Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Hydrogenated terphenyls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

HYDROGENATED TERPHENYLS is a clear, oily, pale-yellow liquid with a faint odor. A mixture of numerous compounds and isomers depending on the degree and conditions of hydrogenation The 40% hydrogenated mixture has bp: 340°C, density: 1.00 g cm-3, and is insoluble in water .

Anhydrous stemming for blast furnace tapping hole

The invention discloses anhydrous stemming for a blast furnace tapping hole, belonging to the technical field of refractory material for blast furnaces. The anhydrous stemming for a blast furnace tapping hole disclosed by the invention is composed of refractory aggregate and bonding agent, wherein the refractory aggregate comprises the following components in parts by mass: 12-14 parts of titanium dioxide, 3-5 parts of titanium carbide, 20-25 parts of corundum, 15-18 parts of silicon carbide, 30-38 parts of mullite, 5-7 parts of calcium-free chromium slag, 6-8 parts of blast furnace gas ash, and 9-11 parts of coke; and the bonding agent comprises the following components in parts by mass: 40-50 parts of asphalt, 4-6 parts of hydrogenated terphenyl, 10-12 parts of organic silicon resin, 8-11 parts of furan resin, and 11-15 parts of melamine-formaldehyde resin, wherein the mass ratio of the refractory aggregate to the bonding agent is 100:13-15. The anhydrous stemming disclosed by the invention has good opening performance, moderate plasticity, can resist scouring and erosion of high-temperature iron slag, does not pollute the environment, and is low in production cost.

Owner:ANHUI SAFE ELECTRONICS

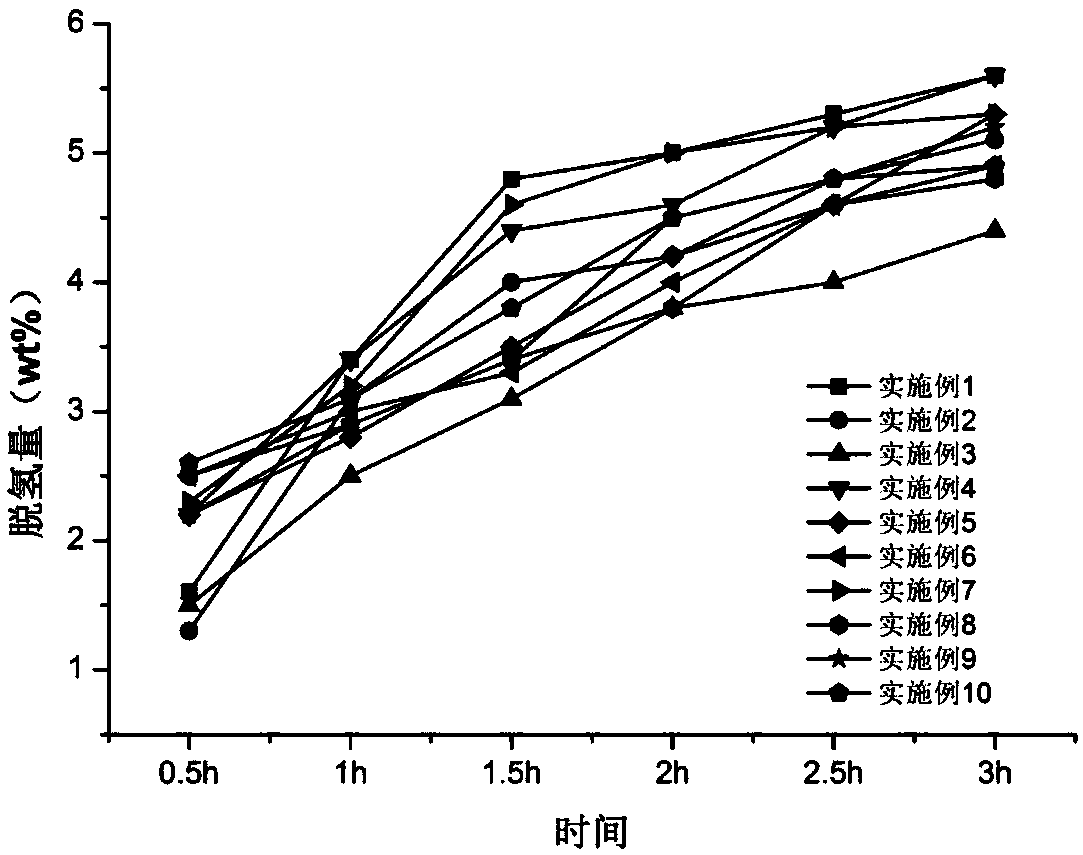

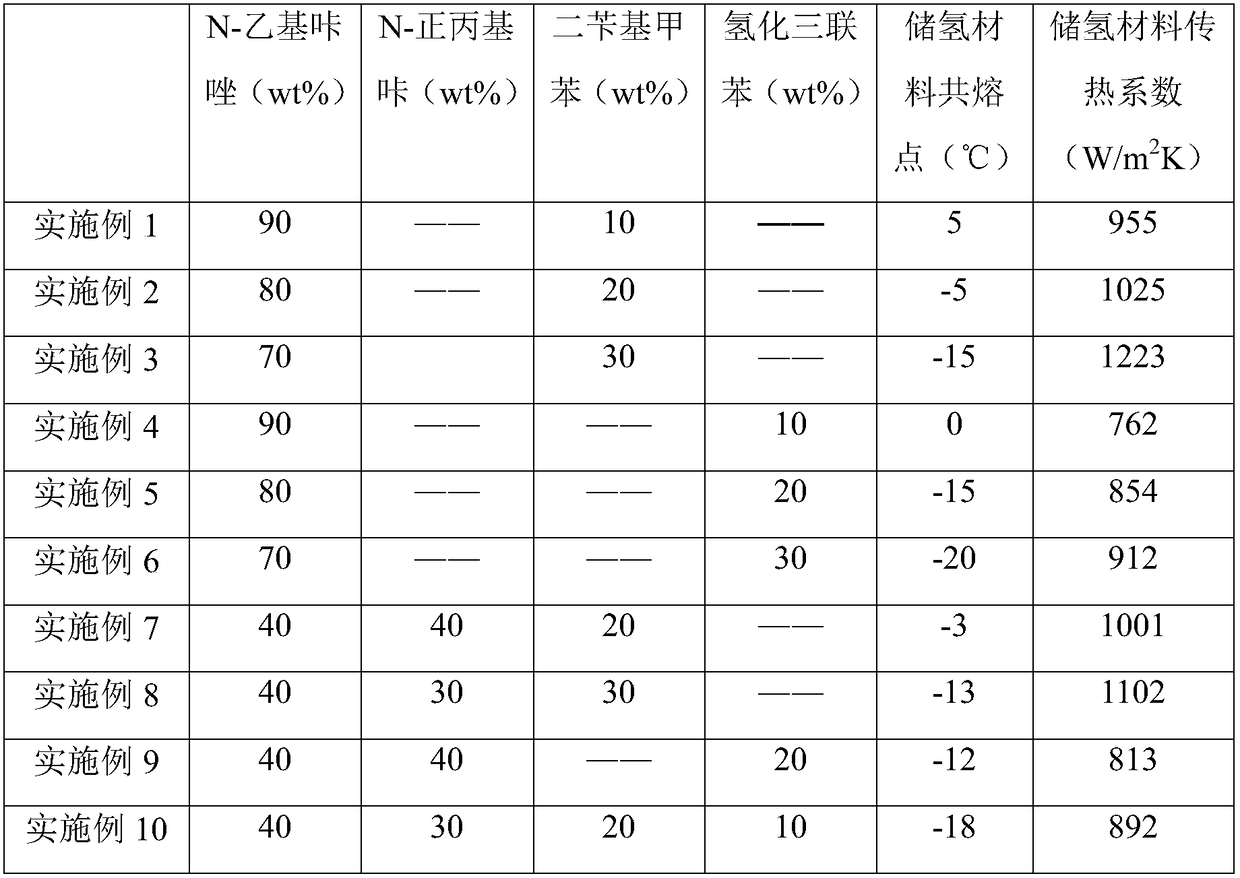

Liquid hydrogen storage material and preparation method thereof

InactiveCN109353987ALow melting pointLower heat transfer coefficientHydrogenDibenzyltolueneLiquid hydrogen

The invention relates to a liquid hydrogen storage material and a preparation method thereof. The liquid hydrogen storage material comprises a carbazole type hydrogen storage component and an additivewith a low melting point and a high heat transfer coefficient; the carbazole type hydrogen storage component is at least one of carbazole, N-methyl carbazole, N-ethyl carbazole, N-n-propyl carbazole,N-isopropyl carbazole or N-n-butyl carbazole; the heat conduction additive component with a low melting point is at least one of benzyltoluene or hydrogenated terphenyl. The liquid hydrogen storage material is a mixture formed by mixing the carbazole type hydrogen storage material with a high melting point with the heat conduction additive with a low melting point and has an eutectic point whichis at least lower than the melting point of one component, and the melting point of the entire hydrogen storage material can drop to 0 DEG C or below. At the same time, the heat conduction additive with a low melting point has a high heat transfer coefficient, and the heat conductivity coefficient of the mixture formed after the additive is mixed with the carbazole type hydrogen storage material can be higher than that of the carbazole type hydrogen storage material; the whole hydrogen storage material can quickly reach the dehydrogenation temperature during dehydrogenation, so that the release rate of hydrogen is increased.

Owner:FAW JIEFANG AUTOMOTIVE CO

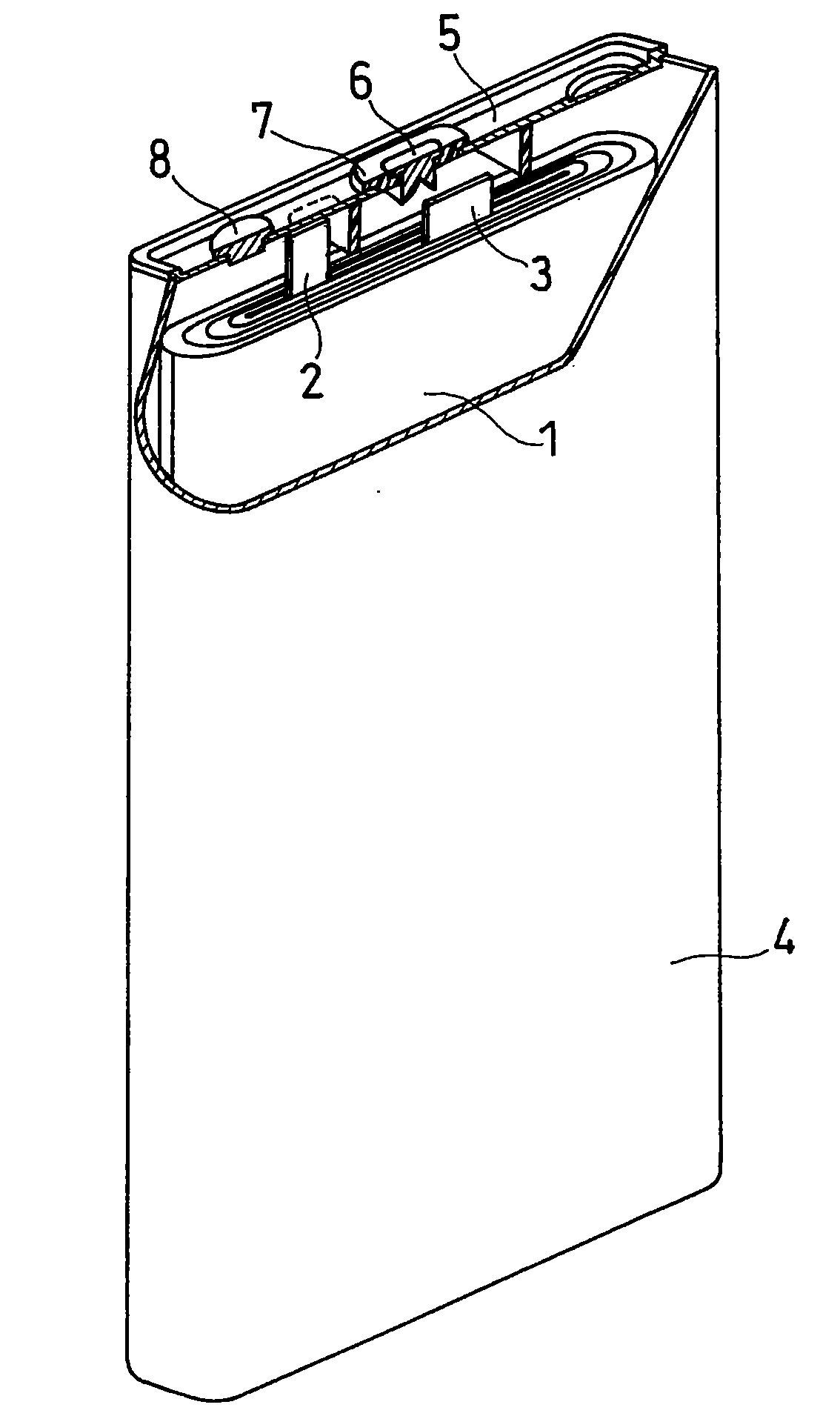

Non-aqueous electrolyte secondary battery

ActiveUS20100227218A1Improve securityIncrease resistanceAlkaline accumulatorsNon-aqueous electrolyte accumulatorsCarbon compositesSolvent

A non-aqueous electrolyte secondary battery wherein the non-aqueous electrolyte contains a non-aqueous solvent, a solute dissolved in the non-aqueous solvent, and hydrogenated terphenyl, the solute includes a boron-containing alkali salt and a boron-free alkali salt, the negative electrode includes a negative electrode active material comprising a randomly oriented carbon composite (A), and the carbon composite (A) contains a graphitic carbon substance (B) and a carbon substance (C) that is different from the graphitic carbon substance (B).

