Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Diethylethanolamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

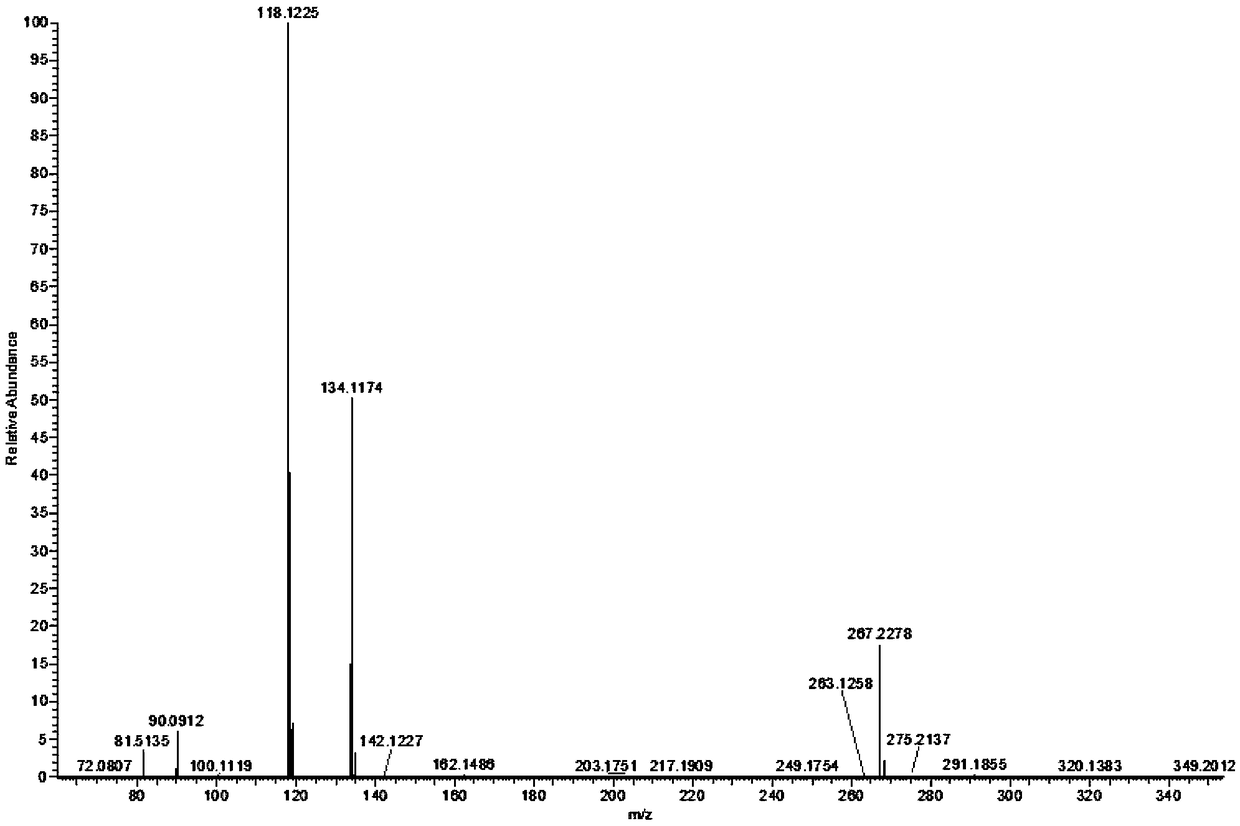

Diethylethanolamine (DEAE) is a chemical compound with the molecular formula C₆H₁₅NO. It is used as a precursor in the production of a variety of chemical commodities such as the local anesthetic procaine. It can be reacted with 4-aminobenzoic acid to make procaine. DEAE can be used as a precursor for DEAE-cellulose resin, which is commonly used in ion exchange chromatography. DEAE can also be conveniently obtained from renewable sources. It is chemically stable and able to absorb carbon dioxide (CO₂) from its surroundings. In solution, it can decrease the surface tension of water when the temperature is increased.

Amine catalysts suitable for producing low-emanation, recatalysis-stable flexible polyurethane foams

The present invention relates to the use of a reactive amine catalyst, in particular diethylaminoethoxyethanol and / or diethylethanolamine, in aqueous or organic solutions for producing flexible polyurethane foams having an increased recatalysis stability, and also a catalyst combination containing at least one reactive amine catalyst which can be used according to the invention; and at least one organic potassium, tin, bismuth and / or zinc compound; and / or at least one tertiary amine selected from the group consisting of triethylenediamine, triethylamine and / or silamorpholine; and / or at least one acid-blocked derivative of a tertiary amine.

Owner:EVONIK GOLDSCHMIDT GMBH

Non-aqueous decarburization solution for capturing carbon dioxide in mixed gas and application thereof

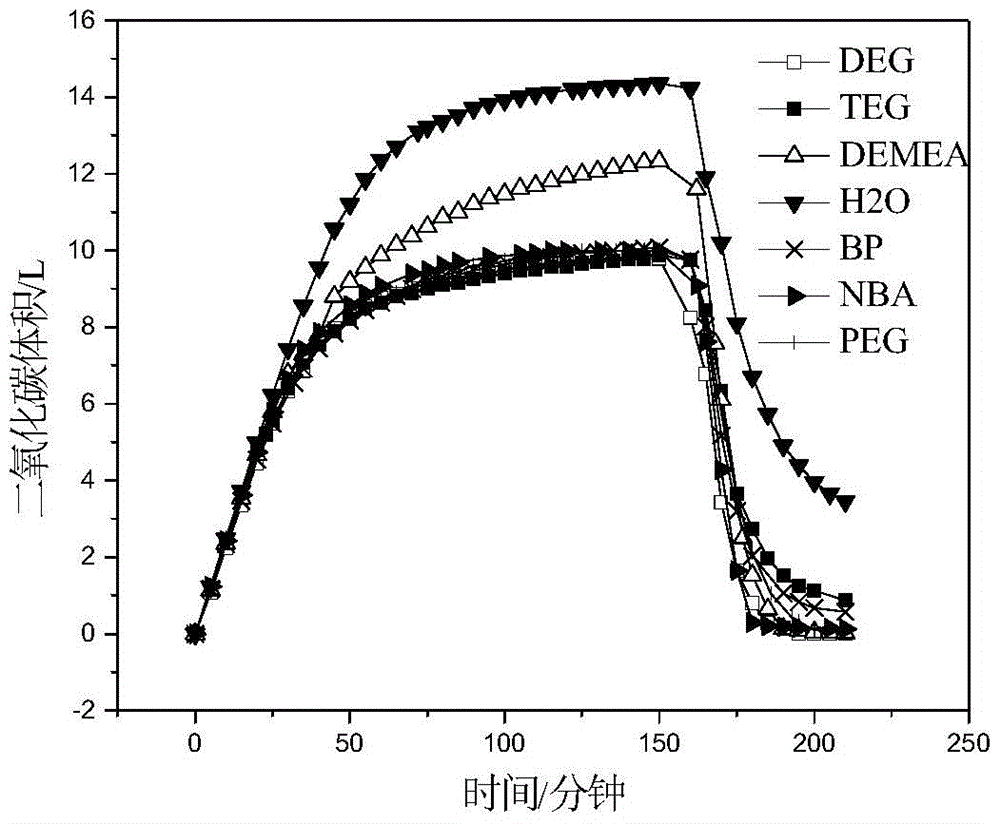

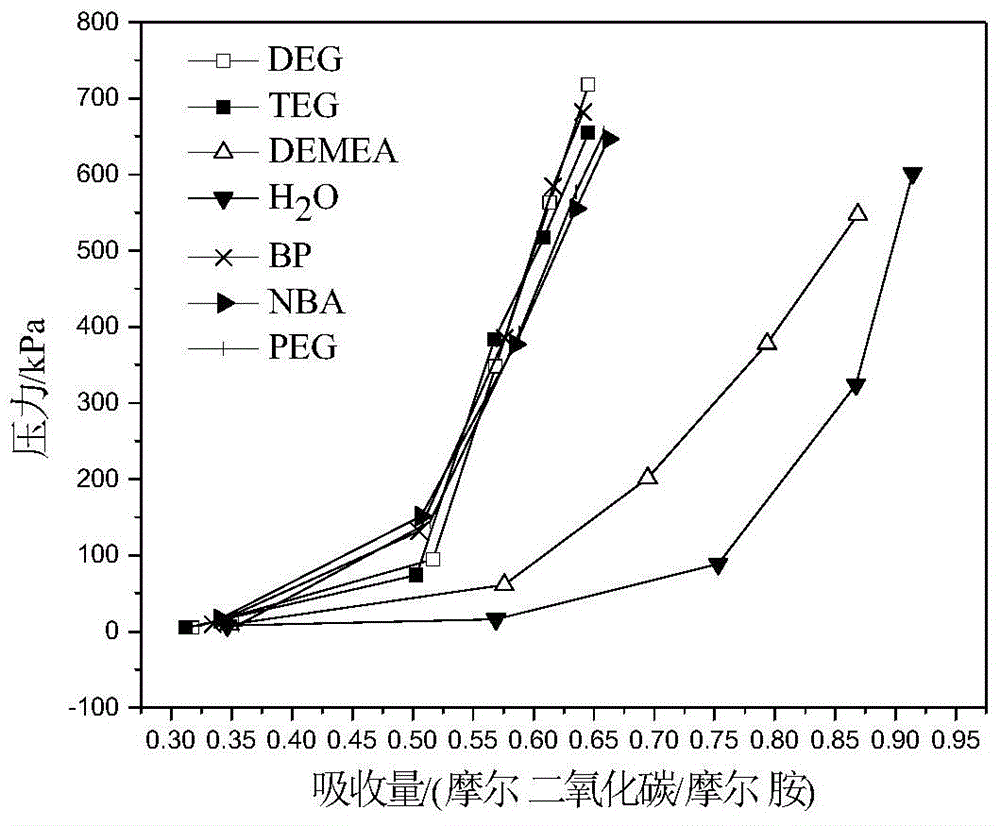

ActiveCN104492226AImprove corrosion resistanceLow regeneration energy consumptionDispersed particle separationAir quality improvementChemical reactionAbsorption capacity

