Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79 results about "Hydrogen selenide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen selenide is an inorganic compound with the formula H₂Se. This hydrogen chalcogenide is the simplest and most commonly encountered hydride of selenium. H₂Se is a colorless, flammable gas under standard conditions. It is the most toxic selenium compound with an exposure limit of 0.05 ppm over an 8-hour period. Even at extremely low concentrations, this compound has a very irritating smell resembling that of decayed horseradish or 'leaking gas', but smells of rotten eggs at higher concentrations.

Manufacturing apparatus and method for large-scale production of thin-film solar cells

InactiveCN1703782ALow costFinal product manufactureSemiconductor/solid-state device manufacturingIndiumManufactured apparatus

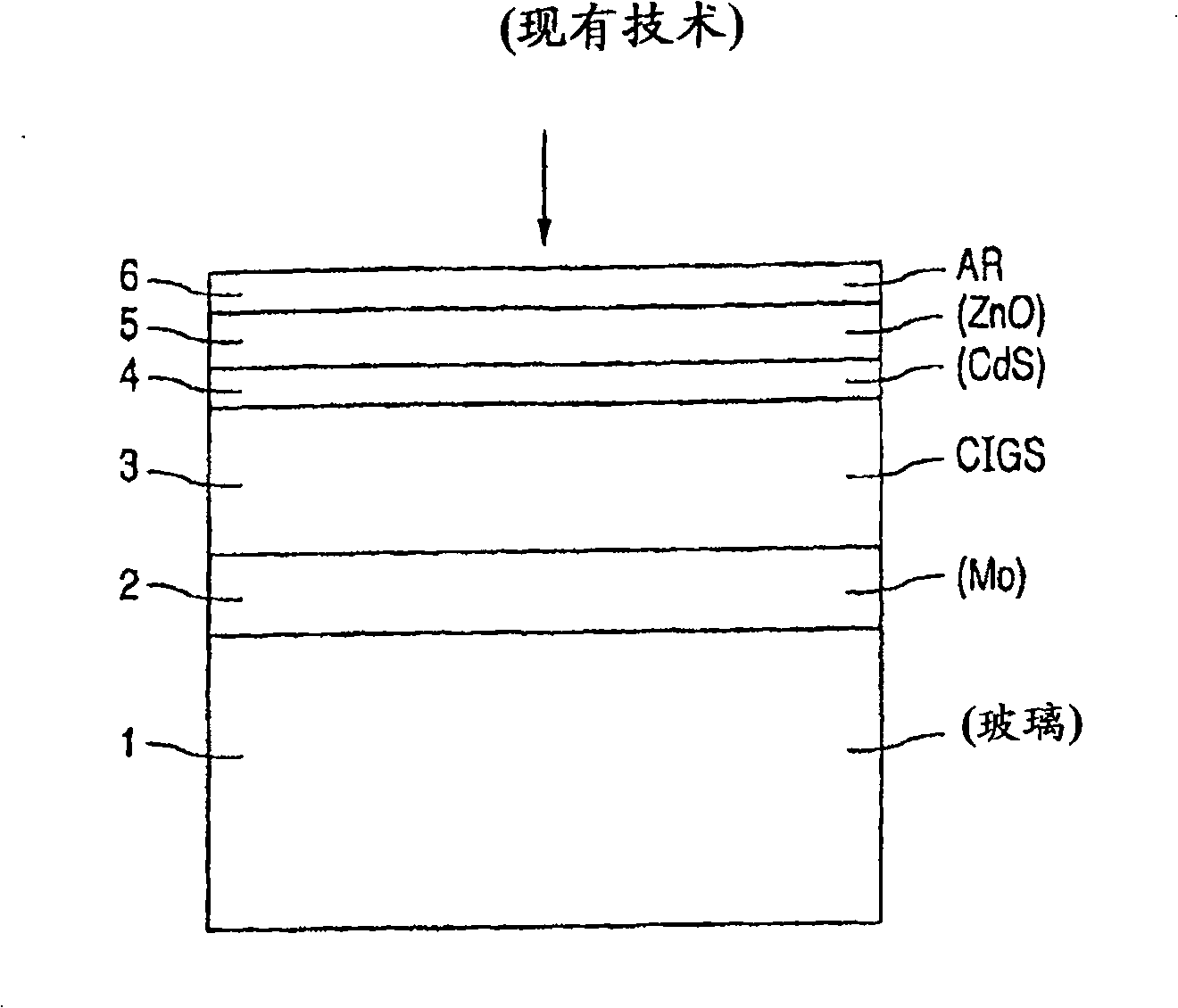

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InxGa1-x)Se2) absorber layer (X ranging from 1 to approximately 0.1) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

