Novel magneticfluid sealant

A magnetic fluid sealing and new material technology, applied in the direction of magnetic liquid, etc., can solve the problems of magnetic fluid sealing pressure drop, sealing failure, etc., and achieve the effect of high transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A new ferrofluid sealing material, its composition and weight percentage are as follows:

[0021] Ferromagnetic particle powder (nano-scale) 6 grams

[0022] Additive 2 grams

[0023] Carrier Liquid 92g

[0024] Wherein, the weight percent of each component that forms the nanoscale ferromagnetic particle powder is:

[0025] Carbonyl iron powder (nano-scale) 60 grams

[0026] Ferroferric oxide powder (nano-scale) 40 grams

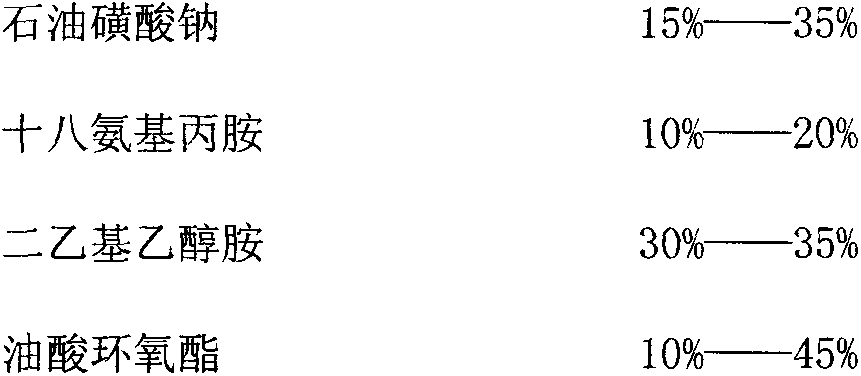

[0027] Wherein, the weight percent of each component that forms additive is:

[0028] Sodium petroleum sulfonate 25g

[0029] Octadecylaminopropylamine 20g

[0030] Diethylethanolamine 30g

[0031] Epoxy Oleate 25g

[0032] Wherein, the weight percent of each component that forms carrier liquid is:

[0033] Chlorinated silicone oil 300g

[0034] Simethicone 700g

[0035] A new ferrofluid sealing material of the present invention, the preparation method of which is as follows:

[0036] 1. Prepare the carrier liquid first: add chlorinated si...

Embodiment 2

[0041] A new ferrofluid sealing material, its composition and weight percentage are as follows:

[0042] Ferromagnetic particle powder (nano-scale) 2 grams

[0043] Additive 1 g

[0044] Carrier fluid 97g

[0045] Wherein, the above 2 gram of spare ferromagnetic particle powder (nano-level), 1 gram of spare additive, 97 gram of spare carrier liquid are taken out from embodiment one, so their respective components and weight percentages are the same as those in embodiment one. exactly the same as described.

[0046] A new ferrofluid sealing material, the preparation method of which is the same as that described in Example 1 except that the weight percentage of its components is different.

Embodiment 3

[0048] A new ferrofluid sealing material, its composition and weight percentage are as follows:

[0049] Ferromagnetic particle powder (nano-scale) 4 grams

[0050] Additive 2 grams

[0051] Carrier Liquid 94g

[0052] Wherein, the above 4 gram standby ferromagnetic particle powder (nano-level), 2 gram standby additives, 94 gram standby carrier liquids are taken out from embodiment one, so their respective components and weight percentages are the same as those in embodiment one. exactly the same as described.

[0053] A new ferrofluid sealing material, except for the different weight percentages of its components, its preparation method is consistent with that described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com