Owner:PANASONIC HLDG CORP

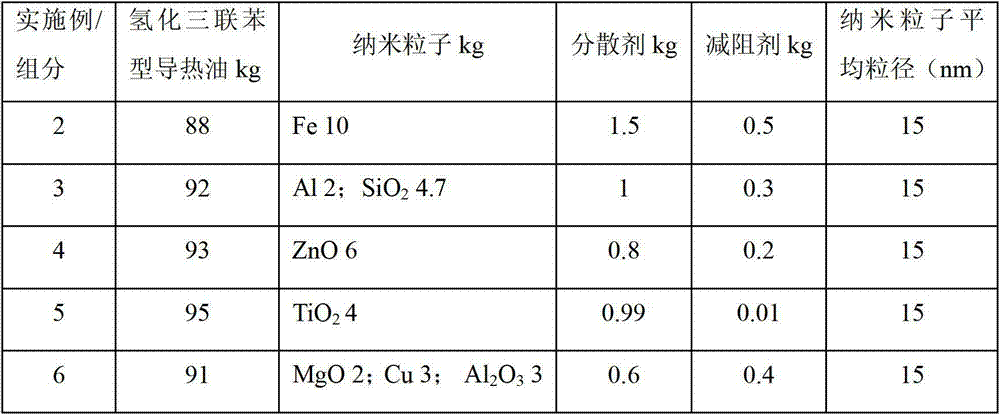

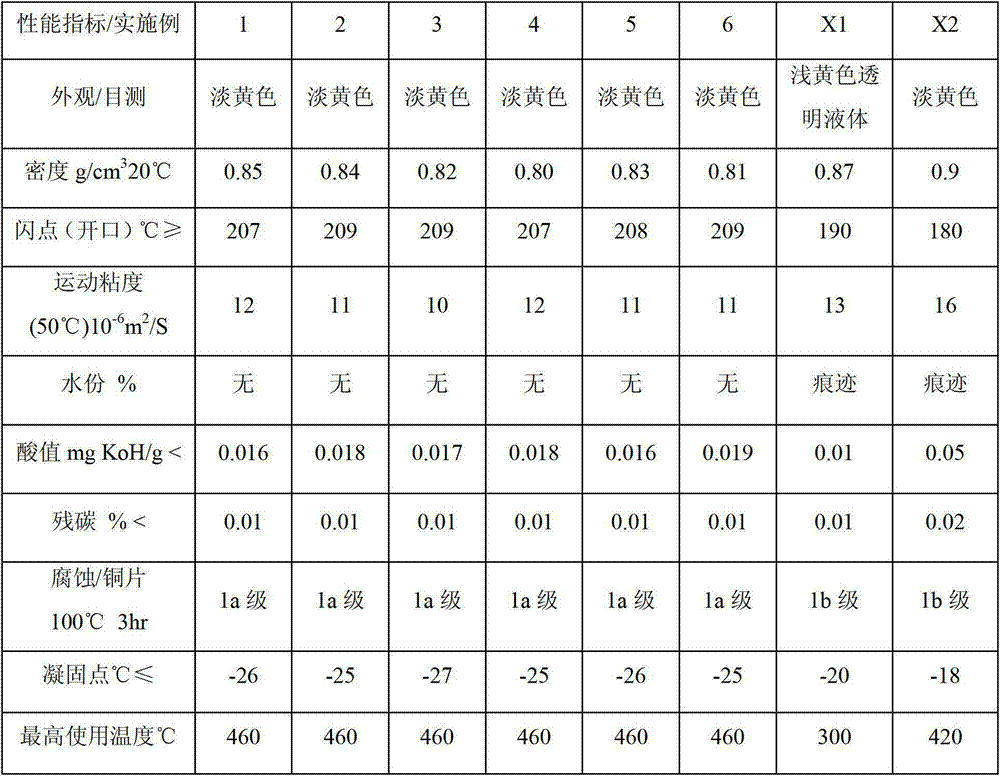

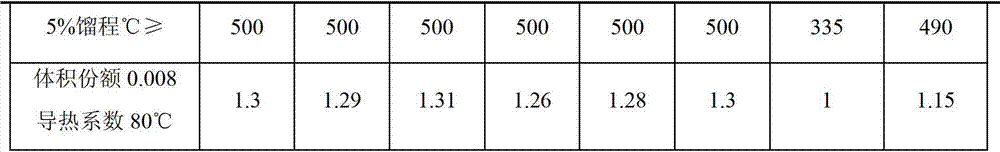

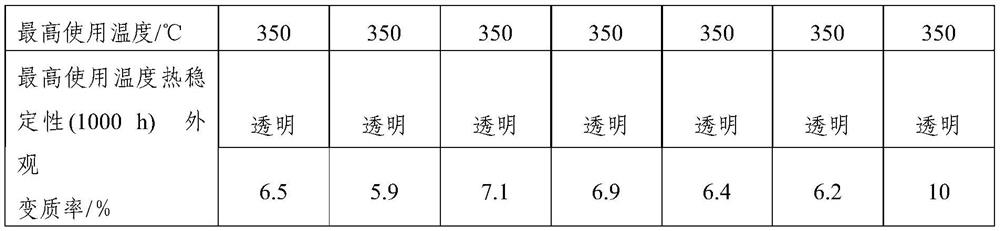

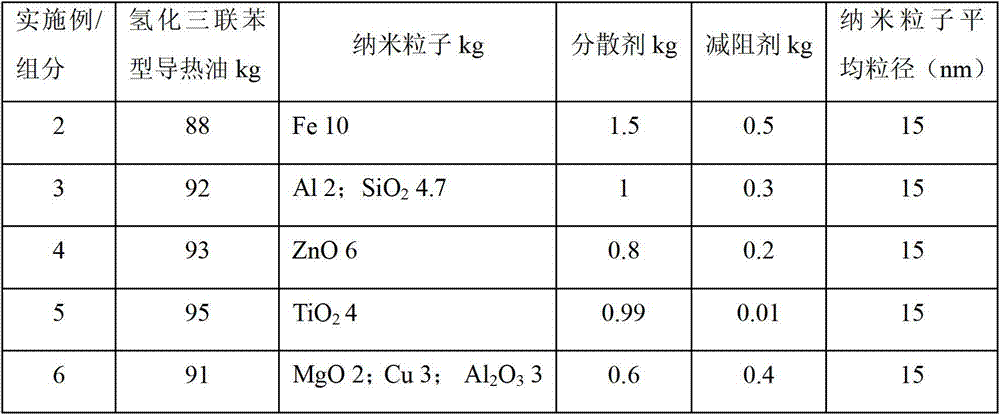

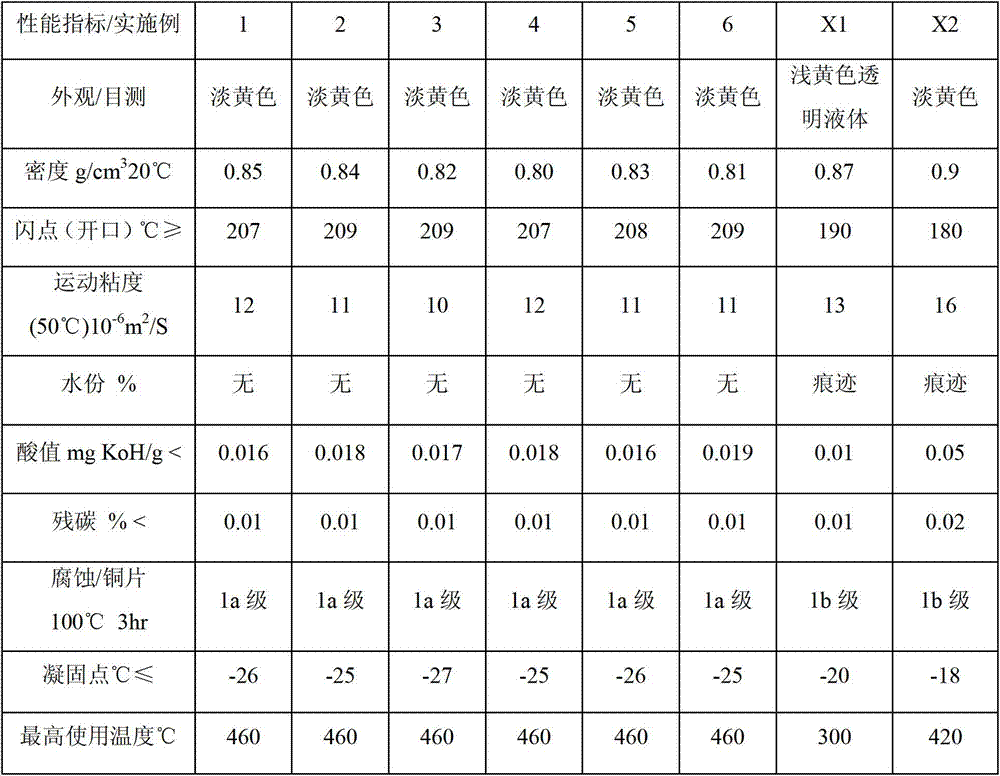

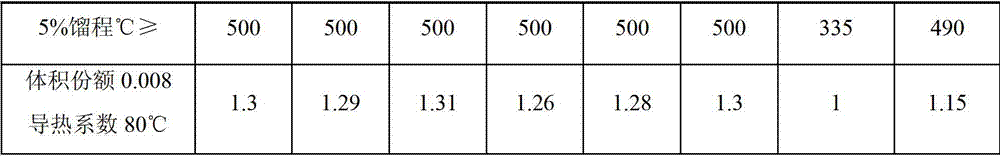

Hydrogenated terphenyl type high-temperature nanometer heat-conduction oil, and preparation method and application thereof

InactiveCN103923617AImprove suspension stabilityGood dispersionSolar heat devicesHeat-exchange elementsNanoparticles dispersionHydrogenated terphenyls

The invention provides hydrogenated terphenyl type high-temperature nanometer heat-conduction oil, and a preparation method and application thereof. The heat-conduction oil comprises hydrogenated terphenyl heat-conductive oil, nanoparticles, a drag reducer and a dispersant, the surfaces of the nanoparticles are coated with the dispersant to form modified nanoparticles, and the modified nanoparticles are dispersed in the heat-conductive oil to form the suspension type heat-conduction oil. The nanoparticles are metal, metal oxides, nonmetal and / or nonmetal oxides. In heat-conduction mediums, the heat-conduction oil disclosed by the invention has the advantages of good thermal stability, fast heat conduction speed, uniform heating and large energy storage amount, the highest usage temperature is 460 DEG C, and the service life is 3 years or more.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

Bonding agent for stemming of large-scale blast furnace

The invention discloses a bonding agent for stemming of a large-scale blast furnace, belonging to the technical field of stemming of a blast furnace. The bonding agent for stemming of the large-scale blast furnace comprises the following components in parts by mass: 40 to 50 parts of asphalt, 4 to 6 parts of hydrogenated terphenyl, 10 to 12 parts of organic silicon resin, 8 to 11 parts of furan resin and 11 to 15 parts of melamine formaldehyde resin, wherein the furan resin is furfuryl alcohol resin; the asphalt is petroleum asphalt, wherein the earth asphaltene in the petroleum asphalt is of 25 to 30%. According to the bonding agent disclosed by the invention, the organic silicon resin, the furan resin and the melamine formaldehyde resin are compounded to be served as the component of the curing agent, and moreover, the hydrogenated terphenyl is served as the synergist, thus high plasticity can be obtained, and low curing rate is ensured; reduction of the curing rate of the bonding agent is beneficial for improving the liquidity of the stemming at high temperature, therefore, the stemming is hardly blocked in a mud gun; if the bonding agent disclosed by the invention is added for preparing the stemming, the stemming has good performance on opening; and moreover, the bonding agent has resistance to scouring and eroding of high-temperature scrap iron in slag, and has no pollution to the environment.

