Lithium ion battery cathode slurry and preparation method thereof

A lithium-ion battery and negative electrode slurry technology, which is applied in the direction of electrode manufacturing, secondary batteries, active material electrodes, etc., can solve the problems of insufficient stability, high cost of oily slurry, poor consistency of slurry, etc., and achieve stability Effects of improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This example illustrates the preparation method of the oil-water mixed negative electrode slurry and the battery produced by the present invention.

[0019] 1. Preparation of negative electrode

[0020] Add 2700g deionized water and 340g NMP into the mixing tank to make a solution, then add 120g binder LA132 (Chengdu Yindile Power Technology Co., Ltd.), mix and stir for 6-8 hours to make glue, and then add 2300g graphite, 50g Add carbon black, mix and stir for 8-12 hours (use graphite, carbon black, and binder LA132 as solid raw materials, take 25g / part as an example), make a slurry, and apply it on a 12μm copper foil with a coater. After heating and drying in vacuum at 135°C for 3 hours, roll pressing into 550mm (length) × 122mm (width) × 130μm (thickness) pole pieces, the compacted density is 1.3g / cm 3 .

[0021] 2. Preparation of positive electrode

[0022] Add 4350g of dried lithium manganate, 175g of carbon black, and 225g of polyvinylidene fluoride (PVDF, F2) i...

