Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98 results about "Cadmium stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cadmium stearate or cadmium distearate is a chemical compound with the formula C₃₆H₇₀CdO₄. It is classified as an extremely hazardous substance in the United States as defined in Section 302 of the U.S. Emergency Planning and Community Right-to-Know Act (42 U.S.C. 11002), and is subject to strict reporting requirements by facilities which produce, store, or use it in significant quantities.

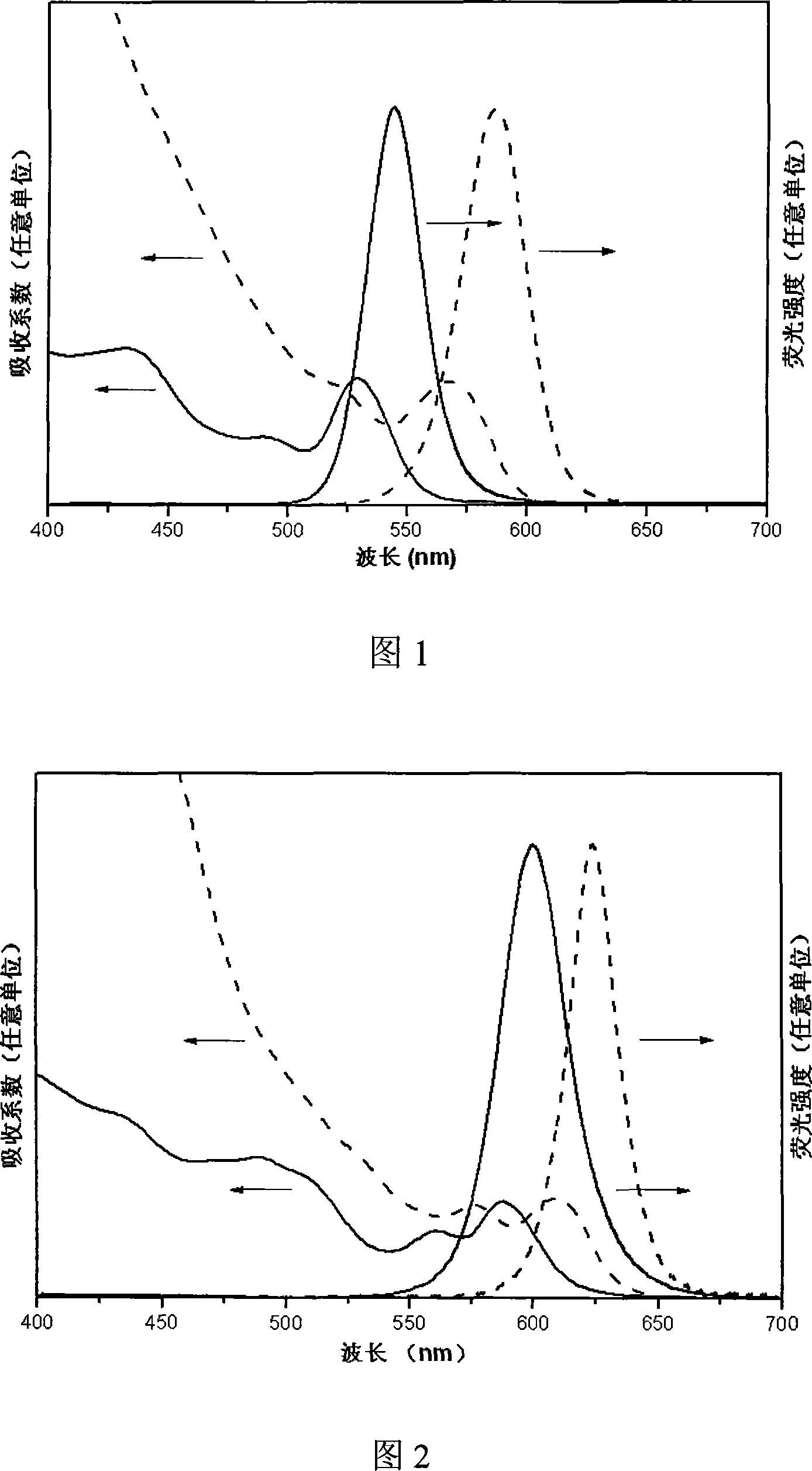

Method for preparing cadmium selenide/cadmium sulfide /zinc sulfide core-shell quantum dots

InactiveCN101168663AEasy to operateRaw material safetyLuminescent compositionsCadmium selenideSolvent

The invention discloses the preparation method of low cost cadmium selenide (CdSe) / cadmium sulphide (CdS) / zinc sulphide (ZnS) quantum point. The invention is characterized in that ethide xanthic acid cadmium and ethide xanthic acid zinc are adopted to be respectively dissolved in the mixed solvent of oleic amine and oleic acid, as well as cadmium stearate and zinc stearate; as the front dirking liquid of clads CdS and ZnS of a SdSe quantum point, the invention is slowly dropped into the mixed liquor of octadecene and octadecylamine dissolved with CdSe quantum point, so as to obtain CdSe / CdS / ZnS quantum points. The invention has the advantages that the price of the raw material is cheap, the toxicity is low, the operation is simple, and the mass synthesis is proper.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

PE wood/plastic composite sectional material and manufacturing method thereof

The invention discloses a PE wood / plastic composite sectional material and relates to the technical field of composite materials. The PE wood / plastic composite sectional material is made from the following raw materials in parts by weight: 10-70 parts of wood flour, 20-50 parts of polyethylene, 3-20 parts of calcium carbonate powder or talc powder, 0.1-1 part of stearic acid or n-butyl stearate, 0.4-1.5 parts of one or a combination of more than one of calcium stearate, lead stearate, barium stearate, cadmium stearate, lanthanum stearate, zinc stearate, PE wax, or oxidized polyethylene wax OPE or 0.1-1.5 parts of paraffin, 0.5-3 parts of a coupling agent, 0.5-2 parts of an antioxidant, 0.05-2 parts of a UV absorbent, a light shielding agent, quencher or free radical scavenger, and 3-12 parts of titanium pigment. The PE wood / plastic composite sectional material provided by the invention has the advantages of water resistance, insect resistance, rust corrosion resistance, convenience for fabrication, safety in use, strong plasticity, energy conservation, environmental friendliness and no formaldehyde, benzene or other poisonous substances.