Owner:卫勤玲

Preparation method of bonding agent for blast furnace stemming with good opening performance

ActiveCN102887719AImprove liquidityNot easy to agglomeratePhysical chemistryMelamine formaldehyde resin

The invention discloses a preparation method of a bonding agent for blast furnace stemming with good opening performance, belonging to the field of the blast furnace stemming. The preparation method comprises the following steps of: (1) weighing 40-50 parts of asphalt and 4-6 parts of hydrogenated terphenyl in parts by weight, adding the asphalt and the hydrogenated terphenyl in a reaction kettle in sequence, and agitating and mixing for 20 minutes at the temperature of 55-60 DEG C; and (2) weighing 10-12 parts of organic silicon resin, 8-11 parts of furan resin and 11-15 parts of melamine-formaldehyde resin in parts by weight, controlling the temperature rise rate of the reaction kettle in the step (1) to be 3-4 DEG C / min, adding the organic silicon resin, the furan resin and the melamine-formaldehyde resin in the reaction kettle in sequence after the temperature of the reaction kettle reaches 72-76 DEG C, and continuously agitating and mixing for 16 minutes. The preparation method disclosed by the invention is simple in machining process and low in production cost; and once the bonding agent prepared by the invention is added to make the stemming, the stemming is good in opening performance, is resistant to the scouring and corrosion of high-temperature slag iron, and does not generate pollution to the environment.

Owner:郯城县医化产业发展集团有限公司

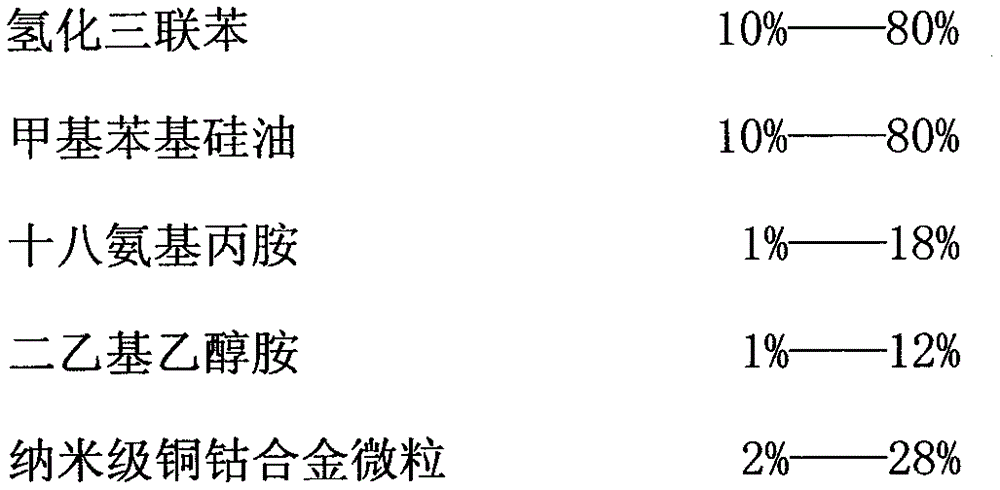

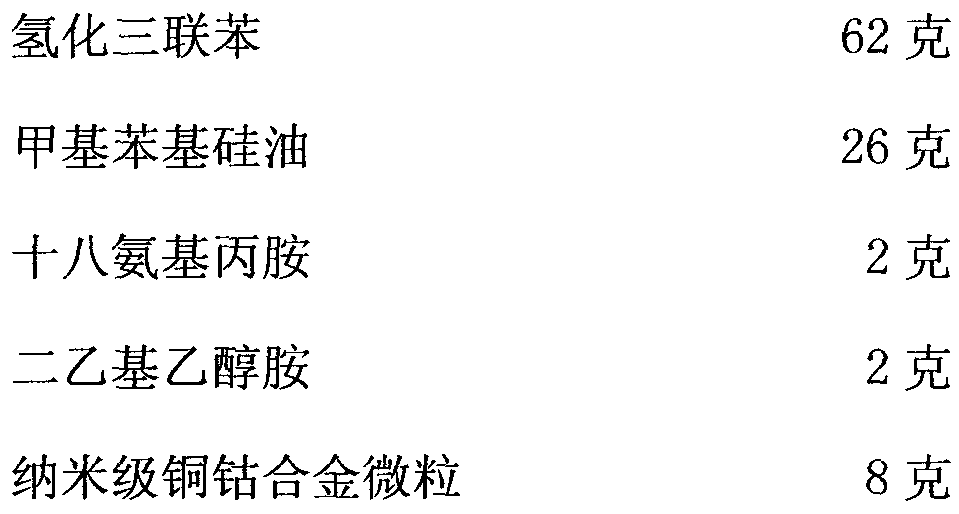

Novel nanometer-grade copper-cobalt alloy micro-particle heat conducting liquid material

InactiveCN104479640AFast heat dissipationHeat-exchange elementsHeat conductingHydrogenated terphenyls

The invention discloses a novel nanometer-grade copper-cobalt alloy micro-particle heat conducting liquid material and belongs to the field of energy chemistry. The prescription of the novel nanometer-grade copper-cobalt alloy micro-particle heat conducting liquid material is characterized by consisting of hydrogenated terphenyl, methyl phenyl silicone oil, octadecylamino-propylamine, diethylethanolamine and nanometer-grade copper-cobalt alloy micro-particles. The invention aims to provide a novel heat conducting liquid material which is high in heat conduction efficiency, rapid in cooling and mainly applied to a solar CSP photo-thermal power generation system and takes nanometer-grade copper-cobalt alloy micro-particles as a dispersion phase. The novel nanometer-grade copper-cobalt alloy micro-particle heat conducting liquid material disclosed by the invention is 1.32W / m.K to 2.6W / m.K in heat conduction coefficient which is about ten times that of the prior art and is far faster than the same type of products in the prior art in cooling speed, which is just the core value of the novel nanometer-grade copper-cobalt alloy micro-particle heat conducting liquid material disclosed by the invention.

Owner:冯智勇

Method for preparing 2,7-dicarboxylic-3,6-diacid naphthalinum 3,6-naphthalenedicarboxylate

InactiveCN101654412AFew synthetic stepsEasy to operateProductsOrganic compound preparationBenzenePotassium

The invention provides a method for preparing 2,7-dicarboxylic-3,6-naphthalenedicarboxylate. The method comprises the following steps: firstly, converting 2,7-dicarboxylic naphthalinum into 2,7-dicarboxylic potassium salt by alkalization; then adding a high-temperature heat medium of hydrogenated terphenyl, obtaining naphtholate; afterwards introducing carbon dioxide, reacting for 4 hours at the temperature of 300-330 DEG C and the pressure of 4-6MPa and obtaining a yellow solid product of the 2,7-dicarboxylic-3,6-naphthalenedicarboxylate by the post-treatment steps of dissolving, filtering, drying and the like. The invention has less synthesis steps, easy operation and low cost. Compared with the prior art, the yield is enhanced by more than 4 times.

Owner:SICHUAN UNIV

Bonding agent for stemming of large-scale blast furnace

The invention discloses a bonding agent for stemming of a large-scale blast furnace, belonging to the technical field of stemming of a blast furnace. The bonding agent for stemming of the large-scale blast furnace comprises the following components in parts by mass: 40 to 50 parts of asphalt, 4 to 6 parts of hydrogenated terphenyl, 10 to 12 parts of organic silicon resin, 8 to 11 parts of furan resin and 11 to 15 parts of melamine formaldehyde resin, wherein the furan resin is furfuryl alcohol resin; the asphalt is petroleum asphalt, wherein the earth asphaltene in the petroleum asphalt is of 25 to 30%. According to the bonding agent disclosed by the invention, the organic silicon resin, the furan resin and the melamine formaldehyde resin are compounded to be served as the component of the curing agent, and moreover, the hydrogenated terphenyl is served as the synergist, thus high plasticity can be obtained, and low curing rate is ensured; reduction of the curing rate of the bonding agent is beneficial for improving the liquidity of the stemming at high temperature, therefore, the stemming is hardly blocked in a mud gun; if the bonding agent disclosed by the invention is added for preparing the stemming, the stemming has good performance on opening; and moreover, the bonding agent has resistance to scouring and eroding of high-temperature scrap iron in slag, and has no pollution to the environment.

Owner:卫勤玲

Method for preparing release agent for precision casting

InactiveCN102989996AThere will be no deterioration and failureGood release effectFoundry mouldsFoundry coresDioxyethylene EtherDibutyltin dilaurate

The invention discloses a method for preparing a release agent for precision casting, belonging to the technical field of release agents. The method comprises the steps of: (1) weighing 3-5 parts of titanium dioxide, 11-16 parts of quicklime, 7-9 parts of zinc oxide and 8-12 parts of polyoxyethylene octylphenol ether by mass and adding into a dispersion machine; (2) adding the dispersed mixture obtained in the step (1) into a reaction kettle, when the temperature of the reaction kettle reaches 40-45 DEG C and the thermostatic reaction is carried out for 30-35 minutes, weighing 6-7 parts of dibutyltin dilaurate by mass and adding into the reaction kettle, controlling the heating rate to be 3-4 DEG C / min and when the temperature of the reaction kettle reaches 58-62 DEG C, weighing 27-30 parts of hydrogenated terphenyl and 20-25 parts of 320 conduction oil by mass; and (3) cooling the mixture obtained in the step (2) to 20-25 DEG C, weighing 5-8 parts of kerosene and 10-13 parts of butyl acrylate by mass and mixing with the mixture obtained in the step (2). The method disclosed by the invention has the advantages that the production cost is low; the demoulding effect of the release agent is good; and the rejection rate is reduced.

Owner:高金菊

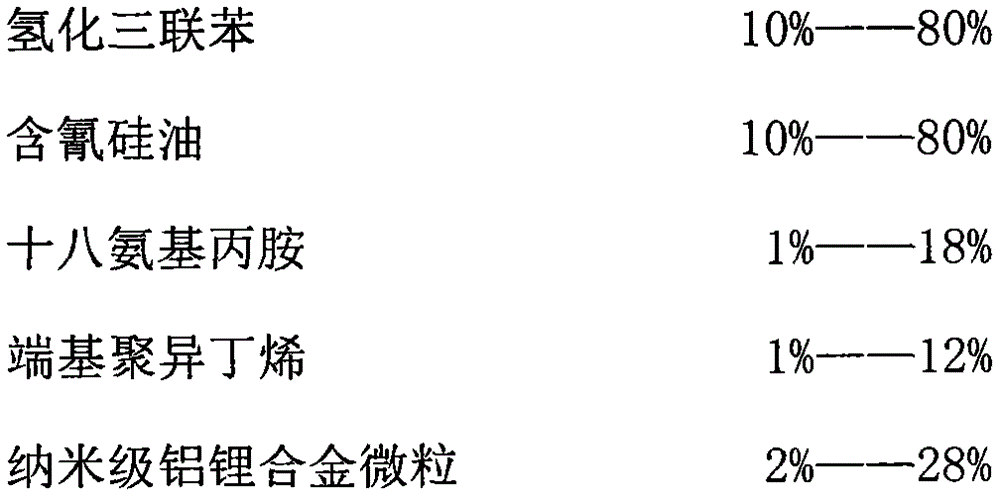

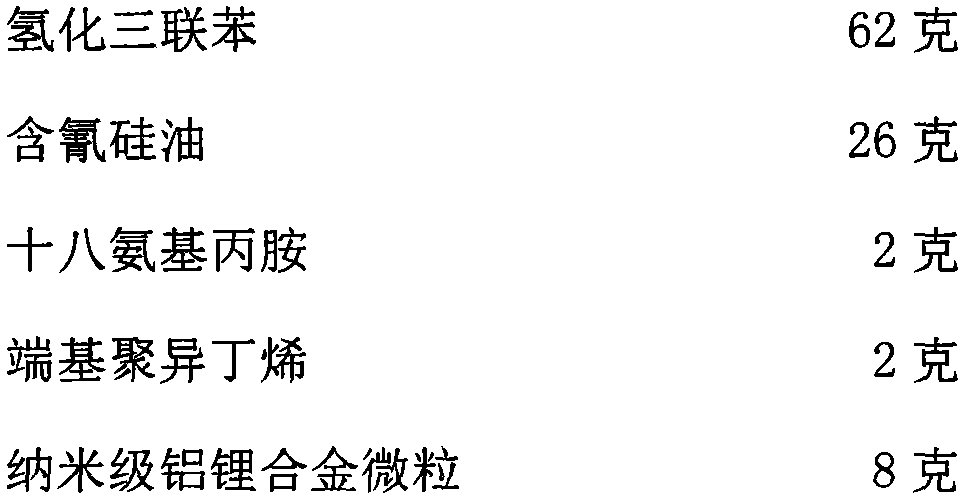

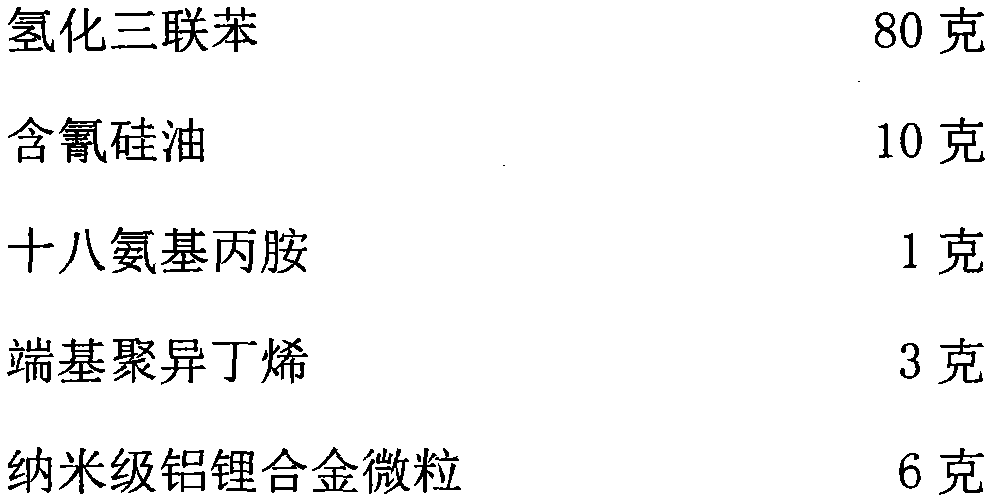

New heat conduction liquid material containing nanometer aluminum-lithium alloy particles

The invention discloses a new heat conduction liquid material containing nanometer aluminum-lithium alloy particles, and belongs to the field of energy chemistry. The formula of the new heat conduction liquid material comprises hydrogenated terphenyl, cyanogens-containing silicone oil, octaamino propylanmine, terminal-based polyisobutylene and the nanometer aluminum-lithium alloy particles. The new heat conduction liquid material containing the nanometer aluminum-lithium alloy particles as a dispersion phase has the characteristics of high heat transfer efficiency and fast heat radiation, and is mainly used in solar CSP photothermal electric generation systems. The new heat conduction liquid material has the following advantages: the heat conduction coefficient of the material is 1.65-2.55W / m.K, and is about 10 times that of like products in prior art; and the heat radiation speed of the material is far larger than that of the like products in the prior art.

