Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "No adverse effect on performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphate aluminum cement. The method comprises the following steps: preparing cement raw meal by proportioning limestone, phosphogypsum, low grade alumina and coke; uniformly grinding and calcining at high temperature; in the calcining process, promoting phosphogypsum to be decomposed as much as possible; replacing partial limestone by calcium oxide generated by decomposition; collecting sulfur dioxide to prepare sulfuric acid; and adding natural dihydrate gypsum in the cement clinker and grinding to prepare a cement product. Compared with the existing conventional production methods, according to the method, the utilization of phosphogypsum can be greatly improved, the utilization concentration of sulfur dioxide discharged by decomposition of little gypsum in the production process can be guaranteed to be reached, the use level of limestone is further reduced and emission of carbon dioxide is reduced. Cement calcined is wide in adaptability, can be widely applied to production of sulphate aluminum cement by phosphogypsum, and further can be suitable for producing high early strength cement, expansive cement and the like.

Owner:CHONGQING UNIV

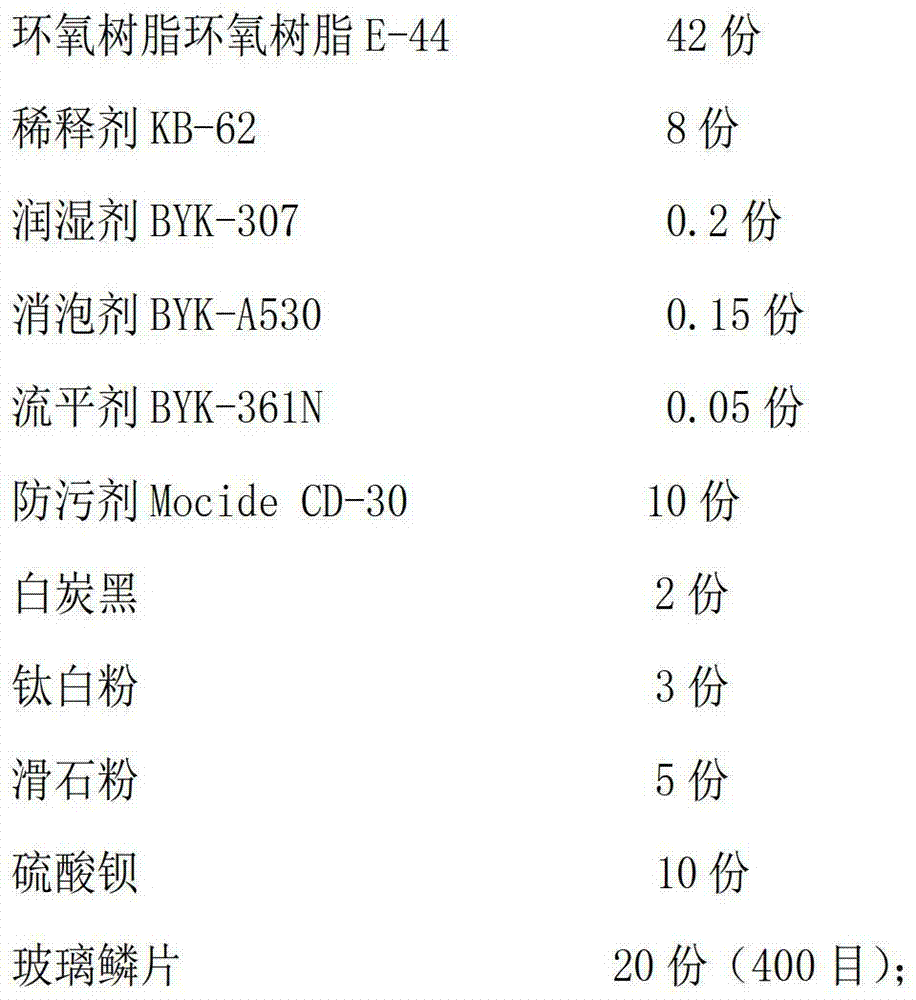

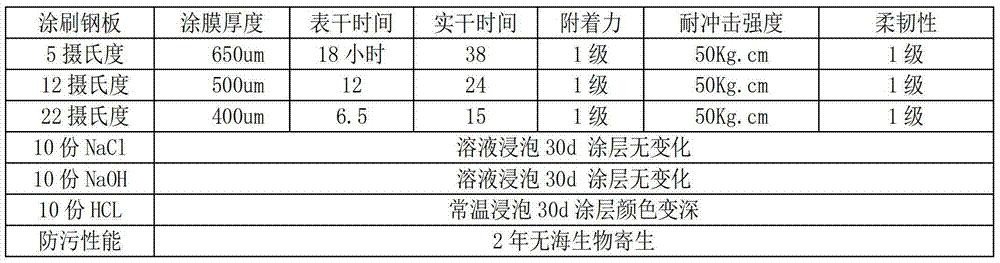

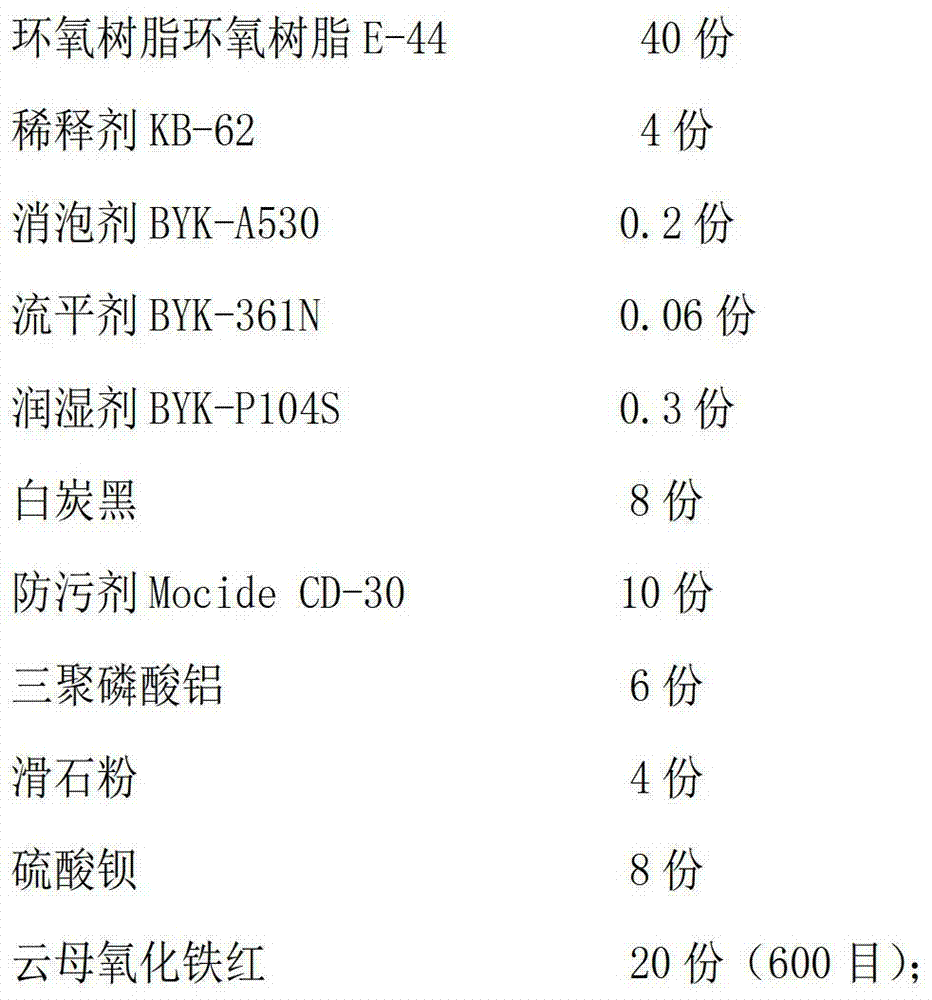

Underwater coating anti-pollution and anti-corrosion epoxy coating and preparation method thereof

InactiveCN103289531ALow halogen contentNon-irritatingAntifouling/underwater paintsPaints with biocidesUnderwaterCarbonate

The invention discloses an underwater coating anti-pollution and anti-corrosion epoxy coating and a preparation method thereof. The underwater anti-pollution and anti-corrosion epoxy coating provided by the invention can solve the difficult problem that an amine type curing agent which is matched with the epoxy coating used at normal temperature for underwater coating reacts with water and carbon dioxide in the water or air to generate carbonates, so that a bonded layer is isolated by the carbonates, the adhesion is greatly reduced, the bonding force is reduced by above 50% in comparison with a dry environment, a coat is easy to shed, and the anti-corrosion capability is poor. The anti-pollution and anti-corrosion coating disclosed by the invention has the advantages of good underwater coating anti-corrosion performance, strong adhesion, great impact resistance and good flexibility, and can effectively prevent the problems that a paint film is damaged, and the damages and corrosion of a steel plate and concrete are accelerated due to the parasitic attachment of marine organisms.

Owner:CHANGSHA SHENGKANG HIGH POLYMER MATERIAL TECH

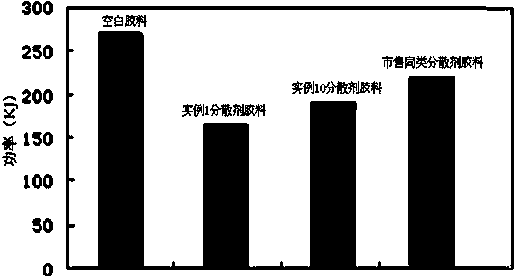

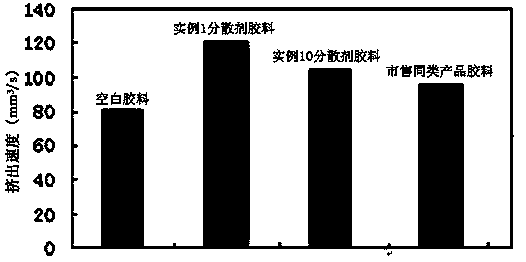

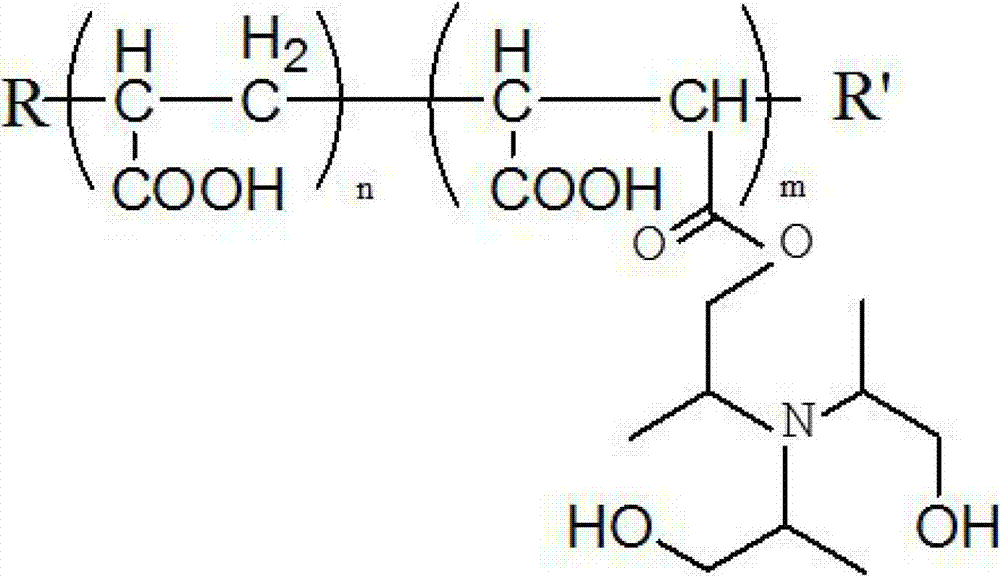

White carbon black dispersant for rubber and preparation method of white carbon black dispersant

ActiveCN103450504AIncreased process safetyImprove mechanical propertiesRubber materialPolymer science

The invention discloses a white carbon black dispersant for rubber. The white carbon black dispersant is characterized by comprising the following raw materials in parts by weight: 30-70 parts of fatty acyl amide / acid amide, 10-30 parts of fatty acid ester and 0-30 parts of fatty acid soap salt. The invention also discloses a preparation method of the white carbon black dispersant. The preparation method is simple and rapid; and the obtained white carbon black dispersant has multiple functions such as dispersion, lubrication and chemical modification, can be used for improving the processing safety performance as well as physical and mechanical properties of a rubber material and increasing the curing speed of the rubber material and is remarkable in effect.