Owner:LINYI KANGYIJIA ECOLOGY WOOD

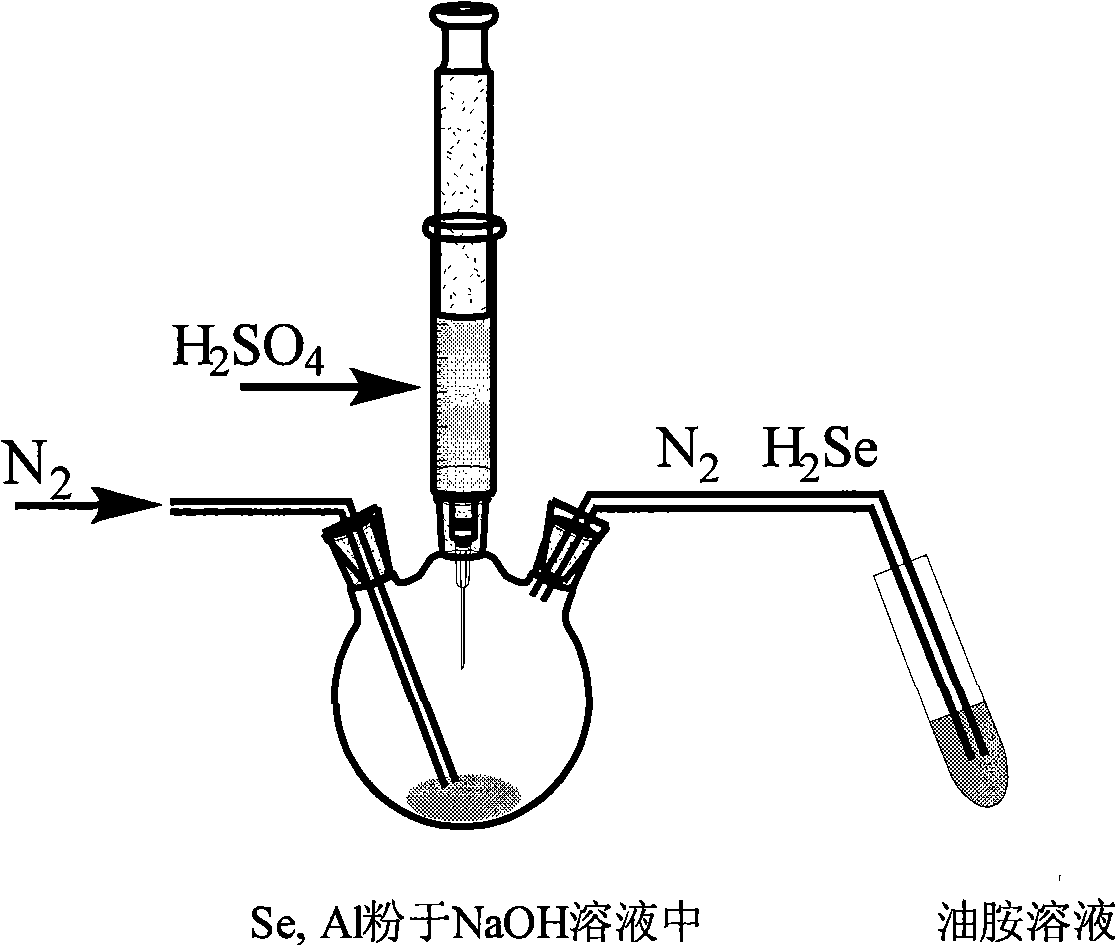

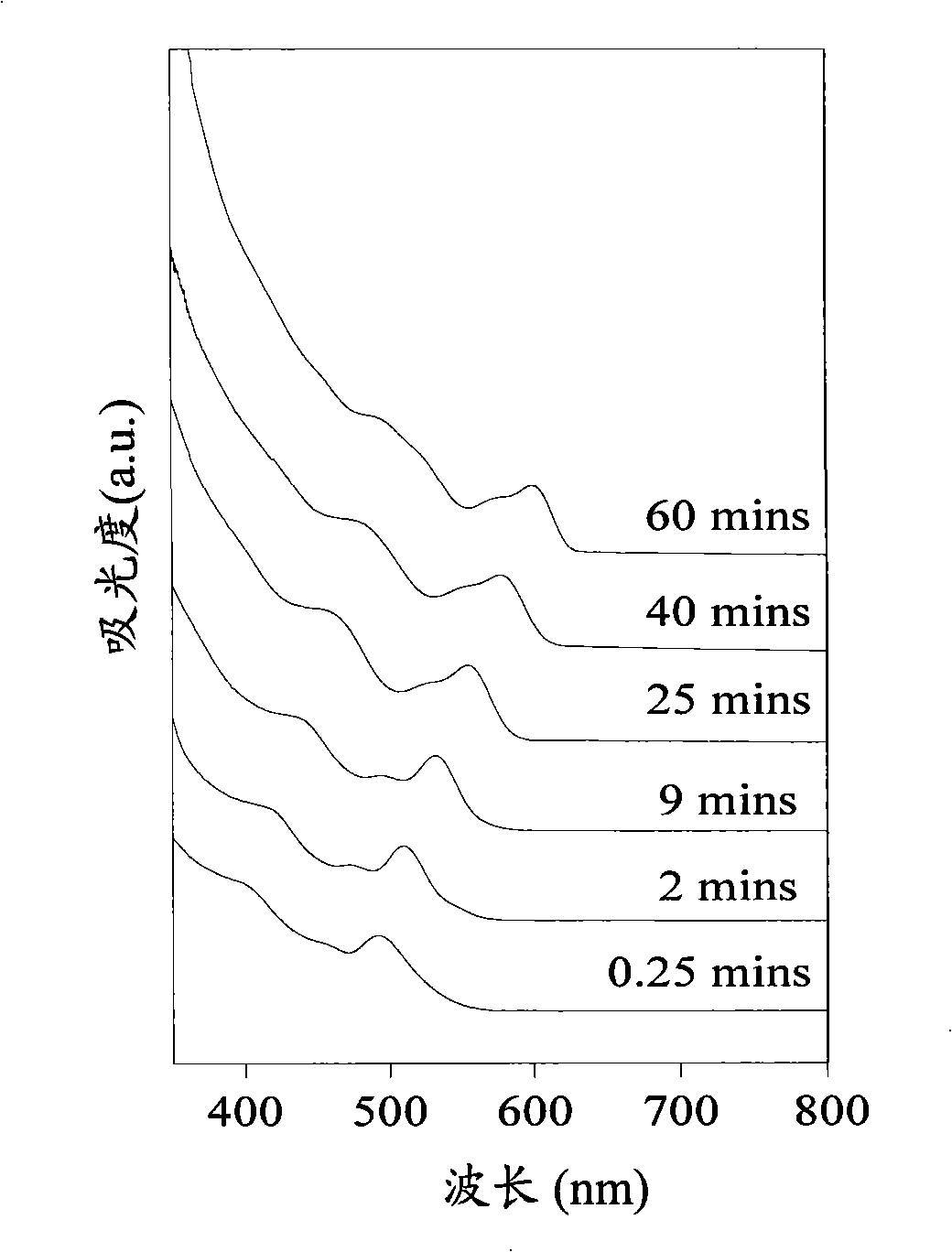

Method for preparing CdSe and ZnSe quantum dot nanometer granules

InactiveCN101332979AReduce manufacturing costGuaranteed decentralizationTenebresent compositionsBinary selenium/tellurium compoundsFluorescenceStearic acid