Owner:冯智勇

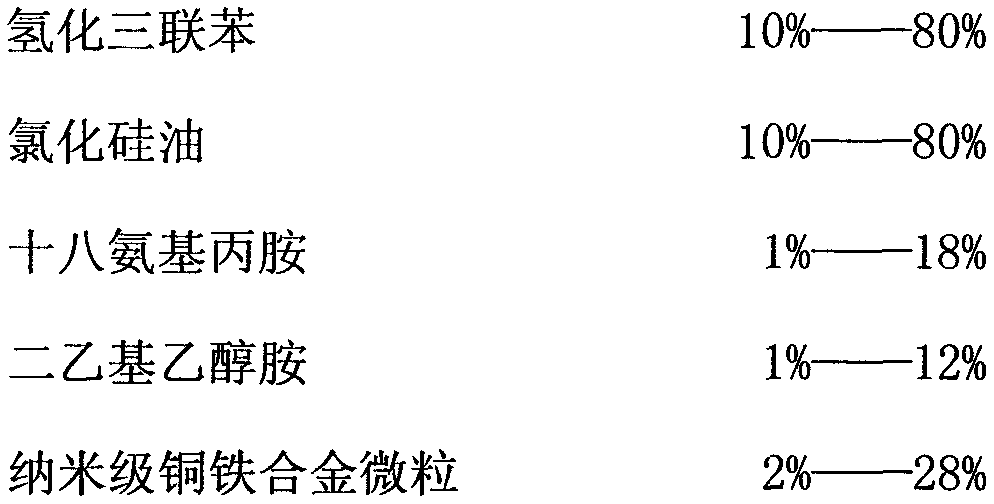

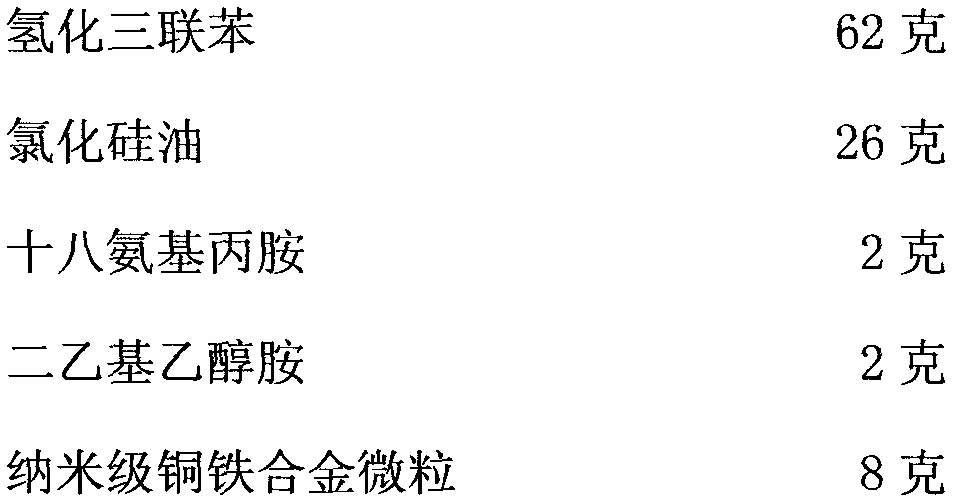

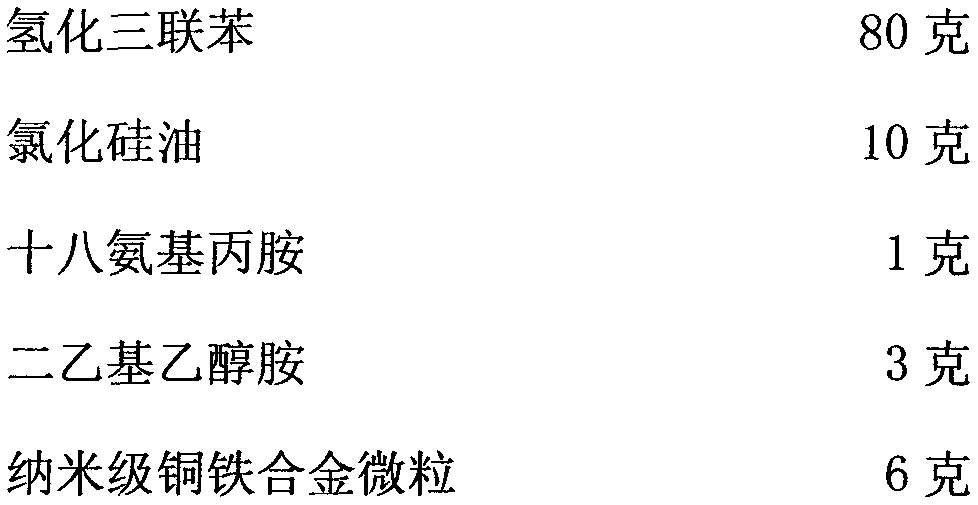

Novel nanometer-grade copper-iron alloy micro-particle heat conducting liquid material

The invention discloses a novel nanometer-grade copper-iron alloy micro-particle heat conducting liquid material and belongs to the field of energy chemistry. The prescription of the novel nanometer-grade copper-iron alloy micro-particle heat conducting liquid material is characterized by consisting of hydrogenated terphenyl, chloridized silicon oil, octadecylamino-propylamine, diethylethanolamine and nanometer-grade copper-iron alloy micro-particles. The invention aims to provide a novel heat conducting liquid material which is high in heat conduction efficiency, rapid in cooling and mainly applied to a solar CSP photo-thermal power generation system and takes nanometer-grade copper-iron alloy micro-particles as a dispersion phase. The novel nanometer-grade copper-iron alloy micro-particle heat conducting liquid material disclosed by the invention is 1.2W / m.K to 2.3W / m.K in heat conduction coefficient which is about ten times that of the prior art and is far faster than the same type of products in the prior art in cooling speed, which is just the core value of the novel nanometer-grade copper-iron alloy micro-particle heat conducting liquid material disclosed by the invention.

Owner:冯智勇

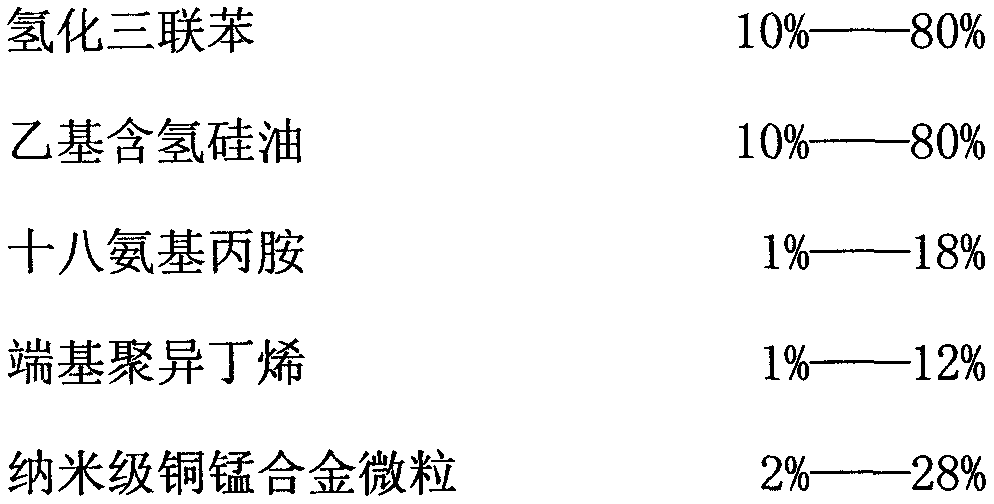

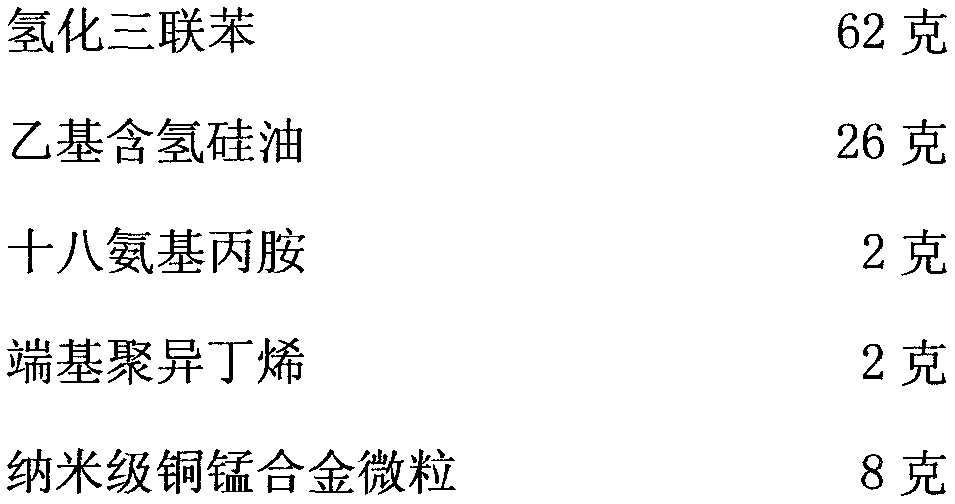

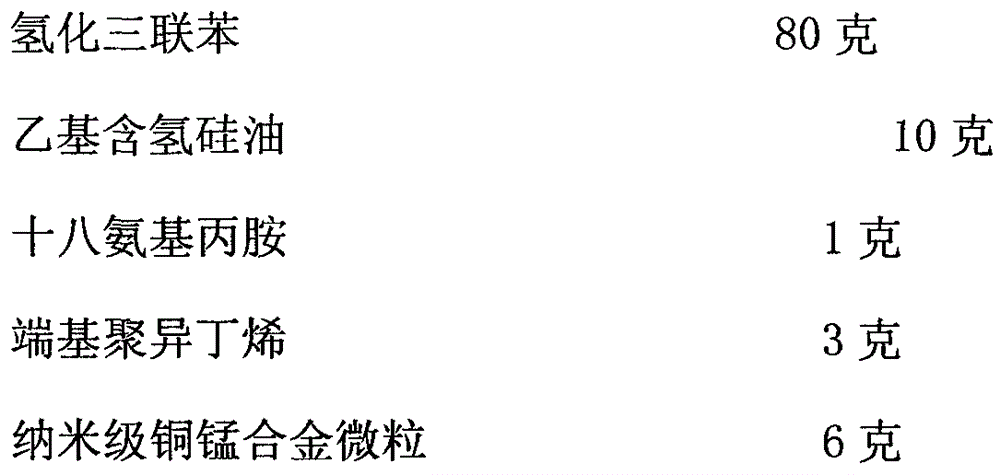

Novel nanometer-grade copper-manganese alloy micro-particle heat conducting liquid material

The invention discloses a novel nanometer-grade copper-manganese alloy micro-particle heat conducting liquid material and belongs to the field of energy chemistry. The prescription of the novel nanometer-grade copper-manganese alloy micro-particle heat conducting liquid material is characterized by consisting of hydrogenated terphenyl, hydrogen-containing ethyl silicone oil, octadecylamino-propylamine, terminal polyisobutene and nanometer-grade copper-manganese alloy micro-particles. The invention aims to provide a novel heat conducting liquid material which is high in heat conduction efficiency, rapid in cooling and mainly applied to a solar CSP photo-thermal power generation system and takes nanometer-grade copper-manganese alloy micro-particles as a dispersion phase. The novel nanometer-grade copper-manganese alloy micro-particle heat conducting liquid material disclosed by the invention is 1.26W / m.K to 2.5W / m.K in heat conduction coefficient which is about ten times that of the prior art and is far faster than the same type of products in the prior art in cooling speed, which is just the core value of the novel nanometer-grade copper-manganese alloy micro-particle heat conducting liquid material disclosed by the invention.