Embodiment 2

[0037] Embodiment 2: performance test of slurry of the present invention

[0038] 1. Slurry Stability Test

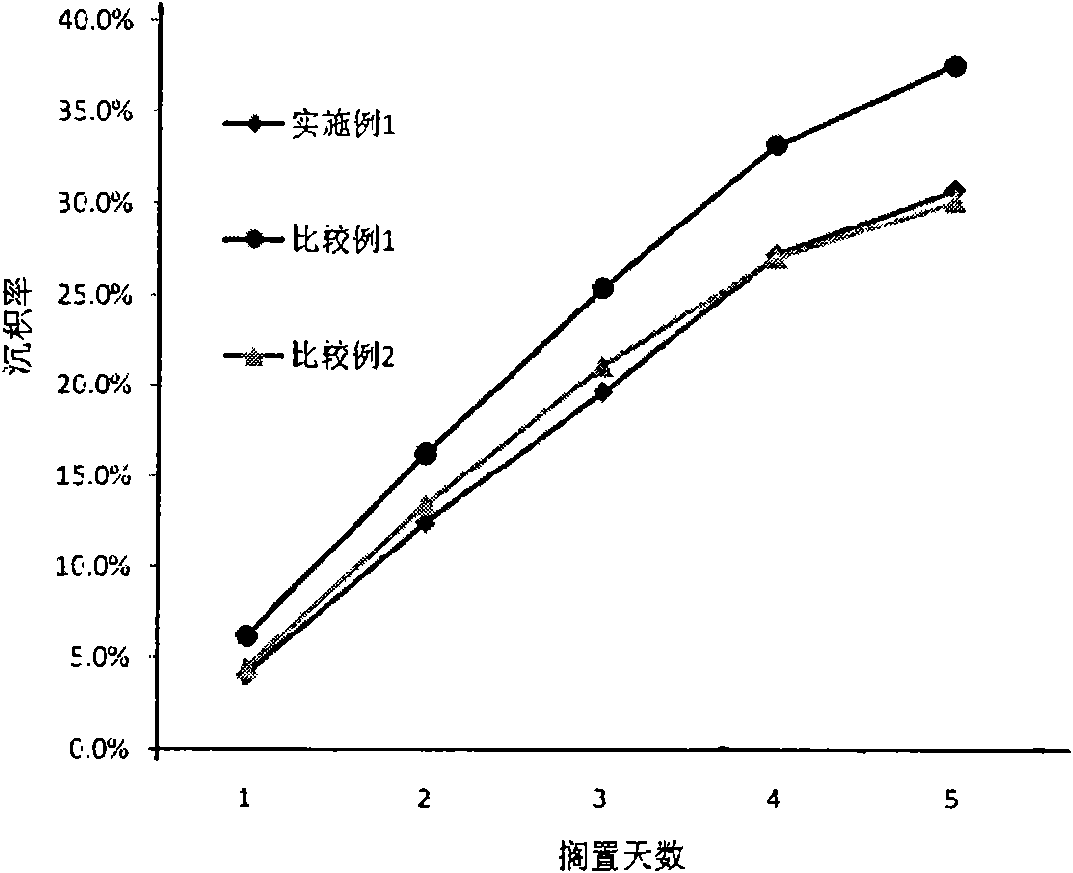

[0039] Put the slurry into a test tube and seal it, place it vertically, and test the change of the deposition rate with the time of holding it, the results are shown in figure 1 .

[0040] Sedimentation rate = supernatant liquid height of slurry / total slurry height × 100%

[0041] From figure 1 From the data, it can be seen that the stability of Example 1 (mixed negative electrode slurry) and Comparative Example 2 (oily negative electrode slurry) is equivalent, which is obviously better than that of Comparative Example 1 (water-based negative electrode slurry).