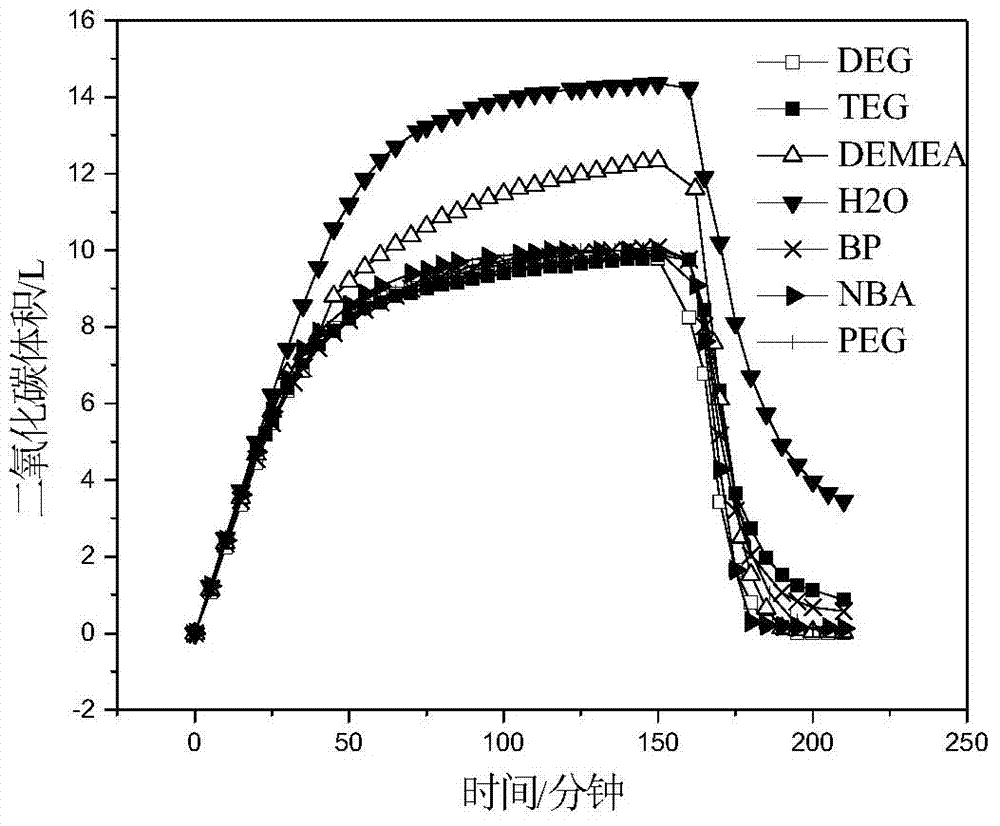

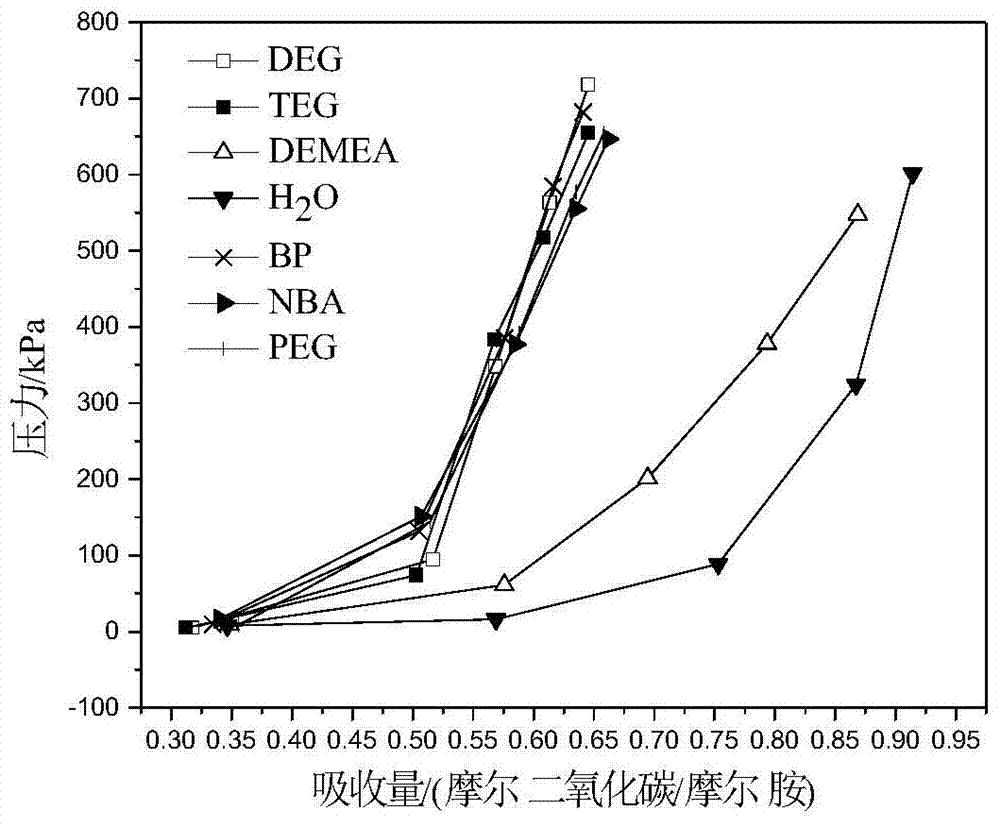

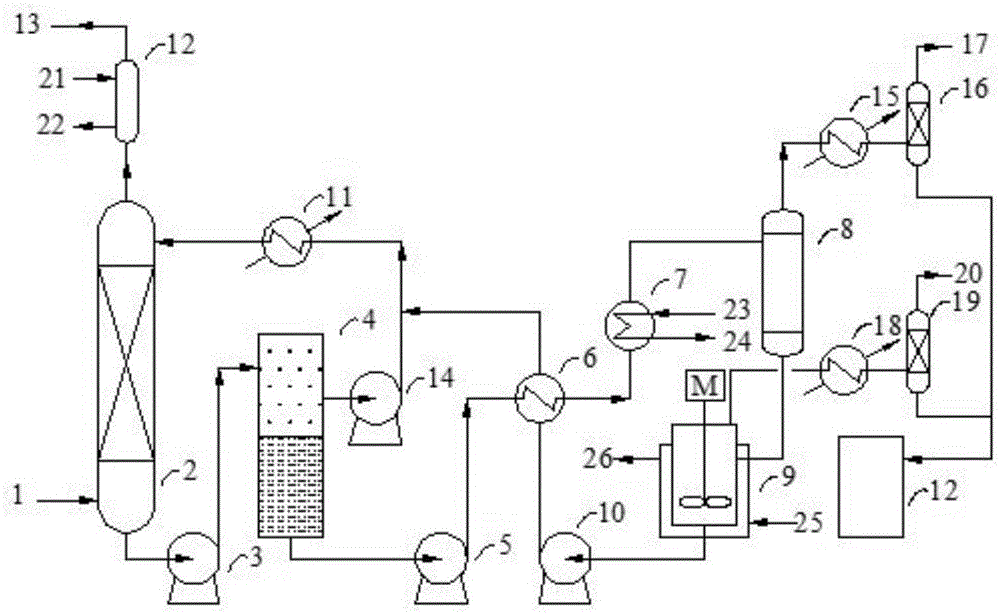

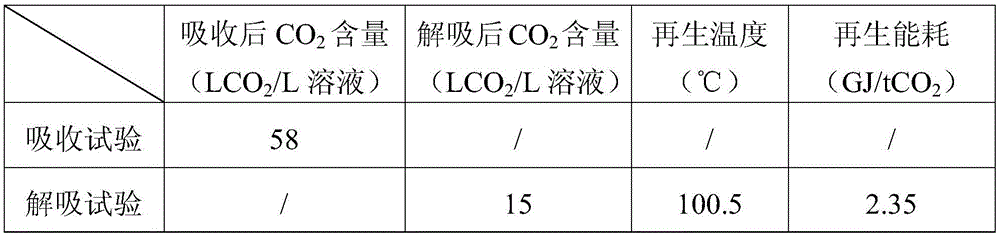

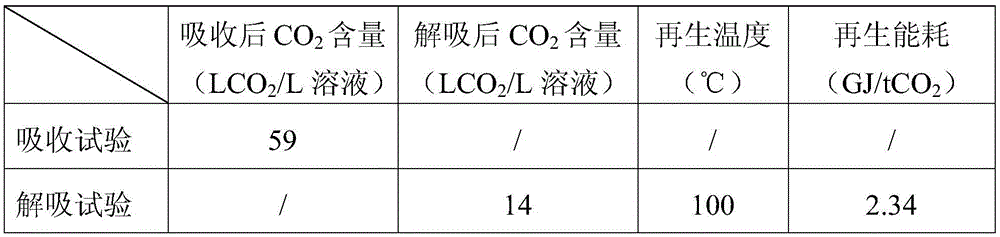

The invention provides non-aqueous decarburization solution for capturing carbon dioxide in a mixed gas, and belongs to the technical field of capturing of carbon dioxide gas. The invention relates to a non-aqueous decarburization solution, wherein a main absorption component is N-ethyldiethanolamine, and a solvent is N,N-diethylethanolamine. Because the non-aqueous decarburization solution has a high boiling point and low viscosity, uses tertiary amine capable of participating in CO2 absorption as the solvent, and uses secondary amine with a fast absorption speed and a high absorption amount, and easy to regenerate as the main absorption solvent, the absorption capacity, purification degree and desorption speed for carbon dioxide are increased, the temperature range of the reaction is expanded, the volume of a regeneration tower is reduced, the energy consumption of the regeneration is greatly reduced, and the equipment investment and operation cost are reduced. The non-aqueous decarburization solution provided by the invention is mainly used for capturing carbon dioxide in the tail gases of multiple chemical reactions, the tail gases of steel plants and cement plants, ore decomposition gas, combustion flue gas, natural gas, city gas and marsh gas, and has wide application prospect.

Owner:DALIAN UNIV OF TECH

Amine catalysts suitable for producing flexible polyurethane foams having low emissions and being recatalysis stable

The present invention relates to the use of a reactive amine catalyst, in particular diethylaminoethoxyethanol and / or diethylethanolamine, in aqueous or organic solutions for producing flexible polyurethane foams having an increased recatalysis stability, and also a catalyst combination containing at least one reactive amine catalyst which can be used according to the invention; and at least one organic potassium, tin, bismuth and / or zinc compound; and / or at least one tertiary amine selected from the group consisting of triethylenediamine, triethylamine and / or silamorpholine; and / or at least one acid-blocked derivative of a tertiary amine.

Owner:TH GOLDSCHMIDT AG

Novel two-phase mixture for trapping carbon dioxide

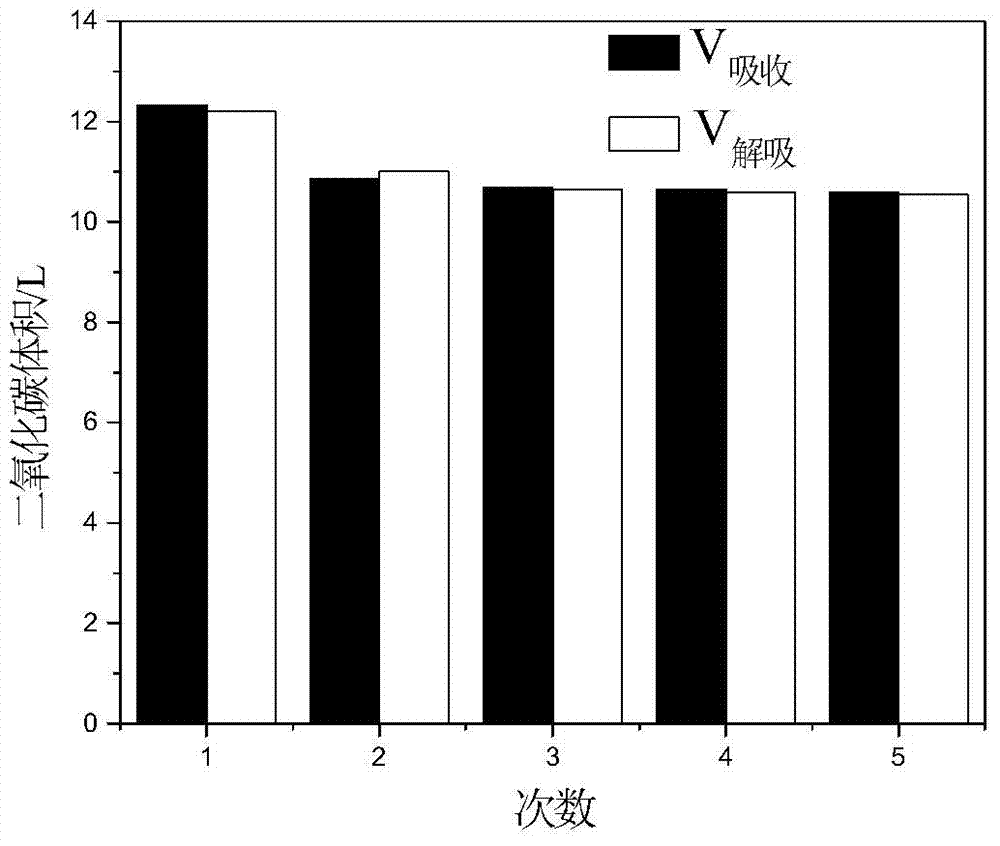

ActiveCN106984152APromote absorptionIncrease desorptionGas treatmentDispersed particle separationEthylene diamineDesorption