Owner:SHANDONG YANGGU HUATAI CHEM

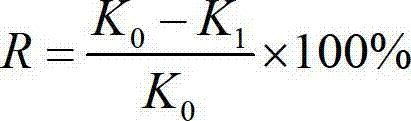

Grinding additive for powder-grinding steel slag in vertical mill

The invention discloses a grinding additive for powder-grinding steel slag in a vertical mill. The grinding additive is prepared from the following raw materials in percentage by weight: 1-5 percent of polyacrylic acid, 5-10 percent of molasses, 1-5 percent of sodium hexametaphosphate, 2-6 percent of tetraethylammonium oxalic acid, 3-10 percent of triethanolamine, 5-20 percent of aluminum sulfate and 46-81 percent of carriers. All components of the grinding additive are cooperated with each other, so that the grinding efficiency of the steel slag in the vertical mill is improved, the active indexes are improved, and the adverse effect on cement and concrete performance is avoided. Compared with the prior art, the grinding additive for grinding steel slag in the vertical mill has the advantages that a material layer can be stabilized, the yield of the mill is increased, and the active indexes of the high steel slag powder 7d and 28d can also be increased.

Owner:SHANDONG HONGYI TECH

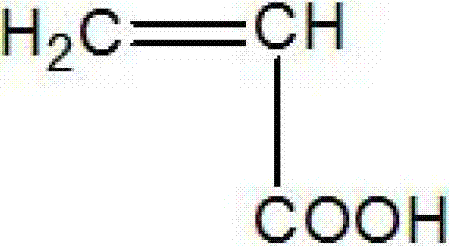

Synthetic method of polyethylene glycol amine ester-carboxylic acid macromolecule grinding aid

InactiveCN103113510ALarge specific surface areaNo adverse effect on performancePolyethylene glycolCarboxylic acid

The invention relates to a synthetic method of a polyethylene glycol amine ester-carboxylic acid macromolecule grinding aid. The synthetic method comprises the following steps of: weighing crylic acid, triisopropanolamine and maleic anhydride according to molar ratio of raw materials, firstly adding the maleic anhydride and the triisopropanolamine, and heating for reaction to obtain solution 1; then neutralizing the crylic acid by NaOH solution to obtain solution 2; dropwise adding an initiator peroxosulfuric acid after the two solutions are mixed, and stirring for reaction to obtain the polyethylene glycol amine ester-carboxylic acid macromolecule grinding aid. By utilizing the synthetic method, the effective mixing amount of the grinding aid can be greatly reduced to reduce the production cost.

Owner:NANCHANG UNIV

Composite foamable agent and its preparation method

ActiveCN1907552AImproved dispersion and fluidityImprove liquidityTransportation and packagingMixingBicarbonateSodium bicarbonate

The invention relates to a composites foaming agent, which comprises inorganic foaming agent as bicarbonate and molecule screen, while the amount of molecule screen is 0.5-50 deals when the bicarbonate is 100 deals, wherein the bicarbonate can use baking soda, potassium acid carbonate, or ammonium acid carbonate or the mixture of them; and the preparation comprises: selecting the bicarbonate; breaking with machine or airflow; then mixing the inorganic foaming agent with molecule screen in the mixer; the invention has the advantages that: 1, it has better flow property and disperse property; it can effectively increase the foaming time and the contract rate of product; 3, it can foam the macromolecule polymer that sensitive to water; 4, the added macromolecule screen will not affect the property of macromolecule polymer.