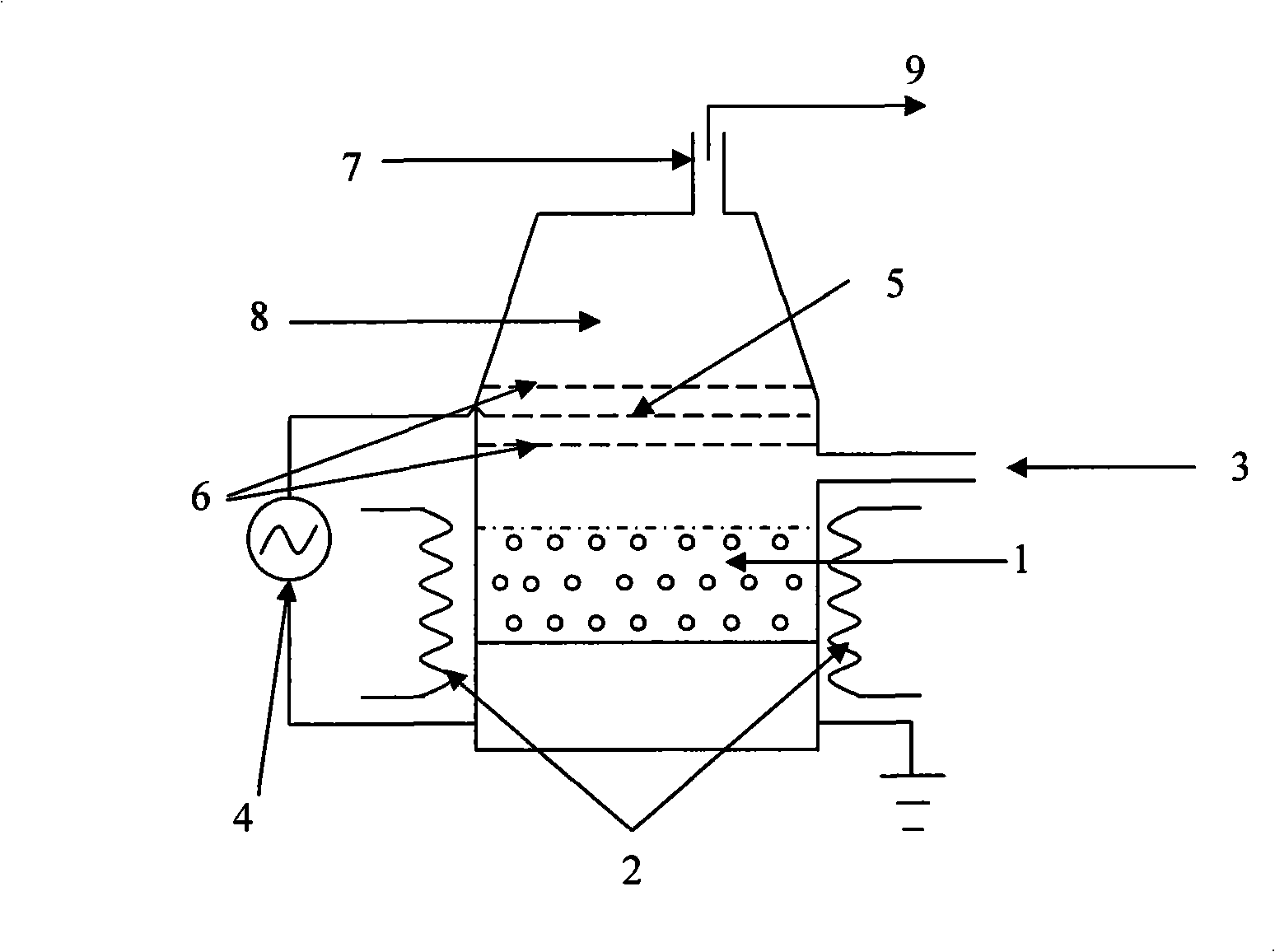

Preparing method of high active selenium source for selenylation, apparatus and applications

ActiveCN101284654AEasy transportationEasy to saveFinal product manufactureChemical industryNegative glowMixed gas

The invention discloses a method for generating a highly active selenium source used for selenizing treatment, and a device and application thereof. The method comprises the steps of heating and vaporizing solid selenium to generate selenium gas; adding hydrogen or a mixture of hydrogen and argon to the selenium gas generated by the last step; and subjecting the mixture of gases in the last step to glow discharge decomposition and synthesis to obtain hydrogen selenide and highly active selenium gas. The device for generating the selenium source comprises an airtight reaction tank, a solid selenium source in the reaction tank, a positive and a negative glow discharge electrodes, a hydrogen selenide reaction cavity, as well as a heating device and an excitation power supply outside the reaction tank. A gas inlet is further arranged on the lateral wall of the reaction tank; a gas outlet is arranged on the top of the reaction tank. The method not only retains the advantages of the solid selenium, namely low cost, non-toxicity and easiness to transport and store, prepares the hydrogen selenide and the highly active selenium ambience with the characteristics of the hydrogen selenide and the highly active selenium, but also saves a large amount of selenide materials, reduces the cost and has important practical value.

Owner:NANKAI UNIV

Method capable of improving selenium content for preparing polysaccharide selenite

The invention discloses a method capable of improving selenium content for preparing polysaccharide selenite. The method comprises the steps of adding a selenium compound solution having the mass fraction of 60-80% by spraying to a polysaccharide or a polysaccharide complex under a stirring condition and reacting at a temperature in the range of 120-160 DEG C; after the reaction is completed, purifying and drying the reaction product to obtain polysaccharide selenite, wherein the selenium compound is seleninic acid or a selenite. The method is simple in process, easy in after-treatment, controllable in reaction conditions and good in repeatability; in the production process, the generation of toxic gases such as hydrogen selenide is avoided and the use of a strong acid and heavy metals such as a barium salt to catalyze the reaction and the use of toxic organic solvents such as pyridine and benzene are avoided, and therefore, the production process is green and environment-friendly; the polysaccharide selenite prepared by the method is low in toxicity and high in bioavailability, and the selenium content of the polysaccharide selenite is higher than 18% which is far higher than the selenium content of less than 2% of the present commercial organic selenium products.