Owner:冯智勇

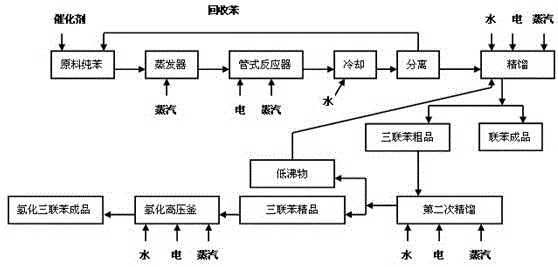

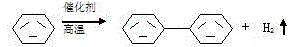

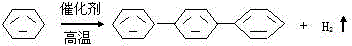

A kind of method for preparing hydrogenated terphenyl

ActiveCN103804114BImprove conversion rateReduce the impactHydrocarbon by hydrogenationHydrogenated terphenylsEnergy consumption

The invention discloses a method for preparing hydrogenated terphenyl. The method comprises the following steps: (1) synthesizing biphenyl; (2) rectifying for the first time; (3) rectifying for the second time; (4) hydrogenating. According to the method, an efficient and energy-saving pipe type reactor is utilized, so that the energy consumption can be greatly reduced and the conversion rate of a product is high. By technically improving the process, the conversion rate of the terphenyl can be greatly improved under the conditions of not influencing the service life of equipment and not increasing the energy consumption, and the conversion rate can be up to about 70%; the raw material problems of the hydrogenated terphenyl can be sufficiently solved so that the market requirements can be met relatively.

Owner:安徽奥瑞化工有限公司

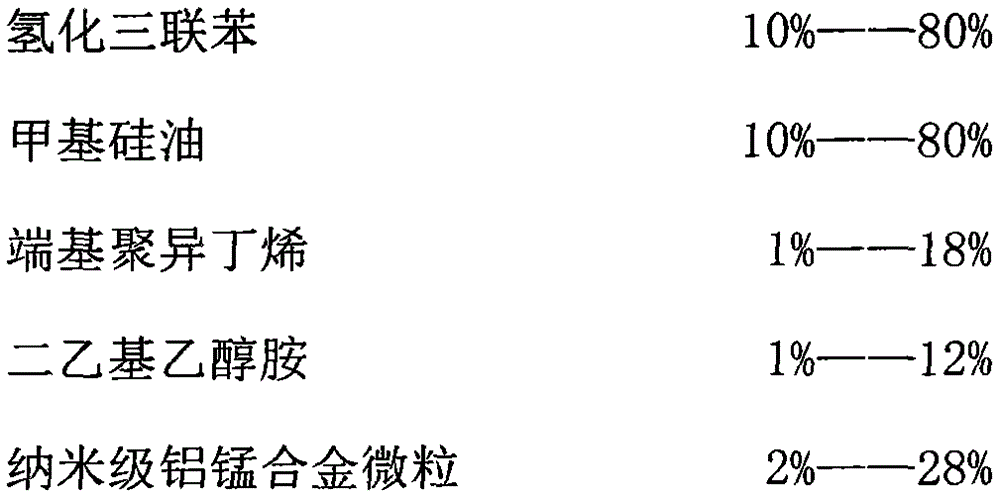

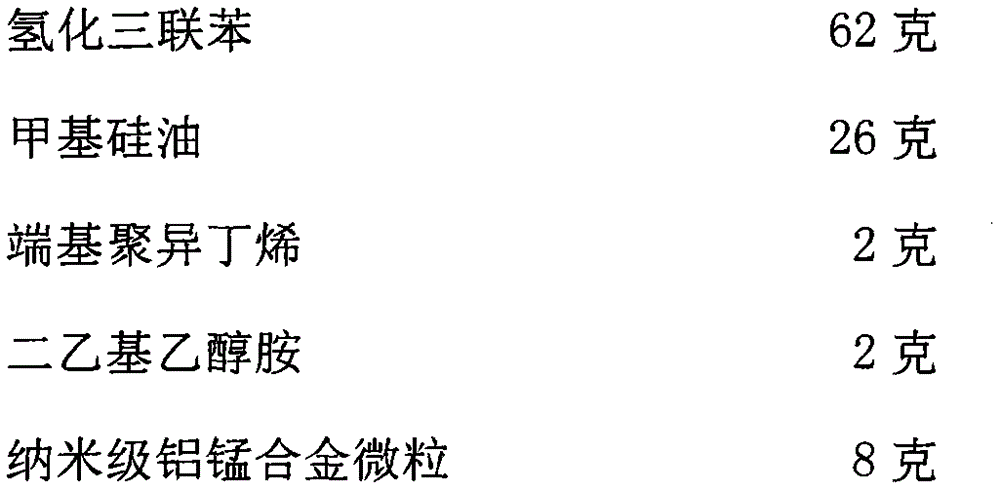

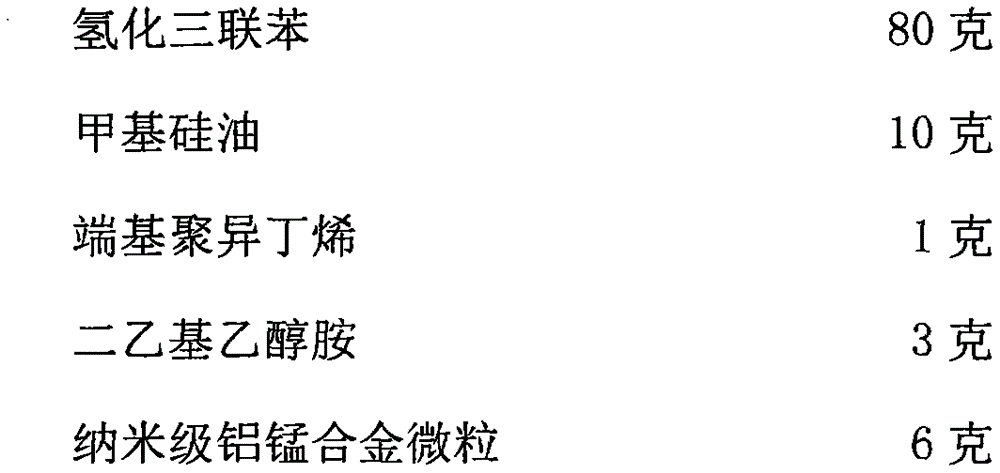

New heat conduction liquid material containing nanometer aluminum-manganese alloy particles

The invention discloses a new heat conduction liquid material containing nanometer aluminum-manganese alloy particles, and belongs to the field of energy chemistry. The formula of the new heat conduction liquid material comprises hydrogenated terphenyl, methyl silicone oil, terminal-based polyisobutylene, diethyl ethanolamine and the nanometer aluminum-manganese alloy particles. The new heat conduction liquid material containing the nanometer aluminum-manganese alloy particles as a dispersion phase has the characteristics of high heat transfer efficiency and fast heat radiation, and is mainly used in solar CSP photothermal electric generation systems. The new heat conduction liquid material has the following advantages: the heat conduction coefficient of the material is 1.33-2.65W / m.K, and is about 10 times that of like products in prior art; and the heat radiation speed of the material is far larger than that of the like products in the prior art.

Owner:冯智勇

Non-aqueous electrolyte secondary battery

ActiveUS8367252B2Improve securityIncrease resistanceAlkaline accumulatorsNon-aqueous electrolyte accumulatorsCarbon compositesBoron containing

A non-aqueous electrolyte secondary battery wherein the non-aqueous electrolyte contains a non-aqueous solvent, a solute dissolved in the non-aqueous solvent, and hydrogenated terphenyl, the solute includes a boron-containing alkali salt and a boron-free alkali salt, the negative electrode includes a negative electrode active material comprising a randomly oriented carbon composite (A), and the carbon composite (A) contains a graphitic carbon substance (B) and a carbon substance (C) that is different from the graphitic carbon substance (B).

Owner:PANASONIC HLDG CORP

Method for preparing 2,7-dicarboxylic-3,6-diacid naphthalinum 3,6-naphthalenedicarboxylate

Owner:SICHUAN UNIV

Preparation method of high-purity hydrogenated terphenyl heat conduction oil

InactiveCN111018652AReduce contentHigh purityChemical industryDistillation purification/separationDistillationHydrogenation reaction

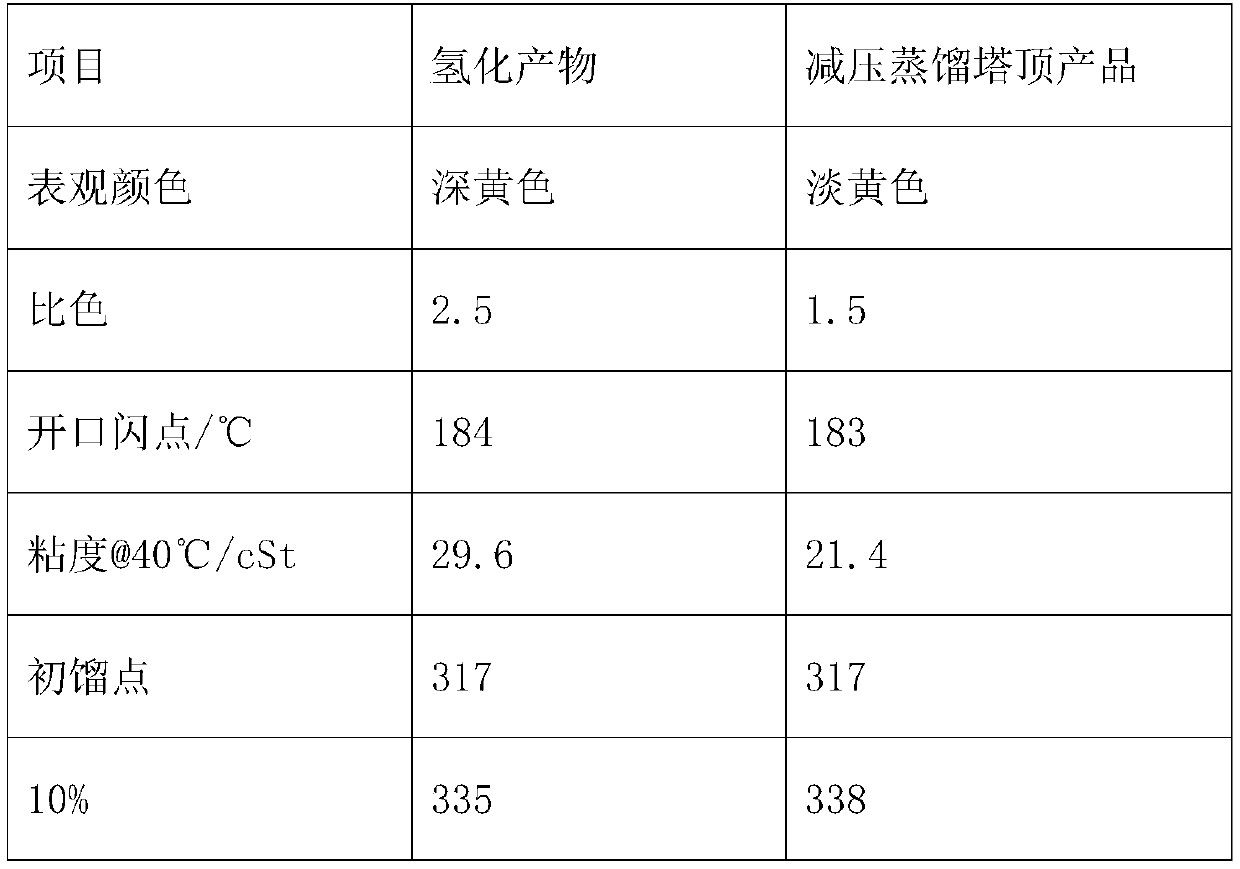

The invention discloses a preparation method of a high-purity hydrogenated terphenyl heat conduction oil. The preparation method comprises the following steps: (1) connecting a reduced pressure distillation tower behind a terphenyl hydrogenation reaction kettle; (2) sampling a product obtained after the hydrogenation reaction of terphenyl, and carrying out chromatographic analysis to determine each component and the content thereof in the product; (3) vacuumizing the reduced pressure distillation tower, and self-sucking a material in a hydrogenation reaction kettle into the reduced pressure distillation tower; and (4) closing a feed port valve after charging is finished, opening a tower top valve, carrying out reduced pressure distillation to collect tower top materials, cooling the towertop materials through a heat exchanger, and feeding into a product storage tank. By adopting the method disclosed by the invention, the content of non-ideal components, namely hydrogenated tetraphenyland hydrogenated pentaphenyl, is reduced, the purity of hydrogenated terphenyl is improved, the heat conductivity coefficient is increased, and when the hydrogenated terphenyl is used as heat conduction oil, the heat transfer efficiency of the product is improved, the energy consumption is reduced, and the problems of pipeline blockage and equipment corrosion are avoided.