Owner:HANGZHOU HI TECH FINE CHEM

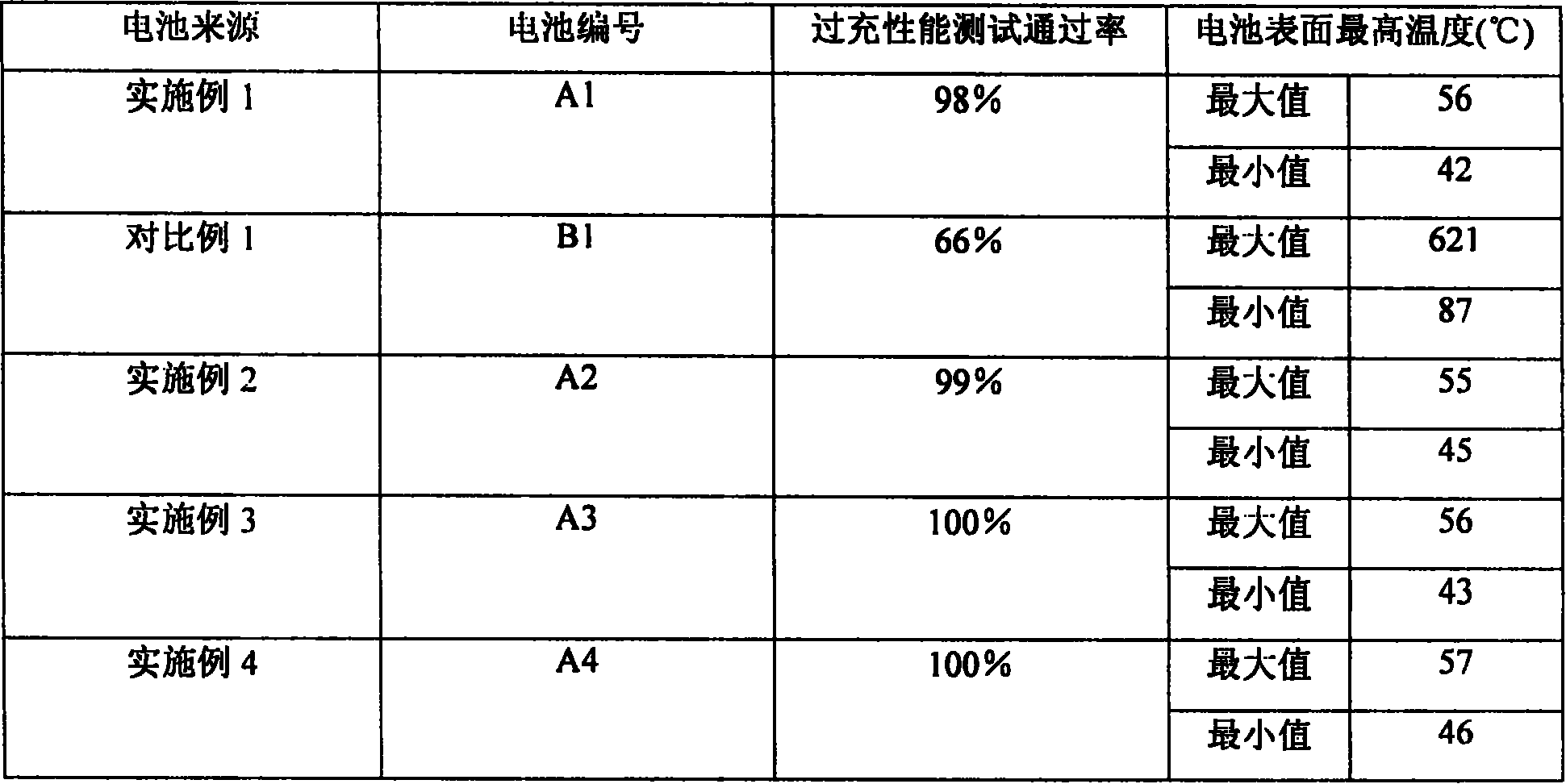

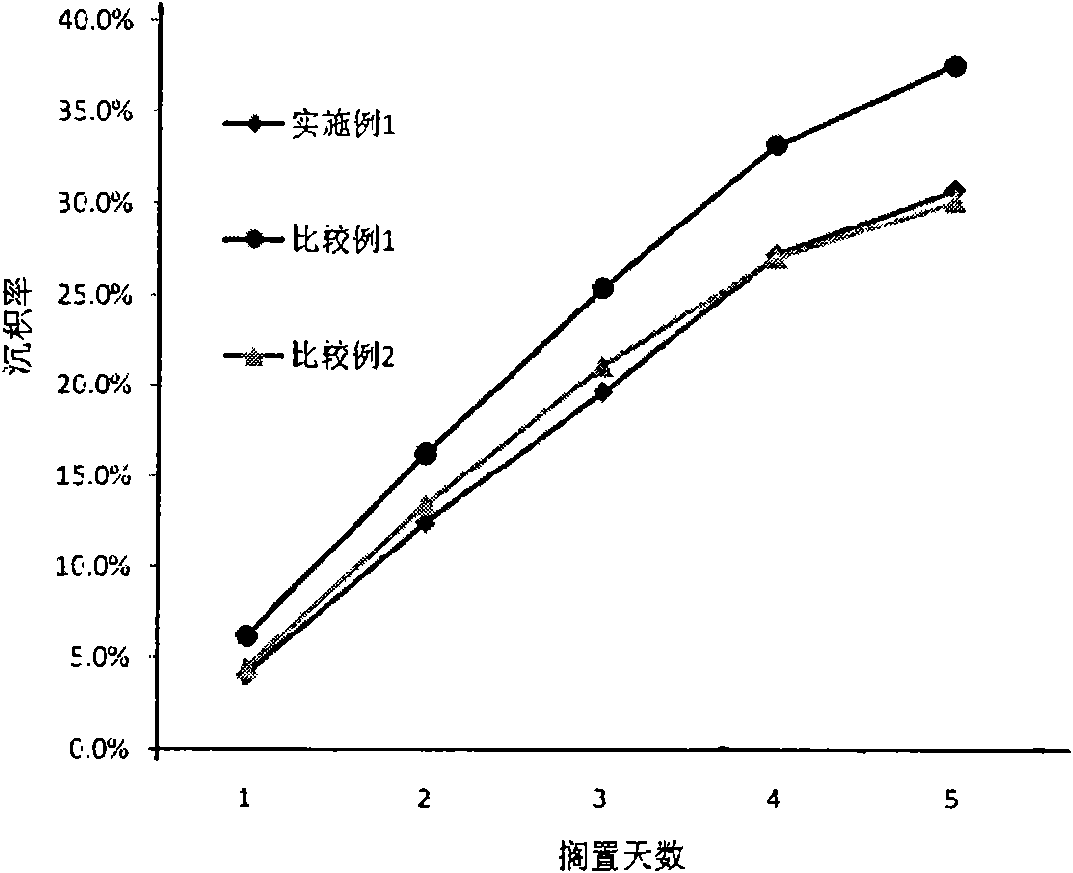

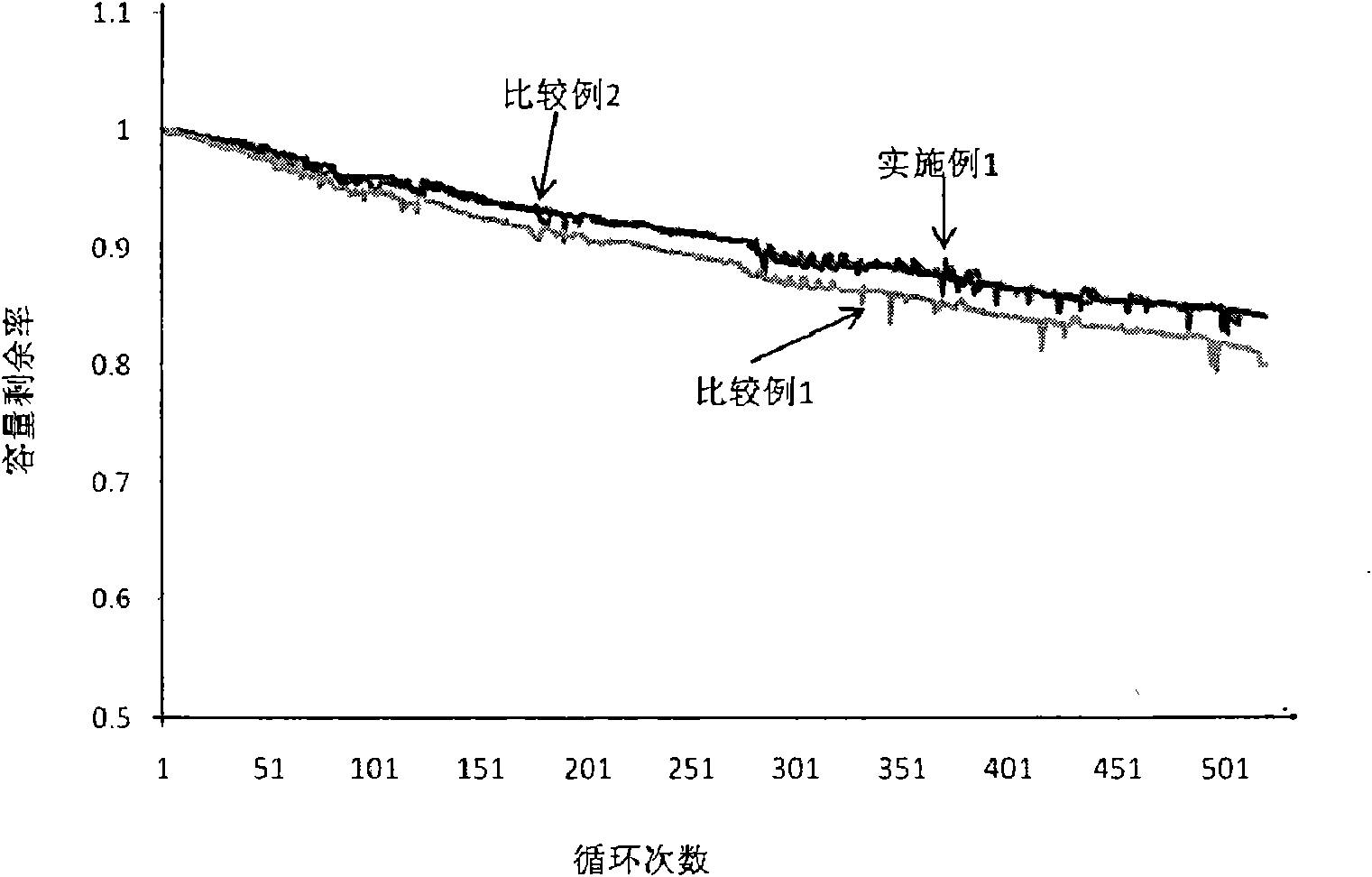

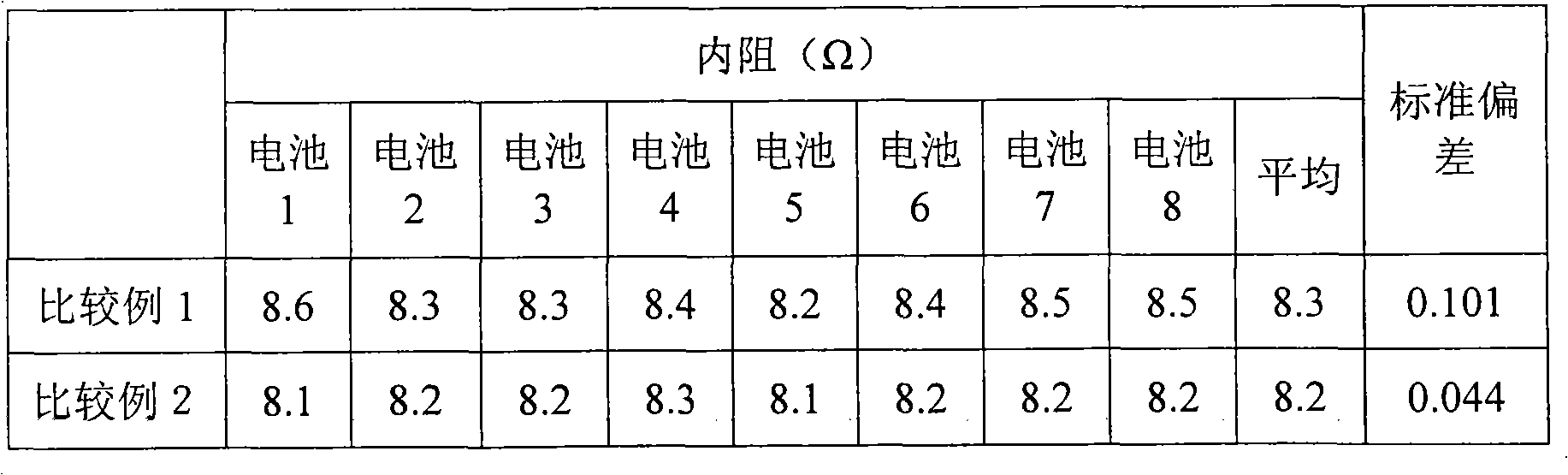

Method for producing anode of lithium ion battery

ActiveCN101179123AImprove overcharge performance test pass rateNo adverse effect thicknessElectrode manufacturing processesAdhesivePass rate

A preparation method for making lithium ion battery cathode, including the processes: coat current collector with cathode slurry and then parch chip to get the current collector which contains cathode material layer; squash current collector which contains cathode material layer; the cathode material layer contains cathode active substance and adhesive; the adhesive is at melting when squashing current collector which contains cathode material layer. The invention gets battery positive plate by hot-pressing when the adhesive is at melting and improves the pass rate of over-charge property of battery which adopts the cathode plate remarkably; for example, the pass rate of over-charge property of the lithium ion battery which is made according to the invention method is much higher than that of the lithium ion battery which is made according to the current method.

Owner:BYD CO LTD

High-temperature-resistant viscosity-reduction filtrate reducer for drilling fluid and preparation method of filtrate reducer

The invention relates to a high-temperature-resistant viscosity-reduction filtrate reducer for a drilling fluid and a preparation method of the filtrate reducer. The filtrate reducer comprises the raw materials of waste acrylon fibers, alkali, mineral acid, hydrogen peroxide, lignite, a sulfonating agent, formaldehyde, copperas and water, wherein the waste acrylon fibers and part of alkali are added in water for reaction at the temperature of 85-95 DEG C; the mineral acid and the hydrogen peroxide are added when the temperature is reduced to 80-85 DEG C, and then the temperature is increased to 85-95 DEG C for reaction for 1-3 h; the remained alkali, lignite, sulfonating agent and formaldehyde are added for reaction for 1-3 hours at the temperature of 85-95 DEG C; the temperature is reduced to 60-80 DEG C, and then ferrous sulfate is added for reaction for 10-30 min; and finally, the product is fetched for drying and smashing. The obtained filtrate reducer not only can reduce the drilling fluid viscosity, but also has a good de-filtration effect and is resistant to high temperature. The filtrate reducer takes the waste acrylon fibers and the lignite as main raw materials, is low in cost and simple in process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