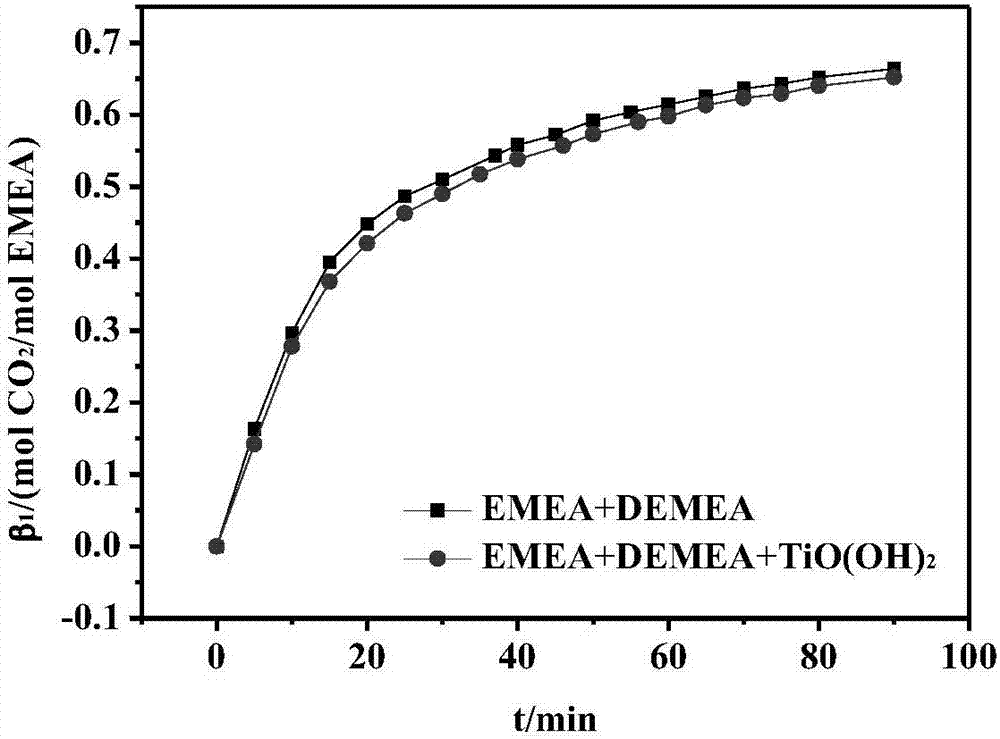

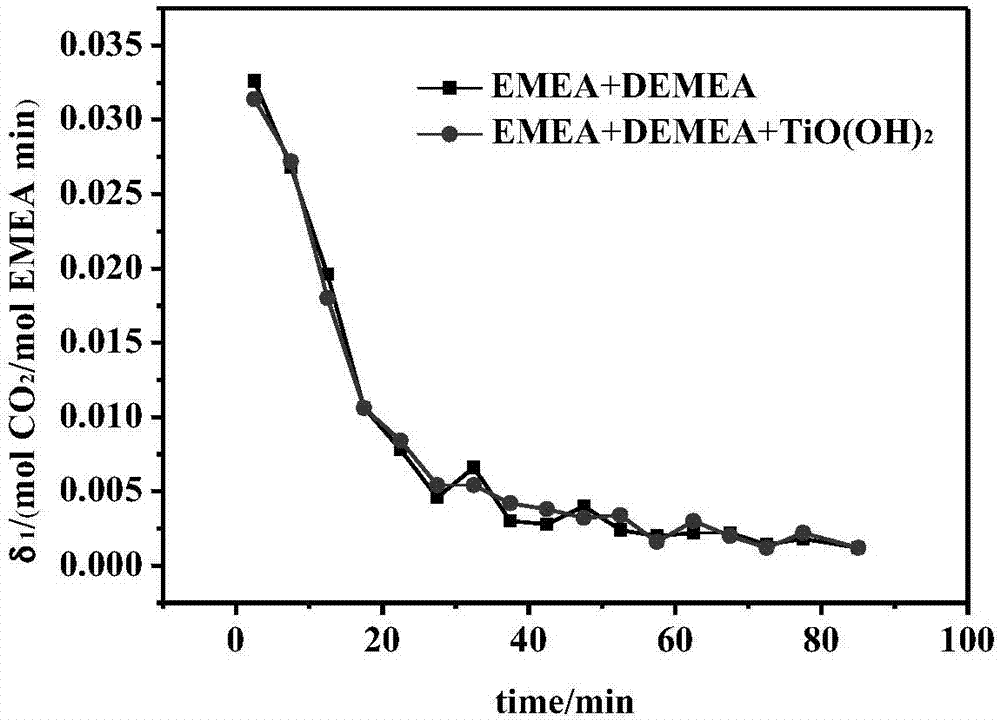

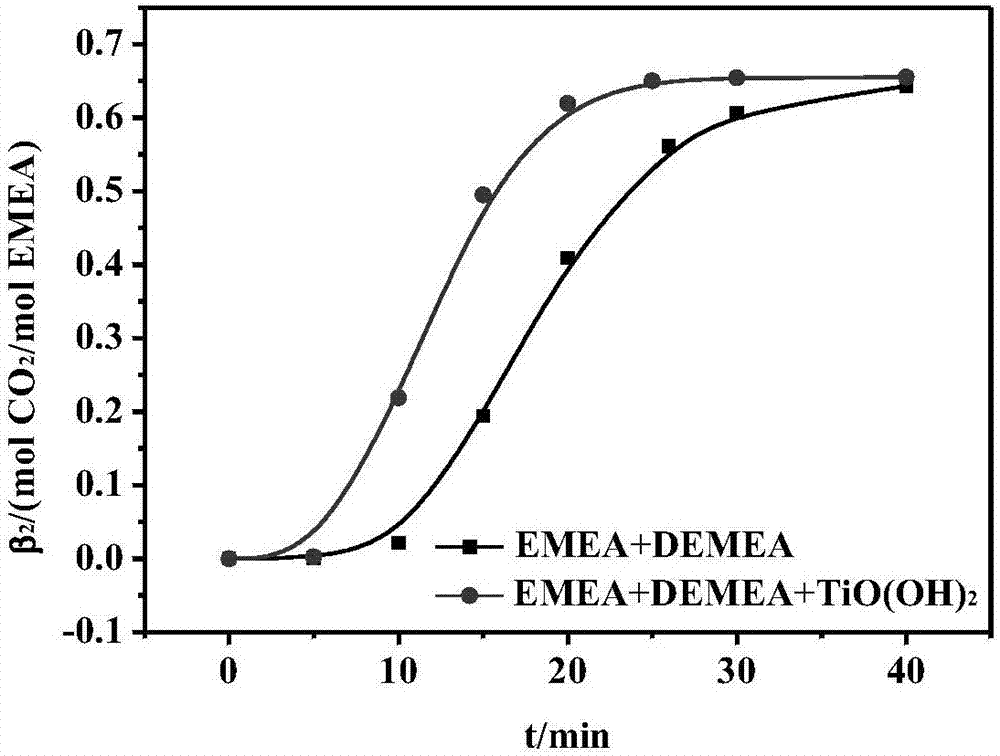

The invention provides a novel two-phase mixture for trapping carbon dioxide, and belongs to the field of technologies for trapping carbon dioxide gas. The novel two-phase mixture comprises two phases including, by weight, 99.0-99.5 wt% of non-aqueous solution and 0.5-1.0 wt% of porous solid materials. The non-aqueous solution comprises, by weight, 30-50 wt% of solutes and 50-70 wt% of solvents, and the solutes are N-ethylethanolamine; the solvents are N, N-diethyl ethylene diamine. The solid porous materials are TiO (OH) 2. The novel two-phase mixture has the advantages that the non-aqueous solution is modified by the TiO (OH) 2, absorption effects of the non-aqueous solution cannot be improved by the TiO (OH) 2, but the desorption rate can be greatly increased by the TiO (OH) 2, the optimal desorption rate can reach 250 Nm<3> CO2 / m<3> solution, and the desorption rate can be increased as compared with the original non-aqueous solution.

Owner:DALIAN UNIV OF TECH

Four-component fuel hypergolic with 70%-98% of hydrogen peroxide

InactiveCN102863994ANot easy to age and deteriorateImprove specific impulseLiquid carbonaceous fuelsHigh concentrationKerosene

The invention relates to a four-component fuel hypergolic with 70%-98% of hydrogen peroxide. The fuel is a novel non-toxic hypergolic miscible fuel (NHMF). Aiming at the conditions that some problems exist in formulas and problem-free formulas do not open to the public in the prior art, the fuel takes alkyl-substituted alcamines compounds such as cobaltous acetate tetrahydrate, cobalt iso-octoate or cobalt acetylacetonate as main catalysts, takes dimethylethanolamine, diethylethanolamine, diisopropylethanolamine, dibutyl eth-anolamine as auxiliary catalysts, takes ethanol, propanol or butanol as a solvent, and takes aviation kerosene as an incendiary agent, and the four components are evenly mixed into an unsaturated solution. The novel fuel has the advantages of being non-toxic actually, not prone to aging and deterioration, high in specific impulse, short in ignition delay period, hypergolic and storable, capable of being applied to liquid rockets, igniters and fuel / air explosives, and the like; and is hypergolic with hydrogen peroxide with the relative high concentration.

Owner:葛明龙

Anti-oxidative non-aqueous decarbonization solution for trapping carbon dioxide in mixed gas

ActiveCN109012090AImprove corrosion resistanceLow regeneration energy consumptionGas treatmentDispersed particle separationChemical reactionAbsorption capacity

The invention provides an anti-oxidation non-aqueous decarbonization solution for trapping carbon dioxide in a mixed gas, and belongs to the technical field of carbon dioxide gas trapping. The invention relates to a non-aqueous decarbonization solution, which is composed of a main absorption component N-ethylethanolamine and a solvent N, N-diethylethanolamine. The non-aqueous decarbonization solution has high boiling point, low viscosity and fast absorption rate for carbon dioxide. The absorption capacity is high and the product is easy to regenerate. By adding the antioxidants 2-butanone oxime, pyrogallol, carbohydrazide and N, N'-bis(salicylidene)-1,2-propylenediamine, the main absorption component and the solvent can be effectively prevented from being oxidized by oxygen, thus guaranteeing good performance and service life of the non-aqueous decarbonization solution. The non-aqueous decarbonization solution of the invention is mainly used for trapping carbon dioxide in various chemical reaction tail gases, tail gases from steel plants and cement plants, ore decomposition gas, combustion flue gas, natural gas, city gas and biogas, and has a broad application prospect.

Owner:DALIAN UNIV OF TECH

Novel magneticfluid sealant

ActiveCN104008845AFast deliveryGuaranteed normal operationMagnetic liquidsWater turbineMicroparticle

Owner:冯智勇

Mixed absorbent for gathering or separating carbon dioxide

The invention relates to a mixed absorbent for gathering or separating carbon dioxide from a gas mixture, which mainly comprises the following components in percentage by weight: 21 to 45 percent of diethylethylenediamine, 5.0 to 9.9 percent of primary amine containing one nitrogen atom and / or secondary amine containing one nitrogen atom, and the balance of water. The absorbent has high solubility and good desorption effect on low-pressure carbon dioxide, simultaneously absorbs less reaction heat, and has low energy consumption for gathering or separating the low-pressure carbon dioxide; because the diethylethylenediamine is tertiary amine and has high boiling point and better molecular stability than the primary amine and secondary amine, so the degradation loss of a solvent in the using process can be greatly reduced. The mixed absorbent can be used for gathering or separating various normal-pressure gas mixtures, such as carbon dioxide in flue gas discharged from coal fired power plants, and enterprises in the steel, cement, petrochemical engineering and other industries.

