Preparation method of high-purity hydrogenated terphenyl heat conduction oil

A hydrogenated terphenyl and heat transfer oil technology, applied in chemical instruments and methods, heat exchange materials, distillation purification/separation, etc., can solve the problem of non-ideal components of pentaphenyl and pentaphenyl, Issues such as by-products of quaterphenyl and pentaphenyl were not raised, which achieved the effects of reducing energy consumption, improving purity, and avoiding pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of the high-purity hydrogenated terphenyl heat-conducting oil of the present embodiment comprises the following steps:

[0022] ① A vacuum distillation tower is connected behind the terphenyl hydrogenation reactor, and the feed port of the vacuum distillation tower is connected with the outlet port of the hydrogenation reactor.

[0023] ② Sampling the product after terphenyl hydrogenation reaction for gas chromatography analysis to determine the components and their content in the product.

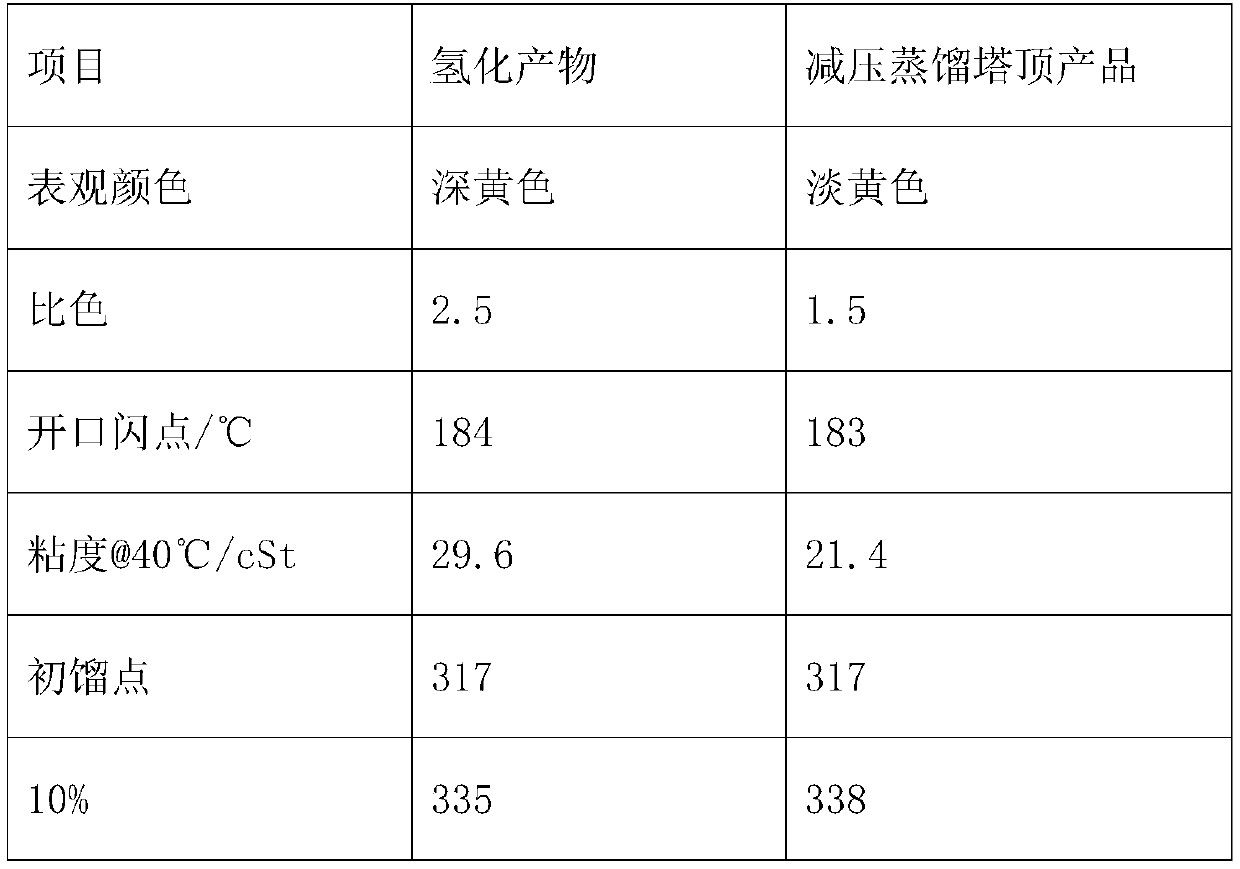

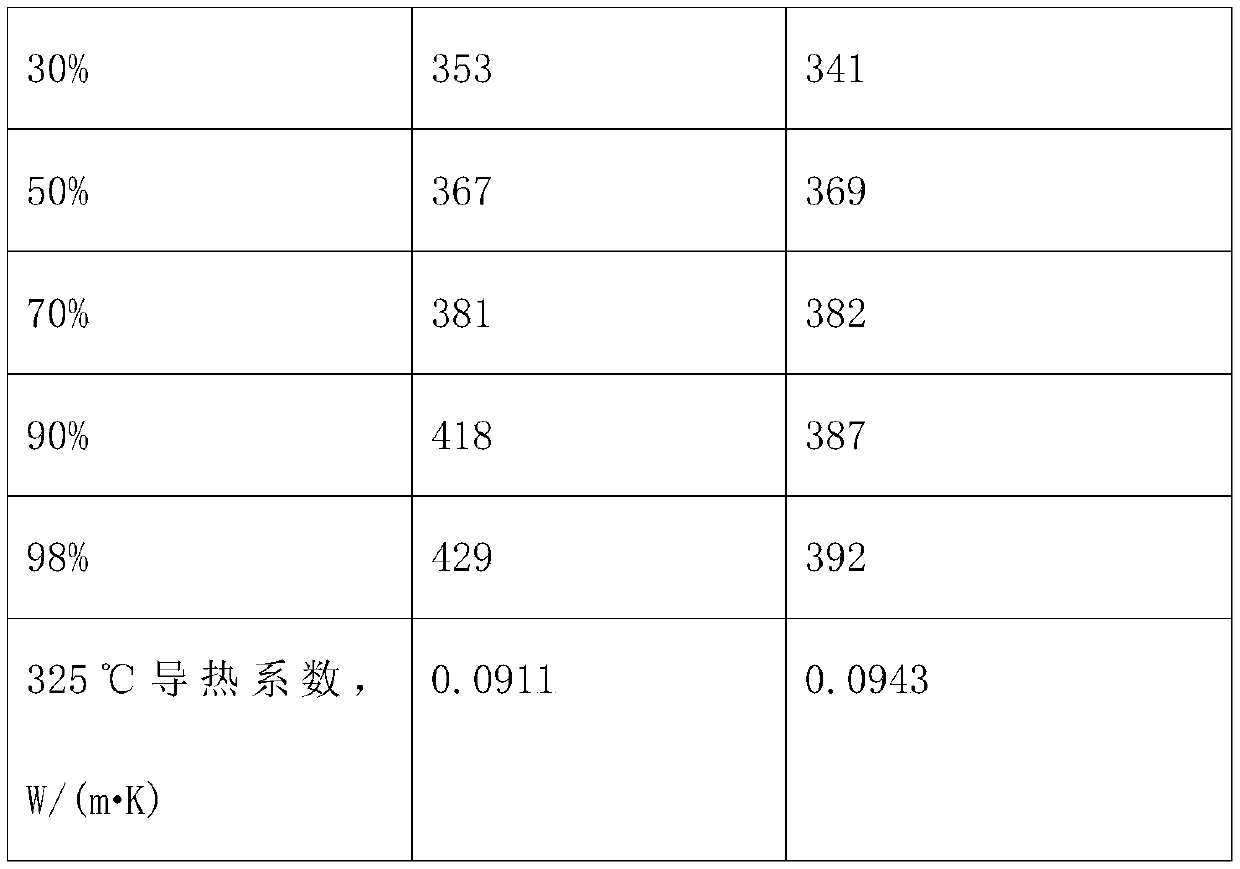

[0024] In this example, after gas chromatography analysis, the contents of each component in the product after the terphenyl hydrogenation reaction are as follows: 32.7% of partially hydrogenated o-terphenyl, 31.5% of partially hydrogenated m-terphenyl, 20.3% of partially hydrogenated p-terphenyl, and 20.3% of partially hydrogenated Querphenyl isomer mixture 9.7%, partially hydrogenated pentphenyl isomer mixture 4.3%, unknown component 1.5%.

[0025] ③ Open t...

Embodiment 2

[0034] The rest of the preparation method of the high-purity hydrogenated terphenyl heat-conducting oil of the present embodiment is the same as that of Example 1, the difference being: 4. close the feed inlet valve after the loading is complete, open the tower top valve, The temperature of the vacuum distillation tower is raised to 283°C, and the material at the top of the tower enters the product storage tank after being cooled by a heat exchanger.

[0035] Sampling chromatographic analysis showed that the content of hydrogenated terphenyl was 93.6%.

Embodiment 3

[0037] All the other preparation methods of the high-purity hydrogenated terphenyl heat-conducting oil of the present embodiment are the same as in Example 1, the difference being: 4. close the feed inlet valve after the loading is complete, open the tower top valve, The temperature of the vacuum distillation tower is raised to 248°C, and the material at the top of the tower is cooled by a heat exchanger and then enters the product storage tank.

[0038] Sampling chromatographic analysis showed that the content of hydrogenated terphenyl was 93.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com