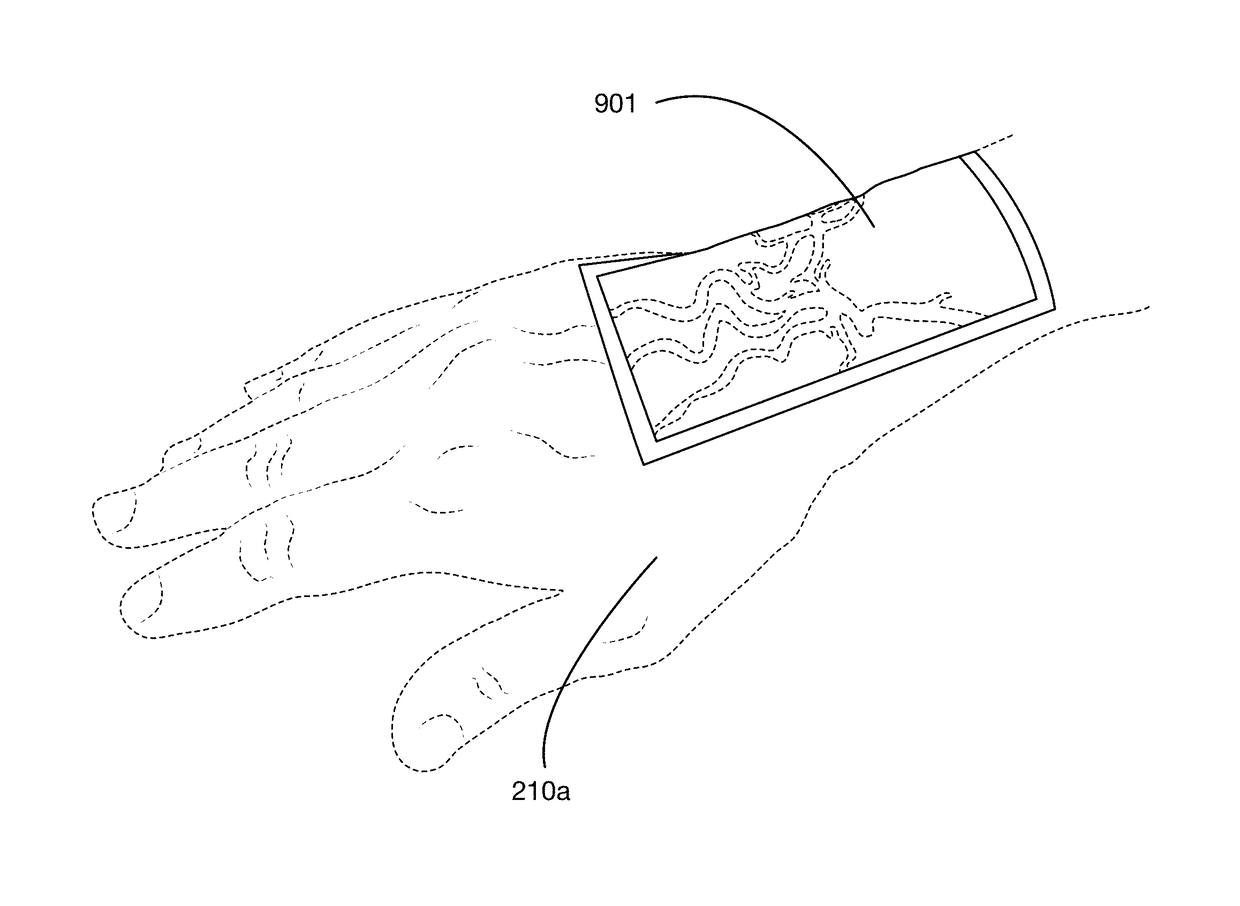

Surface mountable sensor array fabric

InactiveUS10010254B2Protection elementOrgan movement/changes detectionStethoscopeSensor arraySurface mounting

A fabric with an integrated sensor array and optionally with an integrated display; the fabric may be mounted to the surface of an object to be measured or monitored. The fabric may comprise multiple laminar layers, such as sensor layers, processing layers, display layers, and cladding layers for protection and sealing. Data analysis performed by processing layers may include beamforming operations, frequency filters, or any desired transformations. An illustrative display uses a layer of liquid crystal cells sandwiched between polarizing filter layers. An illustrative sensor array is an array of piezoelectric acoustic sensors formed by adjacent layers of calcium carbonate cells and potassium bitartrate cells. An application of acoustic sensor arrays may include for example a patch attached to a person's skin that senses and displays the location and size of blood vessels under the skin using the sound generated by blood flow.

Owner:WAVE ARRAY SCI INC

Food additive for swelling agent

InactiveCN106805197ARaw materials are easy to getLow costFood scienceFood additiveAdditive ingredient

The invention provides a leavening agent food additive, comprising the following ingredients in parts by weight: 35-45 parts of baking soda, 25-35 parts of ammonium bicarbonate, 5-15 parts of citric acid, 12-20 parts of potassium hydrogen tartrate, diced 0.4-3 parts of hydroxyanisole, 12-20 parts of gum arabic, 1-2 parts of triethanolamine lauryl sulfate, 1-2 parts of polyethylene glycol, 1-2 parts of hexabromocyclododecane, etc. The invented food additive has the advantages of readily available raw materials, low cost, no aluminum, environmental protection, convenient use and good effect.

Owner:王俊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com