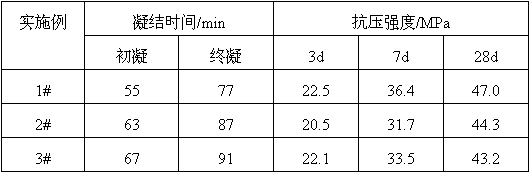

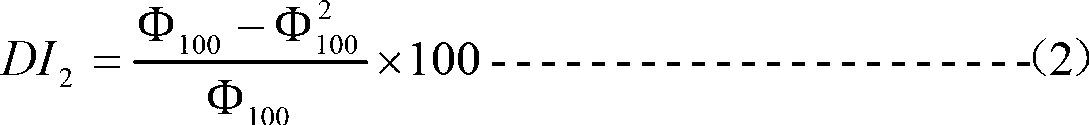

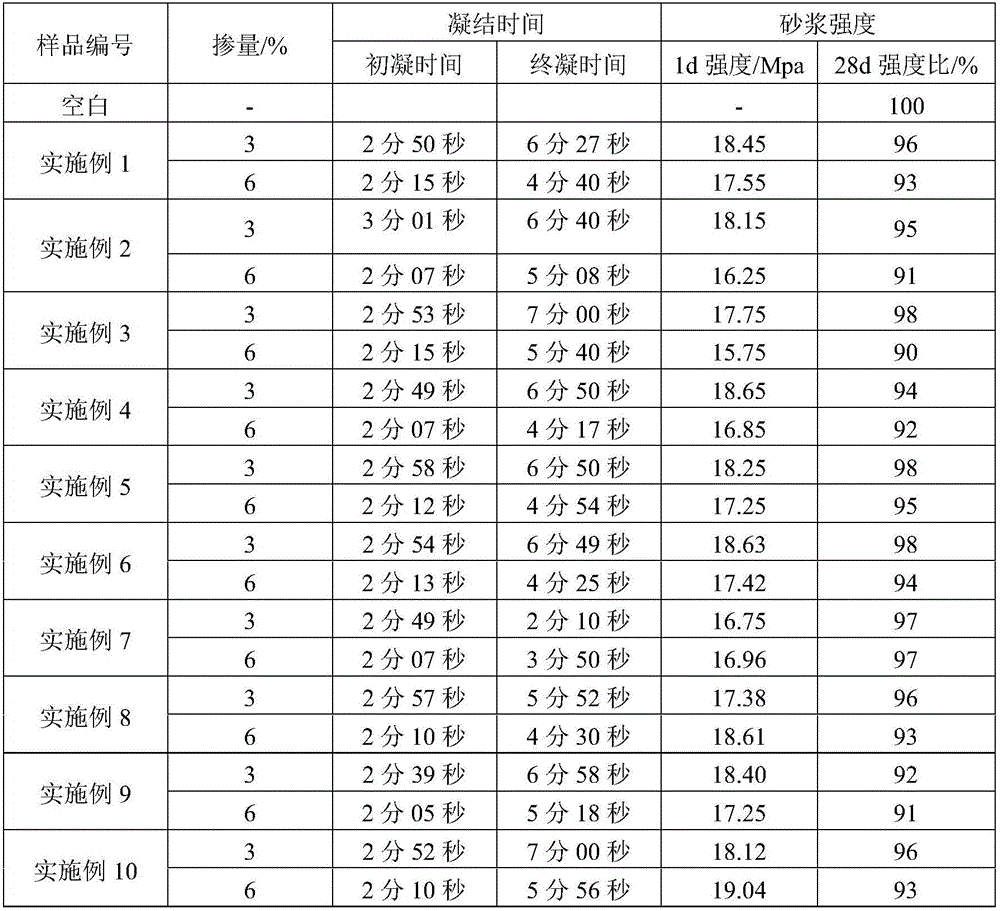

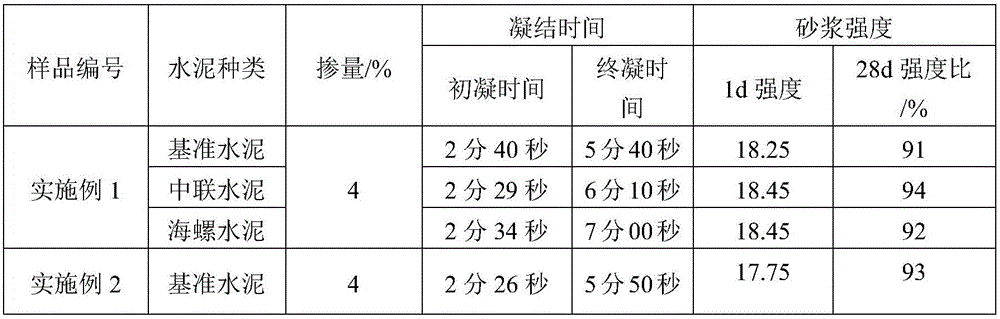

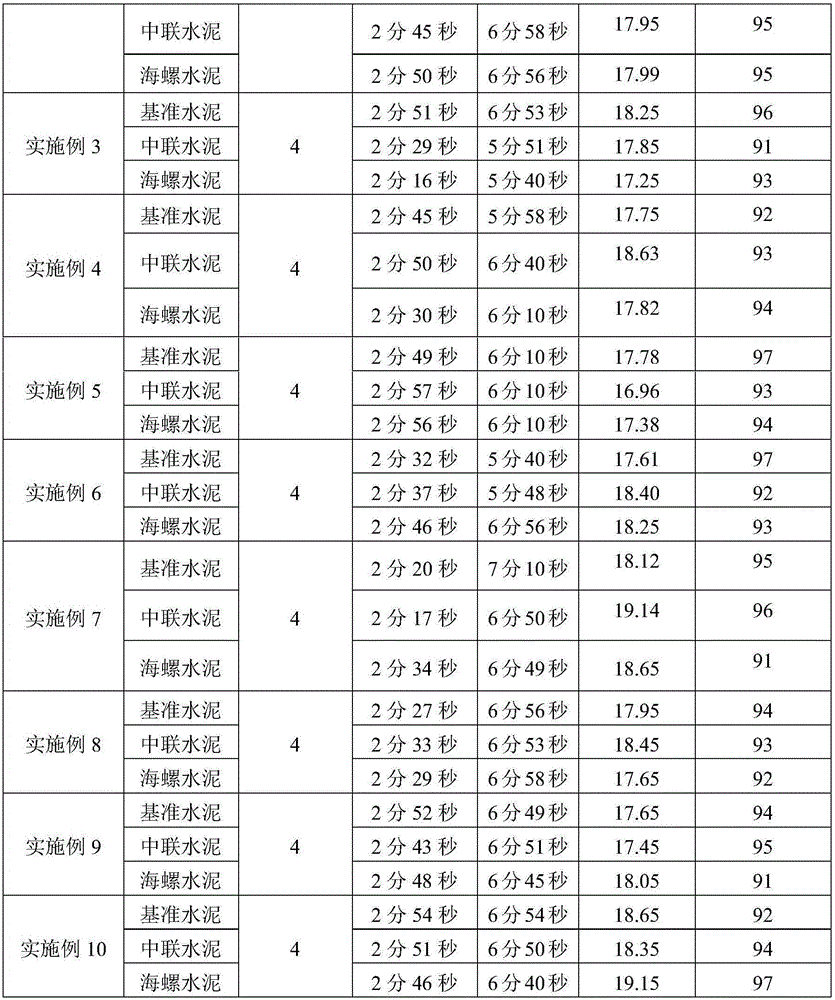

Preparation method for reinforced low-resilience and low-alkaline liquid concrete accelerator

The invention discloses a preparation method for a reinforced low-resilience and low-alkaline liquid concrete accelerator. The accelerator comprises material components with mass percentages as follows: 30-54% of liquid modified sodium aluminate, 0.8-5% of modified alcohol-amine organic micromolecules,0.1-0.3% of polyacrylamide and the balance of water; firstly, modified alcohol-amine organic micromolecules are prepared and then dropwise added into modified sodium aluminate solution, water is added under stirring, then polyacrylamide is added under stirring, and the reinforced low-resilience and low-alkaline liquid concrete accelerator is prepared. The method has the advantages that the preparation cost is low, the process is simple, and the prepared concrete accelerator has good stability suitable for concrete wet-spraying process and has the advantages of low admixture amount, low resilience ratio, short condensation time, low alkali content, good adaptability to cement, no adverse effect on concrete performance, and the like.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

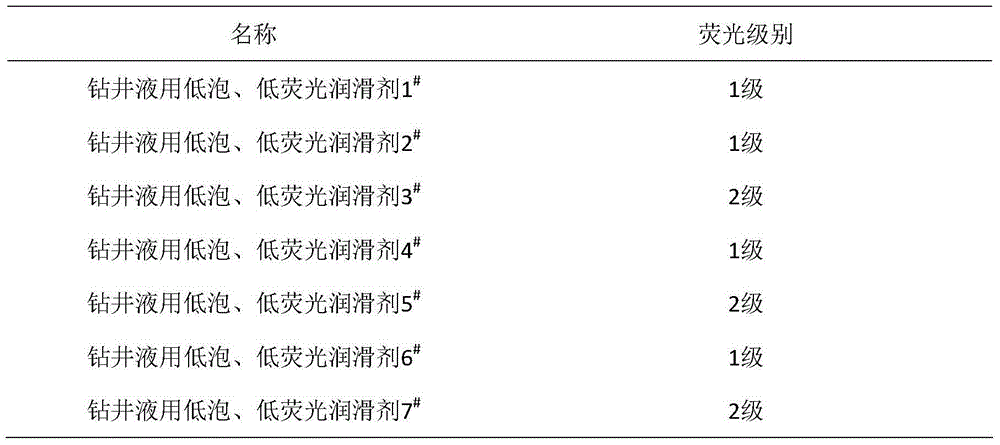

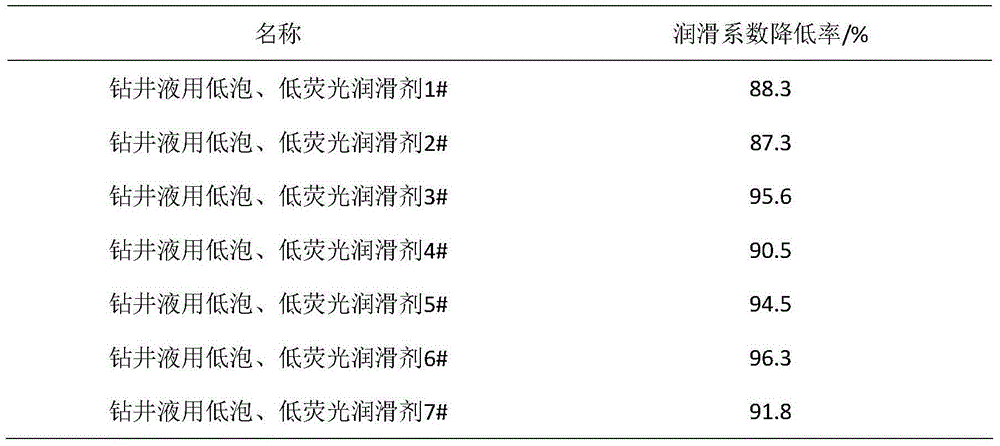

Lubricant and preparation method thereof

InactiveCN104877652ALow fluorescence levelDoes not affect geological loggingDrilling compositionBase oilSURFACTANT BLEND

The invention discloses a lubricant for drilling fluids, which is composed of the following components in percentage by mass: 20-40% of base oil, 40-60% of fatty acid ester, 5-10% of surfactant and 3-10% of defoaming agent. The preparation method of the lubricant comprises the following steps: adding the base oil and fatty acid ester into a reaction kettle, heating to 50-80 DEG C, stirring at high speed for 0.5-1 hour, slowly adding the surfactant, stirring at high speed for 0.5-1 hour, heating to 70-100 DEG C, adding the defoaming agent, continuing stirring for 0.5-1 hour, and cooling.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Lithium ion battery cathode slurry and preparation method thereof

InactiveCN101609882ANo adverse effect on performancePerformance impactElectrode manufacturing processesActive material electrodesSlurryOil water

The invention belongs to the field of lithium ion batteries and discloses lithium ion battery cathode slurry and a preparation method thereof. The formula of the slurry is as follows: solid raw materials comprise 90-94 weight parts of graphite, 1-2 weight parts of carbon black and 4-5 weight parts of binding agent LA 132; a solvent is prepared by mixing deionized water with methylpyrrolidone according to the weight ratio of 7:1-12:1; and the weight ratio between the solid raw materials and the liquid material is 1:1.1-1.3. The oil-water mixed slurry prepared according to the preparation method has greatly reduced cost when being compared with oily slurry, can improve the stability of the slurry when being compared with aqueous slurry, and exerts no negative influence on the performance of a battery.

Owner:JIANGSU FRONT NEW ENERGY

Water-based drilling fluid plugging material and preparation method thereof

InactiveCN106609126AWide range of particle size distributionGood dispersionDrilling compositionFiberWater based

The invention discloses a water-based drilling fluid plugging material and a preparation method thereof, and relates to the technical field of water-based drilling fluid plugging materials. The water-based drilling fluid plugging material is characterized by comprising, by mass, 20-50% of water-soluble expansion materials, 5-15% of a cross-linking agent, 5-10% of a retarder, 10-25% of modified fibers and 10-30% of calcium carbonate. The water-based drilling fluid plugging material has the advantages of being large in plugging coverage, high in pressure bearing capacity, good in plugging effect, simple in site configuration process and the like, and can achieve the purposes of reducing the well leakage loss and reducing the composite cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