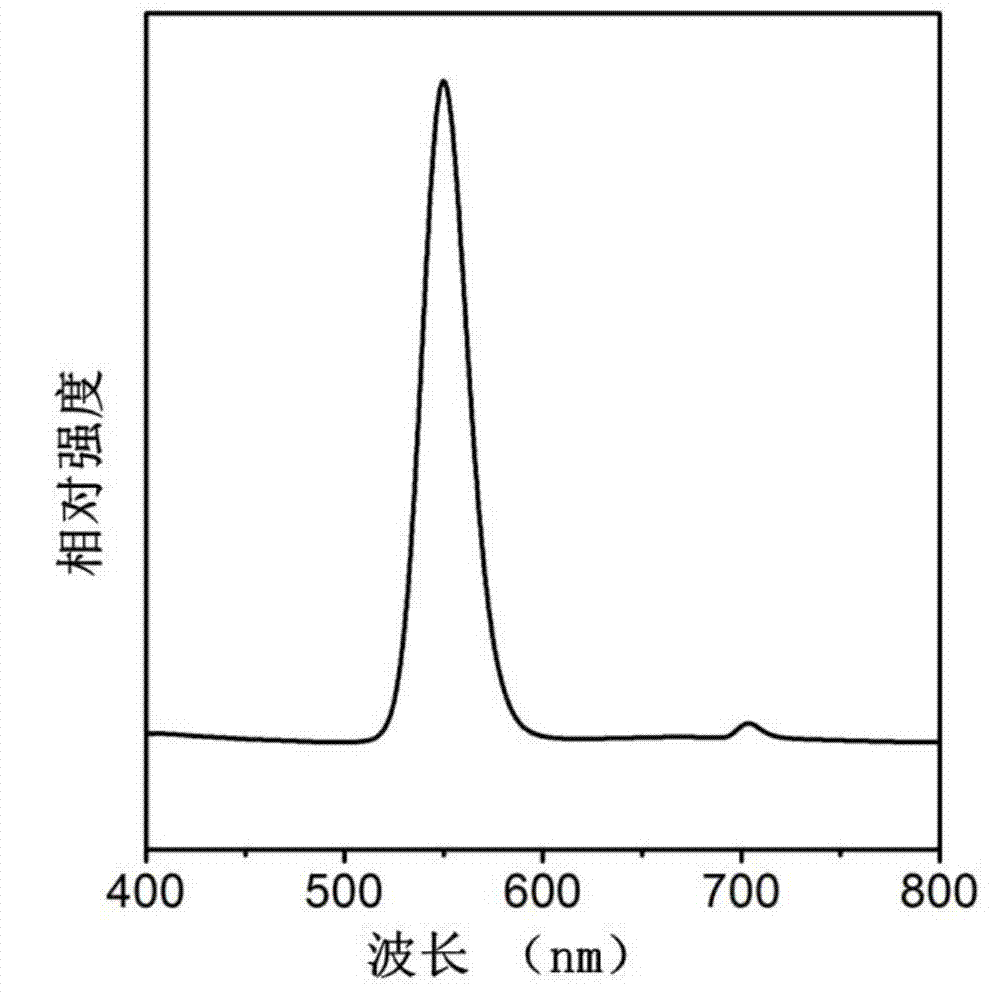

The invention discloses a method for preparing CdSe and ZnSe quantum dots nanometer particles. Aluminum powder and strong base solution are adopted for the reduction of selenium powder and sulphuric acid is added to generate hydrogen selenide, the hydrogen selenide is brought out by the flow of high purity nitrogen and dissolved in oil amine to obtain oil amine-hydrogen selenide composite; the oil amine-hydrogen selenide composite which is taken as a new selenium precursor, together with cadmium stearate and orzinc stearate, is used for preparing the CdSe and ZnSe quantum dots nanometer particles at high temperature; the prepared quantum dots nanometer particles have controllable spectrum and excellent performance and can be applied to the fields such as biological fluorescence label, optoelectronic materials, etc. Furthermore, the method for preparing quantum dots nanometer particles can avoid the adoption of trioctylphosphineoxide (TOP) which has strong toxicity and high price, and is low in cost and suitable for industrial production.

Owner:HUNAN UNIV

Coating material for high anticorrosive pack, and preparation method

InactiveCN101050329AExcellent physical and chemical propertiesGood chemical resistanceRosin coatingsAnti-corrosive paintsEpoxySolvent

This invention discloses a high-strength antirust packaging paint, which is composed of: ethylene resin, epoxy resin, polyurethane alkyd resin, rosin-modified resin, acrylate resin, cadmium stearate, lanoline, diphenyl amine, barium petroleum sulfonate, essence, antirust oil, plasticizer, heat stabilizer, antirust agent, diluting agent, adhesion promoter, leveling agent, UV absorbent, dispersant, defoamer and flame retardant. The packaging paint can be directly sprayed, soak-coated or brush-coated onto objects with any shape or appearance. A bright and smooth protective film is formed several minutes later. The protective film has high antirust performance, and can be stripped off for recycling.

Owner:郑州博庆环保科技有限公司 +2

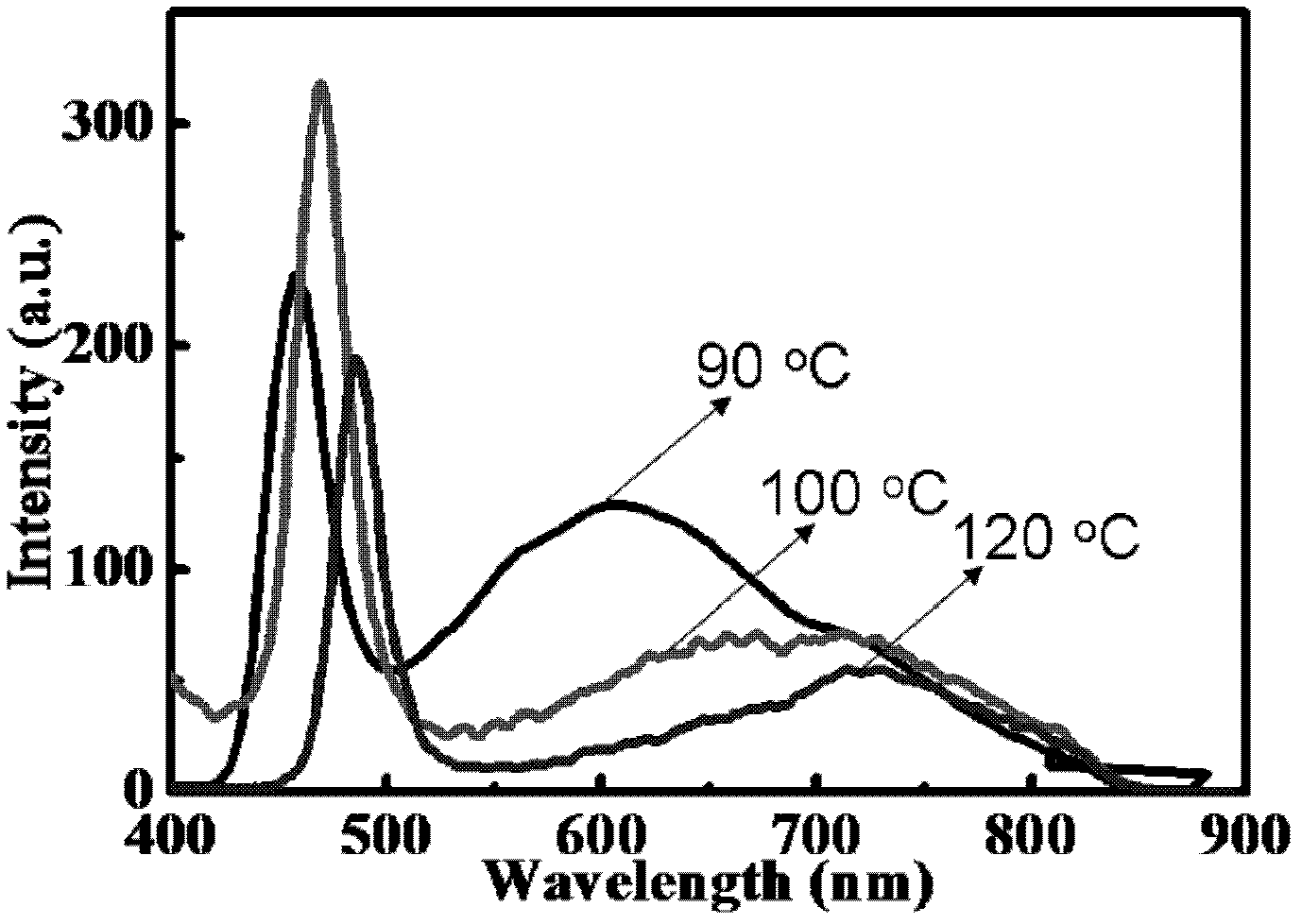

Luminescence-adjustable ligand-free cadmium sulfide semiconductor quantum dot and preparation method thereof

InactiveCN102634336ARaw materials are easy to getLow costCadmium sulfidesLuminescent compositionsThioureaCadmium acetate

The invention discloses a method for preparing a luminescence-adjustable ligand-free cadmium sulfide quantum dot. The quantum dot does not need any organic molecules as ligands, has good stability, can be effectively hybridized with organic materials and prevents the phenomenon of phase separation in the hybridization process, and the luminescence wave length can be precisely adjusted along with a synthesis condition. According to the preparation method of the luminescence-adjustable ligand-free cadmium sulfide semiconductor quantum dot, cadmium acetate, cadmium propionate or cadmium stearate is selected as a cadmium source, and thiourea or sodium sulfide is selected as a sulfur source, and the luminescence-adjustable ligand-free cadmium sulfide semiconductor quantum dot can be prepared without any organic molecules as a cladding agent.