Owner:TSINGHUA UNIV

Nano emulsified fuel addtiive and its perparing method

InactiveCN1587357ALower emission valueReduce concentrationLiquid carbonaceous fuelsPolyethylene glycolAlkylphenol

The present invention discloses nanometer emulsified fuel additive and its preparation process, and belongs to the field of liquid fuel additive technology. The fuel additive is prepared with the components including triethyl tetramine, diethyl ethanolamine, AE03 or AE04, alkylphenol ethoxylate, polyethylene glycol lauryl ether, ethylene glycol monomethyl ether, sorbitan oleate, fatty acid ester, isopropyl nitrate, cobalt naphthenate, acetone and ferrocene. It has an oil saving rate of 7-12 % and obvious pollution reducing effect.

Owner:谢学秀

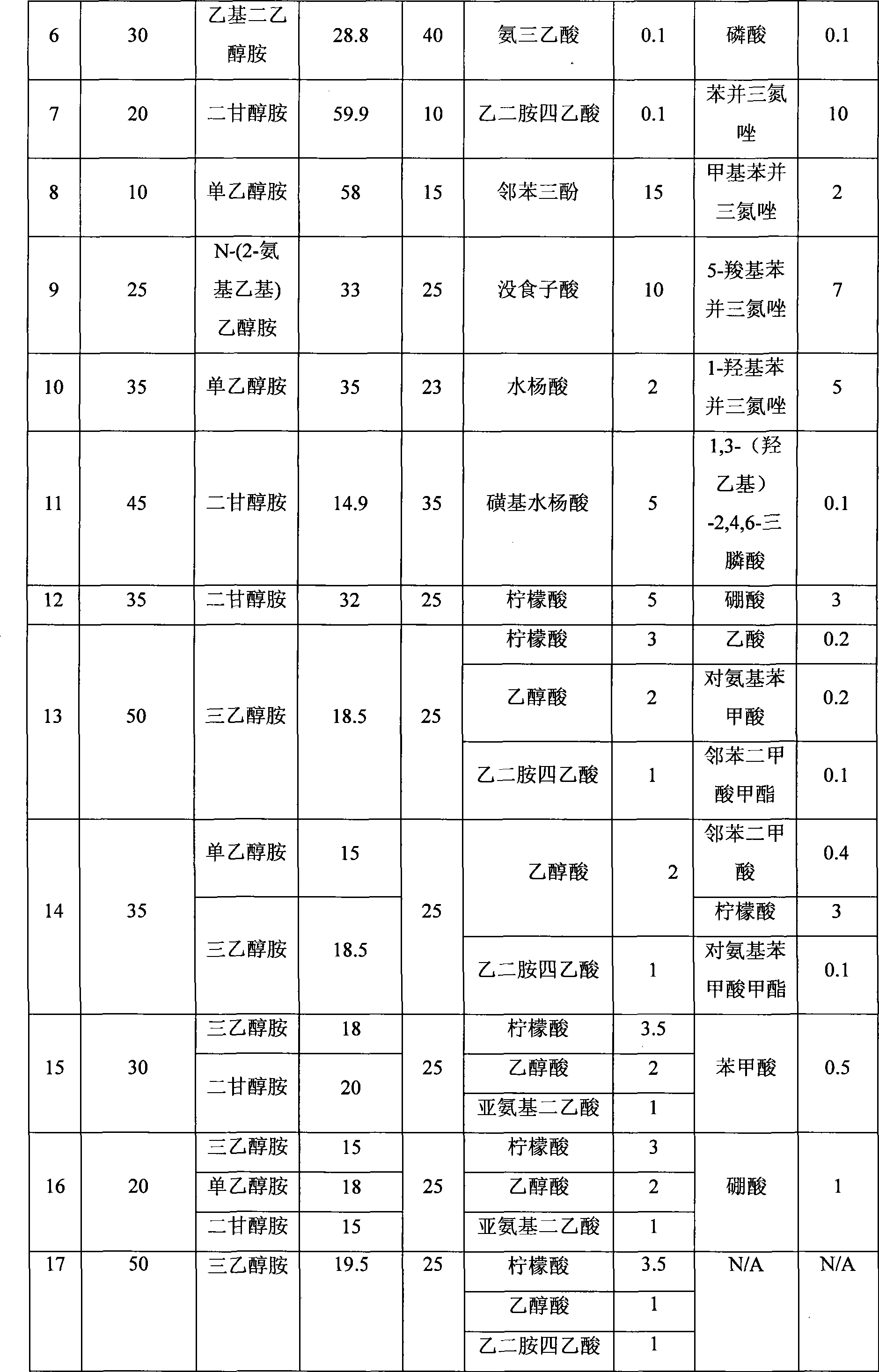

Liquid alkali-free accelerator

The invention discloses a liquid alkali-free accelerator, and belongs to the field of concrete additives. The liquid alkali-free setting accelerator is prepared by uniformly mixing the following raw materials in percentage by mass: 40%-50% of aluminum sulfate, 10%-15% of magnesium sulfate, 0.5%-1.5% of 3-hydroxy-3-carboxyl glutaric acid, 3%-8% of N, N-diethylethanolamine, 1%-3% of ethylenediaminetetraacetic acid disodium salt, 0.1%-0.3% of diethanolisopropanolamine, 0.5%-2% of sodium thiosulfate and the balance of water. The accelerator is used for spraying concrete, the mixing amount is generally 6%-8% of the mass of cement, the accelerating effect is good, excellent early strength and later strength are achieved, and meanwhile the accelerator has long-term stability.

Owner:丰乐宝化学材料(北京)有限公司

Modified polytrifluorochloroethylene plastic for junction box of SF6 density relay

The invention discloses modified polytrifluorochloroethylene plastic for a junction box of an SF6 density relay. Raw materials of the modified polytrifluorochloroethylene plastic in parts by weight are as follows: 20-40 parts of ethylene-vinyl acetate copolymer, 30-40 parts of polytrifluorochloroethylene, 5-15 parts polyacrylic acid, 5-20 parts of bisphenol A type polyarylester, 1-2 parts of dicumyl peroxide, 1-2 parts of diethylenetriamine, 1-2 parts of N,N-diethylethanolamine, 1-2 parts of cerium oxide, 0.5-1 part of lanthanum oxide, 1-3 parts of stearic acid, 1-2 parts of liquid coumarone, 10-20 parts of glass fibers, 20-40 parts of superfine modified kaolin, 5-15 parts of clay, 10-20 parts of glass beads, 10-20 parts of nanosilicon dioxide, 1-2 parts of an anti-ageing agent 264, 1-2 parts of an anti-ageing agent DPPD and 1-2 parts of p-phenylenediamine. The modified polytrifluorochloroethylene plastic disclosed by the invention has excellent heat resistance, ageing resistance and mechanical properties.

Owner:ANHUI RUIXIN AUTOMATION INSTR

Graphene conductive agent

InactiveCN107785585AImprove conductivityIncrease capacityCell electrodesSecondary cellsEpoxyInternal resistance

The invention belongs to the technical field of preparation and application of graphene, and specifically provides a graphene conductive agent. The graphene conductive agent comprises the following components in parts by mass: 70-100 parts of graphene, 30-80 parts of epoxy resin, 10-20 parts of monoethanolamine, 10-20 parts of triethylene tetramine, 10-20 parts of water, 20-30 parts of ethyl alcohol, 12-15 parts of butyrolactone, 12-18 parts of N, N-diethyl ethylene diamine, 5-10 parts of acetone, 10-20 parts of tetrahydrofuran, 2-5 parts of hydroxyethyl cellulose, 1-3 parts of chitosan, 2-6 parts of seaweed mud, 2-8 parts of silane coupling agent, and 5-30 parts of carbon nanotube. According to the graphene conductive agent, a small number of carbon nanotubes are introduced; the capacityof an electrode material is improved based on high conductivity of graphene and the carbon nanotube; the internal resistance of a battery is reduced; and the cycle life of the battery is prolonged while the conductivity of the conductive agent is improved.

Owner:NANJING XUYURUI MATERIAL TECH CO LTD

Life jacket and preparation method thereof

ActiveCN104194119AImprove cold resistanceWidely producedLow-density polyethyleneToluene diisocyanate

The invention discloses a life jacket and preparation method thereof. The life jacket is prepared by weighting the following components in parts by weight: LDPE (Low-Density Polyethylene), toluene diisocyanate, tribasic lead sulfate, polyether triol, DCP (Dicumyl Peroxide), triethylenediamine, a foaming agent, polyoxyalkylene, EVA (Ethylene Vinyl Acetate), diethylethanolamine, a crosslinking agent, dibutyltin dilaurate, zinc oxide, stannous octoate and stearic acid, plastifying and carrying out compression molding to obtain a blank and carrying out foam molding. The relative density of the product is 0.03-0.05, the surface water absorption is 5-15mg / cm<3>, the linear shrinkage percentage is 1-2%, the tensile strength is 0.4-0.8MPa, the elongation is 150-250%, the life jacket dose not change when the life jacket is placed at a high temperature of 80-90 DEG C for 24 hours and at a temperature of minus 50 DEG C for 20-24 hours.

Owner:广东汇乐水上游乐用品有限公司

Medical PS (Poly Styrene) antibacterial film and preparation method thereof

The invention discloses a medical PS (Poly Styrene) antibacterial film and a preparation method thereof. The preparation method comprises the following steps: weighting the following components in parts by weight: PS, CPE (Chlorinated Polyethylene), a nanometer zirconium phosphate silver-loaded antibacterial agent, nanometer LDPE (Low-Density Polyethylene), a styrene-butadiene block copolymer, SEBS (Styrene-Ethylene / Butylene-Styrene), a surface treatment agent, LDPE, dicumyl peroxide, POE (Polyolefin Elastomer), an ultraviolet absorber, N,N-diethylethanolamine, aluminum trichloride, zinc stearate and carbon tetrachloride, evenly mixing and extruding and granulating. At 0 DEG C, the product has longitudinal elongation of 5-45% and tensile strength of 45-65MPa, longitudinal heat shrinkage of 25-45%, transverse shrinkage ratio of 20-40% and tear strength of 10-12kN / m; the antibacterial rate on escherichia coli is 95.9-99.9% and the antibacterial rate on staphylococcus aureus is 97.5-99.5%.

Owner:SUZHOU BEC BIOLOGICAL TECH

Method for controlling pH value of process water circulation system for ethylene production by steam cracking

InactiveCN102910722AHighlight substantive featuresSignificant progressWater/sewage treatment by neutralisationHydrocarbon by hydrocarbon crackingWater qualityWater circulation

The invention discloses a method for controlling the pH value of a process water circulation system ethylene production by steam cracking. The method is characterized in that a water solution having a pH value of 4.7 and containing ring-B ring-C cation polyether with concentration of 10wt% is taken as an anti-phase demulsifying agent, a pentanediol solution having a pH value of more than 6.9 and containing diethylene triamine penta methylene phosphonic acid with concentration of 10wt%-30wt% is taken as a corrosion inhibitor, an alcohol ether solution having a pH value of less than 5.1 and containing naphthalene with concentration of 10wt% is taken as dispersing agent, a water solution having a pH value of more than 13 and containing N.N-diethyl ethylene diamine with concentration of more than 60wt% is taken as a neutralizer, and a water solution having a pH value of more than 13 and containing sodium hydroxide with concentration of more than 10wt% is taken as an alkaline corrosion inhibitor; and the solutions are sequentially injected according to a given injection sequence as well as given injection points and injection amounts, and then are adjusted according to monitoring projects and analysis indexes. According to the method, the pH value of the process water system is stably controlled, the water quality is obviously improved, and the qualified rate is above 98%. During the running of the processing water circulation system for 3 years, the system is not subjected to a process water emulsion phenomenon, and heat exchangers and other equipment as well as pipes are not subjected to leakage.