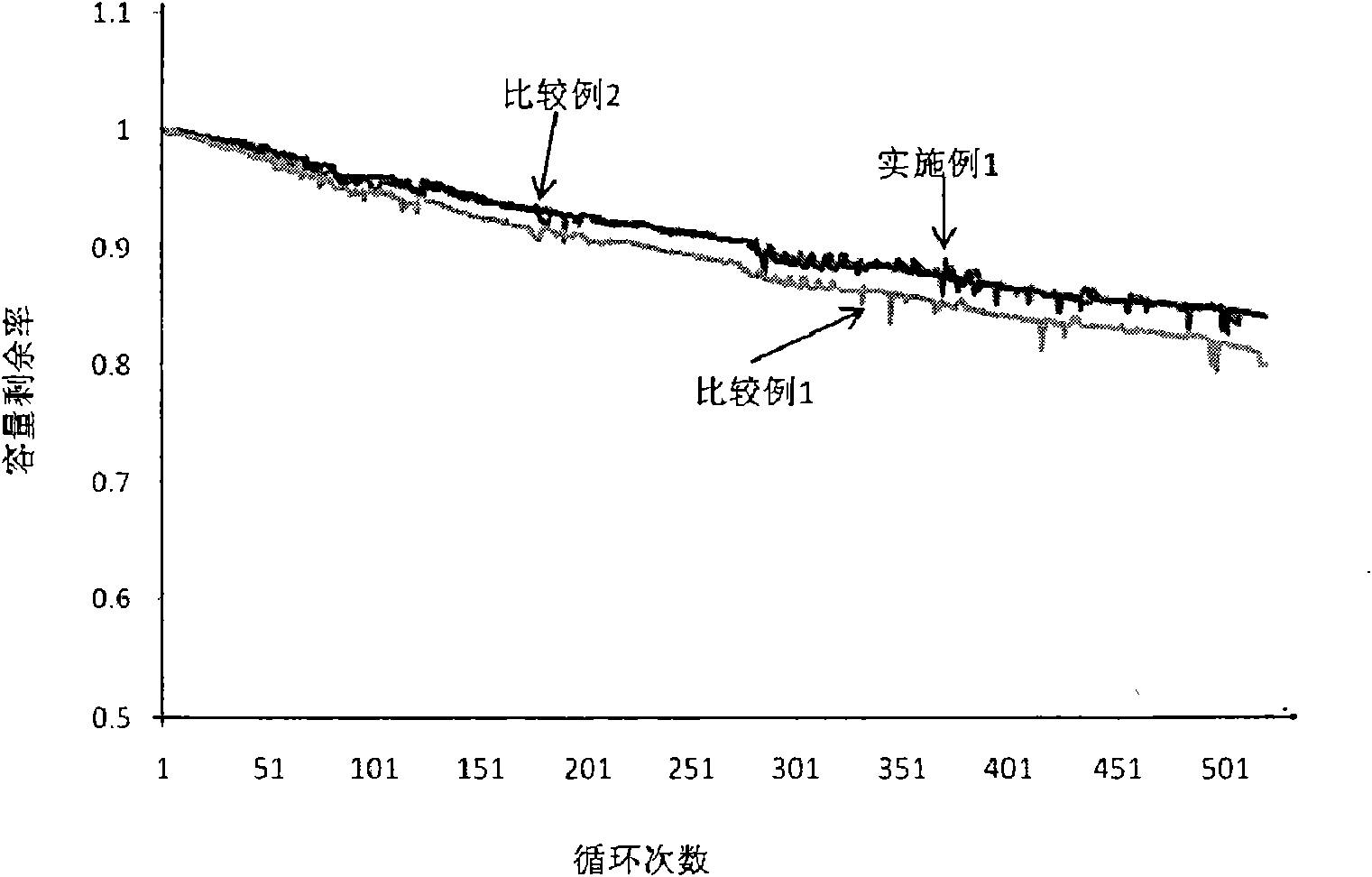

[0042] 2. Battery performance test:

[0043] 1. Battery internal resistance test

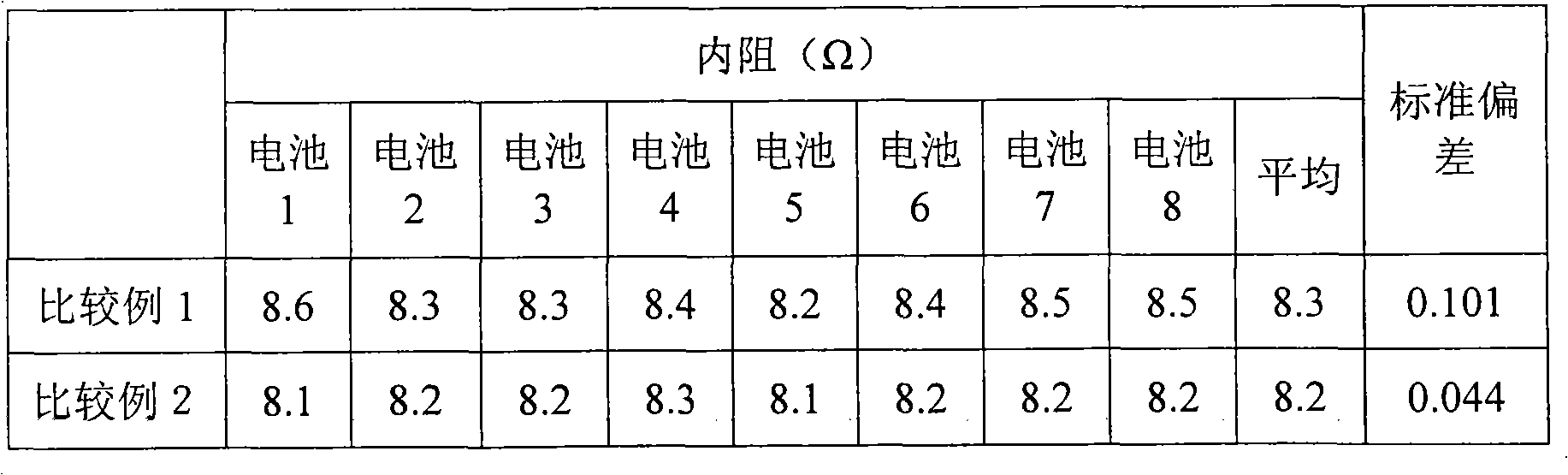

[0044] Use the internal resistance meter to measure 8 pieces of each battery, and the test results are shown in Table 1

[0045] Table 1

[0046]

[0047]

[0048] It can be seen from the actual data that the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com