Hydrogenated terphenyl type high-temperature nanometer heat-conduction oil, and preparation method and application thereof

A hydrogenated terphenyl type and hydrogenated terphenyl technology are applied in the field of hydrogenated terphenyl type high-temperature nano heat-conducting oil, which can solve the problems of increasing the flow resistance of heat-conducting oil, reducing the effect of heating and heat transfer, and affecting the accuracy of temperature control. The effect of flow resistance, fast heat transfer and high suspension stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Prepare 7kg of excess copper nanoparticles by gas phase method.

[0047] 2) Take 3 kg of nanoparticles obtained in step 1), disperse them in deionized water, and use ultrasonic dispersion to disperse them evenly according to the amount of nanoparticles.

[0048] 3) Heating step 2) For the system containing nanoparticles, when the temperature reaches 60°C, stir continuously and slowly add 0.5kg of dispersant Span 85 for coating modification. After continuing for 40min, the modified nanoparticles were made by natural cooling.

[0049] 4) Disperse the above-mentioned modified nanoparticles into 96kg of hydrogenated terphenyl type heat transfer oil at 15°C, stir while heating, gradually raise the temperature to 100°C, and keep it warm for 1h.

[0050] 5) Add 0.5 kg of drag reducer cetyltrimethylammonium chloride to the system in step 4), continue to keep warm and stir for 2 hours, and cool naturally to obtain hydrogenated terphenyl type high-temperature nano heat transf...

Embodiment 2~6

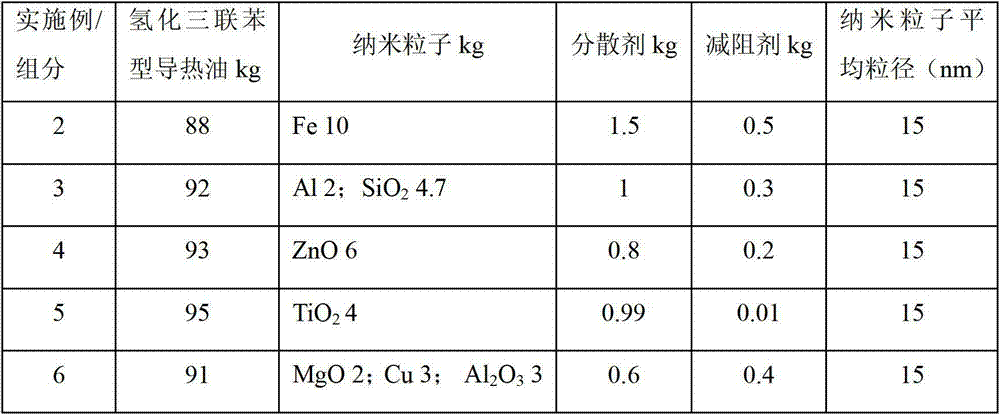

[0052] The preparation methods and conditions of each step in Examples 2-6 are the same as those in Example 1, except that the formula and the dosage of each component are different. The formula and dosage of each component in Examples 2-6 are shown in Table 1.

[0053] Table 1. Examples 2-6 Hydrogenated terphenyl type high-temperature nano heat transfer oil formula and a list of component dosages

[0054]