Owner:PETROCHINA CO LTD

Layered absorbent for trapping CO2 in tail gas

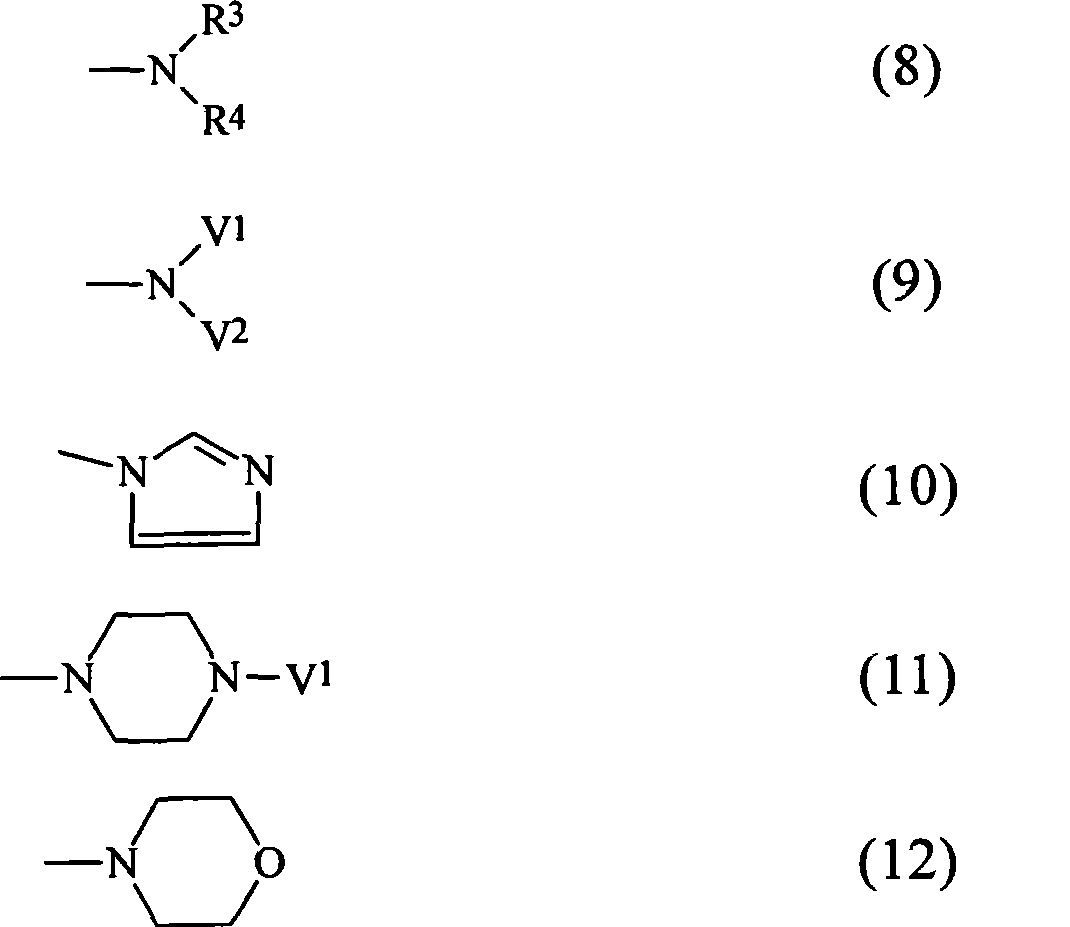

InactiveCN105413396AEffective absorptionEffective implementation of absorptionDispersed particle separationMorpholineN-Propyl alcohol

The present invention provides a layered absorbent for trapping CO2 in tail gas. The absorbent comprises a basic absorbent, an activation agent, a boiling point increasing agent, water and an organic solvent; the basic absorbent is selected from one or more of N,N-dimethylethanolamine, N,N- diethyl ethylene diamine, N,N-dimethyl cyclohexyl amine, N-methyldiethanolamine, 1,4-diaminobutane, 1,5-diaminopentane, bis(2-ethylhexyl)amine, octodrine, di-n-propylamine, tripropylamine and paranitroaniline; the activation agent is selected from one or more of diisopropanolamine, diethanol amine, diglycolamine, triethylene glycol amine, and morpholine; the boiling point increasing agent is selected from one or more of dimethylformamide, dimethylacetamide, ethylene glycol monomethyl ether, and oxalic acid; and the organic solvent is selected from one or more of methanol, ethanol, benzyl alcohol, phenylethanol, n-propyl alcohol, and isopropyl acetate. The layered absorbent for trapping CO2 in the tail gas is high in absorbing ability, fast in absorption rate, low in regeneration temperature, and low in regeneration energy consumption.

Owner:SINOPEC ENERGY & ENVIRONMENTAL ENG CO LTD

Roller shade treatment and method

InactiveUS6511515B1Reduces or eliminates the tendency for the roller shade material to distortGood dimensional stabilityChlorine/hydrogen-chlorideFibre treatmentPolyesterCross-link

A roller shade material, such as 100% polyester, is passed through a bath, so that both sides of the material are coated by the bath. In a preferred embodiment, the bath includes an acrylic polymer finish, and a melamine-formaldehyde cross-linking agent. The acrylic polymer preferably is approximately 45% solid, and comprises about 47% to 48% of the bath by weight. The cross-linking agent preferably comprises about 2.5% of the bath by weight, and is about 80% solid material. The bath should have a pH in the basic range between about 7 and 9.5, and the preferred base used to adjust the pH is N,N-Diethylethanolamine. Optional compounds that may be added to the bath include an anti-stick compound and a defoaming agent. This treatment produces a roller shade having a clear coating that allows the color, texture and weave of the substrate to show, without hindering the ability of light to pass through the material. Further, and more importantly, the coating provides dimensional stability for the roller shade, which reduces or eliminates the tendency of the material to distort by bowing, cupping, or cambering, and preserves the hand and feel of the product.