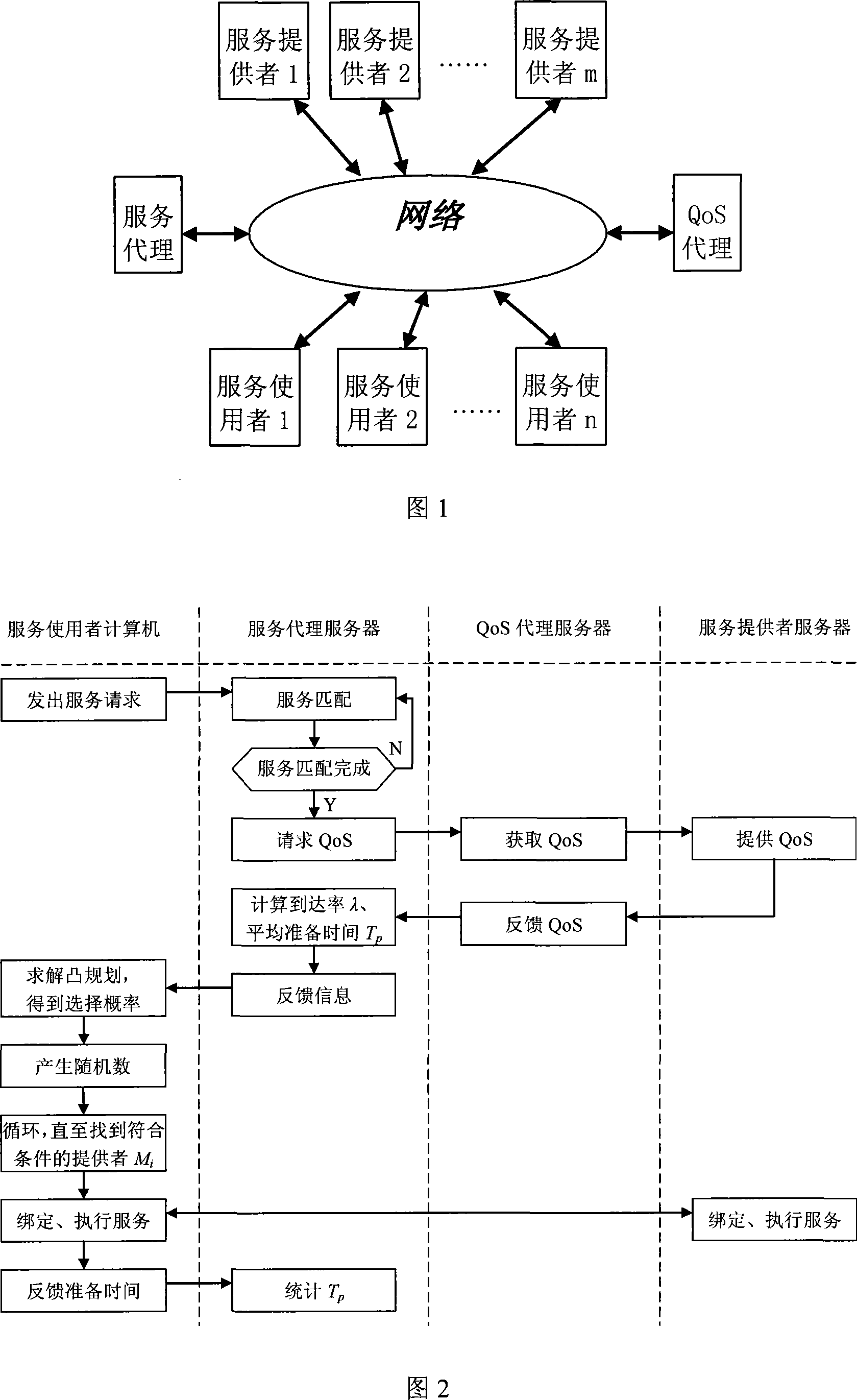

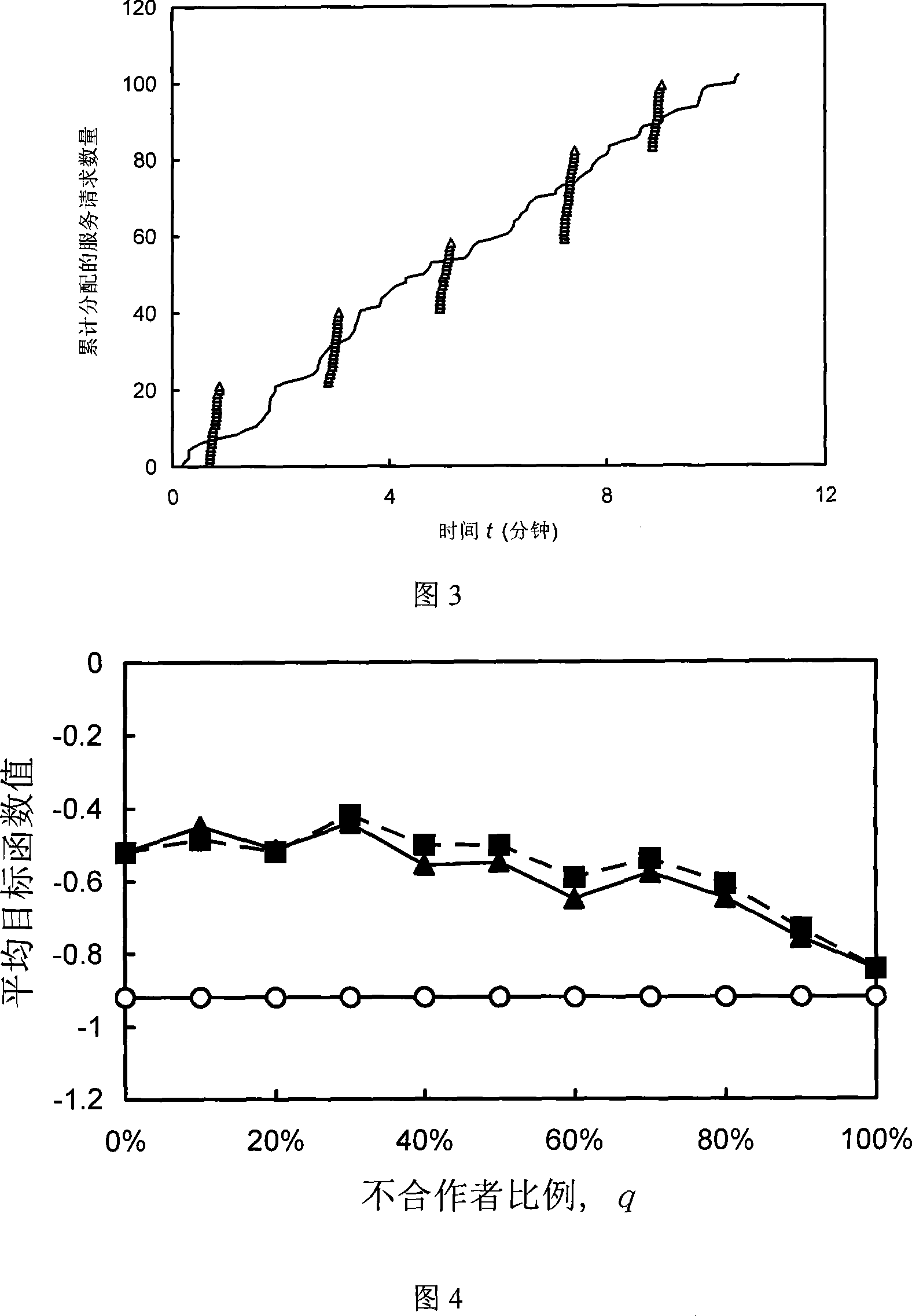

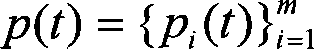

Mixed strategy method for optimizing aggregative indicator under service oriented architecture SOA

InactiveCN101110841ANo adverse effect on performanceReduce paymentTransmissionSpecific program execution arrangementsService providerStrategy method

The present invention discloses an optimizing aggregative indicator mixed strategy method under the service oriented architecture SOA, which belongs to the SOA technical field, and is characterized in that according to demand to each QoS index, the service provider sets the choice probability for the service provider get which is matched and from the service agent, and then a service provider is chosen with the roulette method according to the random number. The method is superior to other methods in the average objective function value, the maximum objective function value, the average waiting time, the maximum waiting time, the average queuing length, and the maximum queuing length.

