A kind of method for preparing hydrogenated terphenyl

A technology for hydrogenating terphenyls and terphenyls, which is applied in the fields of hydrogenation, organic chemistry, etc., can solve the problems of not being able to meet market demand, not being rationally developed, and low level of industrialization, so as to meet market demand, increase energy consumption, and convert high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. Those skilled in the art should understand that the examples are only used to help understand the present invention, and should not be regarded as specific limitations on the present invention.

[0024] In the following examples, unless otherwise specified, various equipments of the present invention are conventional equipments in this field, and the process parameters of various equipments are conventional parameters in this field, and various raw materials used can be obtained commercially. Unless otherwise defined or stated, all professional and scientific terms used herein have the same meanings as those familiar to those skilled in the art.

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

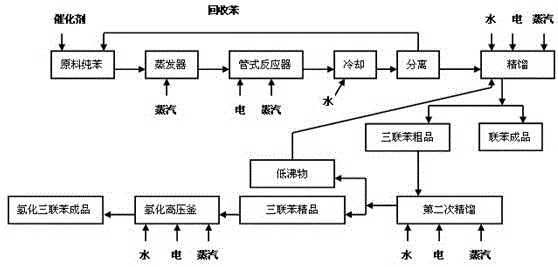

[0026] Such as figure 1 Shown, a kind of method for preparing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com