Owner:MILLIKEN & CO

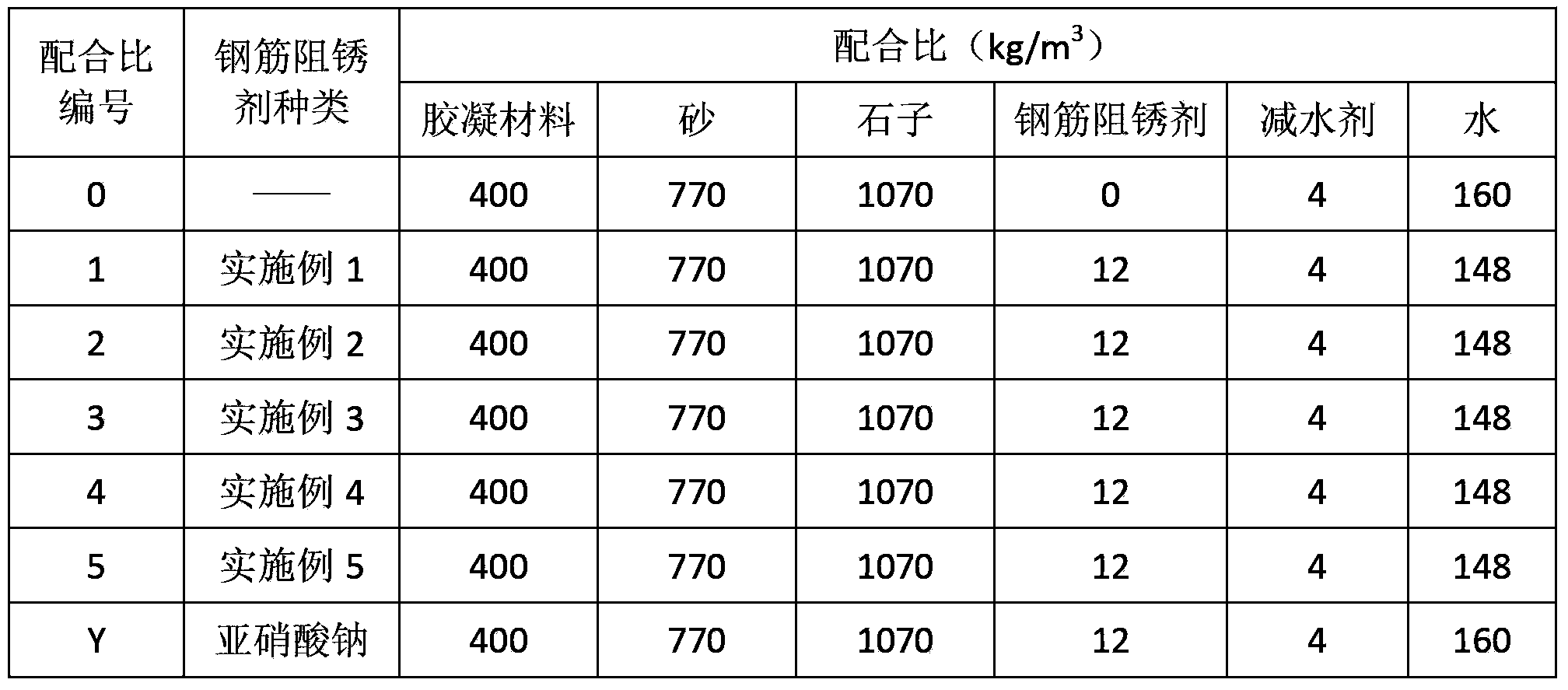

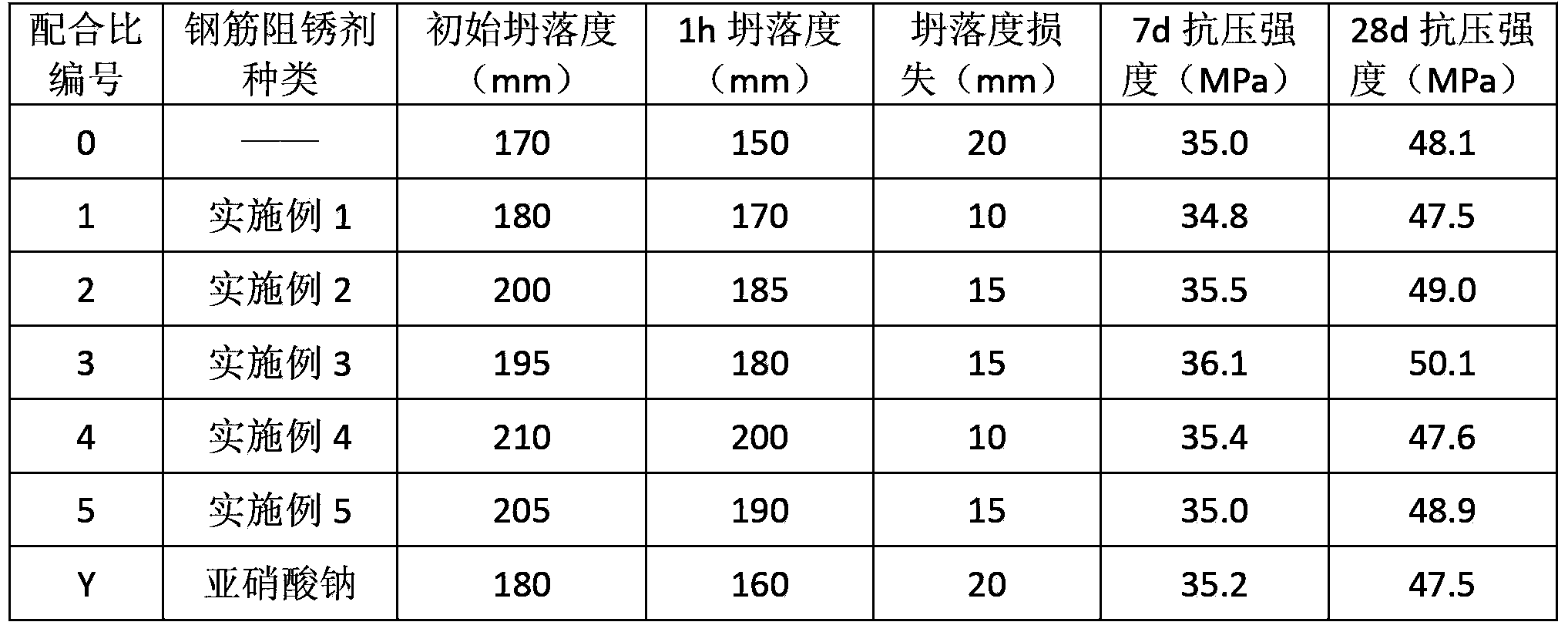

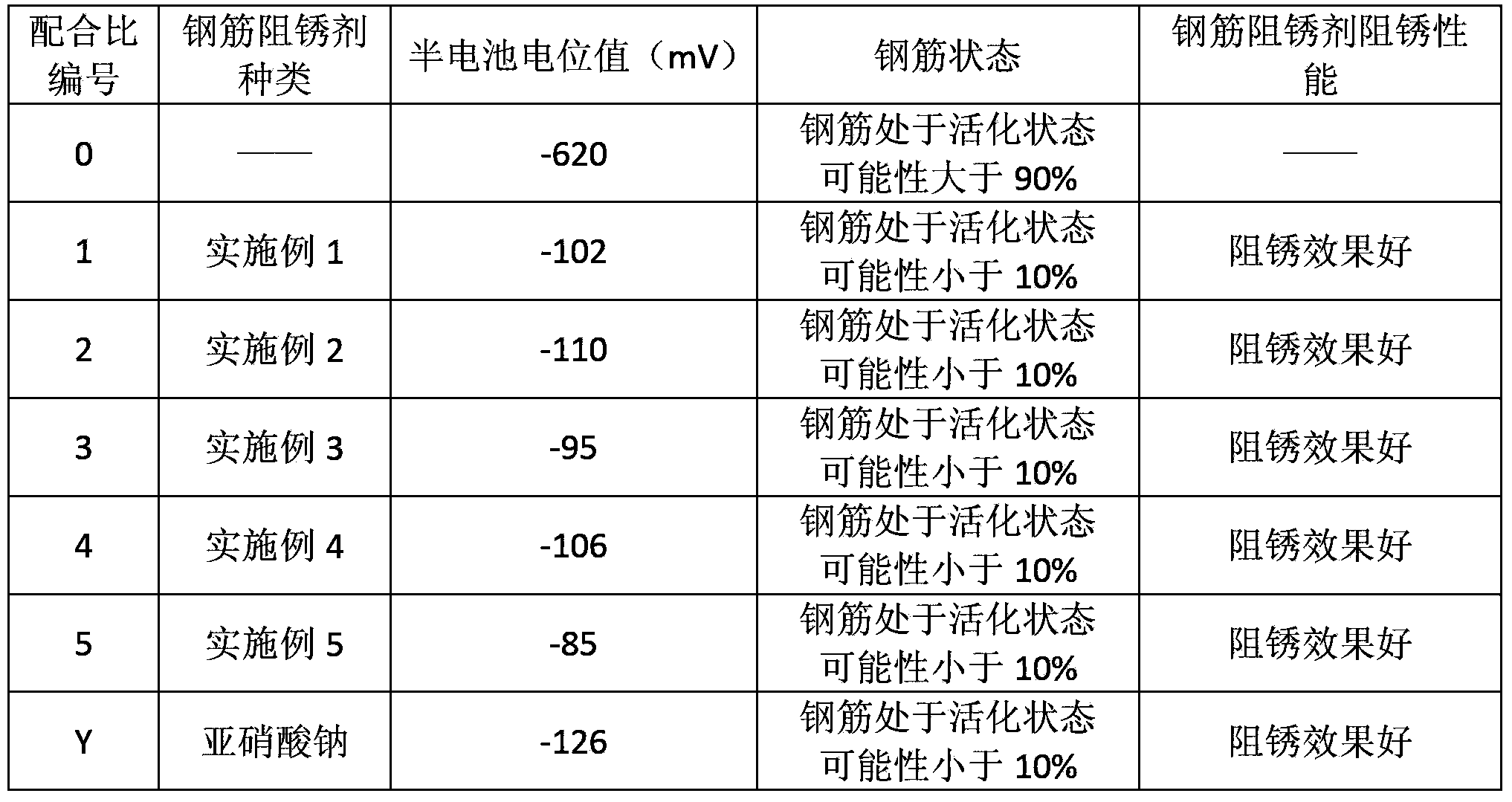

Composite rebar corrosion inhibitor and preparation method thereof

The invention discloses a composite rebar corrosion inhibitor and a preparation method thereof. The composite rebar corrosion inhibitor is prepared from the following components: 10-25% of amino alcohol, 2-10% of amine, 1-10% of sodium benzoate, and the balance of water based on the mass percent of the materials, wherein the amino alcohol is one or more of cholamine, diethanol amine, triethanolamine, N-mono methyl ethanol amine, N,N-dimethylethanolamine, N-ethylethanolamine, N,N-diethyl ethylene diamine, tri-isopropanolamine, N-(2-ethoxy) ethanediamine, and N,N-dihydroxyethyl ethylene diamine; the amine is one or more of methylamine, dimethylamine, ethanediamine, phenylamine, benzene methanamine and dicyclohexylamine. The amino alcohol, the amine and the sodium benzoate weighed according to the mass ratio are orderly added to water to evenly agitate in preparation. The composite rebar corrosion inhibitor disclosed by the invention is good in corrosion inhibition effect, and free of adverse effects on performance of concrete.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparation method of DNL-1 molecular sieve

ActiveCN109574036ASimple methodSimple and fast operationMolecular-sieve aluminophosphatesMolecular-sieve and base-exchange phosphatesALUMINUM PHOSPHATECholine chloride

The invention discloses a preparation method of a DNL-1 molecular sieve. The method comprises the following steps: 1) mixing an aluminum source, a phosphorus source, R1, R2, hydrofluoric acid and deionized water to obtain a primary mixture; 2) crystallizing the obtained primary mixture for 0.5-96 h at the temperature of 150-220 DEG C to obtain an aluminum phosphate molecular sieve, wherein the molar ratio of Al2O3, P2O5, R1, R2, HF and H2O in the primary mixture is 1: 0.5: 1.5: 5-20: 0.1-1.5: 0.1-2: 8-40; R1 is diethylethanol or triethanolamine; and R2 is selected from one or more of butyl trimethyl ammonium chloride, tetramethyl ammonium chloride, diethylamine and choline chloride. The preparation method of the aluminum phosphate molecular sieve DNL-1 is simple, and is simple and convenient to operate and low in cost, raw materials are commercial and easily obtained, and thus, the aluminum phosphate molecular sieve DNL-1 is suitable for being produced industrially.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Graphene material for lithium battery and preparation method thereof

InactiveCN106784844ALower internal resistanceExtend your lifeCell electrodesElectrical batteryInternal resistance

The invention discloses a graphene material for a lithium battery and a preparation method thereof. The graphene material for the lithium battery contains raw materials of potassium hydroxide, active carbon, Ni-Co lithium manganate, graphene oxide, sodium hydroxide, sodium borohydride, lithium nitrate, triethylene tetramine, N, N-diethylhydroxylamine and N, N-diethyl ethylene diamine. The graphene material for the lithium battery, disclosed by the invention, has the advantages that the mechanical property is excellent, the internal resistance of the battery is reduced, the service life of the battery is prolonged, the heat-conducting property is excellent, the raw materials are cheap, the operation is simple, the electrical conductivity is excellent, the battery is rapidly and fully charged within 5-9 minutes, large-current discharging performance and low temperature performance of the battery are improved, the stability of the battery is good, the battery can be charged and discharged for 400-500 times in circulation, the battery capacity reaches 700-900 mAh, the process is simple and easy to operate, the product quality and the product yield are stable and easy to control, and the graphene material can be widely produced and continuously replace the existing materials.

Owner:江苏悠谷未来科技有限公司

Modified alumina dry glue powder, and preparation method and application thereof

ActiveCN108295826AInhibit aggregationEnhanced interactionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAluminium hydroxide

The invention discloses a preparation method of modified alumina dry glue powder. The method comprises the following steps: (1) preparing a mixed solution containing a modifying element and at least one of diethyl ethanolamine and polyethylene glycol, wherein the mass content of a modifying element precursor in the mixed solution is 5-30%, the mass content of the at least one of the diethyl ethanolamine and polyethylene glycol is 0.1-10%, and the modifying element is silicon, magnesium or zinc; (2) preparing an aluminum salt and a precipitant, performing a co-precipitation reaction to obtain asolution containing aluminum hydroxide sol, ageing the solution containing aluminum hydroxide sol for 10-30 min, adding the mixed solution prepared in step (1), and continuing the ageing, wherein theaddition amount of the mixed solution prepared in the step (1) makes the content of the modifying element (by oxide) in a final catalyst be 1-10%; and (3) filtering, washing and drying the obtained aged material to obtain modified alumina. The method facilitates the enrichment and high dispersion of the modifying element on the surface of the alumina carrier, and improves the physical and chemical properties of the alumina dry glue powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

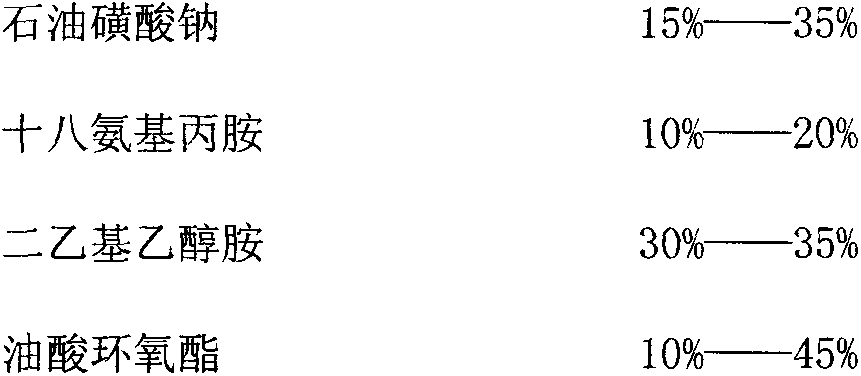

Novel magnetofluid tire sealing material taking methylsilicone oil as continuous phase

The invention discloses a novel magnetofluid tire sealing material taking methylsilicone oil as a continuous phase, and belongs to the technical field of tires. The formula of the material is characterized by consisting of the methylsilicone oil, talcum powder, nanoscale ferroferric oxide powder, nanoscale AlNiCo magnet powder, diethyl ethylene diamine, terminal group polyisobutene, petroleum sodium sulfonate, silicone rubber particles and polyvinyl acetate emulsion. The material provided by the invention is mainly used in a radial tire of a steel cord layer, and is the novel magnetofluid tire sealing material which cannot affect the dynamic balance of a wheel, is capable of filling a gap (the diameter is less than or equal to 10mm) by self, and is free of dried-up and freezing, good in stability and durable. After using the material, along with the rotation of the wheel, a circle of magnetofluid is uniformly hung on the inner wall of the tire; the magnetofluid provided by the invention can be stably and uniformly hung on the inner wall of the tire for a long time due to that fact that the magnetofluid is subjected to the suction effect of a steel cord cloth layer in the tire, so that the dynamic balance of the wheel cannot be affected, and this is revolutionary improvement compared with the prior art.