Owner:NANJING UNIV OF TECH

Polyvinyl chloride (PVC) hard modified plastic

InactiveCN103265777AImprove mechanical propertiesImprove impact resistanceParaffin waxPolymer science

The invention discloses a polyvinyl chloride (PVC) hard modified plastic which is characterized in that a general PVC plastic raw material, a stabilizer, a lubricant, a coloring agent and a filler are mixed and granulated, wherein the stabilizer is tribasic lead sulfate, dibasic lead phosphite, barium stearate or cadmium stearate; the lubricant is stearic acid, paraffin or mineral oil; the coloring agent includes rutile type titanium dioxide, chrome yellow and channel black; and the filler includes calcium carbonate, argil and glass fiber. Through the way, the PVC hard modified plastic disclosed by the invention has better mechanical properties and good heat resistance, resists impact and aging, and is particularly suitable for the buildings such as doors / windows, pipelines, plates and the like and the related industries.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

Constitutes of technical formula in use for dipping plastic

InactiveCN1563178ASuspension evenly distributedReduce plasticizing temperaturePolyvinyl chlorideCadmium stearate

A process formula die carving includes compositions as the follows, 100 kg polyvinyl chloride in paste state, 80-100 kg dicapryl phthalate, 1-5 kg cadmium stearate, 1-5 g barium stearate, 0.5-2 kg bisphenol A and 0.01-1 kg dyestuff. The advantage of the present invention is using paste state polyvinyl chloride as main body, suspending each composition in dicapryl phthalate uniformly, plasticizing in not high temp and having excellent antidegradability.

Owner:ZHEJIANG UNIV

Anti-fogging and non-dropping film and preparation method thereof

The invention provides an anti-fogging and non-dropping film. The anti-fogging and non-dropping film comprises the following components in parts by weight: 70 to 200 parts of LLDPE (Linear Low Density Polyethylene), 15 to 50 parts of LDPE (Low-Density Polyethylene), 10 to 30 parts of EVA (Ethylene-vinyl Acetate), 20 to 50 parts of DOP (Dioctyl-Phthalate), 15 to 30 parts of BBP (Butyl Benzyl Phthalate), 0.5 to 2 parts of dibutyl tin dialurate, 3 to 7 parts of 2-ethylhexyl ester of epoxy fatty acids, 4 to 8 parts of tricresyl phosphate, 1.5 to 4 parts of glyceryl monolaurate, 1 to 6 parts of triphenyl phosphate, 0.2 to 0.8 part of ultraviolet light absorber, 0.5 to 0.9 part of calcium carbonate, 1 to 5 parts of cadmium stearate, 2 to 8 parts of barium stearate, and 0.2 to 0.7 part of sorbitan monostearate. The preparation method comprises the following steps of: drying LLDPE, LDPE and EVA under vacuum; adding other components; performing film blowing through a horizontal extruding and blowing method by utilizing a single-screw extruding film blowing device, thus obtaining the anti-fogging and non-dropping film. The anti-fogging and non-dropping film shows remarkable advantages that water on the surface of the film can flow into the soil along the surface of the film, thus moisture in the air in a greenhouse is reduced, and the anti-fogging effect is realized.

Owner:WUJIANG YINGLIDA PLASTIC PACKAGING

High-toughness high-tear strength modified polyurethane rubber cable material

InactiveCN105602237AGood toughness strengthHigh tear strengthRubber insulatorsPolymer scienceAccelerant

The invention discloses a high-toughness high-tear strength modified polyurethane rubber cable material which comprises the following raw materials: a modified polyurethane rubber cable material, coumarone resin, silicon rubber, polycarbonate, tetrafluoroethylene-propylene rubber, modified calcium sulfate whisker, triallyl isocyanurate, methyl methacrylate, 3-aminopropyl trimethoxy silane, an accelerant M, an anti-aging agent, sulfur, jade powder, zinc oxide, zinc borate, aluminum powder, high-wear resistance carbon black, tributyl citrate, cadmium stearate, magnesium oxide and rosin. The polyurethane rubber cable material disclosed by the invention has excellent properties such as high toughness and high tear strength.

Owner:ANHUI DUJIANG CABLE GROUP

PVC master batch and preparation method thereof

The invention discloses a PVC master batch and a preparation method thereof. According to the preparation method, PVC, ESBO, DOP, ACR, paraffin, carbon black, lead stearate, barium stearate, cadmium stearate, PE wax, antimonous oxide and titanium dioxide are weighed in parts by weight, the product is high in strength, the tensile strength is 50MPa-90MPa, the tensile modulus is 3200MPa -3600MPa, and the Shore hardness is 60D-80D; the appearance of the product is uniform and glossy, the color intensity is 95%-115%, the impact strength is 15kJ / m<2>-35kJ / m<2>, the thermal deformation temperature is 120-140 DEG C, the bending strength of the product is 15MPa-55MPa, the bending modulus is 2GPa-4GPa, the elongation at break is 100%-140%, and the melt flow index is 7g / min-11g / min; and the cost is low, the operation is simple, and the PVC master batch can be widely applied to the production and can be used for continuously replacing existing materials.