Owner:TSINGHUA UNIV

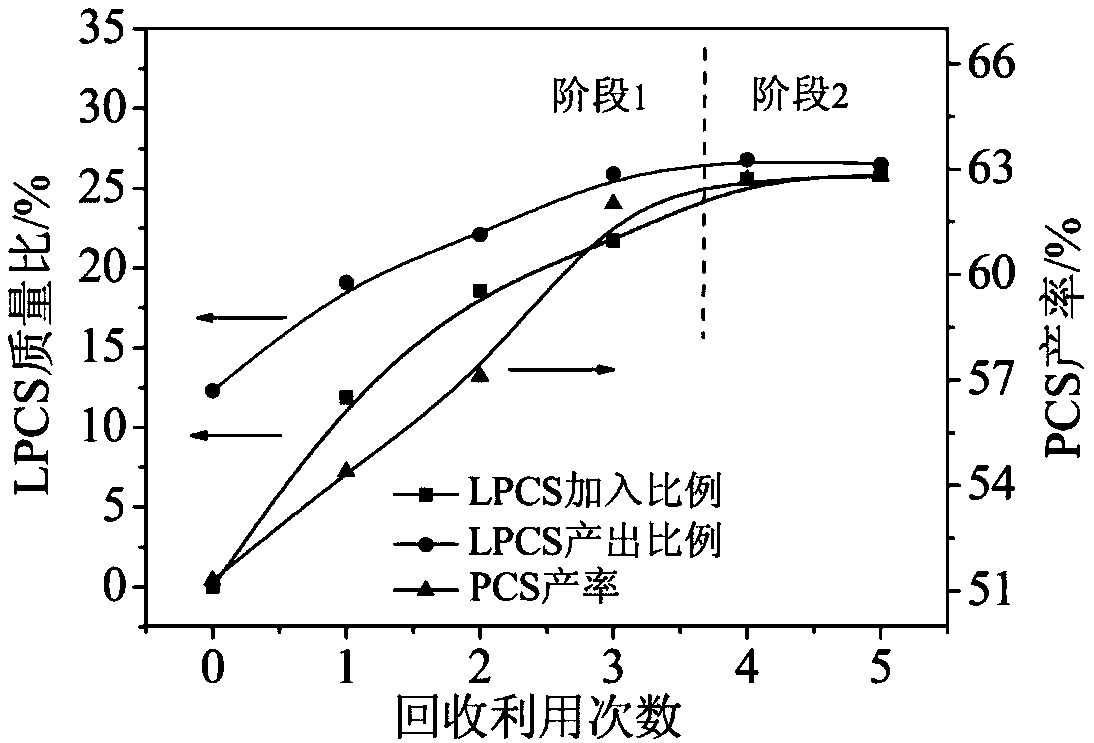

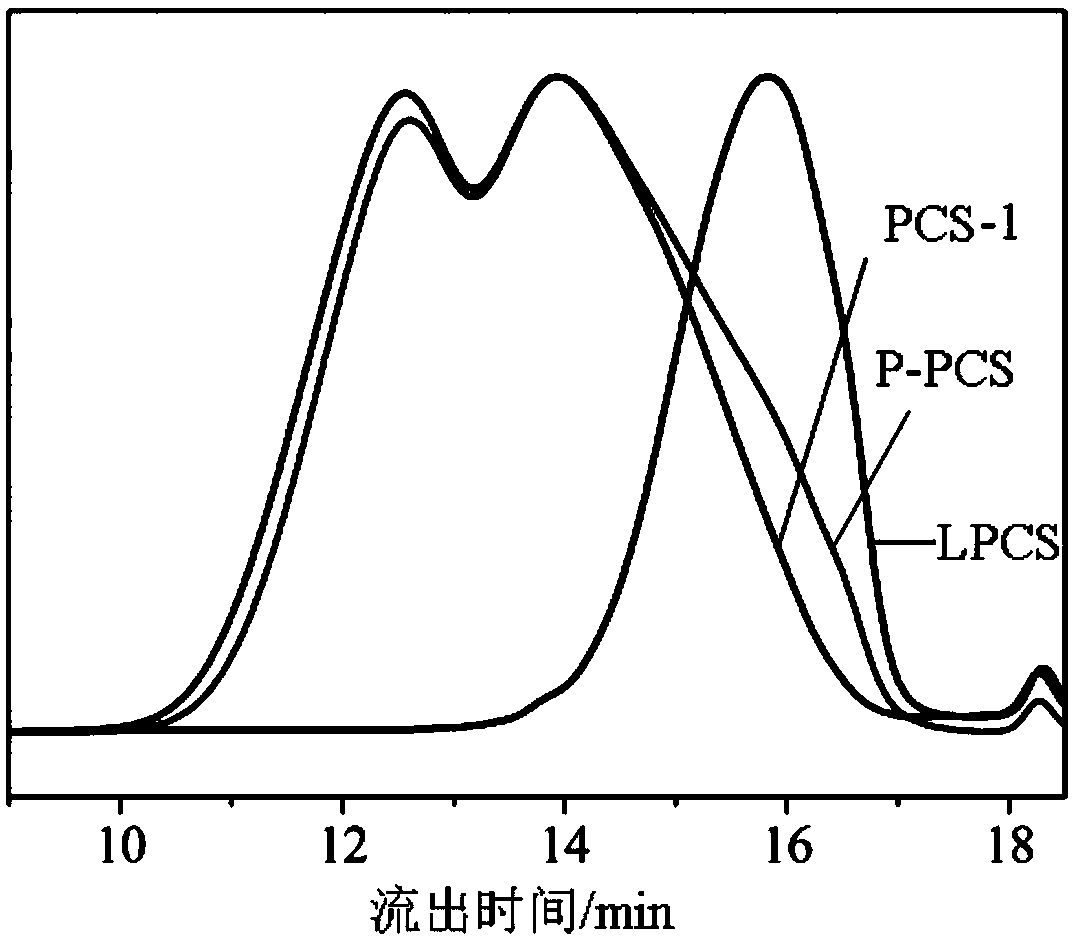

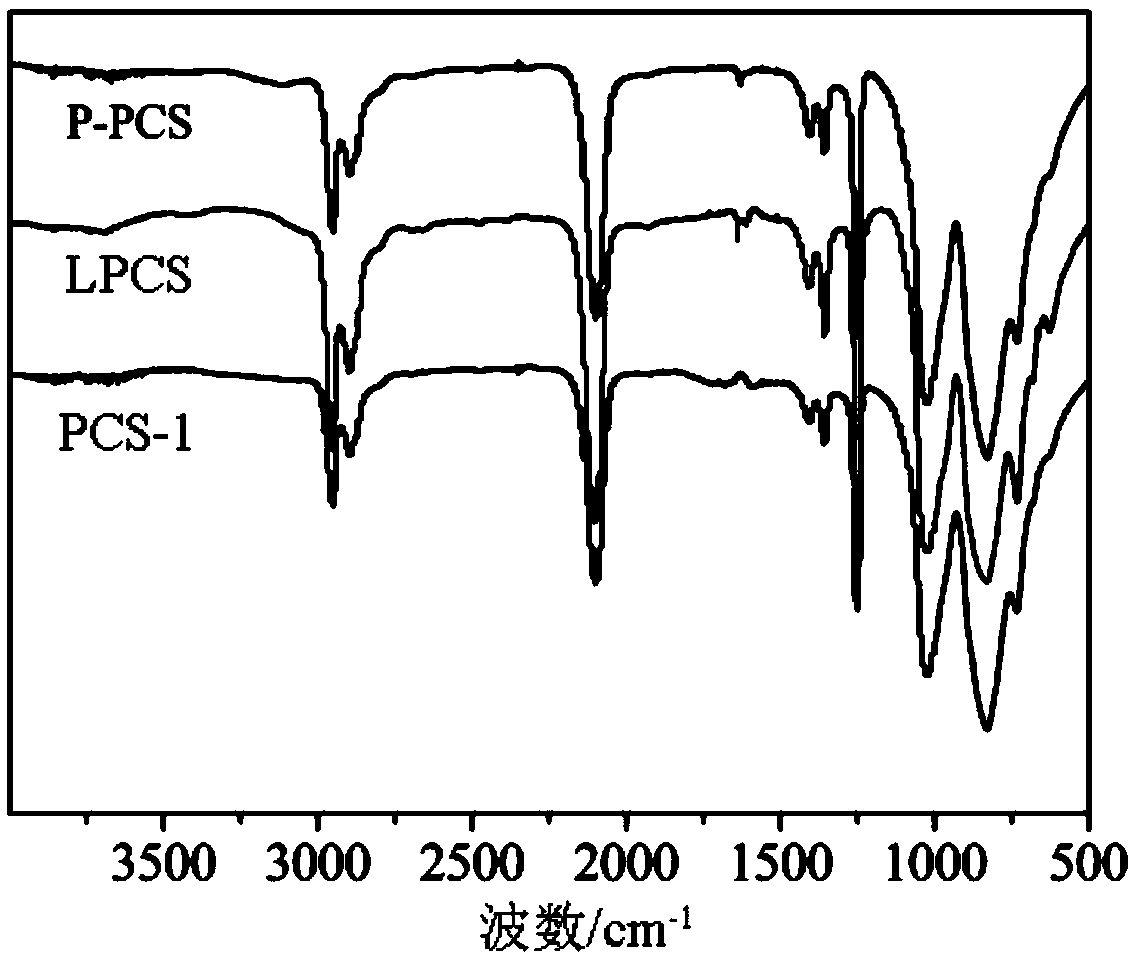

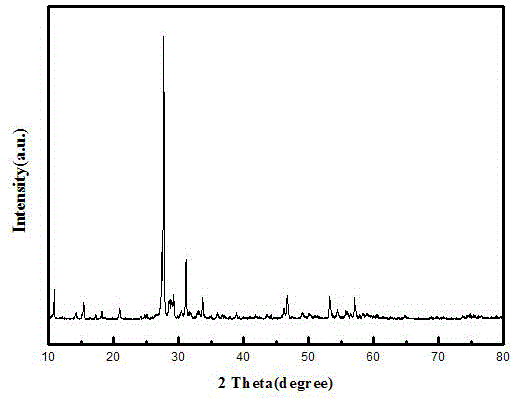

Synthesis method for increasing polycarbosilane (PCS) yield

The invention provides a synthesis method for increasing polycarbosilane (PCS) yield. The method comprises the following steps of using a mixture of polydimethylsilane (PDMS) and liquid polycarbosilane (LPCS) as raw materials, preparing a polycarbosilane pre-product (P-PCS) by pyrolysis rearrangement reaction; sequentially performing dissolving, filtering, atmospheric distillation for solvent removal and vacuum distillation on the P-PCS to obtain PCS and LPCS. According to the method, by recycling the by-product LPCS, the synthesis yield of PCS is increased; meanwhile, the obtained product still contains required PCS, no matter how many times the reaction is carried out, thereby ensuring the normal operation of the reaction and the required PCS yield.

Owner:NAT UNIV OF DEFENSE TECH

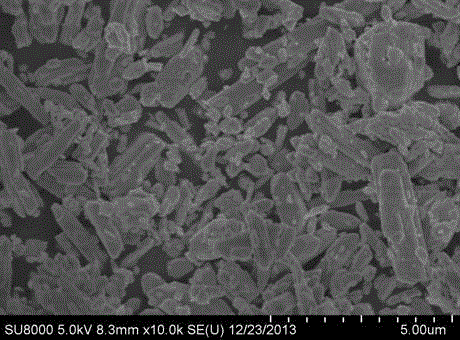

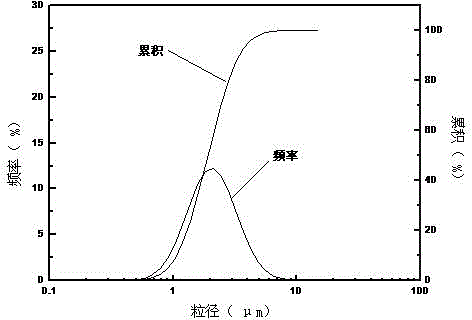

Method for preparing high purity tetrabasic lead sulfate by using lead powder used for production of lead acid battery

ActiveCN103936060AHigh purityNo adverse effect on performanceLead sulfatesCell cycle lifeCapacity loss

The invention discloses a method for preparing high purity tetrabasic lead sulfate by using lead powder used for production of a lead acid battery, which is characterized in that a simple two-step reaction method is used for preparing the tetrabasic lead sulfate, the product purity is high, the particle size is small, the distribution of the particles is uniform, the product raw material lead powder is same with the lead powder used for producing the lead acid battery, impurity is not introduced, no impurity pollution problem is existed, and no adverse influence is generated to cell performance, the lead powder can be taken as an additive for obviously increasing the cell pole plate strength, the capacity loss of the cell at an initial stage is reduced, the cell cycle life is prolonged, in addition, no waste water and waste lead can be generated during a production process, and the method is green and has performance of environmental protection.

Owner:CHAOWEI POWER CO LTD

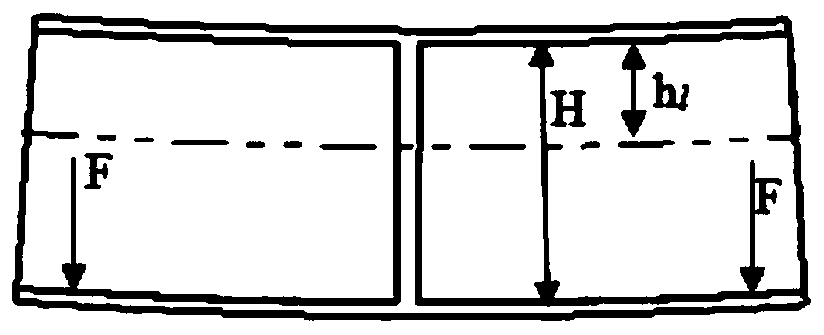

Cold correction method for deformation of aluminum alloy longitudinal beam part

ActiveCN110102603AGreat ability to correct shapeReduce schooling costsAircraft componentsCorrection methodDistortion

The invention belongs to the technical field of machining, and relates to a cold correction method for the deformation of an aluminum alloy longitudinal beam part. A rapid detection tool for appearance is designed and manufactured in an assembling mode, and a part deformation mode is determined by placing a part on the rapid detection tool for appearance; then a web plate surface of the longitudinal beam part is subjected to double-side opposite spray, and deformation of the part in the length direction is corrected; surfaces of both sides of an edge strip is subjected to double-side oppositespraying, and deformation of the part in the width direction is corrected; and finally whether the corrected part meets the design requirements or not can be evaluated. According to the method, the surface of the part is not damaged, and the performance of the part is not adversely affected; the application range is wide, and the method is not limited by the structure (such as the symmetry of thesection and the length direction, the structural distribution of reinforcing ribs, edge strips and the like) and the external dimension of the part; the method is not limited by the deformation mode of the part and the complex deformation such as single curvature and distortion can be corrected; the shape correction capability is high, and the shape correction cost is low; the correction method and parameters can be constant and specified on the process documentation to guide different operators.

Owner:SHENYANG AIRCRAFT CORP

Polylactic acid composite solid resin with electromagnetic shielding performance, and production process thereof

The invention discloses a polylactic acid composite solid resin with an electromagnetic shielding performance, and a production process thereof. The polylactic acid composite solid resin comprises the following components by mass content: 20.0% to 80.0% of polylactic acid resin, 0.1% to 10.0% of interface compatibility agent, 2.0% to 20.0% of plasticizer and 3.0% to 50.0% of electromagnetic shielding powder body. In polylactic acid ink, plastic and fiber materials added with the composite solid resin provided by the invention, the electromagnetic shielding powder body is uniformly dispersed, and has no negative impact on mechanical properties of materials. The polylactic acid composite solid resin has a good electrostatic shielding performance, lower cost and broad prospects in industrial application.

Owner:KUNSHAN XIANGHUAJING BIOTECH

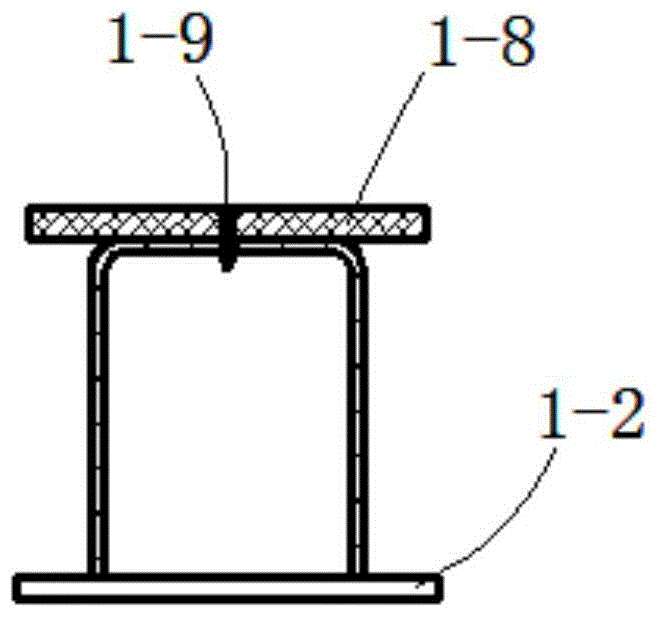

Template system and cast-in-situ concrete floor

ActiveCN104929360AEasy to placeAchieve horizontal supportFloorsForms/shuttering/falseworksReinforced concreteFloor slab

The invention discloses a template system used for a cast-in-situ concrete floor. The template system comprises a template and multiple parallel joists. The end head of at least one joist is provided with a cantilever beam remained in the floor. The cantilever beams are steel components and protrude from the end heads of the joists, the protruded parts of the cantilever beams serve as lapping portions, and the other parts of the cantilever beams are laminated on the top surfaces of the joists and are in detachable connection with the joists through fasteners. The template system can be rapidly installed, has no vertical support, or only has a few of supports. The invention also discloses the cast-in-situ concrete floor, the multiple cantilever beams are arranged at intervals at floor supporting portions, the cantilever beams are the steel components, parts of the cantilever beams are arranged on steel beams or precast concrete beams or precast reinforced concrete shear walls which supporting the floor, and downwardly-through screw holes d and nuts are arranged near the external of a supporting seat. The cast-in-situ concrete floor is convenient to construct and is low in comprehensive cost.

Owner:张玉华

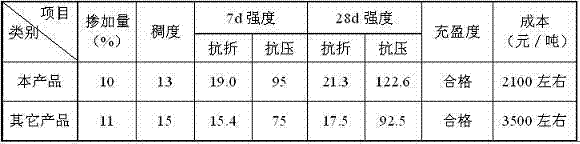

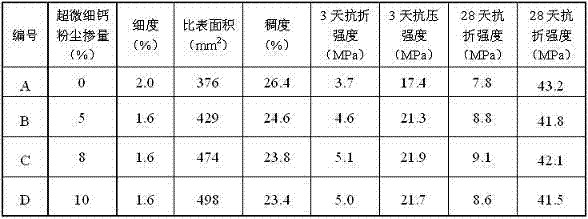

Environment-friendly multifunctional grouting agent

The invention relates to an environmental-friendly multifunctional grouting agent. The environmental-friendly multifunctional grouting agent is prepared by uniformly mixing the following raw materials by weight: 1.2-2.8g of sodium dodecylbenzene sulfonate, 0.4-0.8g of carboxymethyl cellulose, 16-24g of high-performance water reducing agent powder, 13.2-14.8g of granulated blast furnace slag powder, 37.8-42.6g of steel slag powder, 39.6-44.4g of desulfurization gypsum, 79.4-94.6g of high-calcium pulverized fuel ash and 90-110g of ultra-fine calcium dust. The environment-friendly multifunctional grouting agent is low in cost and convenient for realization of industrial production and has a good grouting effect.