Owner:冯智勇

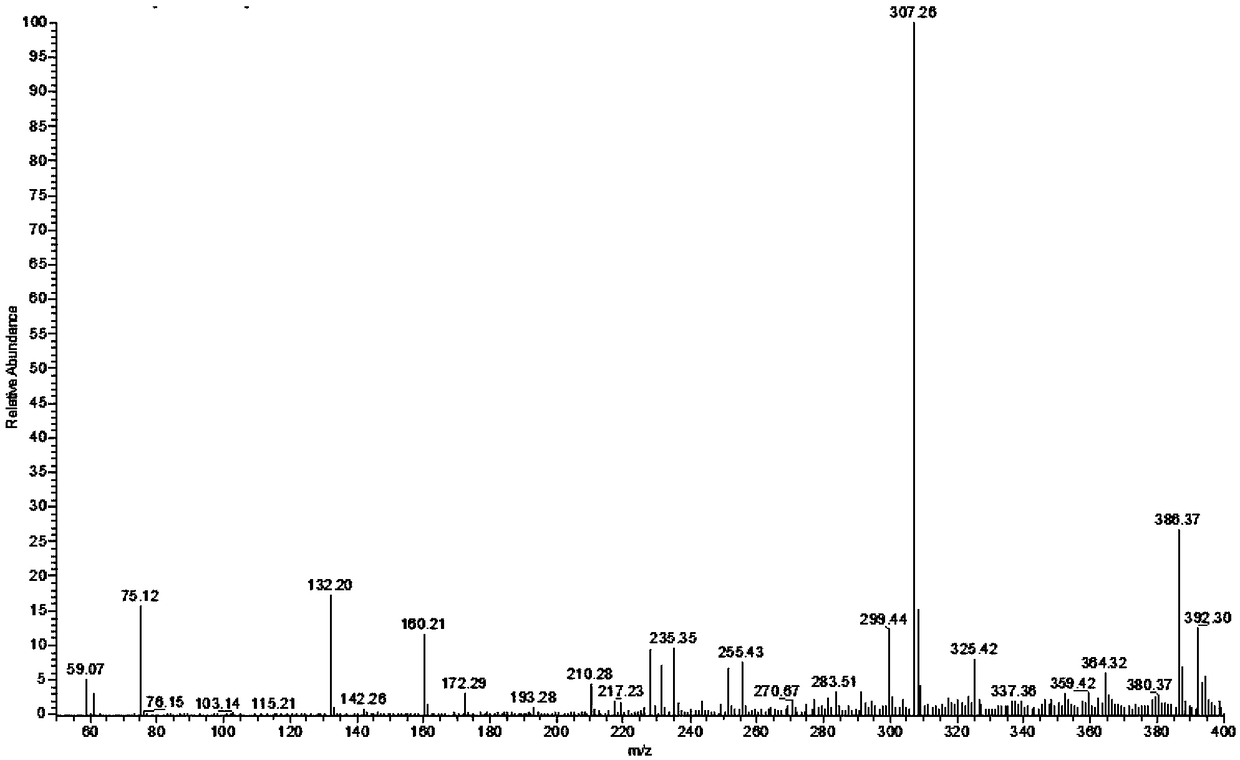

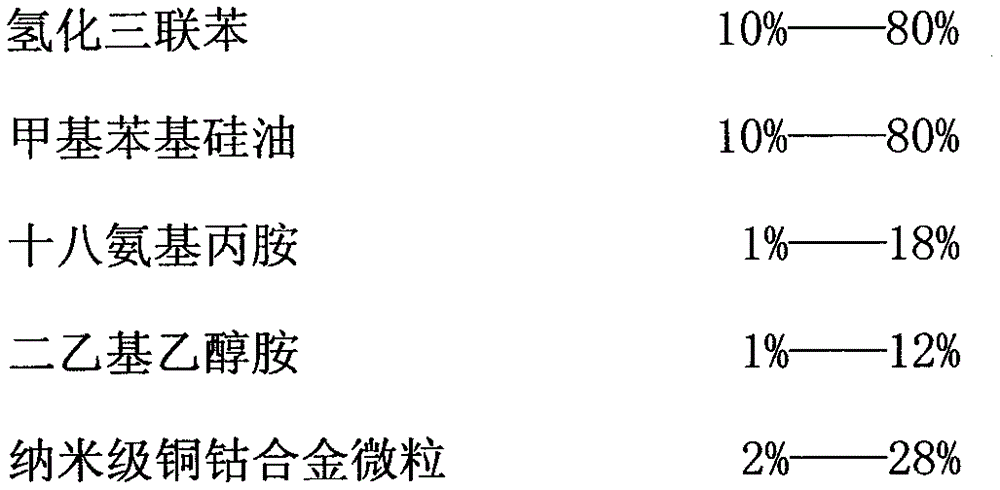

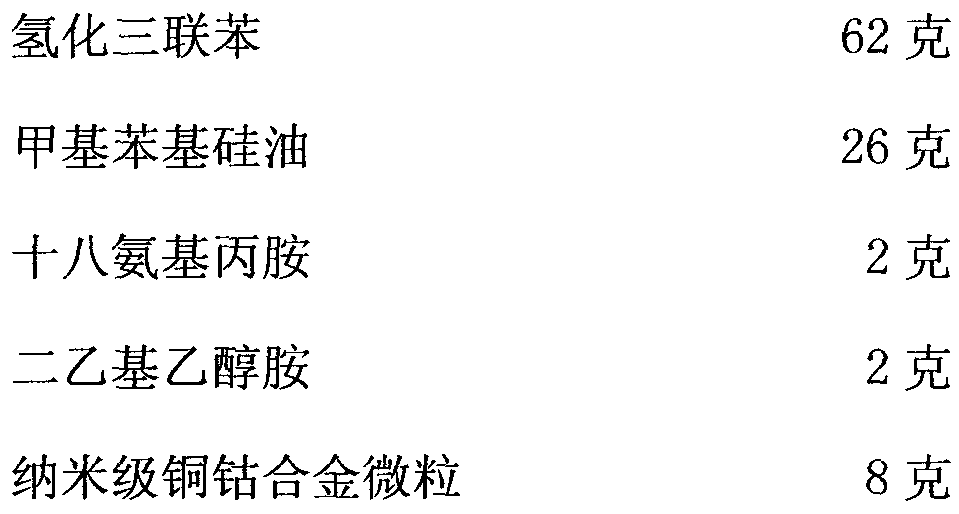

Novel nanometer-grade copper-cobalt alloy micro-particle heat conducting liquid material

InactiveCN104479640AFast heat dissipationHeat-exchange elementsHeat conductingHydrogenated terphenyls

The invention discloses a novel nanometer-grade copper-cobalt alloy micro-particle heat conducting liquid material and belongs to the field of energy chemistry. The prescription of the novel nanometer-grade copper-cobalt alloy micro-particle heat conducting liquid material is characterized by consisting of hydrogenated terphenyl, methyl phenyl silicone oil, octadecylamino-propylamine, diethylethanolamine and nanometer-grade copper-cobalt alloy micro-particles. The invention aims to provide a novel heat conducting liquid material which is high in heat conduction efficiency, rapid in cooling and mainly applied to a solar CSP photo-thermal power generation system and takes nanometer-grade copper-cobalt alloy micro-particles as a dispersion phase. The novel nanometer-grade copper-cobalt alloy micro-particle heat conducting liquid material disclosed by the invention is 1.32W / m.K to 2.6W / m.K in heat conduction coefficient which is about ten times that of the prior art and is far faster than the same type of products in the prior art in cooling speed, which is just the core value of the novel nanometer-grade copper-cobalt alloy micro-particle heat conducting liquid material disclosed by the invention.

Owner:冯智勇

A two-phase mixture for capturing carbon dioxide

ActiveCN106984152BPromote regenerationIncrease speedGas treatmentDispersed particle separationEthylene diamineDesorption

The invention provides a novel two-phase mixture for trapping carbon dioxide, and belongs to the field of technologies for trapping carbon dioxide gas. The novel two-phase mixture comprises two phases including, by weight, 99.0-99.5 wt% of non-aqueous solution and 0.5-1.0 wt% of porous solid materials. The non-aqueous solution comprises, by weight, 30-50 wt% of solutes and 50-70 wt% of solvents, and the solutes are N-ethylethanolamine; the solvents are N, N-diethyl ethylene diamine. The solid porous materials are TiO (OH) 2. The novel two-phase mixture has the advantages that the non-aqueous solution is modified by the TiO (OH) 2, absorption effects of the non-aqueous solution cannot be improved by the TiO (OH) 2, but the desorption rate can be greatly increased by the TiO (OH) 2, the optimal desorption rate can reach 250 Nm<3> CO2 / m<3> solution, and the desorption rate can be increased as compared with the original non-aqueous solution.

Owner:DALIAN UNIV OF TECH

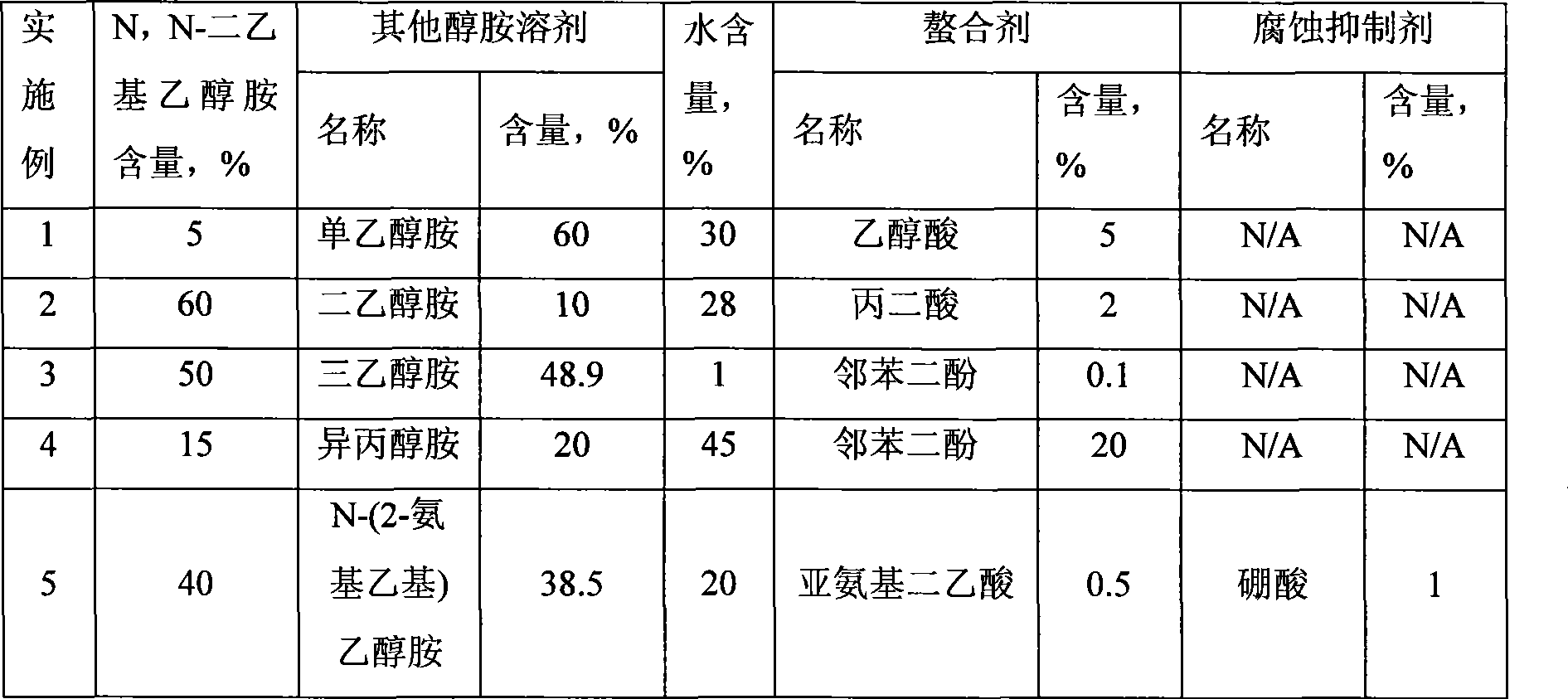

Cleanout fluid for removing photoresist layer residue

ActiveCN101685273BGood removal effectReduce corrosion rateNon-surface-active detergent compositionsDetergent mixture composition preparationAlcoholSolvent

A rinse solution for removal of etching residues includes N,N-diethyl ethanolamine, other alcohol amine, water and chelanting agent. And the corrosion rate of the rinse solution to some metals and some non-metals is low. The rinse solution can be used to remove etching residues of the wafer. And the rinse solution can be used in micro electronic field for the cleaning of metals and semiconductor wafer.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Method for preparing epoxy-group-base conductive ink composition

The invention provides a method for preparing an epoxy-group-base conductive ink composition. Epoxy resin, coloring pigments, tributyl(1-ethoxy ethylene)tin, carbitol acetate and silver-coated copper powder are added into a reaction still by weight, stirring is conducted at the rotational speed of 200-500 rpm for 20-80 min, and grinding is conducted to obtain an intermediate product; then, soybean oil, water, wetting agents and N,N-diethylethanolamine are added, stirring is conducted at the rotational speed of 400-700 rpm for 30-90 min, filtering is conducted, and filtered emulsion is collected; defoaming agents and the intermediate product are added, stirring is conducted at the rotational speed of 200-600 rpm for 60-120 min, and the epoxy-group-based conductive ink composition is obtained.