Owner:江苏曼拓化学有限公司

Heat Transfer Fluid and Process for Preparing Same

A heat transfer fluid comprising about 20 to about 80% by weight terphenyls and from about 20 to about 80% by weight partially hydrogenated terphenyls, wherein preferably the terphenyls and partially hydrogenated terphenyls comprise a reclaimed product from a degraded heat transfer fluid initially comprised primarily of partially hydrogenated terphenyls.

Owner:ORG CHEM GRP

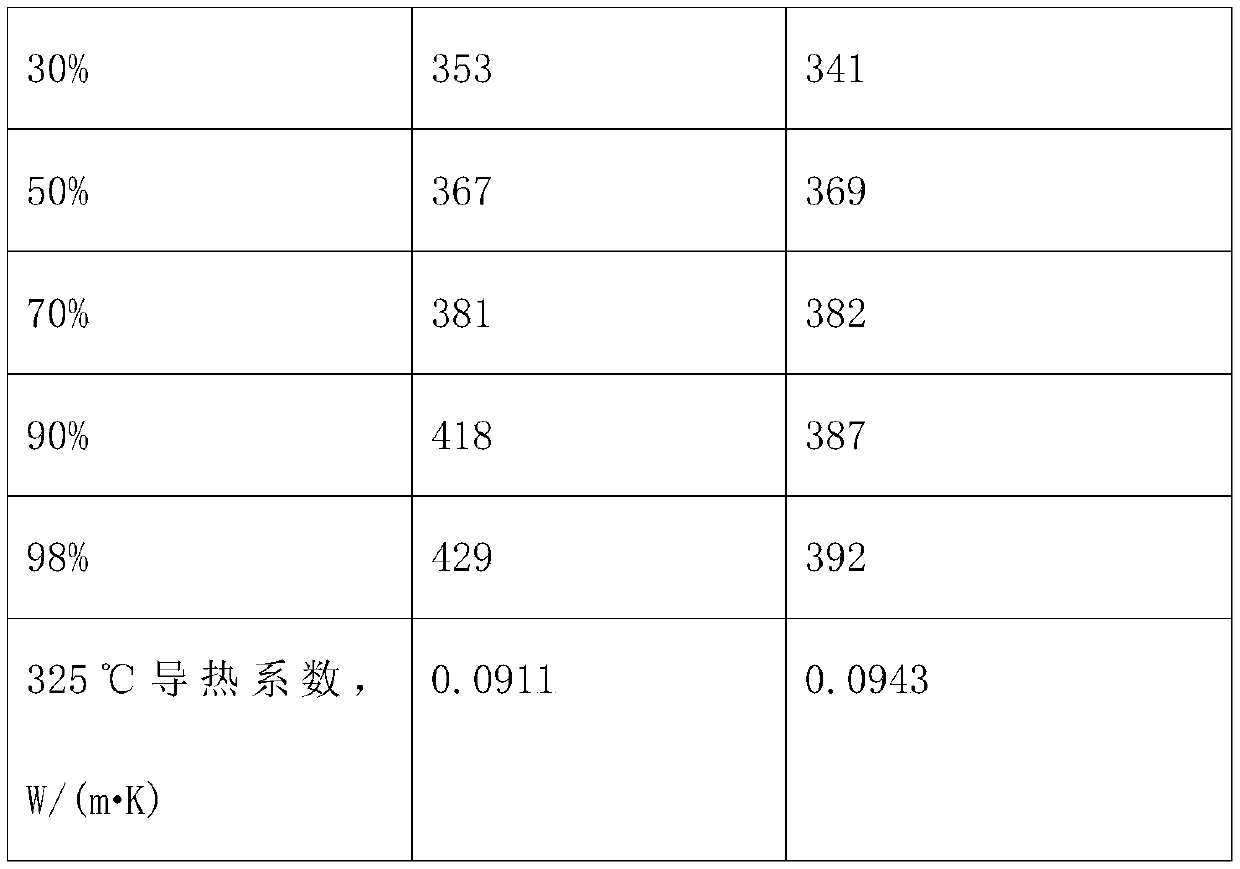

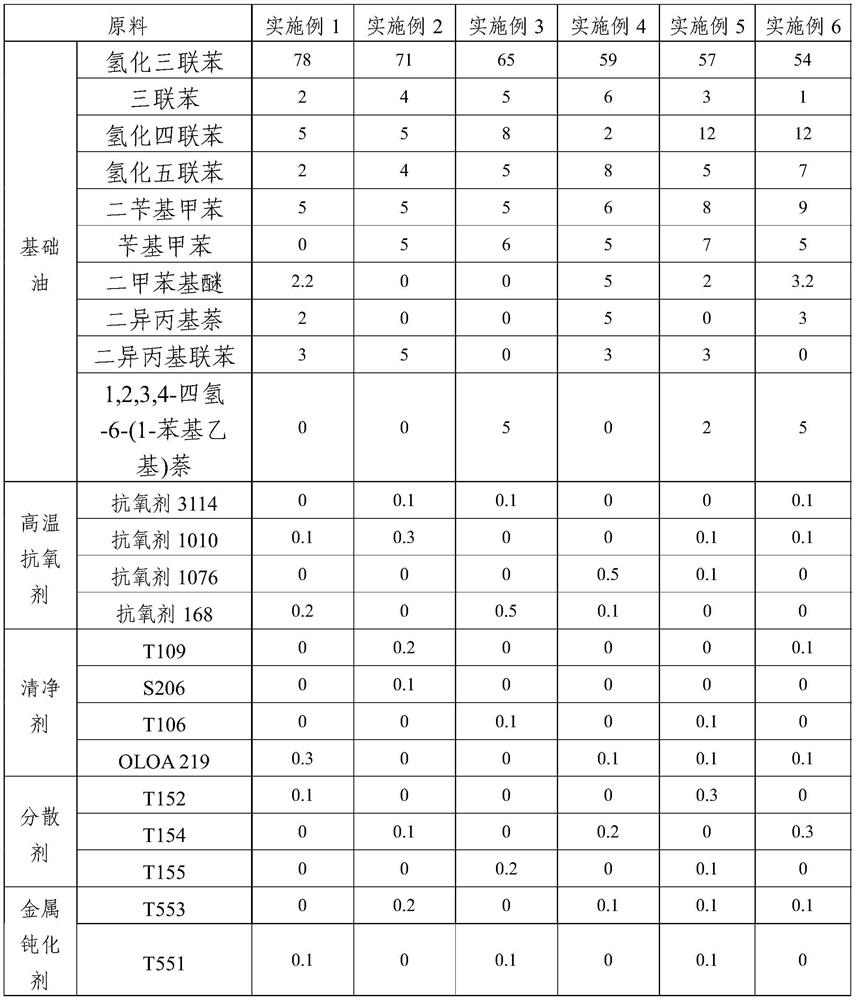

High-temperature heat-conducting oil and preparation method thereof

PendingCN113913164AAchieve synergyImprove thermal stabilityHeat-exchange elementsDibenzyltolueneIsopropylbiphenyl

Owner:CHINA PETROLEUM & CHEM CORP

Formula and preparation method of heat transfer fluid

InactiveCN113278404AGood antifreezeAvoid condensationHeat-exchange elementsPhosphoric acidHeat transfer fluid

The invention discloses a formula and a preparation method of a heat transfer fluid. The heat transfer fluid comprises the following raw materials by mass: 5-7% of hydrogenated terphenyl, 4-8% of polydodecene, 6-9% of cyanogen-containing silicone oil, 3-5% of a nanometer mixture, 2-4% of trisodium phosphate, 1-2% of sodium sulfate, 3-7% of alcohol, 1-2% of polyepoxysuccinic acid, 5-8% of polyether silicone oil, 2-5% of potassium permanganate, 0.5-1% of alkyl aryl sodium iodate, and 45-84% of pure water. The prepared the heat transfer fluid has a good anti-freezing effect, the phenomenon that the heat transfer fluid is condensed in the standing process in winter is avoided, the heat transfer fluid has good anti-corrosion, corrosion inhibition and anti-scaling effects in the using process, the replacement probability and cost of the heat transfer fluid are reduced, the heat transfer fluid does not have a heat gathering phenomenon in the using process, and the stability of the heat transfer fluid in the using process is improved.

Owner:马云华

Preparation method of bonding agent for blast furnace stemming with good opening performance

ActiveCN102887719BImprove liquidityNot easy to agglomeratePhysical chemistryMelamine formaldehyde resin

The invention discloses a preparation method of a bonding agent for blast furnace stemming with good opening performance, belonging to the field of the blast furnace stemming. The preparation method comprises the following steps of: (1) weighing 40-50 parts of asphalt and 4-6 parts of hydrogenated terphenyl in parts by weight, adding the asphalt and the hydrogenated terphenyl in a reaction kettle in sequence, and agitating and mixing for 20 minutes at the temperature of 55-60 DEG C; and (2) weighing 10-12 parts of organic silicon resin, 8-11 parts of furan resin and 11-15 parts of melamine-formaldehyde resin in parts by weight, controlling the temperature rise rate of the reaction kettle in the step (1) to be 3-4 DEG C / min, adding the organic silicon resin, the furan resin and the melamine-formaldehyde resin in the reaction kettle in sequence after the temperature of the reaction kettle reaches 72-76 DEG C, and continuously agitating and mixing for 16 minutes. The preparation method disclosed by the invention is simple in machining process and low in production cost; and once the bonding agent prepared by the invention is added to make the stemming, the stemming is good in opening performance, is resistant to the scouring and corrosion of high-temperature slag iron, and does not generate pollution to the environment.

Owner:郯城县医化产业发展集团有限公司

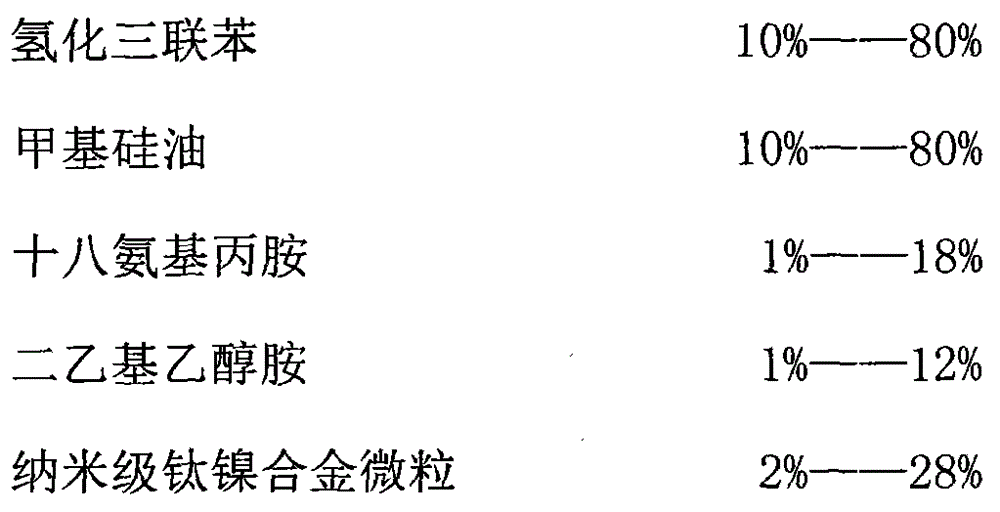

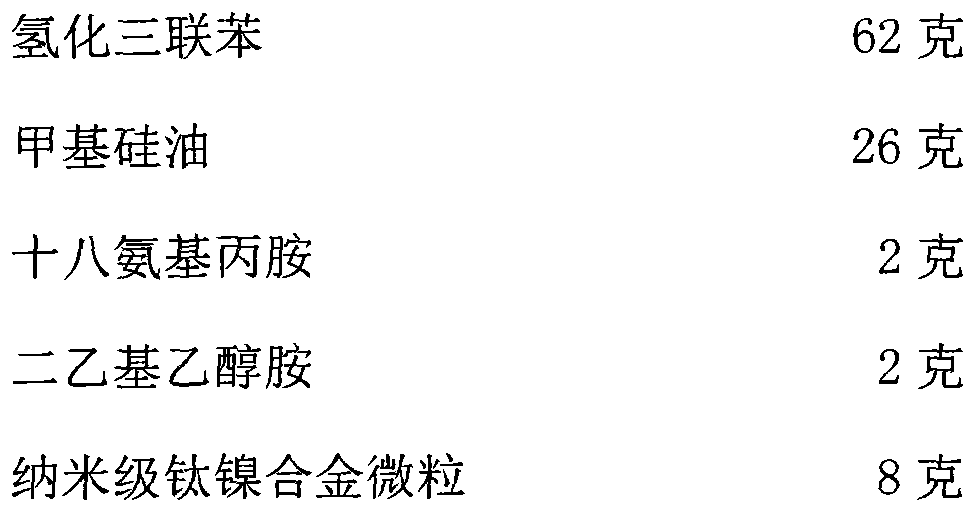

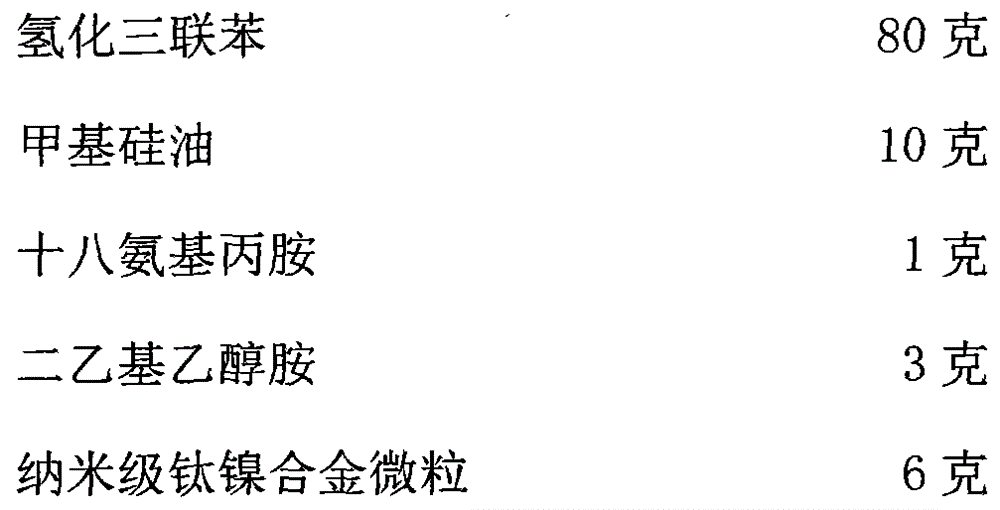

Heat transfer fluid new material internally containing titanium nickel alloy nanoparticles