Owner:陈逸君

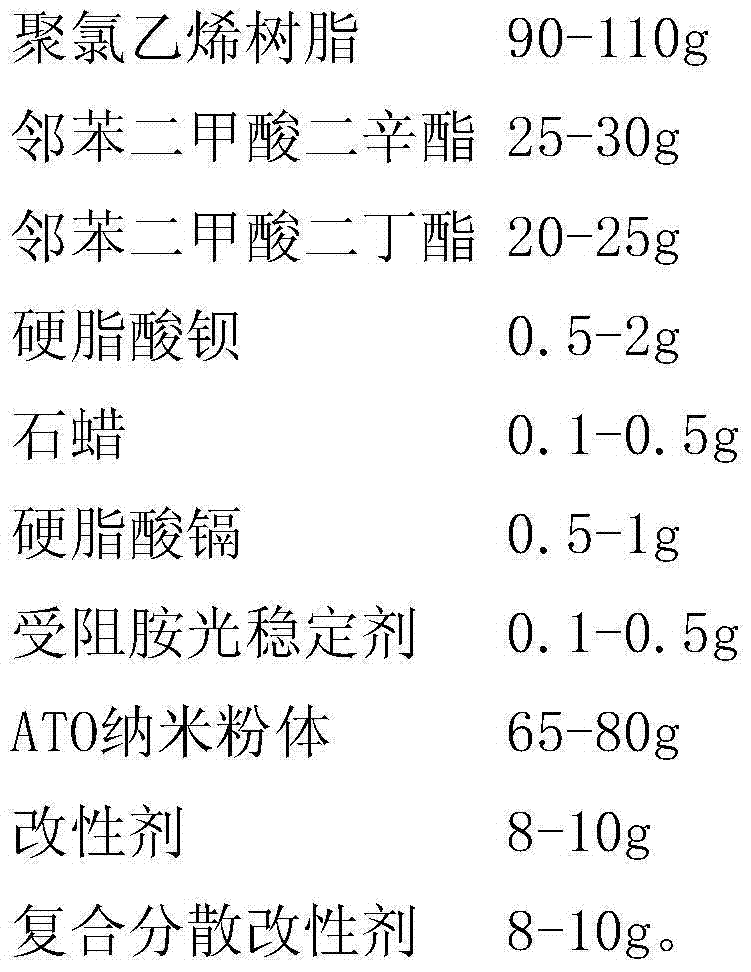

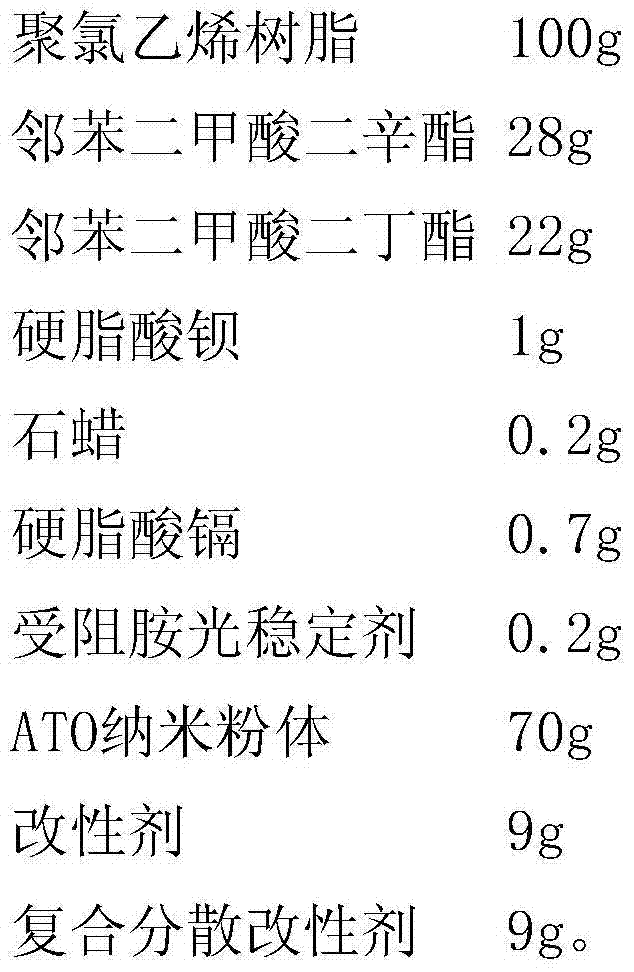

Anti-corrosion wear-resisting and ageing-resistant modified polyvinyl chloride (PVC) plastic composition

The invention discloses an anti-corrosion wear-resisting and ageing-resistant modified polyvinyl chloride (PVC) plastic composition, and relates to the technical field of plastics. The anti-corrosion wear-resisting and ageing-resistant modified PVC plastic composition comprises the following components by weight percent: 90-110g of polyvinyl chloride resin, 25-30g of dioctyl phthalate, 20-25g of dibutyl phthalate, 0.5-2g of barium stearate, 0.1-0.5g of paraffin, 0.5-1g of cadmium stearate, 0.1-0.5g of hindered amine optical stabilizer, 65-80g of ATO nano powder, 8-10g of modifier, and 8-10g of composite disperse modifier. By adopting the anti-corrosion wear-resisting and ageing-resistant modified PVC composition, the PVC has excellent performances such as corrosion resistance and abrasive resistance, can endure relatively high pressure, is not easy to form a dart, and can resist certain negative pressure.

Owner:ANHUI GUANHONG PLASTIC IND +1

Composite for fire hoses and preparation method of composite

InactiveCN108102265AImprove mechanical propertiesImprove waterproof performancePolyvinyl alcoholPolyvinyl chloride

The invention provides a composite for fire hoses and a preparation method of the composite. The composite is prepared from components in parts by weight as follows: 100 parts of sucrose polyester modified polyvinyl chloride resin, 60-70 parts of a fluorine-containing organosilicone modified polyurethane polymer, 40-50 parts of bisphenol A polycarbonate, 30-40 parts of polyphenyl ether, 10-15 parts of polyacrylamide, 10-15 parts of acrylate, 10-12 parts of medium chain triglyceride, 8-12 parts of polyvinyl acetal, 8-12 parts of dibutyl phthalate, 2-3 parts of calcium stearate, 2-3 parts of cadmium stearate, 1-2 parts of 1,4-butanediol diacrylate and 1-2 parts of dibutyltin dilaurate. Main raw materials comprise sucrose polyester modified polyvinyl chloride resin, the fluorine-containing organosilicone modified polyurethane polymer, bisphenol A polycarbonate and polyphenyl ether, and the composite has good mechanical performance, water resistance, wear resistance and aging resistance through cooperation of the four raw materials and the auxiliary function of auxiliary materials.

Owner:FOSHAN SHIRUI LEADING MATERIAL RES INST GENERAL PARTNERSHIP

Antibacterial and ozone-resistant modified calcium carbonate and preparation method thereof

The invention discloses antibacterial and ozone-resistant modified calcium carbonate. Antibacterial and ozone-resistant modified calcium carbonate is prepared from the following raw materials in parts by weight: 0.5-0.7 part of cadmium stearate, 2-3 parts of glycerin, 1-2 parts of activated carbon, 0.4-0.6 part of lanthanium stearate, 2-3 parts of nano attapulgite, 1-1.5 parts of oxidized polyethlene wax, 3-4 parts of barium hydroxide, 2-3 parts of tetrabutyl titanate, 1-2 parts of disproportionated potassium abietate, 2-2.5 parts of eleostearic acid, 4-6 parts of chlorinated polyethylene, 0.8-1.1 parts of nano silver, 0.1-0.2 part of sodium hydroxide, 80-85 parts of light calcium carbonate, 13-16 parts of an auxiliary agent and 120-140 parts of water. According to antibacterial and ozone-resistant modified calcium carbonate disclosed by the invention, the nano silver is added into a filling material to ensure that PVC (polyvinyl chloride) has permanent antibacterial performance; chlorinated polyethylene is added to ensure that the weather resistance, ozone resistance, chemical medicine resistance and aging resistance of the PVC can be increased, and good oil resistance, flame-retardant performance and coloring performance can be provided; by virtue of surface treatment, calcium carbonate disclosed by the invention has good compatibility with PVC, and can be used for improving the mechanical performance of PVC.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

PVC artificial leather for handbags

InactiveCN103485188ANo crackWidely producedSynthetic resin layered productsTextiles and paperPolymer scienceCrazing

PVC artificial leather for handbags is prepared from the following components in parts by mass: 100 parts of PVC, 25-30 parts of DOP, 15-20 parts of DBP, 3-5 parts of DOS, 1-3 parts of epoxidized soybean oil, 3-5 parts of epoxidized zinc stearate easter, 10-15 parts of NBR, 0.5-1 part of zinc stearate, 0.5-1 part of cadmium stearate, 1-1.5 parts of barium stearate, 2-5 parts of an AC foaming agent, 5-10 parts of tricresyl phosphate and 0.3-0.5 part of pigments. The product can resist high temperature of 150-170 DEG C and low temperature of minus 35 DEG C, achieves the peel strength of 18-20 N / cm<2> and tensile strength of 15-25 MPa, avoids cracks when placed at the temperature of minus 35 DEG C for 25 h, is acid and alkali resistant, and wear resistant, can be widely produced and continuously replaces the conventional materials.