Owner:浙江皇冠科技有限公司

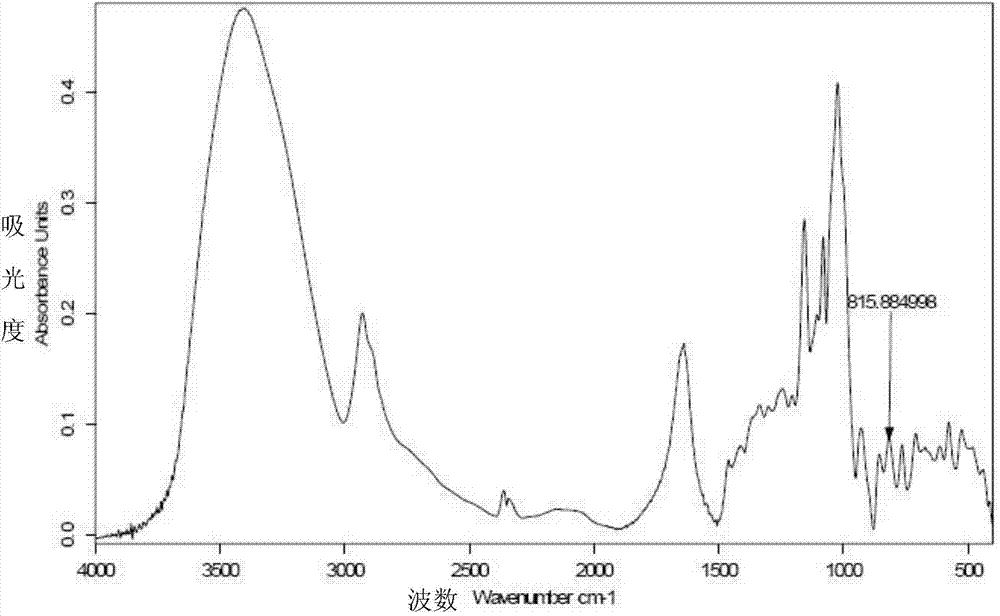

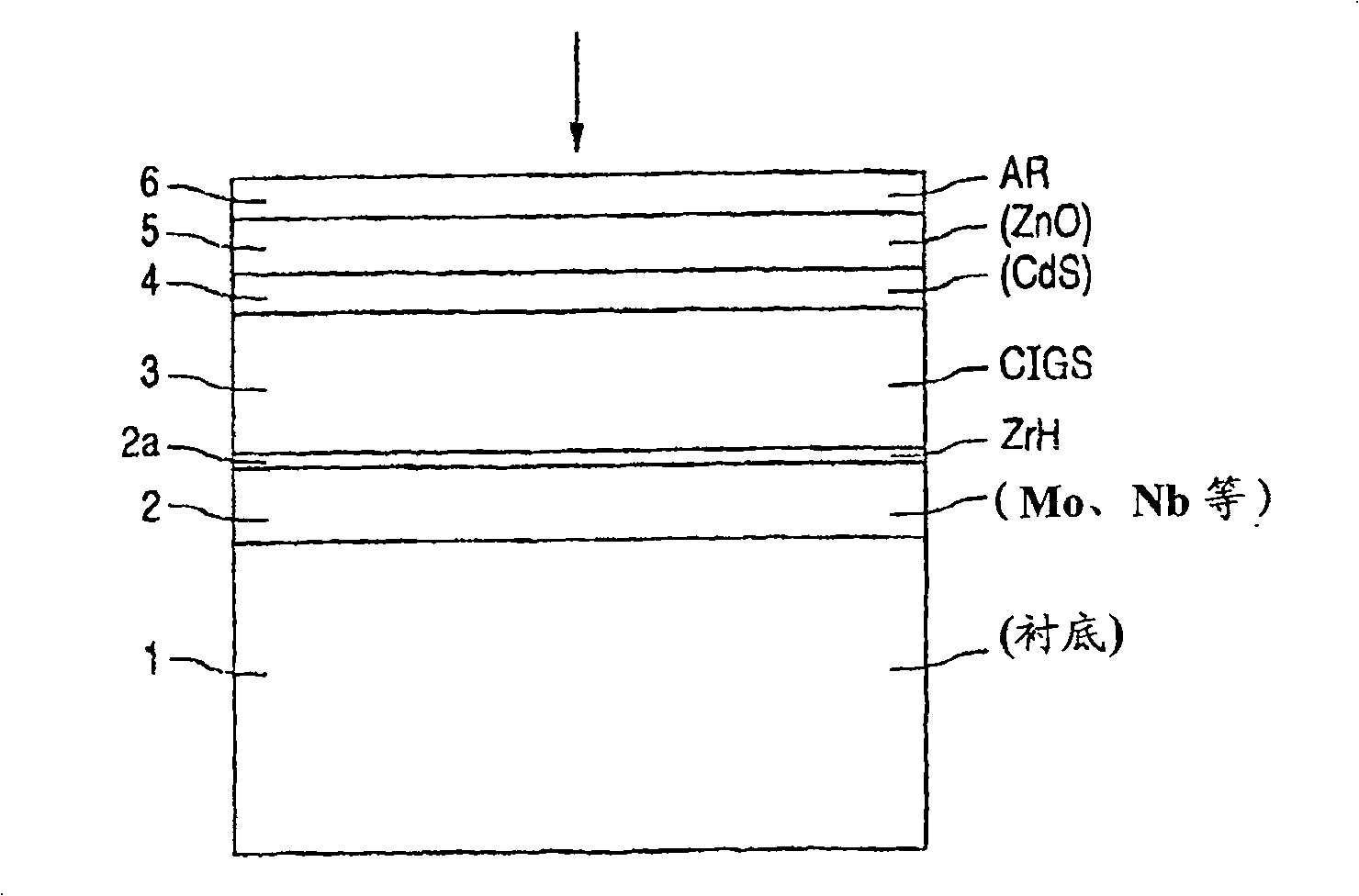

Process for Producing Light Absorbing Layer for Chalcopyrite Type Thin-Film Solar Cell

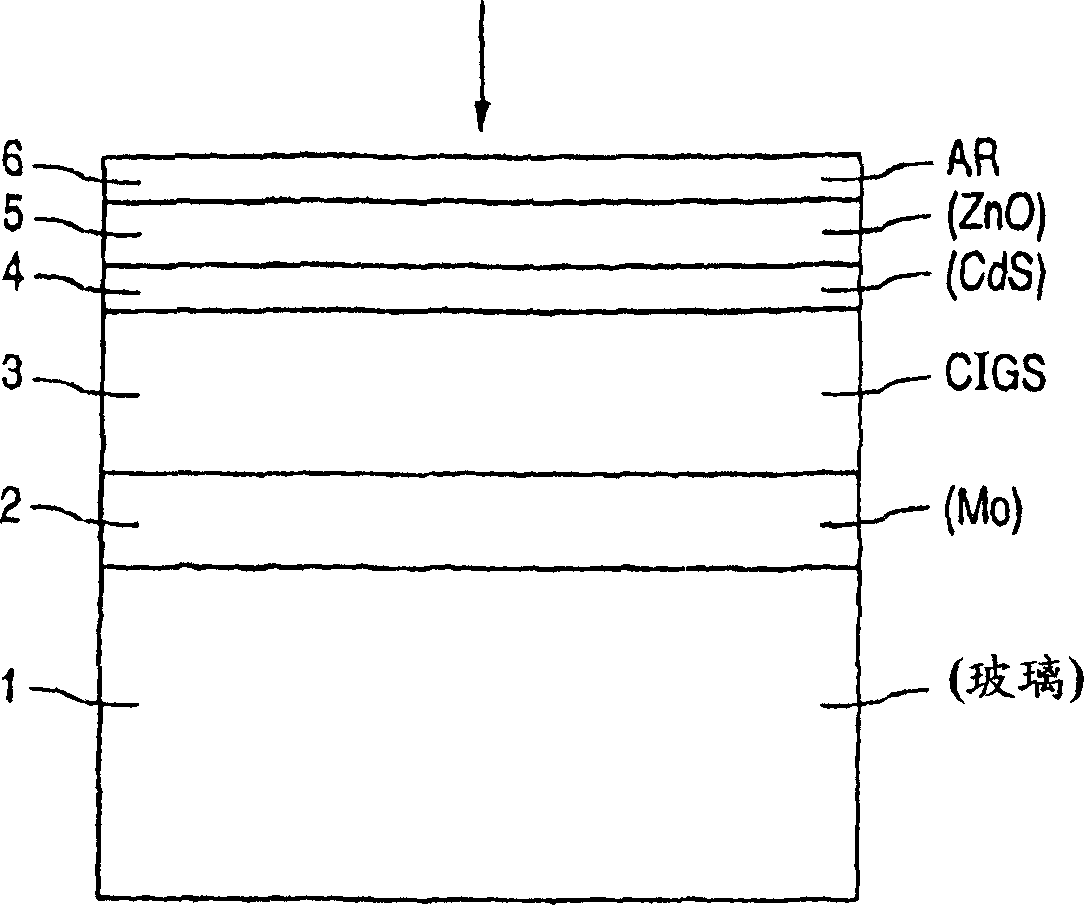

InactiveUS20080035199A1Reduce the temperaturePositively superiorityFinal product manufactureSemiconductor/solid-state device manufacturingHydrogenRoom temperature

A process for producing a light absorbing layer for thin-film solar cell that possesses a film structure having a constituent component of chalcopyrite compound (Cu(In+Ga)Se2) uniformly distributed thereinside. There is provided a process for producing a light absorbing layer, including the precursor forming step of superimposing on an Mo electrode layer, adjacent to the electrode layer, an In metal layer and a Cu—Ga alloy layer according to sputtering technique; a first selenization step of, while accommodating precursor-provided substrate in an airtight space, introducing hydrogen selenide gas in the airtight space conditioned so as to range from room temperature to 250° C.; a second selenization step of additionally introducing hydrogen selenide gas in the airtight space heated so as to range from 250° to 450° C.; a third selenization step of, while causing the hydrogen selenide gas having been introduced up to the second selenization step to remain, heating the interior of the airtight space so as to range from 450° to 650° C. and, within this range of temperature, performing heat treatment of the substrate; and a cooling step of cooling the substrate after the heat treatment.