The invention discloses a heat transfer fluid new material internally containing titanium nickel alloy nanoparticles, belonging to the field of energy chemistry. The formula of the new material is characterized by comprising hydrogenated terphenyl, methyl silicone oil, octadecyl amino propylamine, diethyl ethanolamine, and titanium nickel alloy nanoparticles. The invention is to provide the heat transfer fluid new material internally containing titanium nickel alloy nanoparticles as a dispersion phase. The new material is high in heat transfer efficiency and fast in heat dissipation and mainly applied in a solar CSP solar-thermal power generation system. The product has a thermal conductivity coefficient of 1.25-2.35 W / m.K which is about ten times of that of products in the prior art, and the heat dissipation is faster than that of similar products in the prior art.

Owner:冯智勇

Anhydrous stemming for blast furnace tapping hole

The invention discloses anhydrous stemming for a blast furnace tapping hole, belonging to the technical field of refractory material for blast furnaces. The anhydrous stemming for a blast furnace tapping hole disclosed by the invention is composed of refractory aggregate and bonding agent, wherein the refractory aggregate comprises the following components in parts by mass: 12-14 parts of titanium dioxide, 3-5 parts of titanium carbide, 20-25 parts of corundum, 15-18 parts of silicon carbide, 30-38 parts of mullite, 5-7 parts of calcium-free chromium slag, 6-8 parts of blast furnace gas ash, and 9-11 parts of coke; and the bonding agent comprises the following components in parts by mass: 40-50 parts of asphalt, 4-6 parts of hydrogenated terphenyl, 10-12 parts of organic silicon resin, 8-11 parts of furan resin, and 11-15 parts of melamine-formaldehyde resin, wherein the mass ratio of the refractory aggregate to the bonding agent is 100:13-15. The anhydrous stemming disclosed by the invention has good opening performance, moderate plasticity, can resist scouring and erosion of high-temperature iron slag, does not pollute the environment, and is low in production cost.

Owner:ANHUI SAFE ELECTRONICS

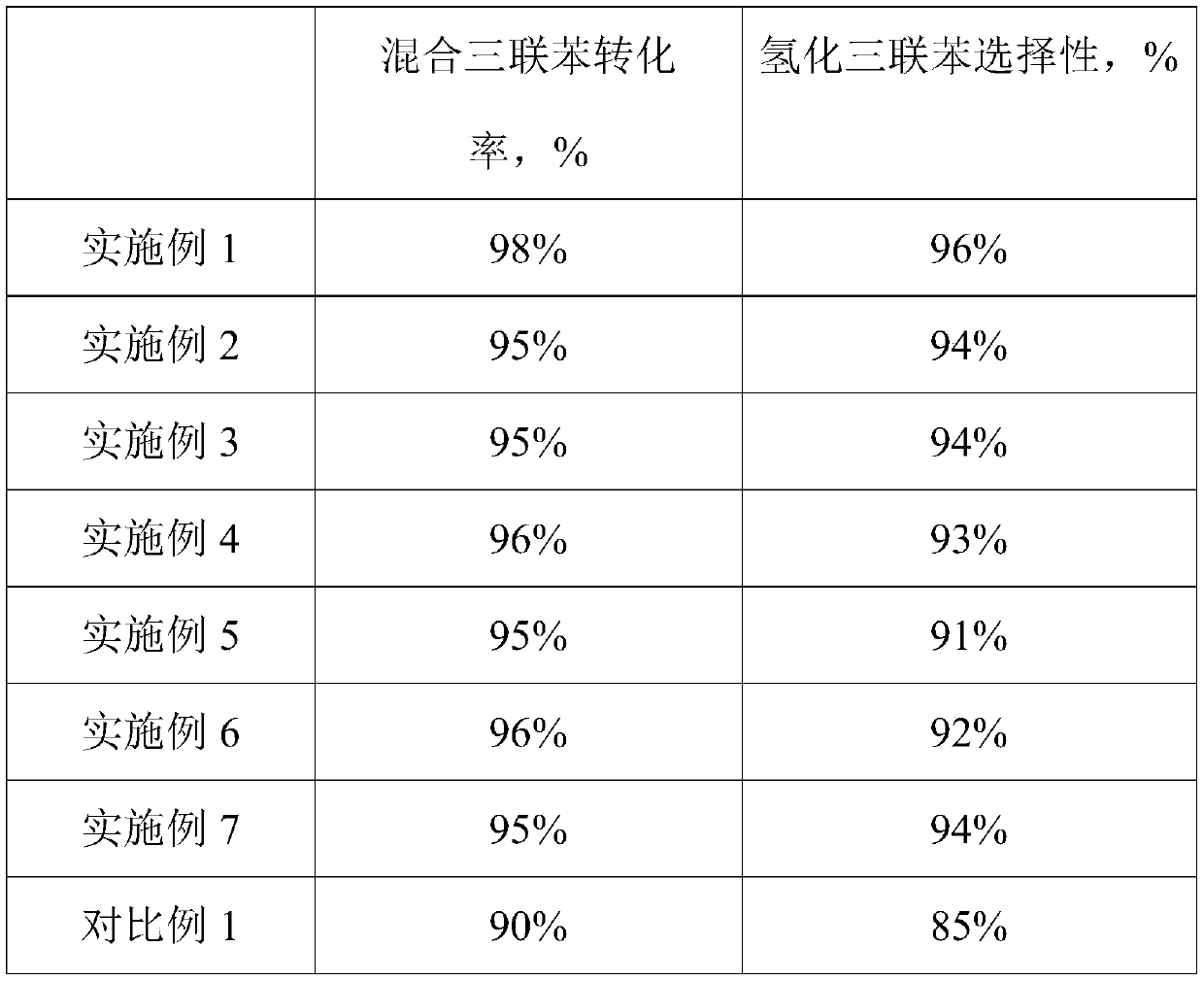

Catalyst for preparing hydrogenated terphenyl as well as preparation method and application thereof

InactiveCN111482177AReduce dosageHigh yieldDistillation purification/separationCatalyst activation/preparationPolymer sciencePtru catalyst

The invention relates to a catalyst for preparing hydrogenated terphenyl as well as a preparation method and an application of the catalyst. The catalyst comprises a carrier and an active component, the carrier includes MgO, wherein the active component comprises a NiB compound; wherein the molar ratio of Ni to B in the NiB compound is 1: 1. (0.34-0.4), the catalyst is used in the process of preparing hydrogenated terphenyl by catalyzing hydrogenation of mixed terphenyl. The catalyst has the advantages of good selectivity, high conversion rate and multiple times of application, the preparationprocess of the catalyst is simple, the cost is relatively low, the catalyst is applied to catalytic preparation of hydrogenated terphenyl, and the problems of low catalytic efficiency, poor selectivity and high production cost of the catalyst in the traditional hydrogenated terphenyl preparation process are solved.

Owner:JIANGSU XINHE AGROCHEM

A hydrogenated terphenyl type high temperature nano heat transfer oil, its preparation method and application

InactiveCN103923617BLow freezing pointReduce penetrationSolar heat devicesHeat-exchange elementsHeat conductingHigh energy

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

Heat transfer fluid and process for preparing same

ActiveUS10584271B2Vacuum distillation separationHeat-exchange elementsPolymer sciencePartial hydrogenation

A heat transfer fluid comprising about 20 to about 80% by weight terphenyls and from about 20 to about 80% by weight partially hydrogenated terphenyls, wherein preferably the terphenyls and partially hydrogenated terphenyls comprise a reclaimed product from a degraded heat transfer fluid initially comprised primarily of partially hydrogenated terphenyls.