Owner:WUJIANG DONGXIN PLASTIC PACKAGING PLANT

High-elasticity high-toughness polypropylene cable material for communication and preparation method thereof

InactiveCN106317622AImprove toughnessIncrease elasticityPlastic/resin/waxes insulatorsInsulated cablesPolypropyleneVolcanic ash

The invention discloses a high-elasticity high-toughness polypropylene cable material for communication and a preparation method thereof. The high-elasticity high-toughness polypropylene cable material for communication is prepared from the following raw materials in parts by weight: 70-90 parts of atactic polypropylene, 25-35 parts of thermoplastic elastomer SEEPS, 14-26 parts of butanediol cycloterephthalate, 15-25 parts of nano cellulose whisker, 12-20 parts of coumarone indene resin, 6-12 parts of hydroxyl aluminum distearate, 20-30 parts of siliceous shale, 16-24 parts of diisodecyl phthalate, 18-32 parts of asbestos tailing, 2-4 parts of cadmium stearate, 10-15 parts of flocking powder, 9-16 parts of basic magnesium sulfate whisker and 15-25 parts of volcanic ash. The toughness and elasticity of the material are improved; by adding the nano cellulose whisker, flocking powder, basic magnesium sulfate whisker and other raw materials into the system, the tensile strength and elongation at break of the material are enhanced; and the heat resistance, wear resistance and corrosion resistance of the material can also be improved.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Telescopic pipe for automobile and preparation method of telescopic pipe

The invention discloses a telescopic pipe for an automobile and a preparation method of the telescopic pipe. According to the method, PVC resin, calcium carbonate, ABS, polyethylene wax, titanium dioxide, MBS, methyl tin mercaptide, barium sulfate, a coupling agent, DOP, lead stearate, stainless steel metal powder, dioctyl terephthalate and cadmium stearate are weighed. The Shore hardness is 85-89 A, the bending strength is 95-115 MPa, the impact strength is 55-75 kJ / m<3>, the Vicat softening point is 90-130 DEG C, and the tensile strength is 75-95 MPa. Oil resistance is good, the time for flaming combustion is 0.4-0.8 second, the time for flameless combustion is 0.01-0.2 second, the breaking elongation is 450-650%, and the telescopic pipe is free of toxicity and healthful. The telescopic pipe is resistant to drop-hammer impact, the impact strength of a gap at -40 DEG C is 5-25 kJ / m<3>, and the telescopic pipe can be widely produced and constantly replace an existing material.

Owner:WUXI YONGXING METAL HOSE

Energy-saving rigid plastic and preparation method thereof

The invention discloses an energy-saving rigid plastic, which is composed of the following raw materials in parts by weight: 0.1-0.3 part of cadmium stearate, 6-10 parts of polyvinyl butyral, 130-170 parts of polyvinyl chloride, 1-2 parts of ammonium alcohol ether sulphate, 2-3 parts of an amino tri methylene phosphonic acid, 3-5 parts of zinc dihydrogen phosphate, 20-30 parts of rigid packing, 0.5-1 part of polyethyleneimine, 10-18 parts of epoxidized linseed oil, 3-4 parts of phytosterol, 0.6-1 part of tert-Butyldiphenylsilane, and 1-2 parts of methyl parahydroxybenzoats. According to the invention, octadecyl trimethyl ammonium chloride and potassium iodide are mixed for preparing hyamine iodide, and then the prepared hyamine iodide and dispersion liquid of aluminium-magnesium silicate are mixed for processing milltailings, in such a way, the water resistance and stability of the packing can be improved; and a rare-earth salt is also added, so that the resistance of the packing is improved. The plastic disclosed by the invention is rigid in surface texture, high in impact strength, and good in weather resistance, therefore, the energy-saving rigid plastic is particularly applicable to construction projects.

Owner:NINGBO SHANGGAO NEW MATERIAL CO LTD

Anti-radiation silicone rubber sealing gasket and preparation method thereof

InactiveCN105802246AImprove radiation resistanceGood high and low temperature resistancePolymer scienceAcrylonitrile

The invention discloses an anti-radiation silicone rubber sealing gasket and a preparation method thereof.The anti-radiation silicone rubber sealing gasket is prepared from, by weight, 29-38 parts of methyl vinyl trifluoropropyl silicone rubber, 21-32 parts of hydrogenated butadiene-acrylonitrile rubber, 20-30 parts of ceramic polishing waste, 4-6 parts of polyamino bismaleimide, 2.5-4 parts of 2,4-dichlorobenzoyl peroxide, 1-2 parts of cadmium stearate, 3-5 parts of polyethylene wax, 5-7 parts of antimony pentasulfide, 4-6 parts of ethyleneglycol dimethacrylate, 15-20 parts of nano barium sulfate, 12-14 parts of polyneopentylene-hexamethylene adipate glycol, 6-12 parts of terpene-styrene resin, 2-3 parts of promoter TBBS, 1.5-2.5 parts of anti-aging agent BLE and 8-12 parts of modifier.The anti-radiation silicone rubber sealing gasket has the excellent anti-radiation property and good high and low temperature resistance, oil resistance, solvent resistance, chemical resistance and ozone aging resistance.

PC (Poly Carbonate) scuffing-resistant lens and preparation method thereof

InactiveCN104194298AGood self-lubricating performanceWidely producedOptical elementsBenzoic acidRefractive index

The invention discloses a PC (Poly Carbonate) scuffing-resistant lens and a preparation method thereof. The PC scuffing-resistant lens is prepared by the following steps of weighing PC, barium stearate, LDPE, cadmium stearate, maleic anhydride, dibutyl tin dilaurate, a heat stabilizer, silica, EVA, a NX8000 nucleating agent, a crosslinking agent, benzoic acid, hydrogenated butadiene, DOP and a styrene block copolymer according to weight ratio, kneading, carrying out extrusion pelletization, curing, trimming, rolling circle, plating a film, cleaning, drying, testing and then packaging. With the adoption of the PC scuffing-resistant lens, the product transmittance is 95-98 percent and is increased by 5-15 percent; the haze is 1-3 percent; the impact strength of a cantilever beam 900-1000J / m, and the impact strength of a notch at 30 DEG C below zero is 18-20kJ / m<2>; the refractive index is 1.8-2.0 and is increased by 0.2-0.5; the bending strength is 125-130MPa.

High-temperature-resistant cable outer sheath layer and preparation method thereof

InactiveCN108117679ASolve the insulation problemSpeed up agingRubber insulatorsVulcanizationEthyl acetate

The invention discloses a high-temperature-resistant cable outer sheath layer and a preparation method thereof. The preparation method comprises the following steps that bentonite, succinyl oxide, fatty alcohol, organic acid and water are mixed; after centrifugal dewatering and spray drying, a filler M is obtained; the filler M is respectively subjected to primary heat treatment and secondary heattreatment to obtain a modified filler M; the modified filler M, neoprene rubber, butylated amino resin, polyvinylidene fluoride, ethyl acetate, cadmium stearate, carbon black, zinc oxide and barium stearate are mixed; after banburying, mixing glue is obtained; the mixing glue is added into a vulcanizing machine; through extrusion vulcanization and hot press molding, the high-temperature-resistantcable outer sheath layer is obtained. The problems that most outer sheath layers of electric wires and cables have heat insulation performance, so that the cable outer sheath layer provides insulation performance; meanwhile, the dissipation of heat inside the electric wires and cables is impeded to a certain degree; the aging speed of the sheath layer can be accelerated due to heat accumulation,so that the service lives of the electric wires and cables are shortened are solved.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Overpressure resistant PVC tubing

The invention discloses an overpressure resistant PVC tubing, which is composed of the following components by weight: 50-70 parts of PVC resin, 3-5 parts of plasticizer, 6-10 parts of lithopone, 10-12 parts of calcium carbonate, 3-5 parts of cadmium stearate, 5-10 parts of impact resistance agent, 3-6 parts of aluminium hydroxide, and 5-10 parts of synthesized paraffin. The impact resistance tubing has the advantages of good toughness and shock resistance, chemical corrosion resistance, improved tensile strength and fracture elongation rate, good toughness without water leakage, water seepage and rupture, and MBS resin is added into the PVC for promoting plasticizing, and enhancing inorganic substance dispersion and processing fluidity of PVC melt, and improving low temperature impact strength of the product.