Owner:HONDA MOTOR CO LTD

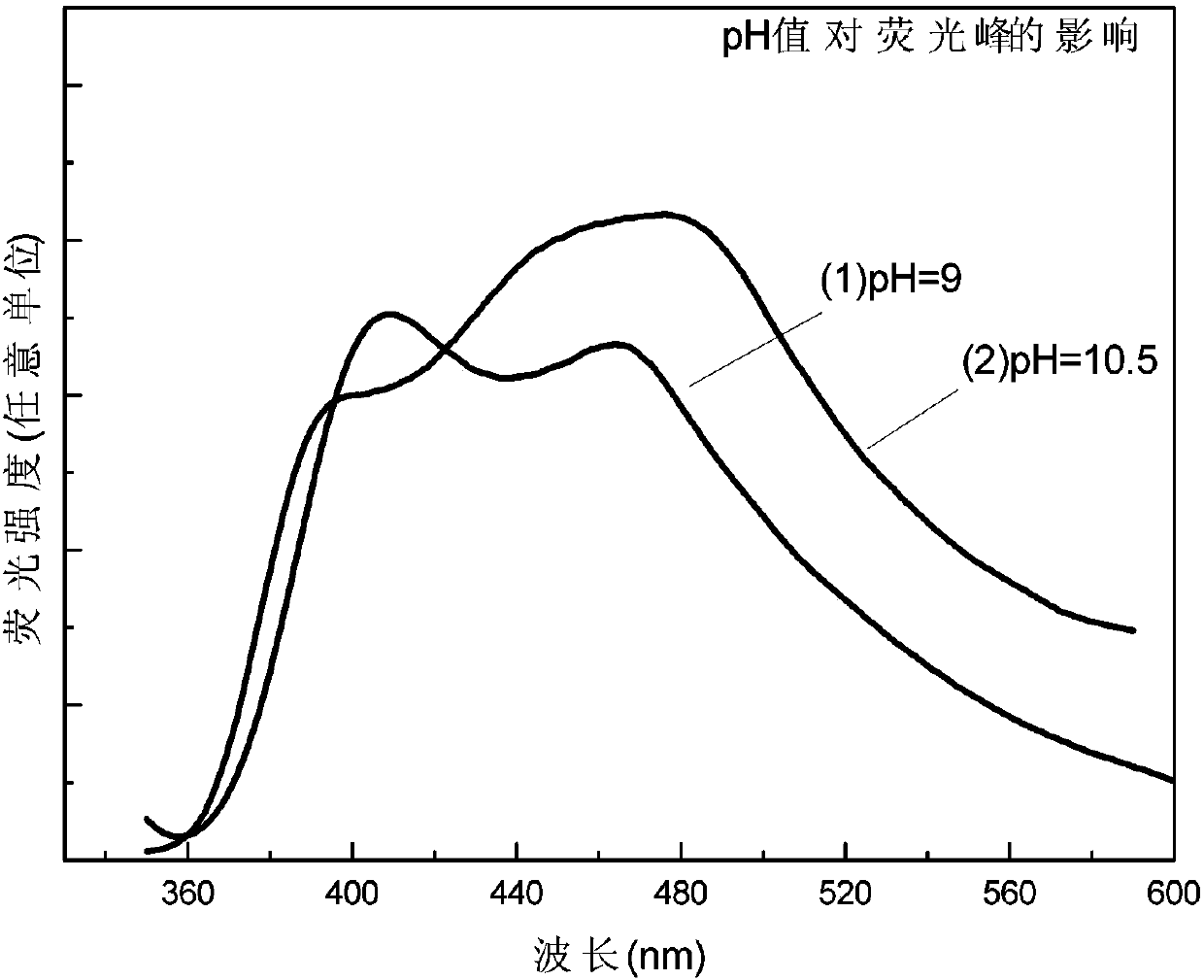

Preparation method of aqueous phase non-toxic white light quantum with multilayer core-shell structure

InactiveCN102618289AGood water solubilityImprove stabilityGas discharge lamp usageLuminescent compositionsPropanoic acidThio-

The invention relates to a preparation method of an aqueous phase non-toxic white light quantum with a multilayer core-shell structure. The preparation method comprises the following specific steps: (a) preparing a shell layer material Zn+mercaptopropionic acid (MPA)+thioacetamide (TAA): taking Zn(NO3)2 and adding the Zn(NO3)2 into a conical flask filled with deionized water, taking the MPA by using a miniature liquid-transferring gun; adding the TAA into the solution; fully stirring the solution and then adjusting the pH value of the mixed solution by using NaOH; and fully stirring the solution for later use; (b) adding the deionixed water, manganese chloride and the MPA in a three-necked bottle, adjusting the pH value and then introducing nitrogen gas and removing air in the three-necked bottle by using high-purity nitrogen gas; injecting sodium hydrogen selenide by using an injector and then allowing the manganese chloride and the sodium hydrogen selenide to be fully acted to form a selenide-rich MnSe quantum dot; then injecting zinc nitrate and growing for one hour; injecting the shell layer material in the step (a) and growing; then adding a copper chloride solution and growing; adding the shell layer material; and finally, regrowing to obtain the required white light quantum dot. The white light quantum dot synchronized by the preparation method is better in water solubility and stability and has broad application prospect.