Owner:ORG CHEM GRP

Process for synthesizing hydrogenated terphenyl heat-conducting oil

Owner:SHE COUNTY JINDONG ECONOMIC & TRADE CO LTD

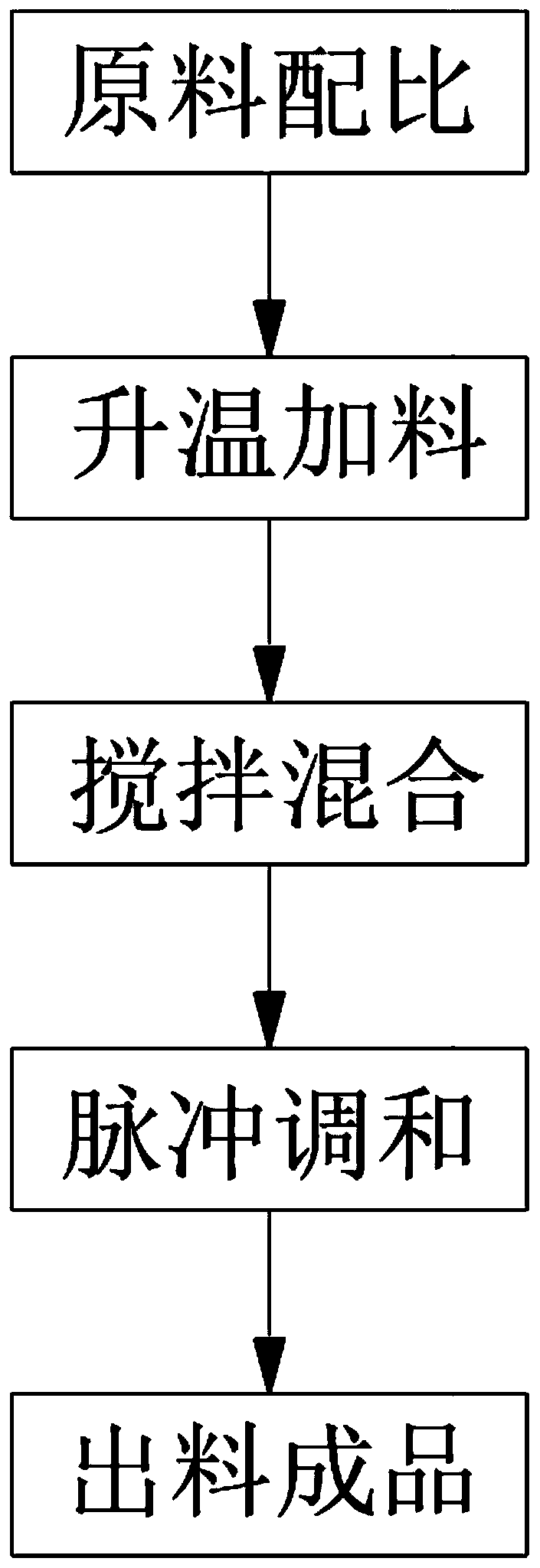

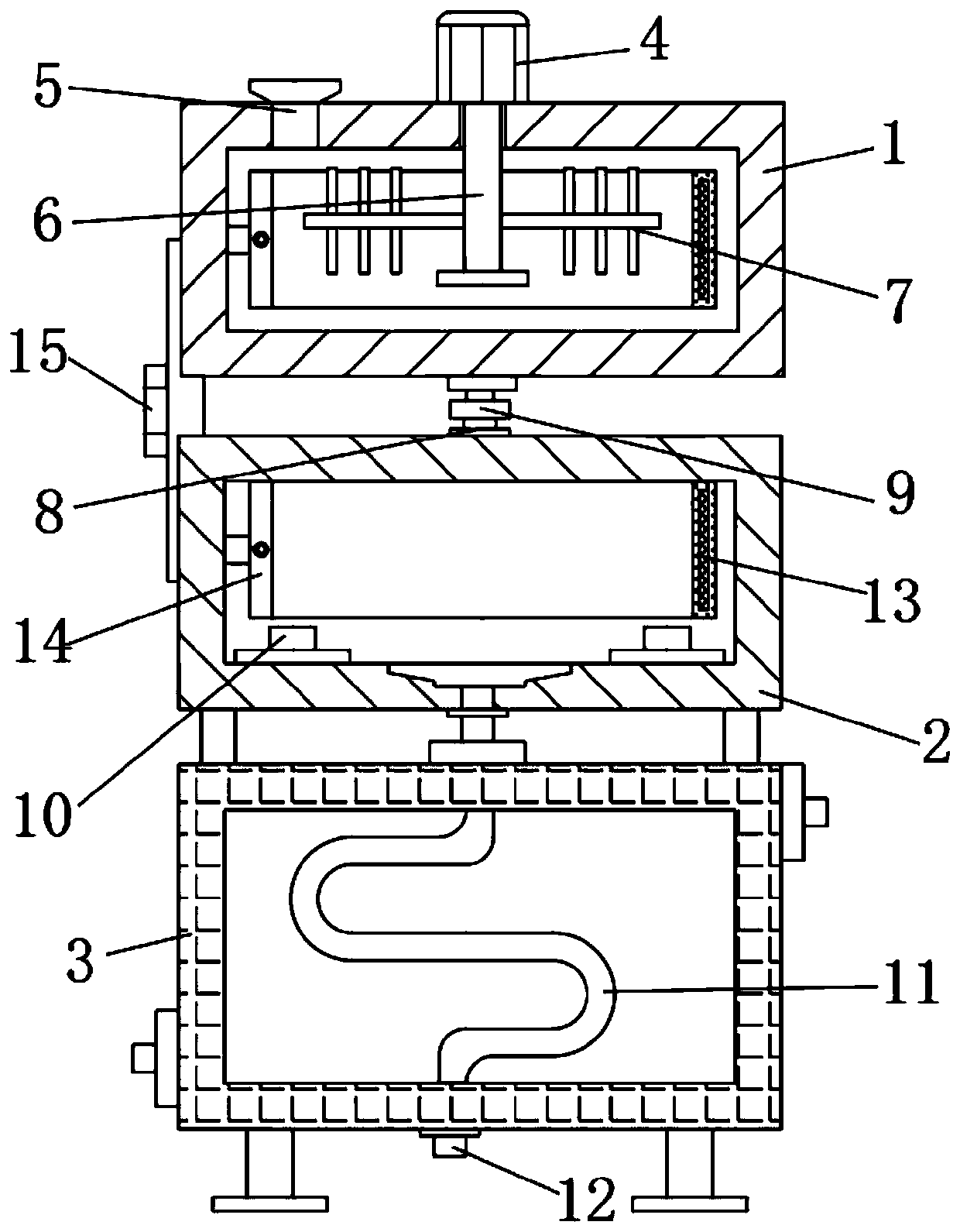

Novel long-service-life energy-saving environment-friendly high-temperature synthetic organic heat carrier

InactiveCN111518523ANo corrosionLow kinematic viscosityHeat-exchange elementsDibenzyltolueneHeat carrier

The invention relates to the technical field of organic heat carrier production, in particular to a novel long-service-life energy-saving environment-friendly high-temperature synthetic organic heat carrier. A method comprises the following steps: 1 preparing raw material; 2, heating and feeding; 3, stirring and mixing; 4, performing pulse blending; and 5, discharging a finished product. The beneficial effects are that according to the invention, imported raw materials are replaced by an isopropyl biphenyl mixture; the product has the advantages of no color, no odor, no corrosion to equipment,low kinematic viscosity, high flow rate, good pumpability, high thermal efficiency, single component, high purity, low vapor pressure, narrow distillation range, good high-temperature thermal stability and good low-temperature flowability, can replace hydrogenated terphenyl and dibenzyl toluene, and has wide market prospects, thereby greatly reduces the production cost. The organic heat carrier completely meets the operation requirement of a low-pressure liquid phase, has a good cleaning function of preventing solid coke scale, is particularly suitable for being used for a long time at the high temperature of 350 DEG C, is long in service life, and has the excellent performances of being renewable, energy-saving, safe, environment-friendly and high in cost performance.

Owner:SHANDONG NORTH ZITE SPECIAL OIL

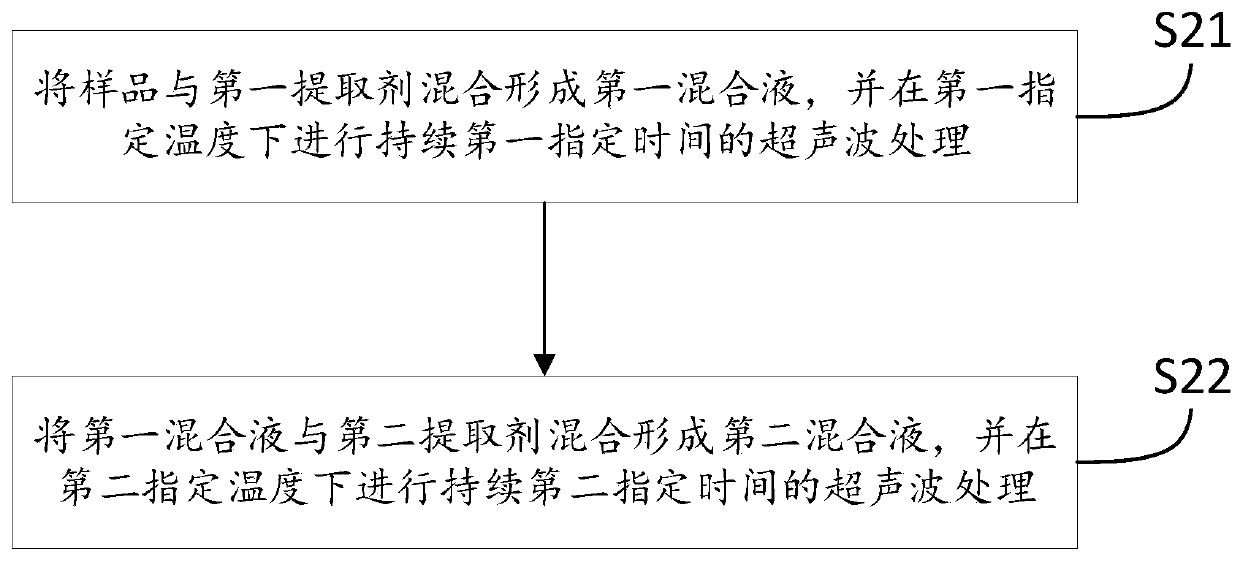

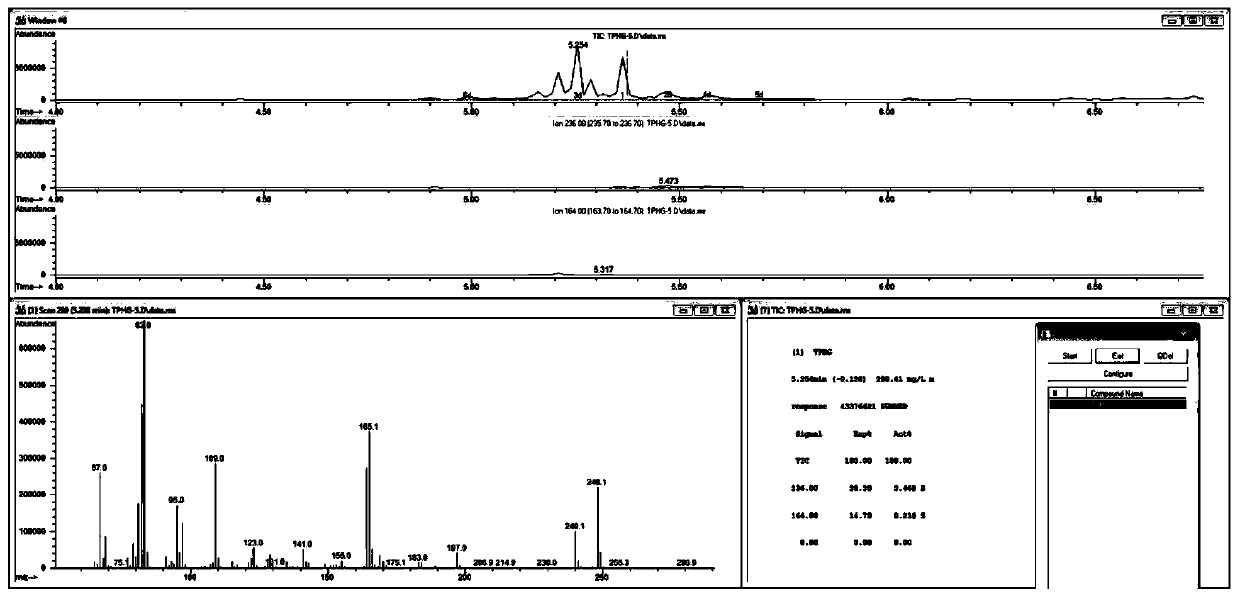

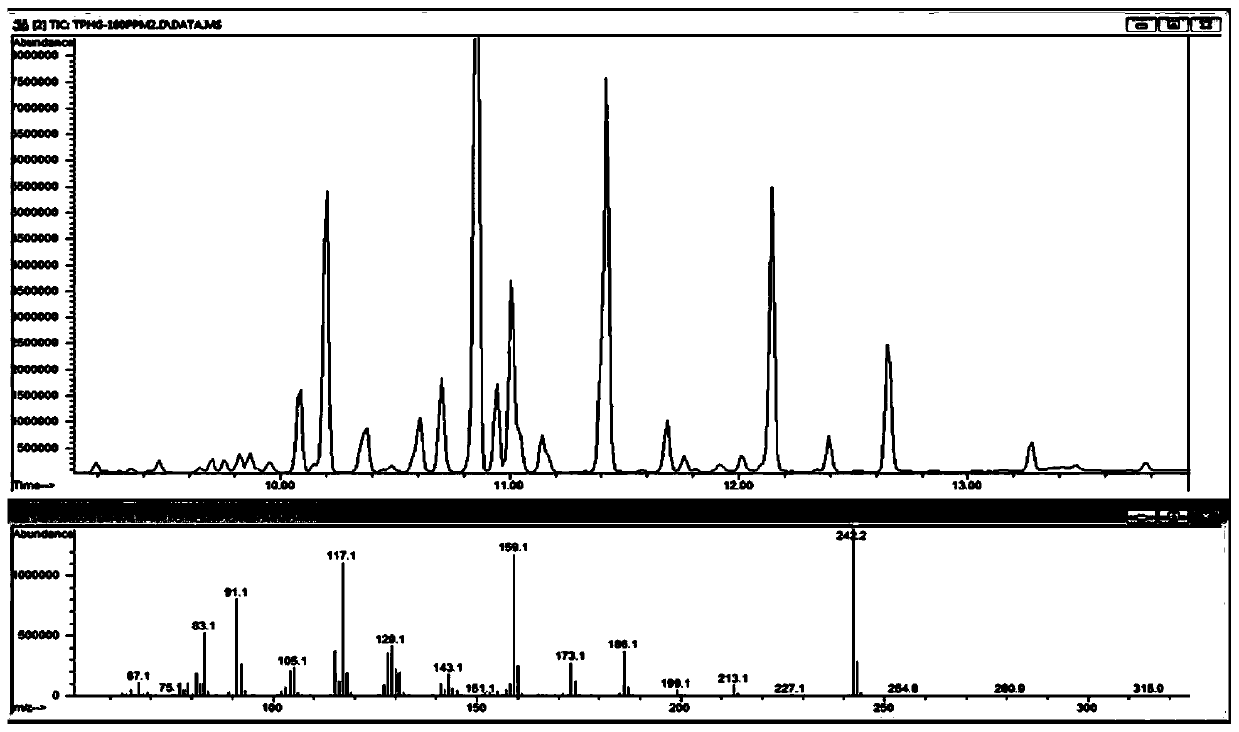

Method for measuring hydrogenated terphenyl

ActiveCN110702814ALow detection limitEasy to operateComponent separationHydrogenated terphenylsEngineering

The invention discloses a method for measuring hydrogenated terphenyl, comprising the steps of: performing sampling; performing pre-treatment and detecting the content of the hydrogenated terphenyl ina target object subjected to the pre-treatment, wherein the pre-treatment comprises the steps of: mixing a sample with a first extracting agent to form a first mixing liquid, and performing ultrasonic treatment at a first designated temperature for a first preset time; mixing the first mixing liquid with a second extracting agent to form a second mixing liquid, and performing ultrasonic treatmentat a second designated temperature for a second preset time. The method of the invention has the beneficial effects that: multiple reagents are reduced, thus the method is environment friendly and healthy for human body; a detection limit is low, operation is simple and promotion performance is strong; a test instrument can be obtained easily, a GC-MS (Gaschromatographic-Mass Spectrometry) analyzer is used, and the GC-MS analyzer is high in sensitivity and good in anti-interference capability.

Owner:深圳天祥质量技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com