Owner:甘肃智通云翔交通科技有限公司

High-temperature resistant viscosity-increasing filtration-loss reducing agent and preparation method thereof used for drilling fluid

InactiveCN102911648ANo pollutionGood viscosity increasing effectDrilling compositionEthylene diamineFiltration

The invention relates to a high-temperature resistant viscosity-increasing filtration-loss reducing agent and a preparation method thereof used for a drilling fluid. The viscosity-increasing filtration-loss reducing agent is prepared by adopting the method: adding waste polyacrylonitrile fibre yarns, alkali and ethylene diamine into water, and reacting for 2-9h at a temperature of 90-95 DEG C; cooling down to below 30 DEG C, adding acrylamide, acrylic acid, 2-acrylamido-2-methyl propanesulfonic acid and an initiating agent, heating up to 30-50 DEG C, and continuing reacting for 1-5h; and taking out a product, drying, crushing, and uniformly mixing with auxiliary materials to obtain the high-temperature resistant viscosity-increasing filtration-loss reducing agent. The high-temperature resistant viscosity-increasing filtration-loss reducing agent has the advantages of simple preparation technology, low cost, good viscosity-increasing performance and filtration-loss reducing function, good compatibility with the drilling fluid, no pollution to the environment, and capability of resisting high temperature above 180 DEG C.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

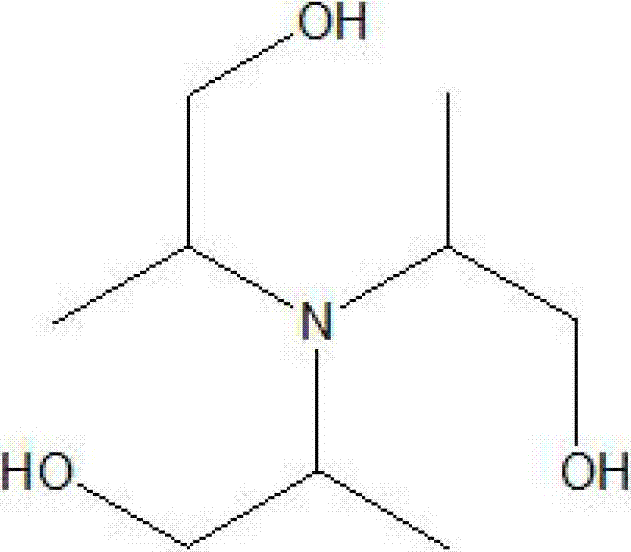

Multifunctional drilling fluid additive and preparation method thereof

InactiveCN102925121AGood defoamingEliminate generationDrilling compositionChemical compoundFluorocarbon

The invention provides a multifunctional drilling fluid additive and a preparation method of the multifunctional drilling fluid additive. The preparation method comprises a first step of heating water up to 35-70 DEG C; cation fluorocarbon surfactant, alcamines chemical compound and nonionic surfactant are respectively added under the condition of stirring. When the cation fluorocarbon surfactant, the alcamines chemical compound and the nonionic surfactant are all added, the mixture of the water, the cation fluorocarbon surfactant, the alcamines chemical compound and the nonionic surfactant are stirred for 0.5-2h. A second step of cooling down the temperature to 30-34 DEG C; antifoaming agents are added, and the water, the cation fluorocarbon surfactant, the alcamines chemical compound, the nonionic surfactant and the antifoaming agents are stirred and emptied to obtain the multifunctional drilling fluid additive. The multifunctional drilling fluid additive and the preparation method of the multifunctional drilling fluid additive are simple in craft and low in cost. The product obtained has the advantages of being lubricated, anti-sloughed and de-filtrated, and reducing surface tension and the like. The ability of resistance to temperature reaches 180 DEG C, and the multifunctional drilling fluid additive and the preparation method of the multifunctional drilling fluid additive can be applied for a deep well and an extradeep well, have good compatibility performance of the drilling fluid, and have no blighting effects on the drilling fluid.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

Biodiesel-fischer-tropsch hydrocarbon blend

InactiveCN1522294AImproved "diesel" characteristicsQuality improvementBiofuelsLiquid carbonaceous fuelsBiodieselEngineering

The invention provides a biodiesel and Fischer-Tropsch derived hydrocarbon blend, whereby the characteristics of the Fischer-Tropsch derived hydrocarbon are used to improve the diesel-like characteristics of biodiesel. The invention also provides a blending component for Compression Ignition engine fuel as well as a method of adjusting the density of a hydrocarbon fuel.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

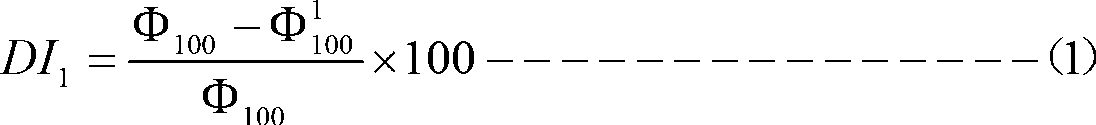

Method for compounding diaphragm and pole piece of wound laminated battery

ActiveCN105742696AImprove adhesion performanceAdhesivelyFinal product manufactureSecondary cellsPolymer chemistryPole piece

The invention discloses a method for compounding a diaphragm and a pole piece of a wound laminated battery. Through cross-linking reaction of a polymerization monomer and a cross-linking agent, the diaphragm can be compounded and adhered to the pole piece. The method comprises the following steps of: firstly, coating a layer of a polymerization monomer solution on a to-be-adhered diaphragm; coating a layer of a cross-linking agent solution on a to-be-adhered pole piece; and finally directly contacting the coated diaphragm with the coated pole piece, exerting the pressure of 0.1-0.5T, heating to 50-100 DEG C, performing cross-linking reaction on the polymerization monomer and the cross-linking agent, thereby compounding and connecting the diaphragm with the pole piece. By adopting the method, a conventional mode that the surface of the diaphragm or the pole piece is coated by an adhesive is avoided, but the diaphragm and the pole piece can be tightly bounded through cross-linking reaction, the chemical bond energy generated in chemical reaction is greatly higher than adhesion strength of a common adhesive, the adhesion property of coated layers can be greatly improved, and the pole piece and the diaphragm can be relatively solidly bounded.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

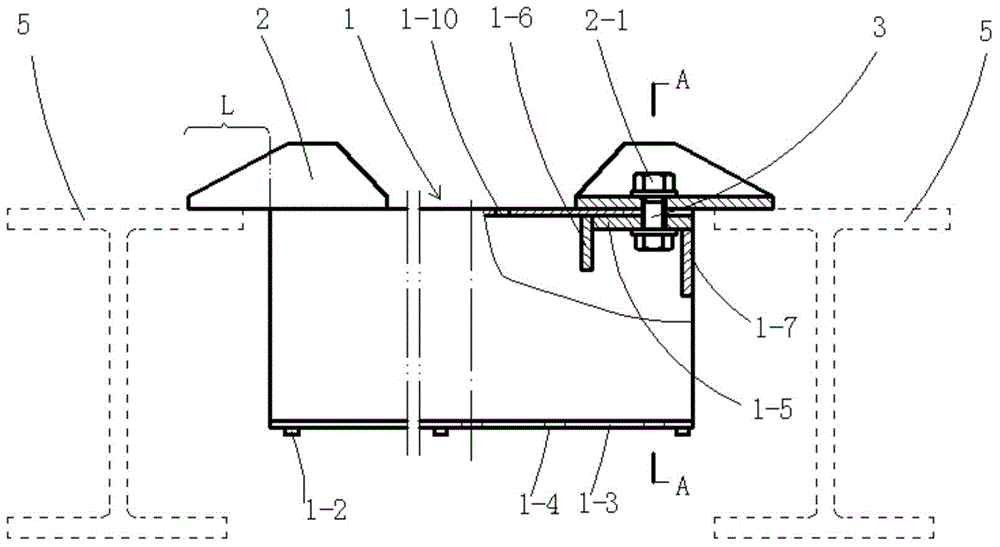

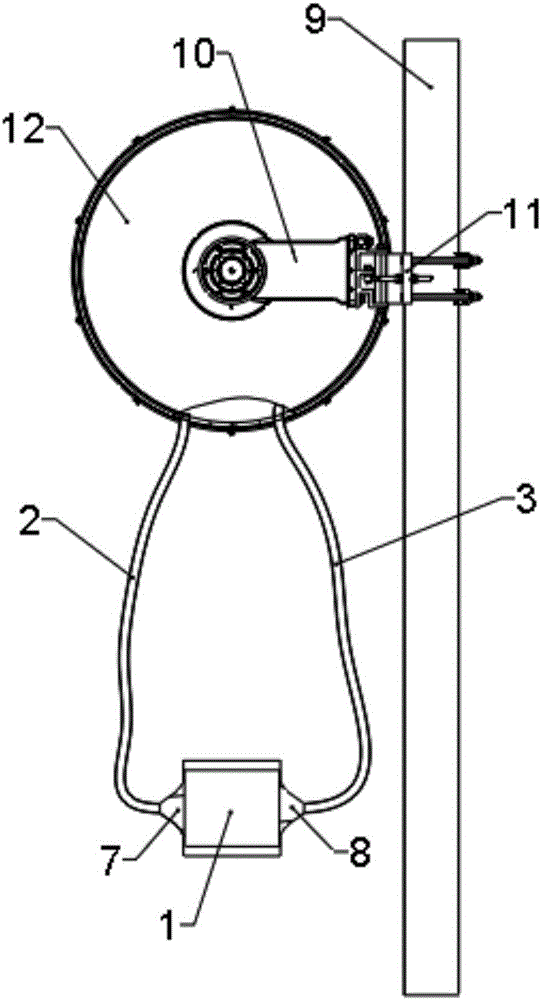

Antenna ice and snow prevention device

PendingCN106785303ASolution to short lifeNo adverse effect on performanceRadiating element housingsDe-icing/drying-out arrangementsTemperature controlValue set

The invention discloses an antenna ice and snow prevention device which is characterized in that the device comprises an air heater, a temperature control system, an air inlet pipeline, an air outlet pipeline and an antenna cover, the antenna cover covers the outside of an antenna body, a ventilation channel, an antenna cover air inlet hole, an antenna cover air outlet hole are formed in the antenna cover, an air outlet of the air heater is connected with the antenna cover air inlet hole through the air inlet pipeline, and an air inlet of the air heater is connected with the antenna cover air outlet hole through the air outlet pipeline, so that a hot air closed-loop recycling system is formed among the antenna cover, the air inlet pipeline, the air outlet pipeline and the air heater. When the temperature is lower than a temperature value set by a temperature control system, the air heater begins to work, the antenna cover is circularly heated, and the surface temperature of the antenna cover is improved. The air heater stops heating when the temperature rises to the temperature value set by the temperature control system. The antenna ice and snow prevention device is simple in structure, convenient to mount and use and more superior in performance as compared with similar products.