Owner:SOUTHEAST UNIV

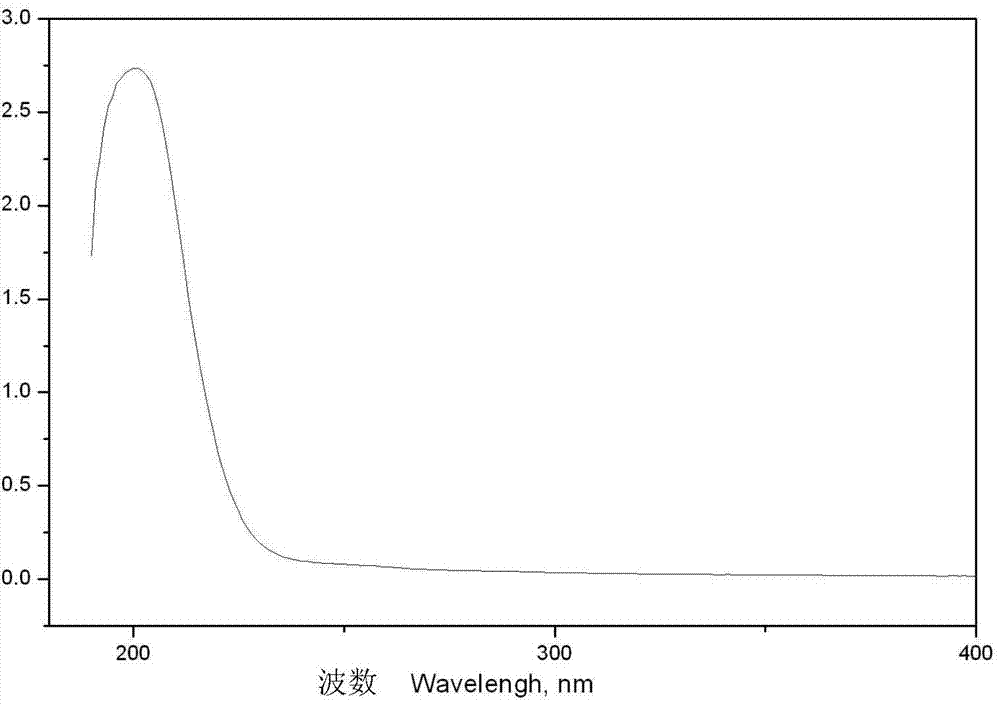

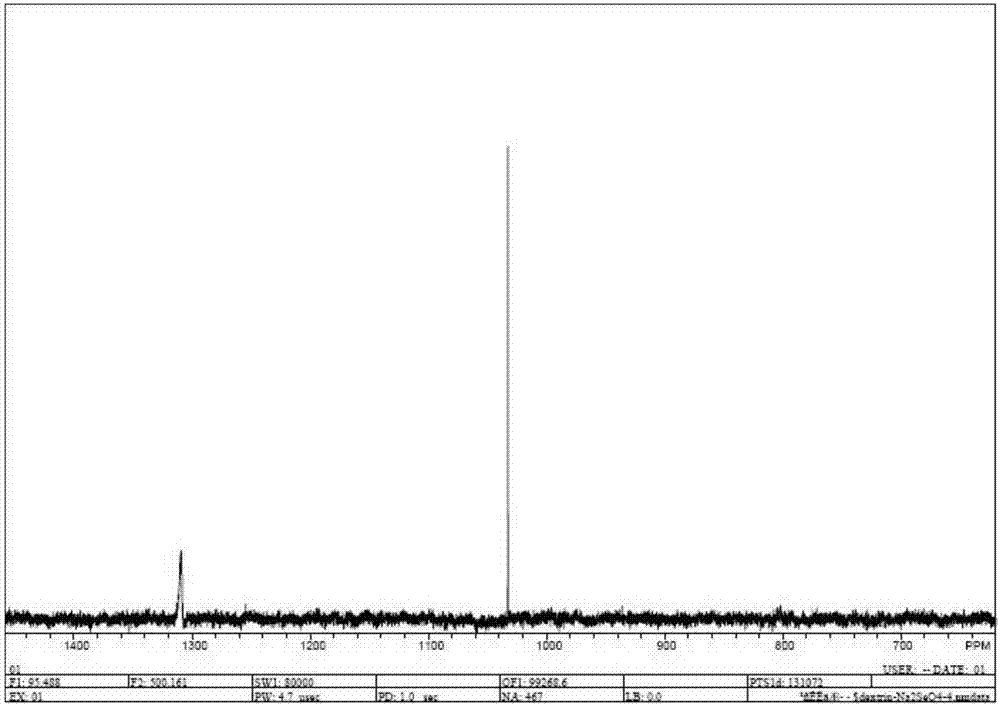

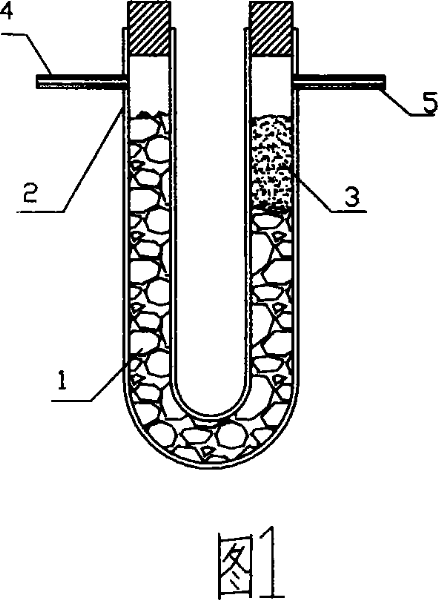

Preparation and purification method of hydrogen selenide

InactiveCN101041425ATake advantage ofReduce pollutionBinary selenium/tellurium compoundsPurification methodsSorbent

The invention discloses a purifying method to prepare hydrogen selenide, which comprises the following steps: reacting Al2Se3 and H2O; getting hydrogen selenide H2Se; removing water of H2Se gas through condensing; using Al2Se3 particle to adsorb remain water; entering into carboy to condense and liquefy; evacuating the carboy under the condition of cool bath; eliminating non-condensable gas impurity of solution in the liquid; closing the valve of carboy; getting purify hydrogen selenide; absorbing water; taking-up active solid of reacting with water as raw material; reacting Al2Se3 and H20; getting H2Se; reaching highly effective dewater effect.

