High-temperature heat-conducting oil and preparation method thereof

A heat-conducting oil and high-temperature technology, which is applied in the chemical industry, can solve the problems that the heat-conducting oil cannot meet the high temperature resistance and stability, and achieve the effects of good thermal oxidation stability, good heat transfer effect, and easy industrial production

Pending Publication Date: 2022-01-11

CHINA PETROLEUM & CHEM CORP

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, with the development of industry, the above-mentioned heat transfer oil can no

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

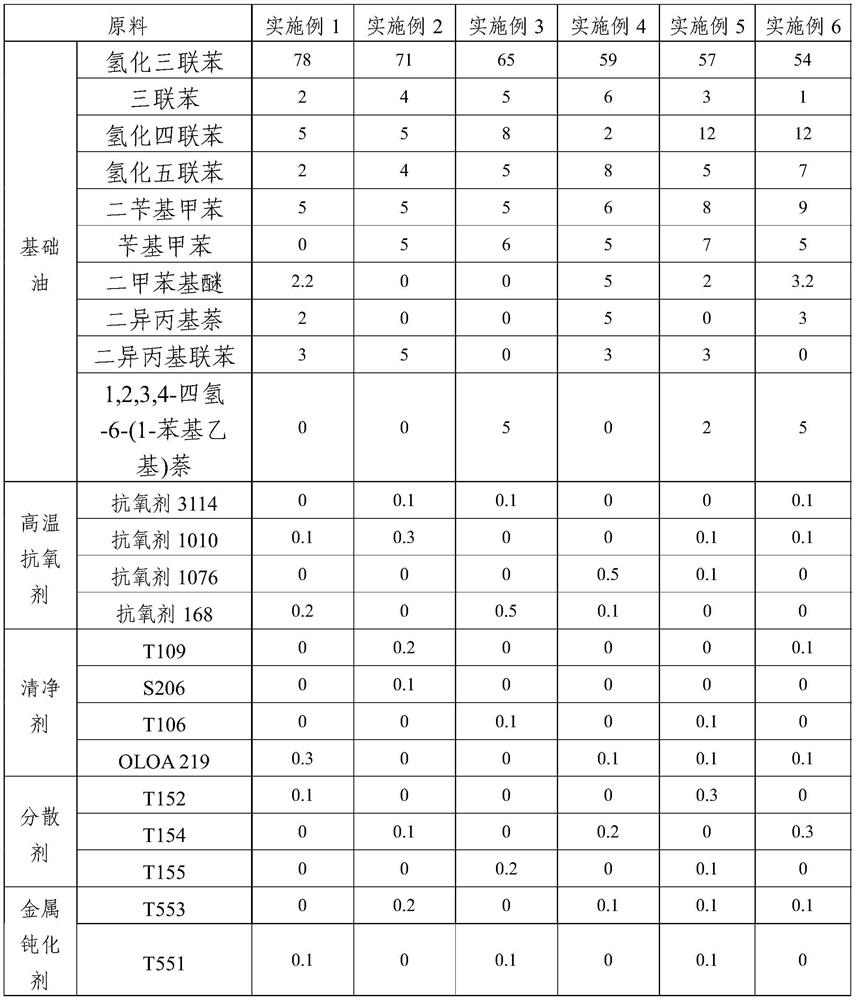

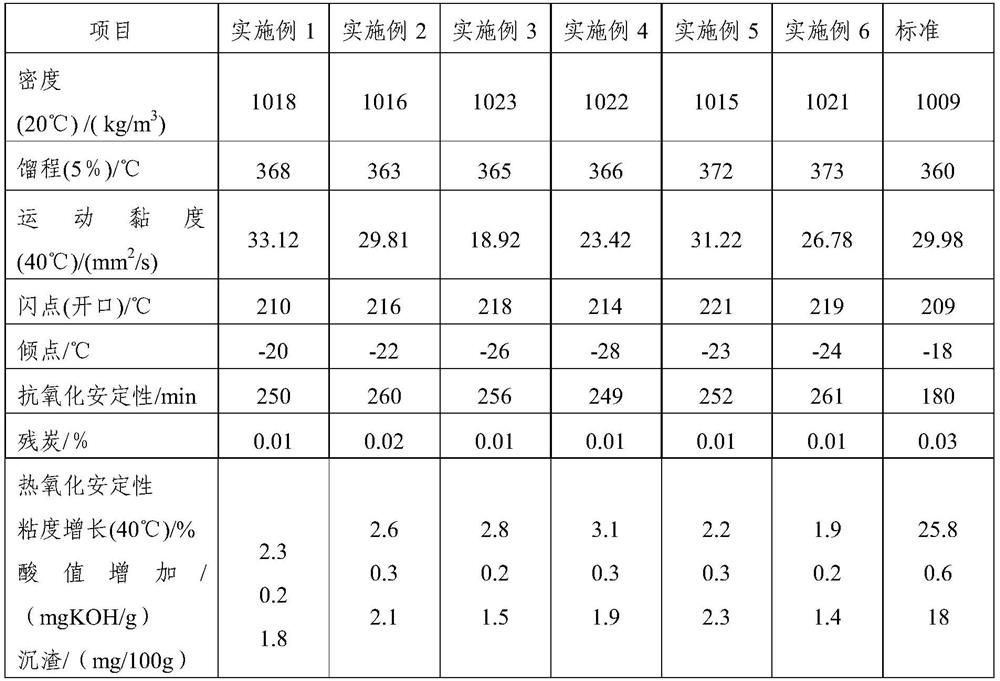

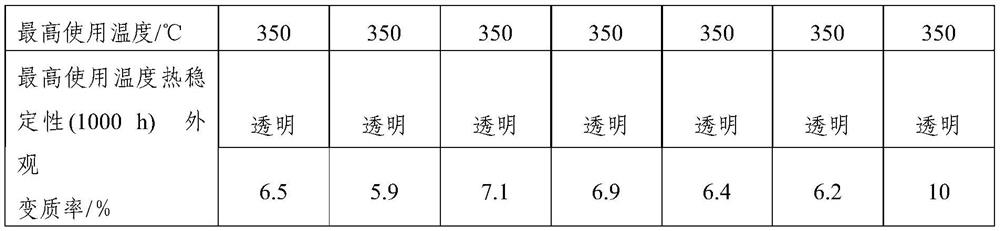

The invention belongs to the technical field of chemical engineering, and particularly relates to high-temperature heat-conducting oil and a preparation method thereof. The high-temperature heat-conducting oil is prepared from the following raw materials in parts by weight: 99-99.5% of synthetic aromatic base oil, 0.01-1.0% of a high-temperature antioxidant, 0.01-1.0% of a detergent, 0.01-1.0% of a dispersant and 0.01-1.0% of a metal deactivator. The synthetic aromatic base oil comprises more selected from hydrogenated terphenyl, terphenyl, hydrogenated quaterphenyl, hydrogenated pentaphenyl, diisopropylnaphthalene, diisopropylbiphenyl, 1,2,3,4-tetrahydro-6-(1-phenylethyl) naphthalene, dibenzyltoluene, benzyltoluene and xylyl ether. The