Owner:GUANGDONG SHENGLU TELECOMM TECH

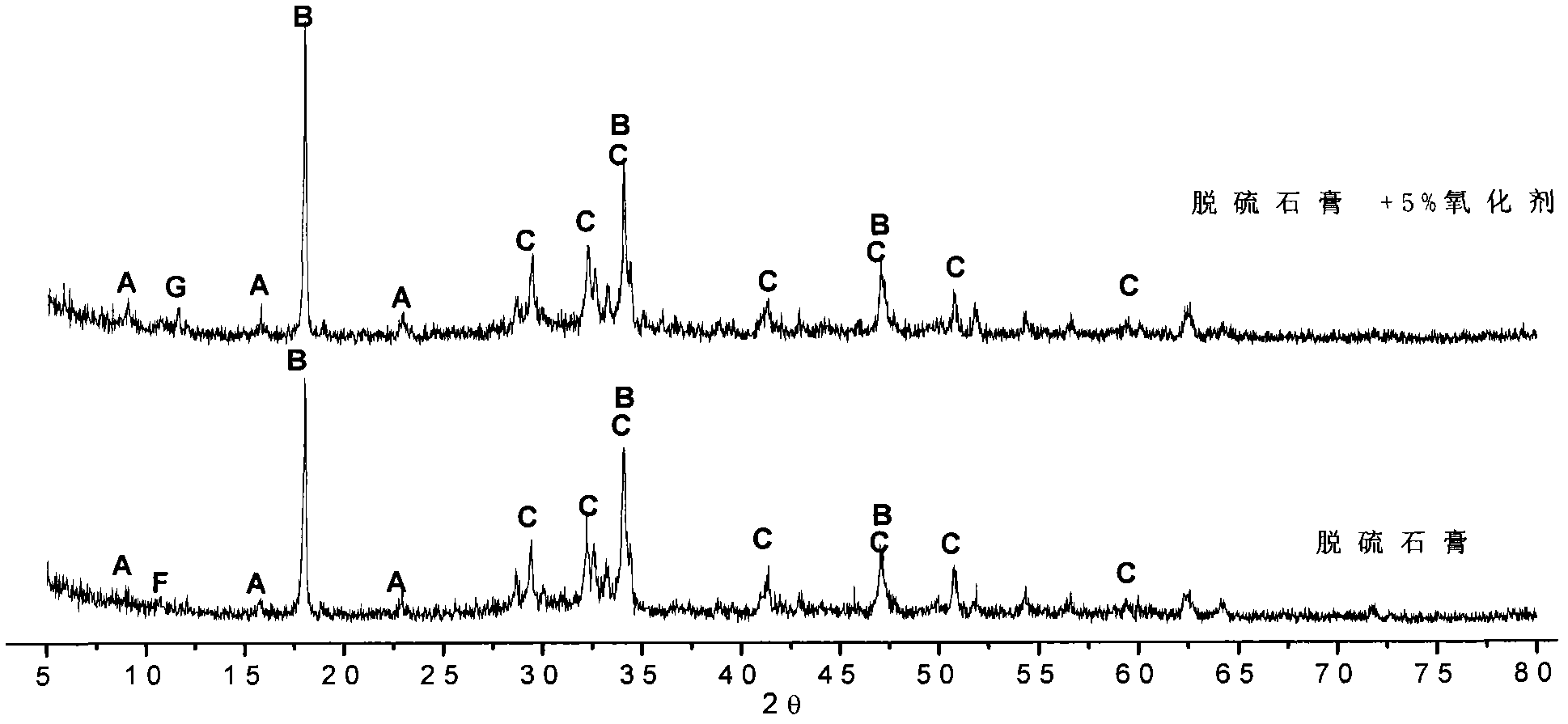

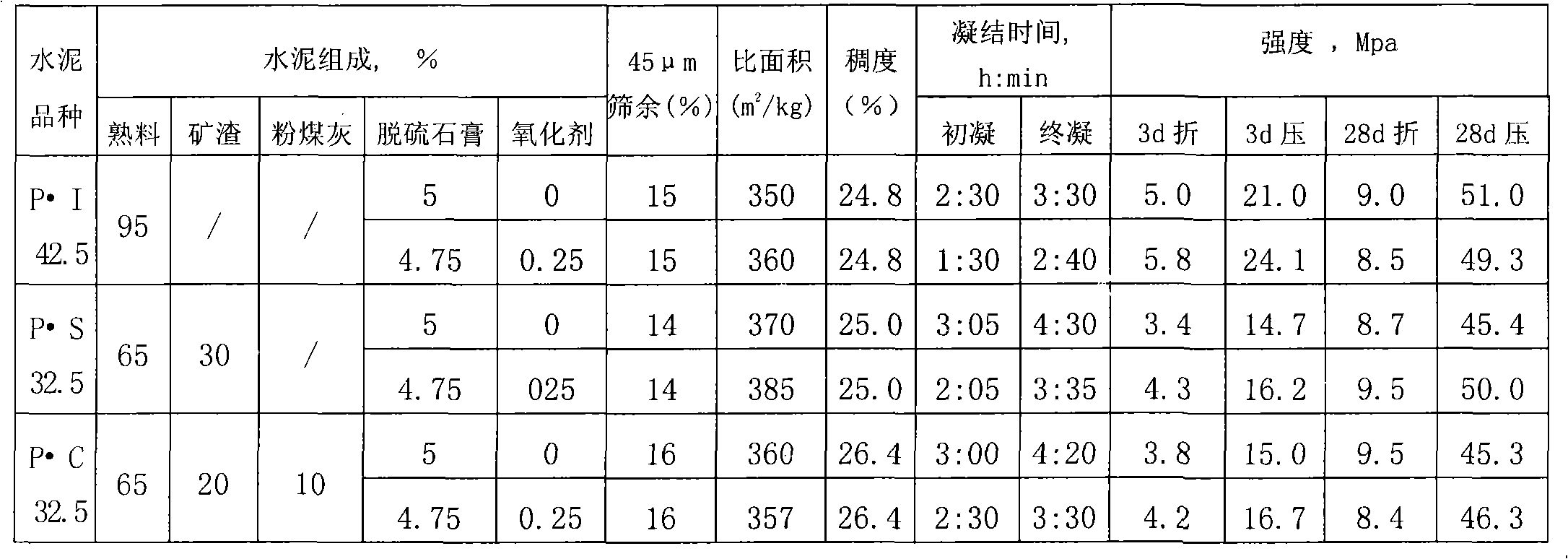

Fast oxidizing agent for calcium sulfite in desulfurization gypsum and application of fast oxidizing agent

The invention discloses a fast oxidizing agent for calcium sulfite in desulfurization gypsum and application of the fast oxidizing agent. The fast oxidizing agent comprises the following components in part by weight: 10 to 30 parts of potassium permanganate, 0 to 20 parts of acetic acid, 40 to 80 parts of ferromanganese alloy slag and 0 to 44 parts of iron pyrite slag. A method for fast oxidizing the calcium sulfite in the desulfurization gypsum comprises the following steps of: uniformly mixing the desulfurization gypsum and the fast oxidizing agent according to a proportion of the desulfurization gypsum to the oxidizing agent of 19 to 1; and placing the mixture under the condition of natural air for at least one day to oxidize the calcium sulfite in the desulfurization gypsum by the oxidizing agent. The test shows that the oxidizing agent is stable in performance, can fast oxidize the calcium sulfite in the desulfurization gypsum and has no harmful effect on the performance of cement and concrete. The method for fast oxidizing the calcium sulfite in the desulfurization gypsum is easy to operate, is economic and reliable, is favorable for popularizing and applying the desulfurization gypsum to cement industries, and has a wide application prospect; and complicated production equipment is not needed.

Owner:CHINA BUILDING MATERIALS ACAD

Method for directly and cyclically recovering and utilizing phosphoric acid waste lead mud of lead-acid storage battery

InactiveCN106299521AImprove use valueReduce processingWaste accumulators reclaimingBattery recyclingPhosphoric acidLead sulfate

The invention discloses a method for directly and cyclically recovering and utilizing phosphoric acid waste lead mud of a lead-acid storage battery. The method comprises the main steps of (1) recovering waste lead mud; (2) determining the content of lead sulfate in the phosphoric acid waste lead mud; (3) performing desulfurization; (4) performing solid and liquid separation; (5) performing cyclical utilization: positive electrode recovery lead mud is added into a positive electrode paste mixing machine to be cyclically utilized; negative electrode recovery lead mud is added into a negative electrode paste mixing machine to be cyclically utilized. The method has the advantages that the method is simple and is easy to implement; the required time is short; the product is uniform and stable; the purity is high; the problem of impurity pollution cannot be caused; no any adverse influence is caused on the battery performance.

Owner:CHAOWEI POWER CO LTD

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphoaluminate cement. Limestone, phosphogypsum, low-grade bauxite and coke are formulated into cement raw meal in a certain proportion, and calcined at high temperature after grinding and mixing. Promote the decomposition of phosphogypsum as much as possible, and the calcium oxide generated by the decomposition can replace part of the limestone. The sulfur dioxide gas can be collected to prepare sulfuric acid. The obtained cement clinker is mixed with natural dihydrate gypsum and ground to make cement products. Compared with the existing traditional production method, the method of the present invention can greatly improve the utilization rate of phosphogypsum, avoid the concentration of sulfur dioxide emitted by a small amount of decomposition of gypsum in the production process, which cannot reach the concentration used, and can also reduce the amount of limestone and carbon dioxide emissions. Burnt cement has wide adaptability and can be widely used in the production of sulphoaluminate cement using phosphogypsum, and is also suitable for the production of rapid hardening cement and expansive cement.

Owner:CHONGQING UNIV

Multifunctional drilling fluid additive and preparation method thereof

InactiveCN102925121BSimple preparation processLow costDrilling compositionChemical compoundFluorocarbon

The invention provides a multifunctional drilling fluid additive and a preparation method of the multifunctional drilling fluid additive. The preparation method comprises a first step of heating water up to 35-70 DEG C; cation fluorocarbon surfactant, alcamines chemical compound and nonionic surfactant are respectively added under the condition of stirring. When the cation fluorocarbon surfactant, the alcamines chemical compound and the nonionic surfactant are all added, the mixture of the water, the cation fluorocarbon surfactant, the alcamines chemical compound and the nonionic surfactant are stirred for 0.5-2h. A second step of cooling down the temperature to 30-34 DEG C; antifoaming agents are added, and the water, the cation fluorocarbon surfactant, the alcamines chemical compound, the nonionic surfactant and the antifoaming agents are stirred and emptied to obtain the multifunctional drilling fluid additive. The multifunctional drilling fluid additive and the preparation method of the multifunctional drilling fluid additive are simple in craft and low in cost. The product obtained has the advantages of being lubricated, anti-sloughed and de-filtrated, and reducing surface tension and the like. The ability of resistance to temperature reaches 180 DEG C, and the multifunctional drilling fluid additive and the preparation method of the multifunctional drilling fluid additive can be applied for a deep well and an extradeep well, have good compatibility performance of the drilling fluid, and have no blighting effects on the drilling fluid.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

High performance antiglare film

InactiveCN105062328AStrong adhesionGood weather resistancePolyurea/polyurethane coatingsEpoxy resin coatingsALUMINUM STEARATESPolymer science

The invention discloses a high performance antiglare film. The raw materials include: a fluorine-containing epoxy acrylate oligomer, a fluorine-containing polyurethane acrylate oligomer, polycarbonate, styrene, hydroxyethyl methacrylate, N-vinyl pyrrolidone, pentaerythritol triarylate, glycerol monostearate, sorbitol, polyethylene glycol, nano-titanium dioxide, nano-silica, aluminum stearate, aluminum-doped zinc oxide, vinyl-tri(2-methoxyethoxy)silane, sodium dodecyl benzene sulfonate, 1-hydroxycyclohexyl phenyl ketone, triphenylphosphine oxide, phenolic resin, amino resin, an additive, and a solvent. The high performance antiglare film provided by the invention has high adhesion with the substrate, good scratch resistance, and excellent anti-static, antiglare and anti-radiation effects.

Owner:ANHUI HERUN SPECIAL GLASS CO LTD

Treatment method of carbon fiber ash for C/C (carbon/carbon) composite material

The invention discloses a treatment method of carbon fiber ash for a C / C (carbon / carbon) composite material. The method comprises the following steps of: 1, preparing a carbon fiber prefabricate from continuous carbon fiber by adopting a traditional prefabricate forming method; 2, placing the carbon fiber prefabricate in a graphitizing furnace and carrying out thermal treatment for 2 hours-5 hours at the temperature of 2450 DEG C-2550 DEG C under the protection of vacuum or inert gas, and then cooling along with the furnace; and 3, preparing the cooled carbon fiber prefabricate into the C / C composite material by adopting a conventional method, or repeating the step 2 1-3 times, and then preparing the carbon fiber prefabricate into the C / C composite material by adopting a conventional method. By using the treatment method, application of high-ash carbon fiber is realized, and adaptability of a raw material is improved; and the mass content of the ash in the carbon fiber prefabricate treated by using the method is not more than 0.05%, and the property of the C / C composite material prepared from the treated carbon fiber prefabricate is excellent and identical to that of the C / C composite material prepared from imported carbon fiber.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com