Owner:DALIAN LIFANG CHEM TECH

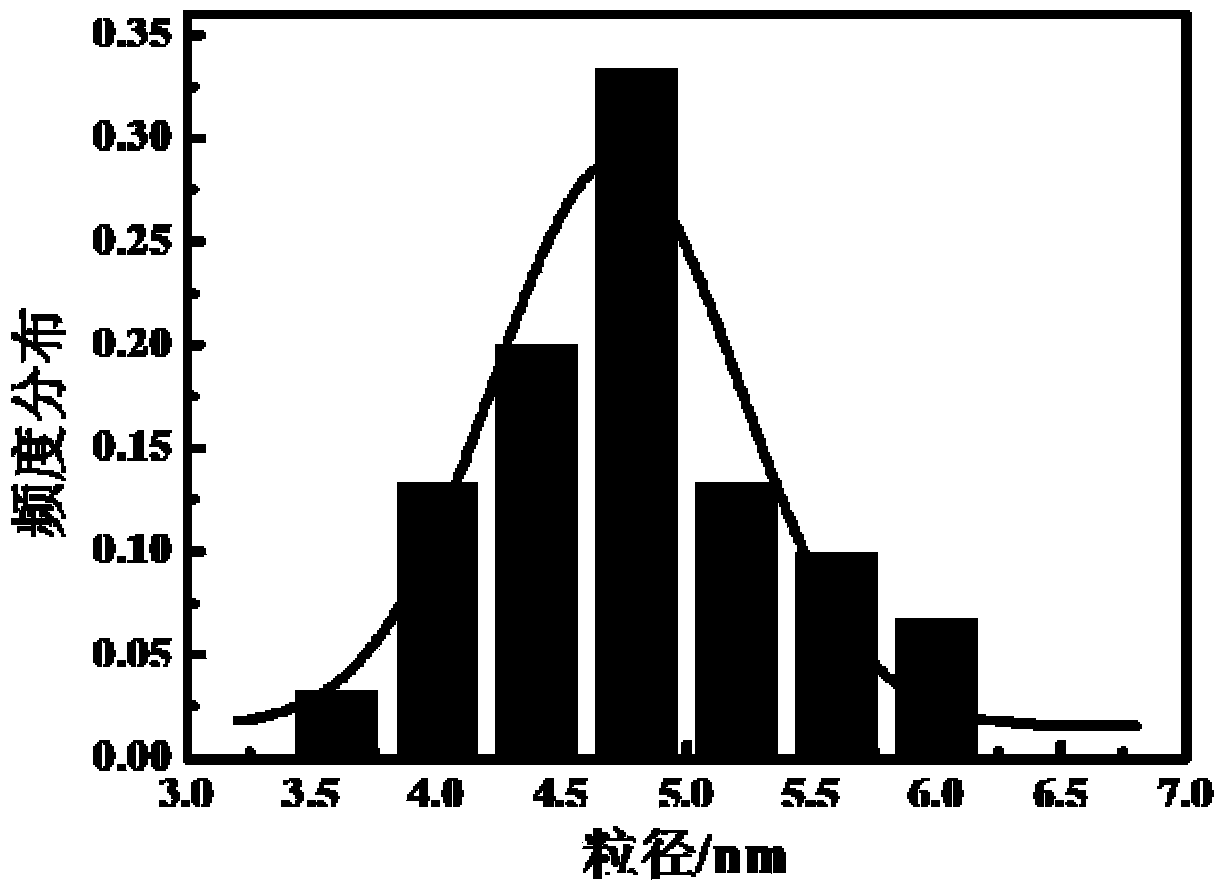

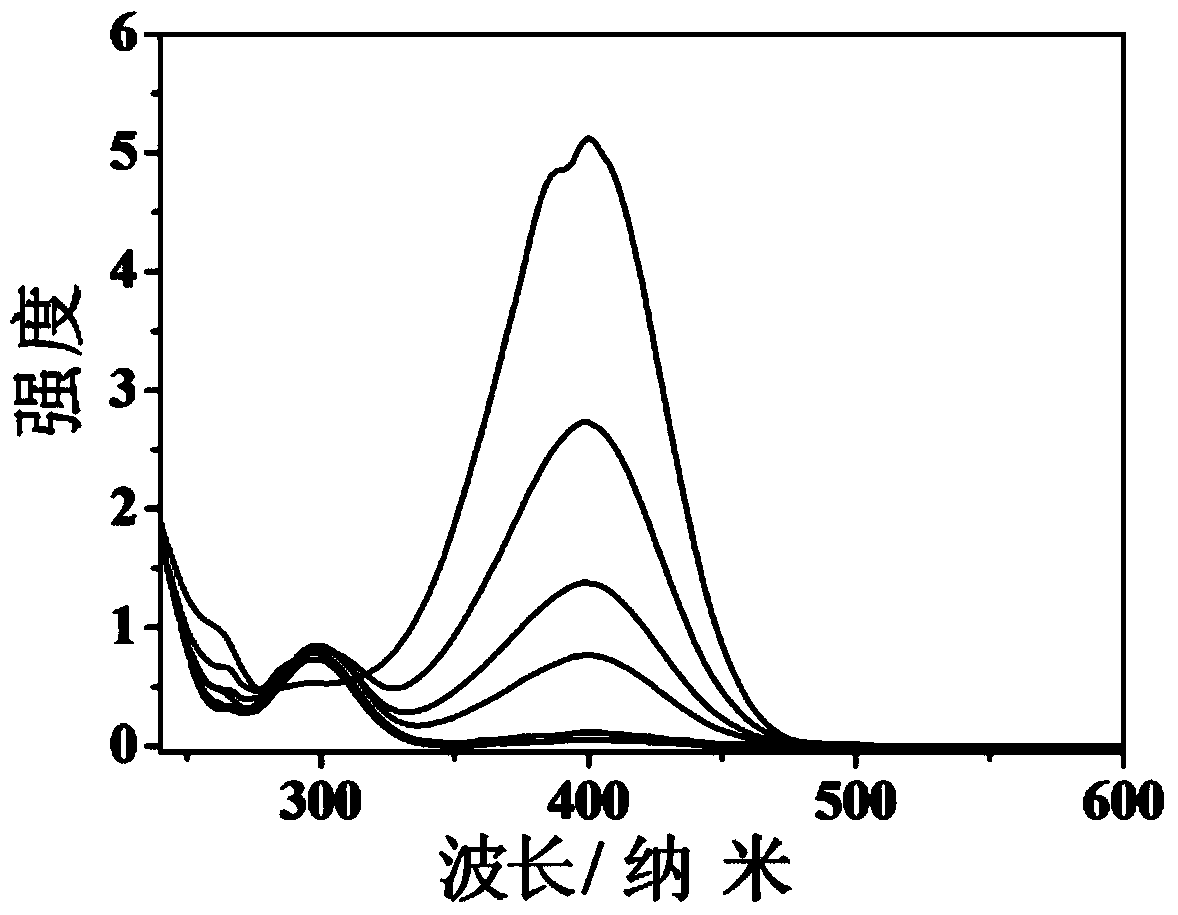

Copper selenide fluorescent quantum dot and preparation method and application thereof

InactiveCN103803511ASimple methodMild conditionsLight-sensitive devicesLuminescent compositionsQuantum yieldSensitized cell

The invention relates to a copper selenide fluorescent quantum dot and a preparation method and application thereof. The copper selenide fluorescent quantum dot is characterized in that the quantum dot is one of Cu2Se, CuSe and Cu(2-x)Se or a combination thereof; the particle size of the quantum dot is 2-10nm, the quantum yield is 10-60%, and the half-peak width of the photoluminescence spectrum is 30-150nm. The preparation method comprises the following steps: with an aqueous solution with copper salt dissolved in as an aqueous phase and an organic solvent with a long-chain ligand dissolved in as an oil phase, stirring in an inertia protective gas, and heating in an oil bath to form a precursor solution; pouring an aqueous solution of sodium hydrogen selenide into the hot precursor solution, and heating for reaction; sampling at different time to obtain organic-phase quantum dot solutions with different emission fluorescence; precipitating the upper-layer organic-phase quantum dot solution; centrifuging and dispersing, and repeating to remove unreacted raw materials to obtain the copper selenide fluorescent quantum dot. The quantum dot does not contain heavy metal elements such as cadmium and the like to realize low toxicity, has the advantages of high quantum yield, uniform particle size, relatively narrow fluorescence emission spectrum and adjustable light color along with excitation wavelength, and can be used for preparing quantum dot solar sensitized cells and LED (light-emitting diode) devices.