high-temperature heat-conducting oil composition taking the synthetic aromatic hydrocarbon base oil as the main component has the advantages of good heat transfer effect, easiness in industrial production and the like, and still has relatively good stability under the condition that the highest use temperature is 350 DEG C.

Description

technical field [0001] The invention belongs to the technical field of chemical industry, and in particular relates to a high-temperature synthetic heat-conducting oil combination and a preparation method thereof. Background technique [0002] Heat transfer oil is a safe and efficient heat transfer medium. It is an organic heat carrier. According to its structure, it can be divided into hydrocarbons, ethers, alcohols, silicone oils, halogen-containing hydrocarbons, and nitrogen-containing heterocycles. At present, the most used heat transfer oil at home and abroad is hydrocarbon, that is, only two kinds of elements are carbon and hydrogen. Compared with water as a heat transfer medium, heat transfer oil has the characteristics of high temperature, low vapor pressure and convenient use. It also has the advantages of good heat transfer effect and uniform heating. It is widely used in heating, cooling, waste heat recovery, solar energy, etc. In the industrial field and in dail...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K5/10

CPCC09K5/10

Inventor 韦安柱张静如贾睿李万英刘卜瑜李永超桂砚楠焦玉萍李耿辉

Owner CHINA PETROLEUM & CHEM CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com