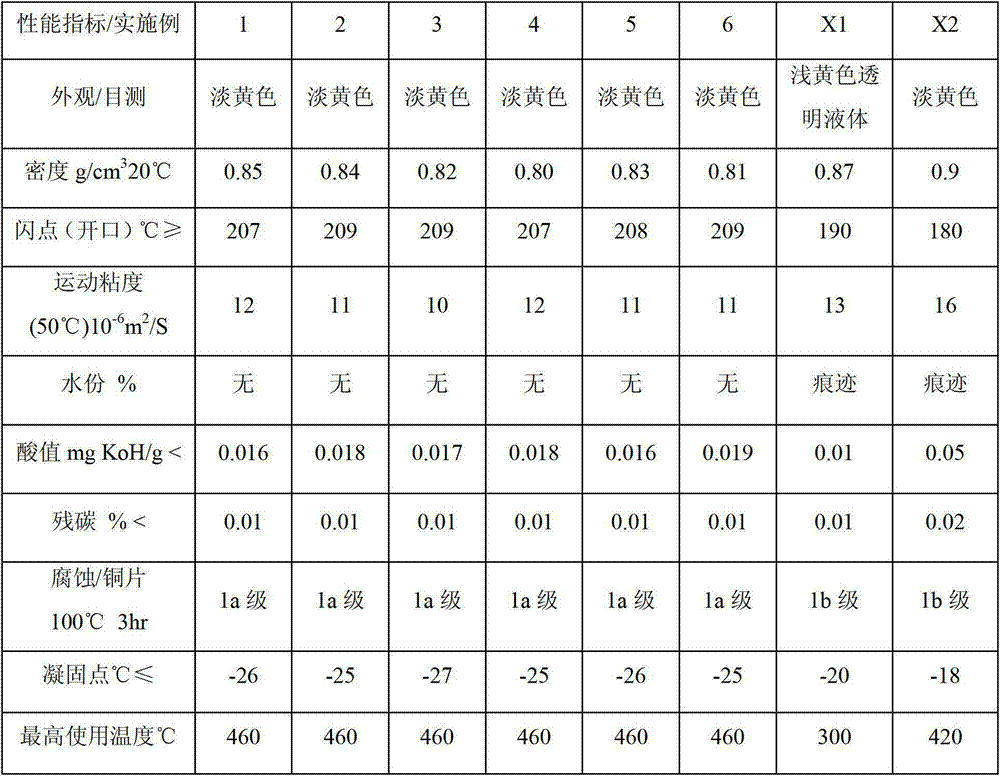

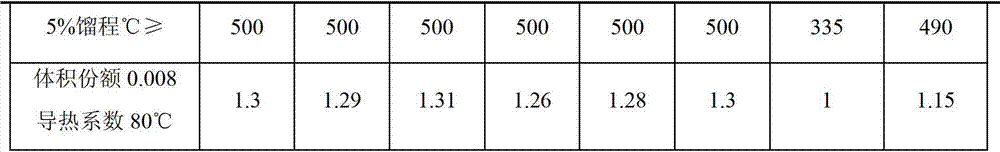

[0055] Table 2 is a comparative list of various performance indicators of the heat transfer oil, including the heat transfer oil obtained in Examples 1 to 6 of the present invention;

[0056] Common heat transfer oil in the prior art (hereinafter referred to as X1), the heat transfer oil prepared by the inventor according to the method of Example 9 of Chinese Invention Patent CN200310114441.6 and the listed ingredients;

[0057] In the prior art, the heat transfer oil with nanoparticles added (hereinafter referred to as X2), the inventor of the present invention prepare...

Embodiment 7

[0062] 1) Prepare 10 kg of aluminum oxide nanoparticles by chemical vapor deposition.

[0063] 2) Take 5 kg of nanoparticles obtained in step 1), disperse them in deionized water, and use mechanical stirring to disperse them evenly according to the amount of nanoparticles.

[0064] 3) Heating step 2) For the system containing nanoparticles, when the temperature reaches 95°C, stir continuously and slowly add 0.5kg of dispersant Span 85 for coating modification. After continuing for 55 minutes, the modified nanoparticles were made by natural cooling.

[0065] 4) At 170°C, disperse the above-mentioned modified nanoparticles into 94kg of hydrogenated terphenyl type heat transfer oil, stir while stirring, when the temperature is 120°C, keep warm for 2h.

[0066] 5) Add 0.5 kg of drag reducer cetyltrimethylammonium chloride to the system in step 4), continue to keep warm and stir for 3 hours, and cool naturally to obtain hydrogenated terphenyl type high-temperature nano heat transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com