Owner:NANJING TECH UNIV

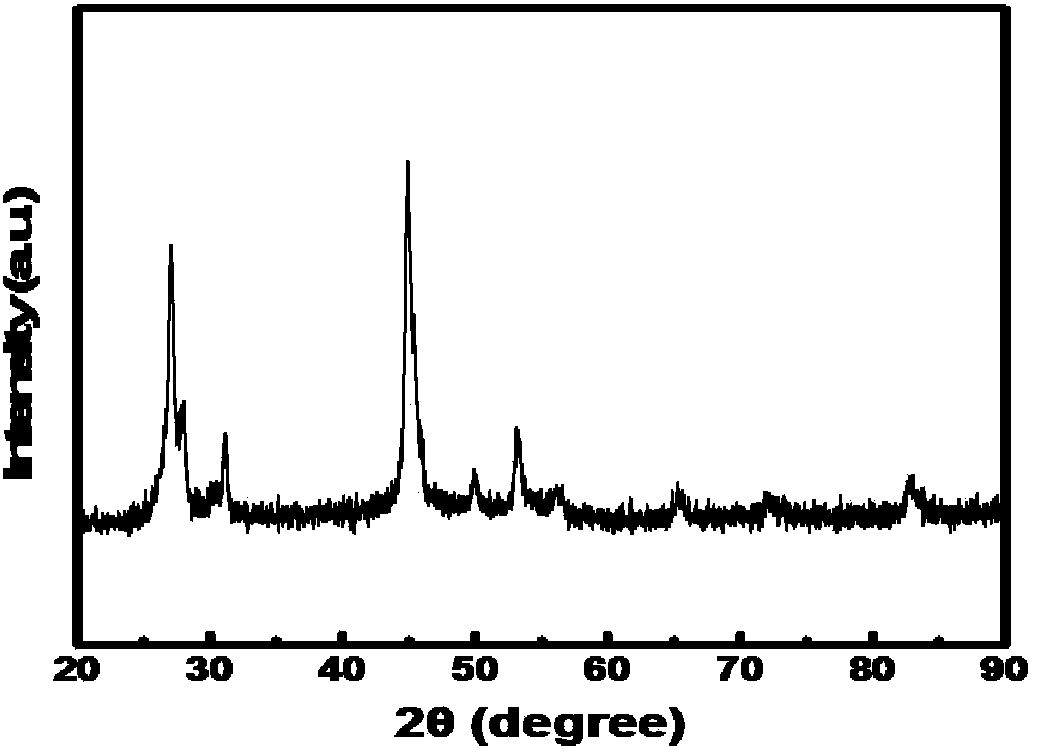

Co<0.85>Se catalyst material and preparation method thereof

InactiveCN103949274AMild reaction conditionsEasy to preparePhysical/chemical process catalystsOrganic compound preparationMicro nanoPolyol

The invention provides a Co<0.85>Se catalyst material and a preparation method thereof. The Co<0.85>Se catalyst material has a beam-shaped structure with a length being 0.8-2.5 microns and a diameter being 300-800nm. The preparation method of the Co<0.85>Se catalyst material comprises the following steps: A, dissolving cobalt salt and carbamide in a mixed solution containing polyhydric alcohols and water, reacting under the hydrothermal condition, and then centrifuging, washing and drying a product to obtain Co(OH)<1.1>(CO3)<0.35>Cl<0.2>.nH2O precursor; and B, mixing the precursor with a sodium hydrogen selenide solution, naturally cooling to room temperature under the hydrothermal condition, and then centrifuging, washing and drying the product to obtain the Co<0.85>Se catalyst material. The Co<0.85>Se catalyst material is capable of realizing controllable synthesis of shapes of catalysts; the obtained Co<0.85>Se micro-nano material is applicable to organic catalysis and dye degradation, shows excellent catalytic activity and has great and potential application value in hydrogenation.