Owner:QINGDAO HUARUI RUBBER IND EQUIP

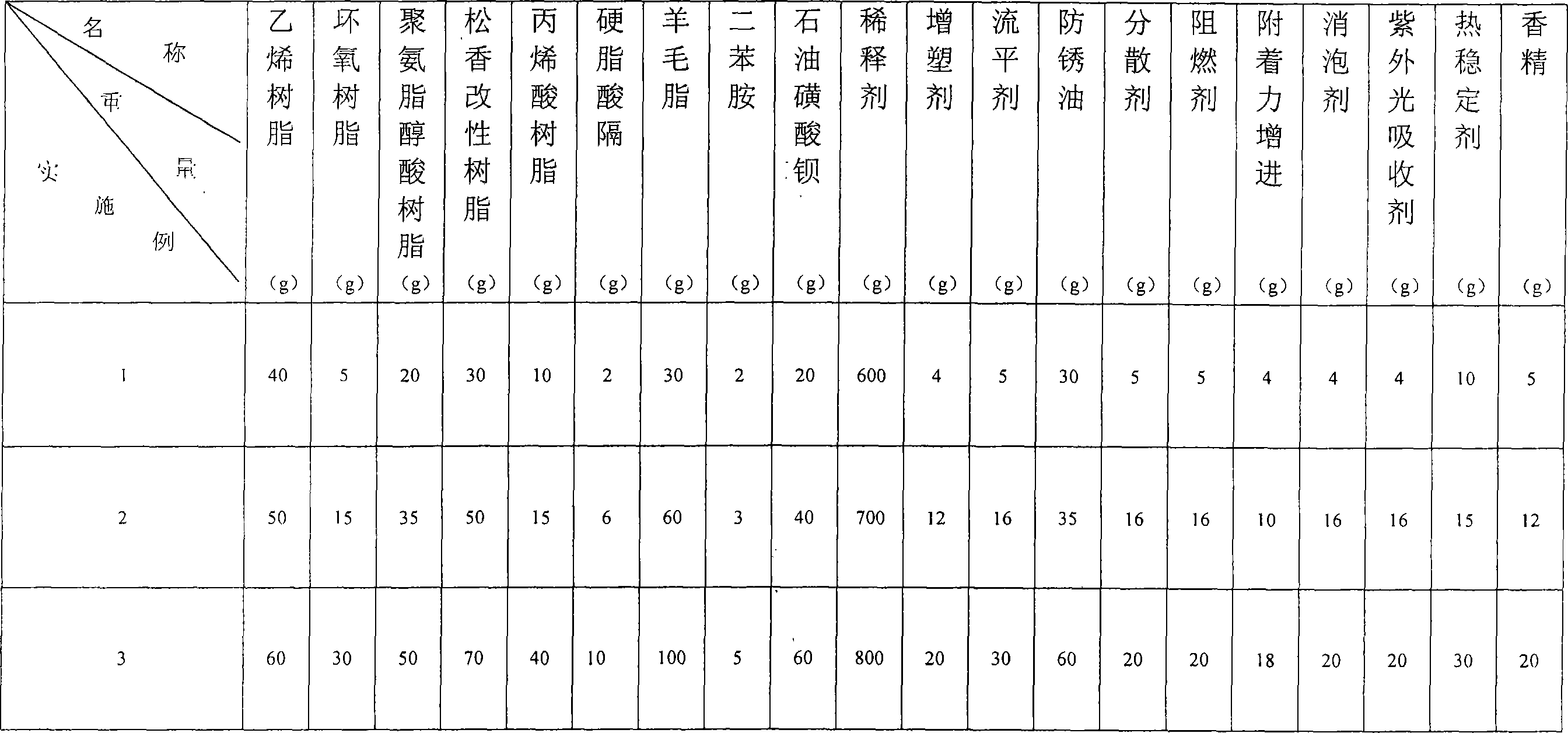

Preparation method of cadmium selenide nanocrystal assembly with narrow size distribution

ActiveCN104495759AImprove stabilityLow costMaterial nanotechnologyMetal selenides/telluridesSolventPrecipitation

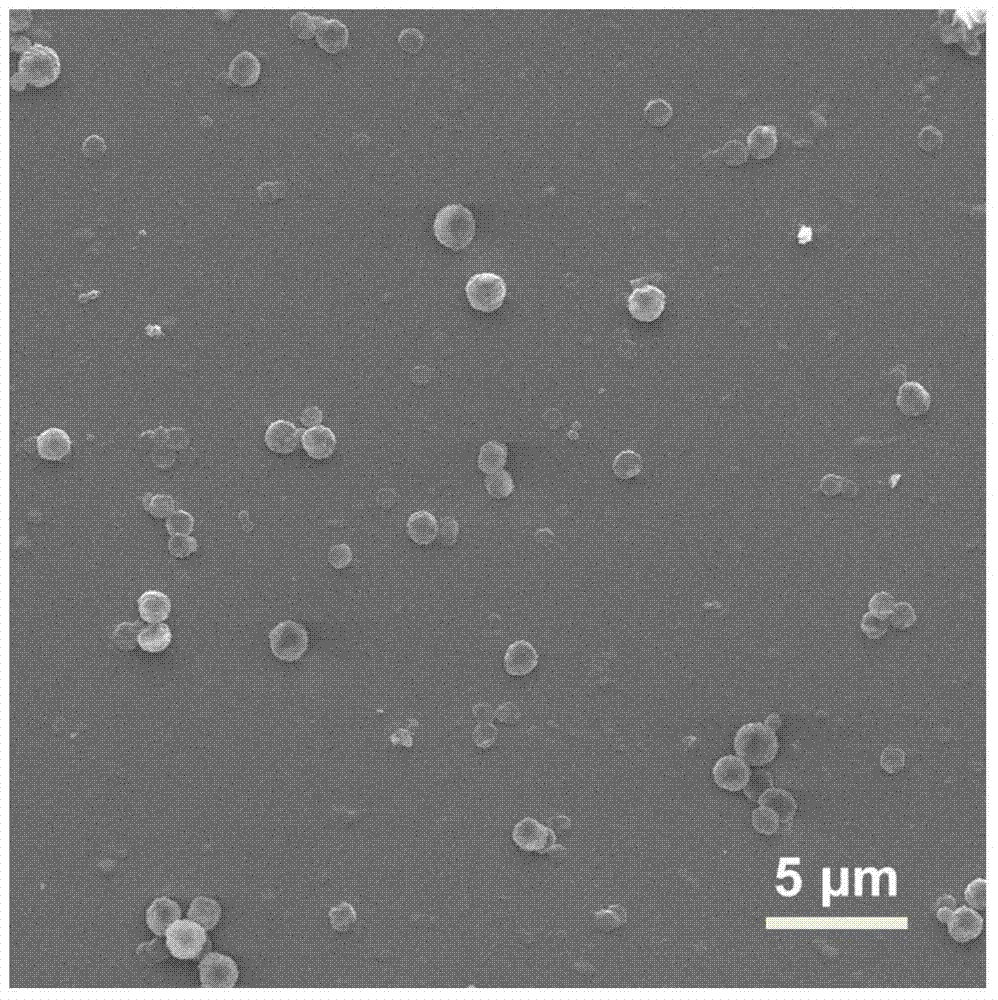

The invention relates to a preparation method of a cadmium selenide nanocrystal assembly with narrow size distribution. The method is as below: filling cadmium stearate and selenium powder at room temperature into a container containing octadecene, and installing a condensation reflux device in the container; introducing inert gas, and heating to 200-300 DEG C for reaction; after the reaction, cooling to room temperature with cooling rate controlled at 5-30 C / min; separating reaction products and collecting a lower layer precipitate; mixing isopropyl alcohol solution with the precipitation for continuous separation, and collecting a lower layer precipitate; and dissolving the precipitate in a toluene solvent, so as to obtain a CdSe nanocrystal assembly with narrow size distribution. The method has the advantages of simple operation, short production cycle, good product stability, low cost, narrow energy gap of CdSe material, more photon absorption and improvement on photovoltaic conversion efficiency. The invention provides a novel thinking for preparation of other organic nanocrystal assembly and provides possibility for the commercialized application of nano-materials.

