A hydrogenated terphenyl type high temperature nano heat transfer oil, its preparation method and application

A technology of hydrogenated terphenyl type and hydrogenated terphenyl type, which is applied in the field of hydrogenated terphenyl type high-temperature nano heat transfer oil, can solve the problems of increasing the flow resistance of heat transfer oil, reducing the effect of heating and heat transfer, and affecting the accuracy of temperature control, etc. Effects of flow resistance, fast heat transfer, and high suspension stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Prepare 7kg of excess copper nanoparticles by gas phase method.

[0047] 2) Take 3 kg of nanoparticles obtained in step 1), disperse them in deionized water, and use ultrasonic dispersion to disperse them evenly according to the amount of nanoparticles.

[0048] 3) Heating step 2) For the system containing nanoparticles, when the temperature reaches 60°C, stir continuously and slowly add 0.5kg of dispersant Span 85 for coating modification. After continuing for 40min, the modified nanoparticles were made by natural cooling.

[0049] 4) Disperse the above-mentioned modified nanoparticles into 96kg of hydrogenated terphenyl type heat transfer oil at 15°C, stir while heating, gradually raise the temperature to 100°C, and keep it warm for 1h.

[0050] 5) Add 0.5 kg of drag reducer cetyltrimethylammonium chloride to the system in step 4), continue to keep warm and stir for 2 hours, and cool naturally to obtain hydrogenated terphenyl type high-temperature nano heat transf...

Embodiment 2~6

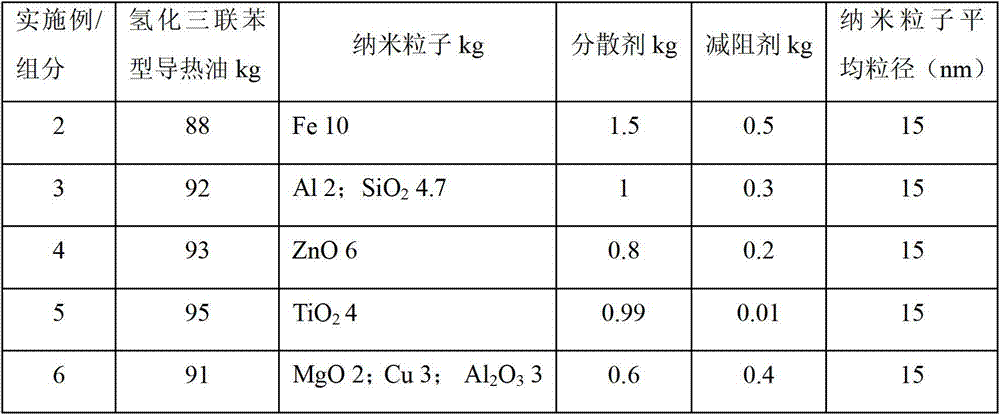

[0052] The preparation methods and conditions of each step in Examples 2-6 are the same as those in Example 1, except that the formula and the dosage of each component are different. The formula and dosage of each component in Examples 2-6 are shown in Table 1.

[0053] Table 1. Examples 2-6 Hydrogenated terphenyl type high-temperature nano heat transfer oil formula and a list of component dosages

[0054]

