New heat conduction liquid material containing nanometer aluminum-manganese alloy particles

An aluminum-manganese alloy and heat transfer liquid technology, applied in the field of energy chemistry, can solve the problems of slow heat dissipation, low heat transfer efficiency, easy oxidation, etc., and achieve the effect of fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

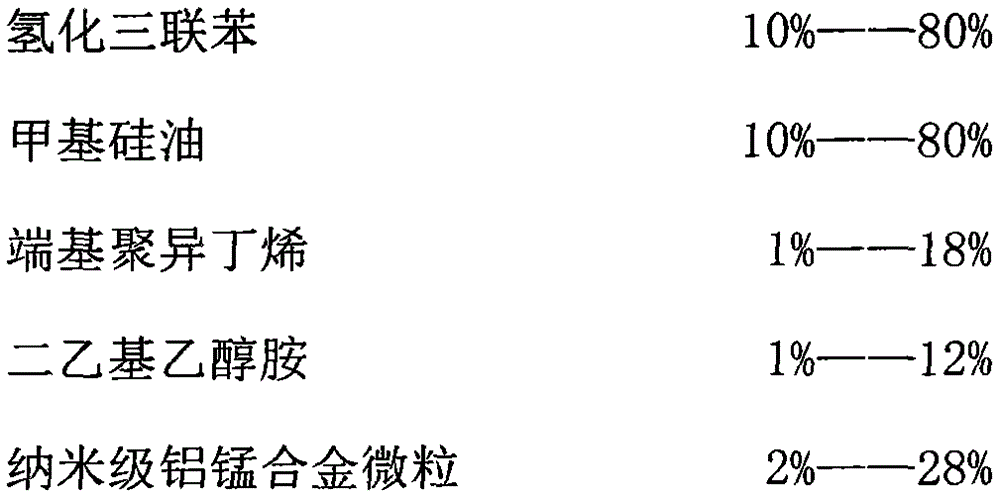

[0012] The new heat transfer liquid material containing nano-scale aluminum-manganese alloy particles has the following components and weight percentages:

[0013]

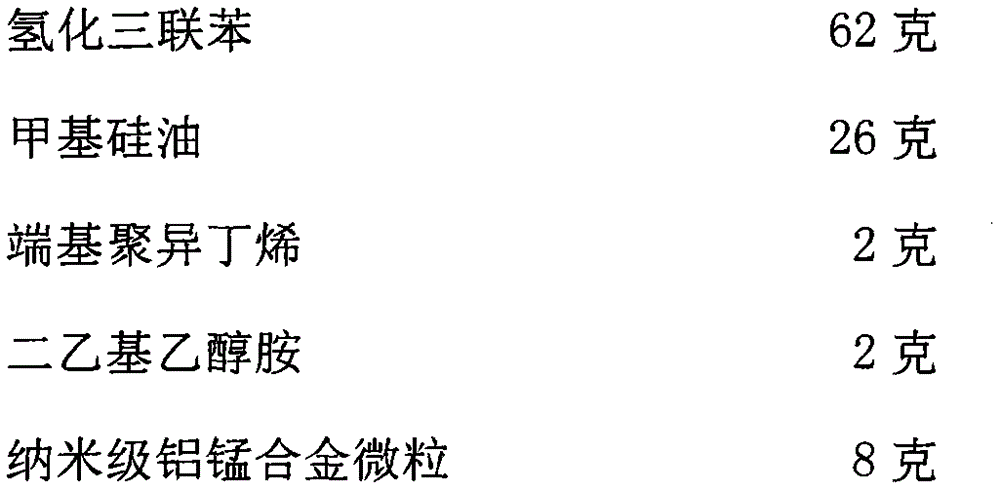

[0014] The new material of heat transfer fluid containing nano-scale aluminum-manganese alloy particles in the present invention is prepared by taking 62 grams of hydrogenated terphenyl, 26 grams of methyl silicone oil, 2 grams of terminal polyisobutylene, and 2 grams of diethylethanolamine and adding one Stir in the reaction kettle for 20 minutes. After stirring evenly, add 8 grams of nano-sized aluminum-manganese alloy particles and continue stirring for 15 minutes. Then take out 100 grams of uniform semi-finished products and put them into a 180W ultrasonic emulsifier for 20 minutes. Cavitation " just obtains the gray translucent or opaque liquid with good fluidity, and this liquid is exactly the finished product of the present invention.

Embodiment 2

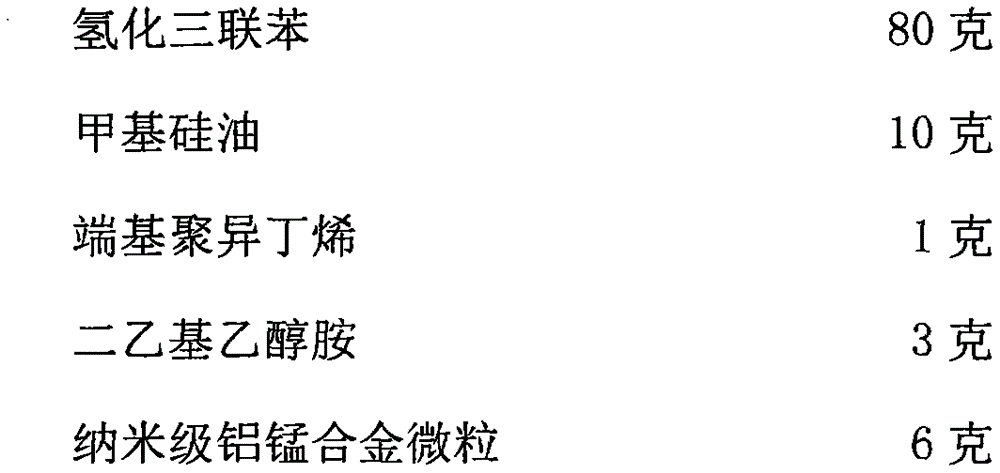

[0016] The new heat transfer liquid material containing nano-scale aluminum-manganese alloy particles has the following components and weight percentages:

[0017]

[0018] The weight percentages of the above components in the second embodiment are different from those in the first embodiment, except that the preparation method is consistent with that described in the first embodiment.

Embodiment 3

[0020] The new heat transfer liquid material containing nano-scale aluminum-manganese alloy particles has the following components and weight percentages:

[0021]

[0022] The weight percentages of the above components in the third embodiment are different from those in the first embodiment, except that the preparation method is consistent with that described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com