Owner:TIANJIN UNIV

PVC film for blood transfusion bag and preparation method of PVC film for blood transfusion bag

The invention discloses a PVC film for a blood transfusion bag and a preparation method of the PVC film for the blood transfusion bag. The preparation method comprises the following steps: weighing PVC, zinc stearate, DOP, aluminum stearate, di(2-ethylhexyl)-4,5-epoxytetrahydrophthalate, cadmium stearate, a stabilizer, DBP, dicumyl peroxide, CPE, an antioxidant, triphenyl phosphate, diisooctyl phenyl phosphate, barium stearate and phenyl methyl silicone oil in parts by weight, and extruding and pelletizing after uniformly mixing so as to obtain the PVC film. The light transmittance of the product is 85-95%, the longitudinal elongation at 0 DEG C is 5-45%, the longitudinal tensile strength is 20-40 MPa, the transverse tensile strength is 25-45 MPa, the longitudinal elongation is 200-600%, the transverse elongation is 400-800%, the longitudinal tear strength is 10-12 kN / m and the transverse tear strength is 12-16 kN / m.

Owner:SUZHOU BEC BIOLOGICAL TECH

Anti-aging injection molding formula

The invention provides an anti-aging injection molding formula which comprises the following raw materials of PVC resin, polycaprolactone, lignin, silicone oil, barium stearate, cadmium stearate, zincstearate, borax, methyl cellulose and calcium carbonate. Compared with the prior art, the anti-aging injection molding formula disclosed by the invention has the following beneficial effects that service life of a manufactured plastic product is greatly prolonged, PVC resin plasticizing time can be shortened, PVC resin processing fluidity is improved, an injection molded part has high strength and is not prone to be broken, and normal work of the injection molded part is ensured.

Owner:夏百庆

PVC foamed artificial leather and preparation method thereof

The invention discloses PVC foamed artificial leather and a preparation method thereof. The PVC foamed artificial leather comprises, by mass, 100 parts of PVC or crosslinking powder, 60-120 parts of plasticizer, 0.1-10 parts of thermal stabilizer, 3-10 parts of AC foamer, 1-15 parts of pigment and 0.1-0.5 part of foam hole adjuster, wherein the plasticizer is one of or a mixture of DOP, DINP and DOA, and the thermal stabilizer is one of or a mixture of barium stearate, cadmium stearate, zinc stearate and lead stearate. Compared with the prior art, the PVC foamed artificial leather is high in thickness which can meet requirements of clients on finished product thickness being 3.0mm and above to meet special using requirements like saddles.

Owner:南亚塑胶工业(南通)有限公司

Battery truck solid tire carcass compound

InactiveCN104693550AImprove wear resistanceHigh tensile strengthSpecial tyresSodium acetateCrack resistance

The invention discloses a battery truck solid tire carcass compound which is prepared from the following materials: neoprene, sodium acetate, cadmium stearate, an oil-extender, furnace black, zinc oxide, magnesium oxide, an anti-aging agent and an accelerant. The carcass compound disclosed by the invention has the performances such as excellent abrasive resistance, high tensile strength and tearing strength, good aging resistance, warping strength, heat resistance, puncture resistance and groove cracking resistance, and the like.

Owner:王东奎

Anti-aging-cracking plastic flooring and preparation method thereof

The invention discloses anti-aging-cracking plastic flooring and a preparation method thereof. The plastic flooring comprises, by weight part, 51-66 of ultrahigh molecular weight polyethylene, 26-40 of poly(p-phenylene terephthalamide), 17-29 of sepiolite fiber, 12-19 of cyclohexane dialkyl dicarboxylate, 5-7 of behenamide, 19-33 of styrene-butadiene segmented copolymer, 11-17 of flocculation lignin fiber, 10-15 of silicon carbide whiskers, 16-23 of chalk powder, 5-10 of methyl 3-mercaptopropionate, 2-3 of cadmium stearate, 1.5-2.5 of barium stearate, and 13-21 of tridecyl trimellitate. The plastic flooring is made by compounding ultrahigh molecular weight polyethylene and poly(p-phenylene terephthalamide), can maintain excellent mechanical properties in a wide temperature range in a high-humidity environment, and is excellent in ageing resistance. Through addition of sepiolite fiber and silicon carbide whiskers, the anti-aging-cracking property and wear resistance of the plastic flooring are improved. Through addition of a plasticizer, such as tridecyl trimellitate, heat resistance and durability of the plastic flooring are further improved.

Owner:JIANGYIN ZHIYUAN AUTOMOBILE DECORATION PARTS CO LTD

Expansion joint and preparation method thereof

The invention discloses an expansion joint and a preparation method thereof. The expansion joint is prepared from butadiene rubber, PVC, tribasic lead sulfate, dibasic lead sulfate, ABS, cadmium stearate, PMMA, dibutyl laurate, zinc borate hydrate, hydrogenated butadiene-acrylonitrile rubber, NBR, stainless steel powder, stannous chloride and benzoin dimethyl ether. The prepared expansion joint has bending strength of 100 to 120 MPa, Shore hardness of 90 to 100 D, flexural modulus of 1.2 to 1.6 GPa, impact strength of 90 to 110 kJ / m<3>, tearing strength of 30 to 50 kN / m, a Vicat softening point of 140 to 180 DEG C, tensile strength of 60 to 80 MPa, oil resistance of 30 to 50% under the condition of standing at 80 DEG C for one day, elastic modulus of 135 to 175 MPa, elongation at break of 650 to 850%, compression set of 10 to 15% and Young modulus of 440 to 480 MPa.

Owner:WUXI YONGXING METAL HOSE

Flame-retardant modified automobile foot pad material and preparation method thereof

InactiveCN106674797AImprove securityImprove flame retardant performanceAluminium hydroxideDioctyl terephthalate

The invention relates to the technical field of an automobile foot pad material, and particularly relates to a flame-retardant modified automobile foot pad material. The flame-retardant modified automobile foot pad material is prepared from the following components in parts by mass: 100 parts of PVC (polyvinyl chloride) resin, 20 parts of plasticizer DOP (Dioctyl-Phthalate), 20 parts of DOTP (dioctyl terephthalate), 15 parts of chlorinated paraffin, 3 parts of flame retardant, 60 parts of aluminium hydroxide, 4 parts of stabilizer, 0.5 part of cadmium stearate, 30 parts of filler, 0.5 part of lubricant and 0.5 part of paraffin. A preparation method of the flame-retardant modified automobile foot pad material comprises the following steps: firstly, uniformly mixing the PVC resin and the plasticizer DOP, then adding the DOTP, the chlorinated paraffin, the flame retardant, the aluminium hydroxide, the stabilizer, the cadmium stearate, the filler, the lubricant and the paraffin; stirring for 5 to 10min in a high-speed mixer at a temperature of 70 to 90 DEG C; after uniform mixing, carrying out extrusion molding by adopting a double-screw extruder. According to the obtained flame-retardant modified automobile foot pad material and the preparation method thereof, the prepared material has good flame retardance, is suitable for being used on a foot pad, and enables safety of the foot pad to be higher.

Owner:桐乡市同益塑业有限公司

Ionic liquid-doped light bamboo-plastic material

The invention discloses an ionic liquid-doped light bamboo-plastic material. The ionic liquid-doped light bamboo-plastic material is prepared from the following raw materials in parts by weight: 10-16parts of light calcium carbonate, 0.4-1 part of stannous octoate, 0.1-0.2 part of 1,2-dimethylimidazole, 110-130 parts of polypropylene, 10-14 parts of organic bamboo powder, 2-4 parts of isooctyl methacrylate, 0.8-1 part of dodecyl trimethyl ammonium chloride, 0.1-0.2 part of cadmium stearate and 0.8-1 part of 1-butyl-3-methylimidazole methanesulfonate. The bamboo-plastic material disclosed by the invention is light in weight, good in thermal stability and superior in comprehensive performance.

Owner:王秋永

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com