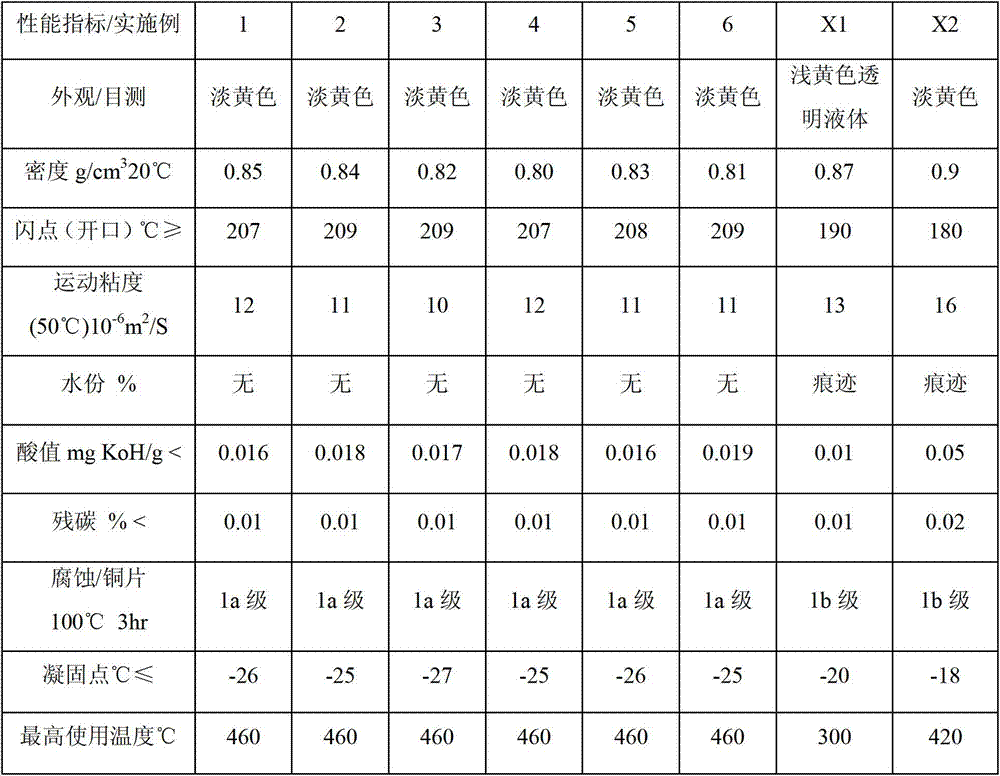

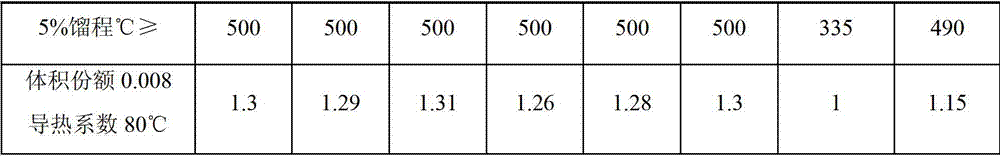

[0055] Table 2 is a comparative list of various performance indicators of the heat transfer oil, including the heat transfer oil obtained in Examples 1 to 6 of the present invention;

[0056] Common heat transfer oil in the prior art (hereinafter referred to as X1), the heat transfer oil prepared by the inventor according to the method of Example 9 of Chinese Invention Patent CN200310114441.6 and the listed ingredients;

[0057] In the prior art, the heat transfer oil with nanoparticles added (hereinafter referred to as X2), the inventor of the present invention prepare...

Embodiment 7

[0062] 1) Prepare 10 kg of aluminum oxide nanoparticles by chemical vapor deposition.

[0063] 2) Take 5 kg of nanoparticles obtained in step 1), disperse them in deionized water, and use mechanical stirring to disperse them evenly according to the amount of nanoparticles.

[0064] 3) Heating step 2) For the system containing nanoparticles, when the temperature reaches 95°C, stir continuously and slowly add 0.5kg of dispersant Span 85 for coating modification. After continuing for 55 minutes, the modified nanoparticles were made by natural cooling.

[0065] 4) At 170°C, disperse the above-mentioned modified nanoparticles into 94kg of hydrogenated terphenyl type heat transfer oil, stir while stirring, when the temperature is 120°C, keep warm for 2h.

[0066] 5) Add 0.5 kg of drag reducer cetyltrimethylammonium chloride to the system in step 4), continue to keep warm and stir for 3 hours, and cool naturally to obtain hydrogenated terphenyl type high-temperature nano heat transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com