Owner:义乌市诠铈新材料有限公司

Method for removing H2S in crude oil

The invention discloses a method for removing H2S in crude oil. A desulfurization agent is made into a plurality of solid desulfurization rods to be added into a well from an inlet, thus a porous channel for the crude oil and natural gas is formed between the solid desulfurization rods, and when the crude oil is out of the well, the solid desulfurization rods make contact with the crude oil and react with the H2S in the crude oil. The raw materials of the solid desulfurization rods comprise N, N-diethyl ethylene diamine, sodium carbonate, triethanolamine, EDTA and polyacrylamide. According tothe method, the concentration of the solid agent is high, dissolution is slow, the action time of the agent is long, removing of the hydrogen sulfide is rapid, dosing is convenient, and the H2S can beremoved before the crude oil is extracted out of the well without additionally arranging other devices in the oil well.

Owner:西安凯尔文石化助剂制造有限公司

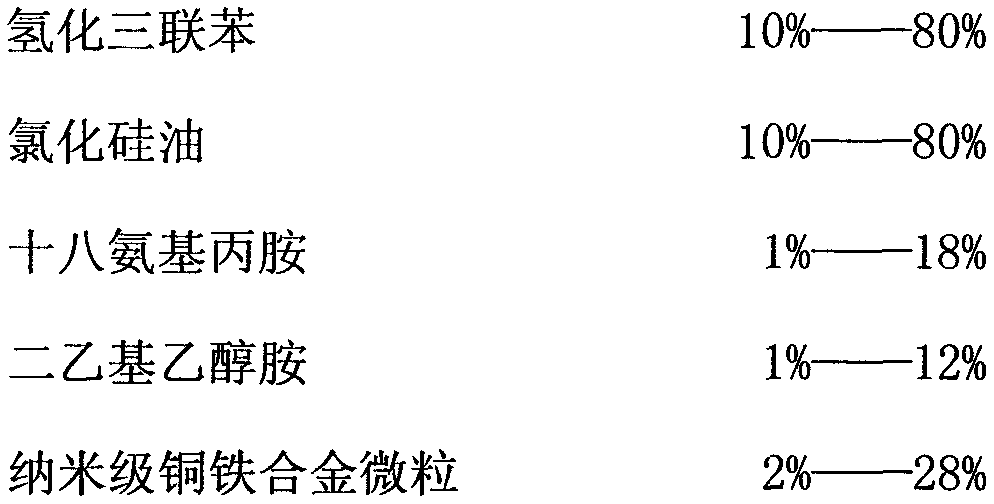

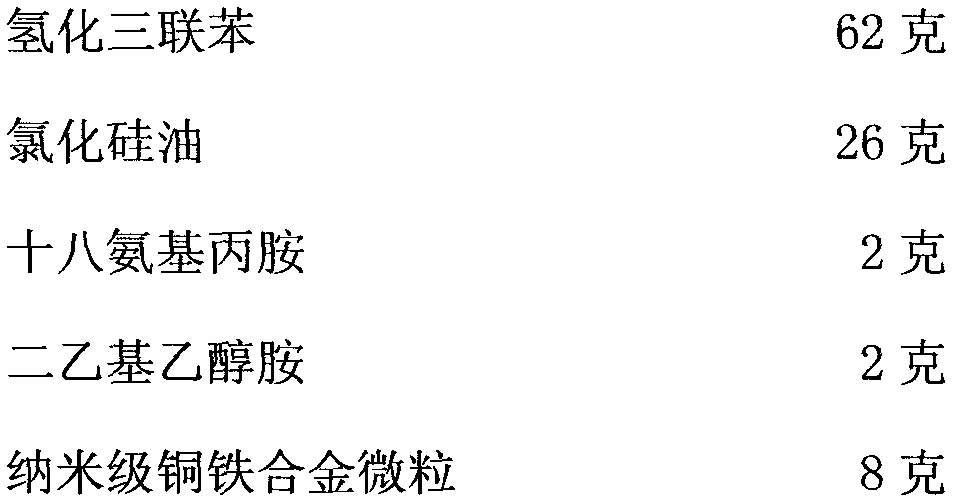

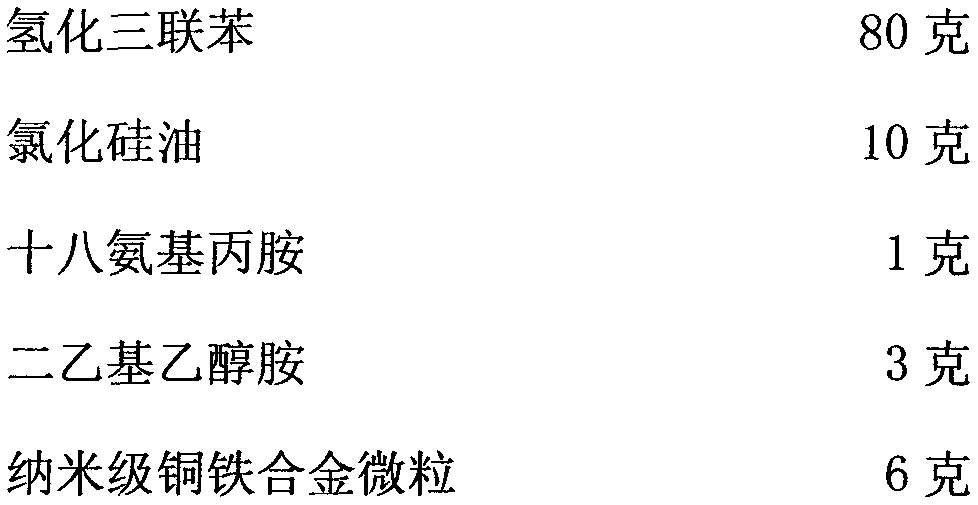

Novel nanometer-grade copper-iron alloy micro-particle heat conducting liquid material

The invention discloses a novel nanometer-grade copper-iron alloy micro-particle heat conducting liquid material and belongs to the field of energy chemistry. The prescription of the novel nanometer-grade copper-iron alloy micro-particle heat conducting liquid material is characterized by consisting of hydrogenated terphenyl, chloridized silicon oil, octadecylamino-propylamine, diethylethanolamine and nanometer-grade copper-iron alloy micro-particles. The invention aims to provide a novel heat conducting liquid material which is high in heat conduction efficiency, rapid in cooling and mainly applied to a solar CSP photo-thermal power generation system and takes nanometer-grade copper-iron alloy micro-particles as a dispersion phase. The novel nanometer-grade copper-iron alloy micro-particle heat conducting liquid material disclosed by the invention is 1.2W / m.K to 2.3W / m.K in heat conduction coefficient which is about ten times that of the prior art and is far faster than the same type of products in the prior art in cooling speed, which is just the core value of the novel nanometer-grade copper-iron alloy micro-particle heat conducting liquid material disclosed by the invention.

Owner:冯智勇

A kind of non-aqueous decarburization solution for capturing carbon dioxide in mixed gas and its application

ActiveCN104492226BIncrease loadHas a steric hindrance effectDispersed particle separationAir quality improvementChemical reactionAbsorption capacity

Owner:DALIAN UNIV OF TECH

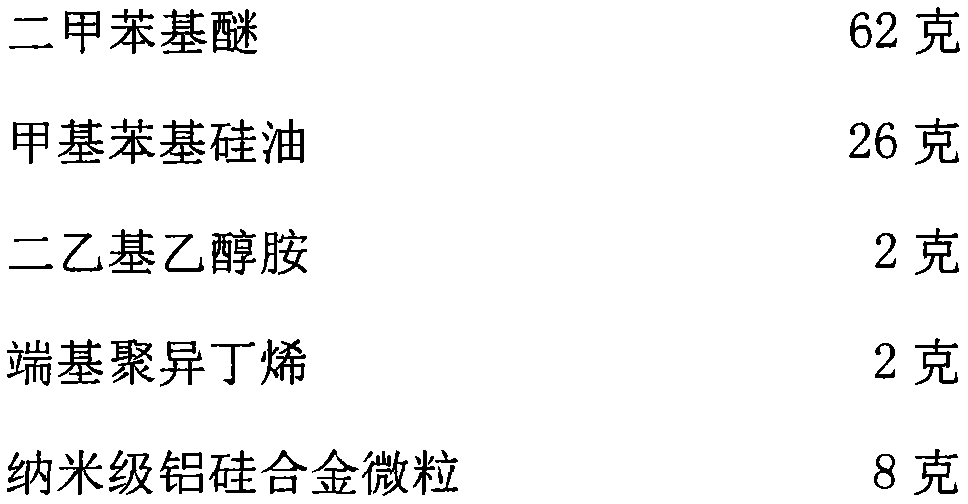

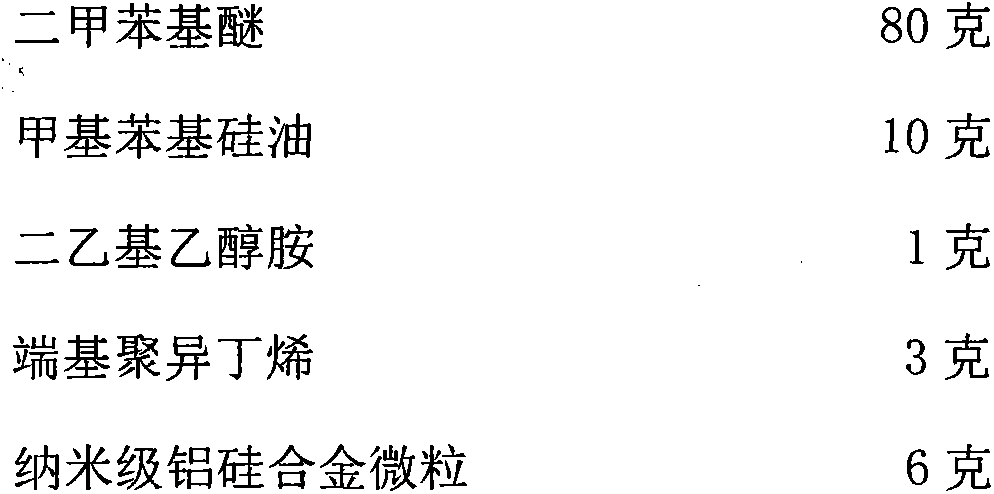

Nanoscale aluminum silicon alloy microparticle containing heat transfer fluid new material

The invention discloses a nanoscale aluminum silicon alloy microparticle containing heat transfer fluid new material, and belongs to the chemical energy field, and the nanoscale aluminum silicon alloy microparticle containing heat transfer fluid new material formula is characterized by comprising ditolyl ether, methyl phenyl silicone oil, diethyl ethanolamine, end group polyisobutylene and nanoscale aluminum silicon alloy microparticles. The purpose of the present invention is to provide a high heat transfer efficiency and fast heat dissipation heat transfer fluid new material which is mainly used in solar CSP solar-thermal generating power system and contains the nanoscale aluminum silicon alloy microparticles as a dispersed phase, the heat transfer coefficient of the heat transfer fluid new material is 1.55 W / m. K-2.45 W / m. K, and is about 10 times of the heat transfer coefficient of existing technology, the heat dissipation speed is far faster than that of the similar products of the existing technology, and the core values of the heat transfer fluid new material is the fast heat dissipation speed.

Owner:冯智勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com