Owner:ANHUI NORMAL UNIV

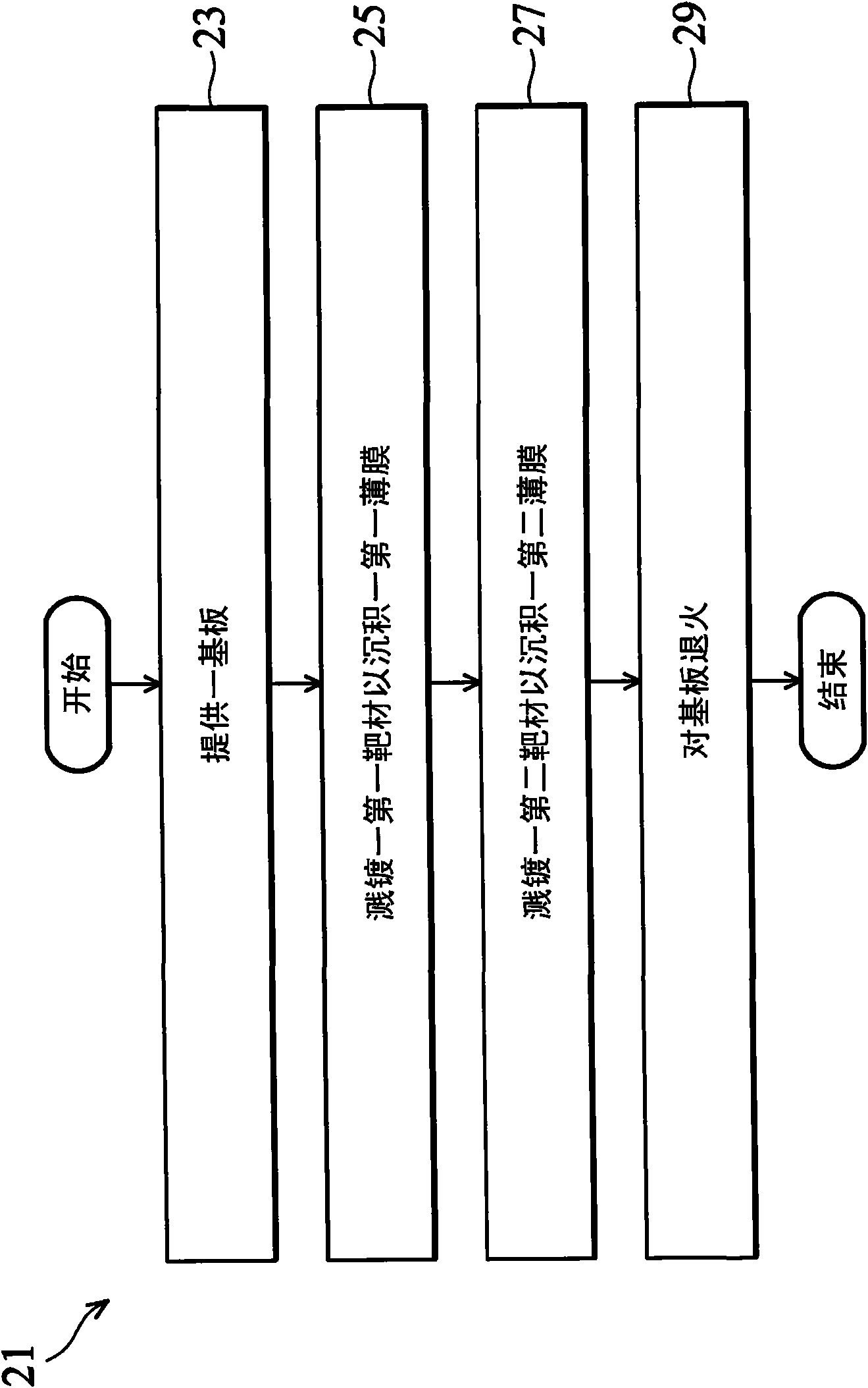

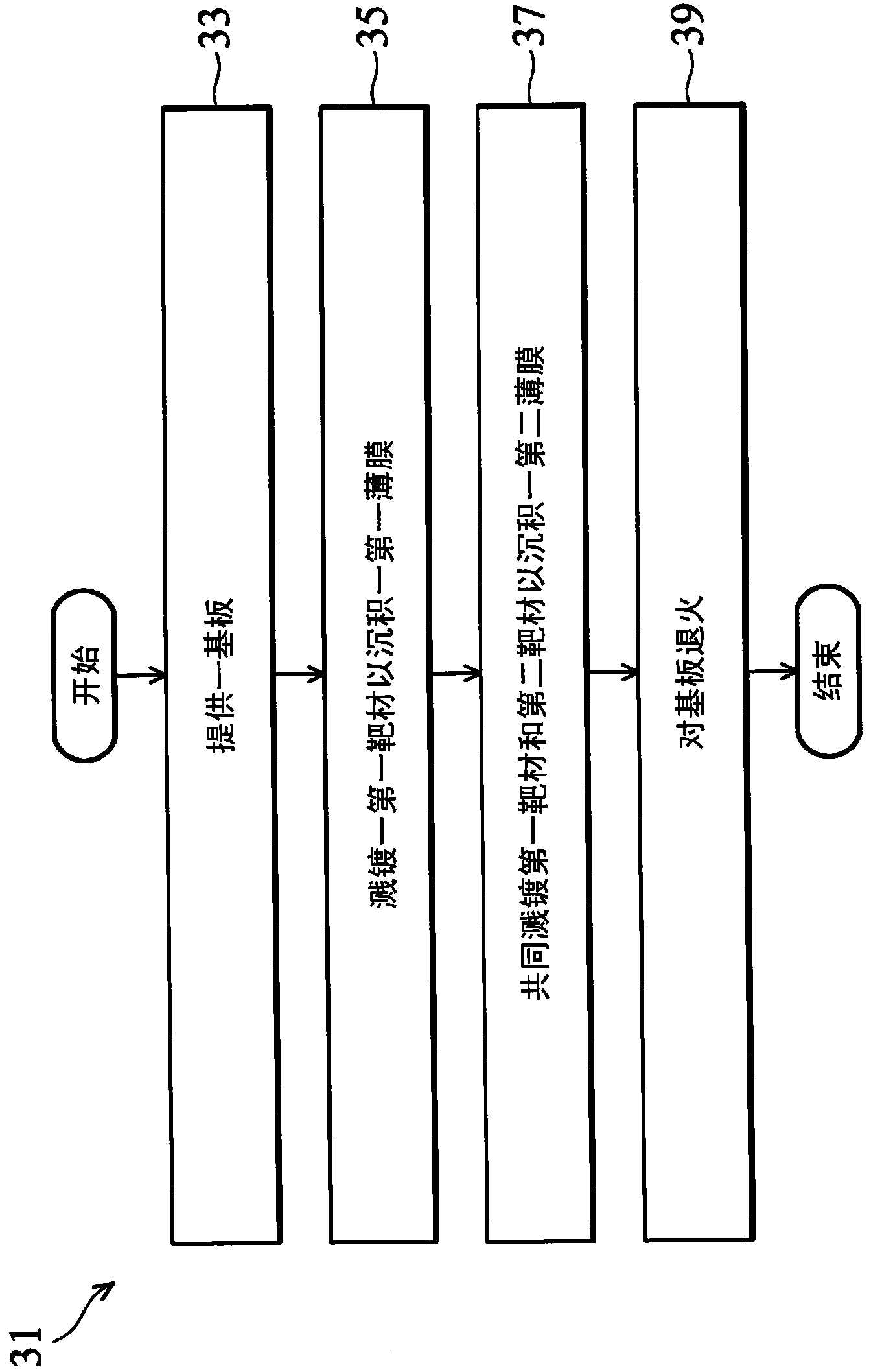

Solar battery manufacturing method

ActiveCN102237439AReduce usageSimple processFinal product manufactureVacuum evaporation coatingSputteringHydrogen

The invention provides a solar battery manufacturing method. Sulfur-containing chalcogenide absorbers in thin film solar cell are manufactured by sequential sputtering or co-sputtering targets, one of which contains a sulfur compound, onto a substrate and then annealing the substrate. The anneal is performed in a non-sulfur containing environment and avoids the use of hazardous hydrogen sulfide gas. A sulfurized chalcogenide is formed having a sulfur concentration gradient. The process operations are simplified and uses only one annealing operation, as opposed to two annealing operations in other processes. Further, the disclosed process avoids the use of selenium containing or sulfur containing gas environments, which are difficult to use in a mass-production environment. Particularly, hydrogen selenide and hydrogen sulfide, both of which are very toxic at low concentrations, are avoided.

Owner:TAIWAN SEMICON MFG CO LTD

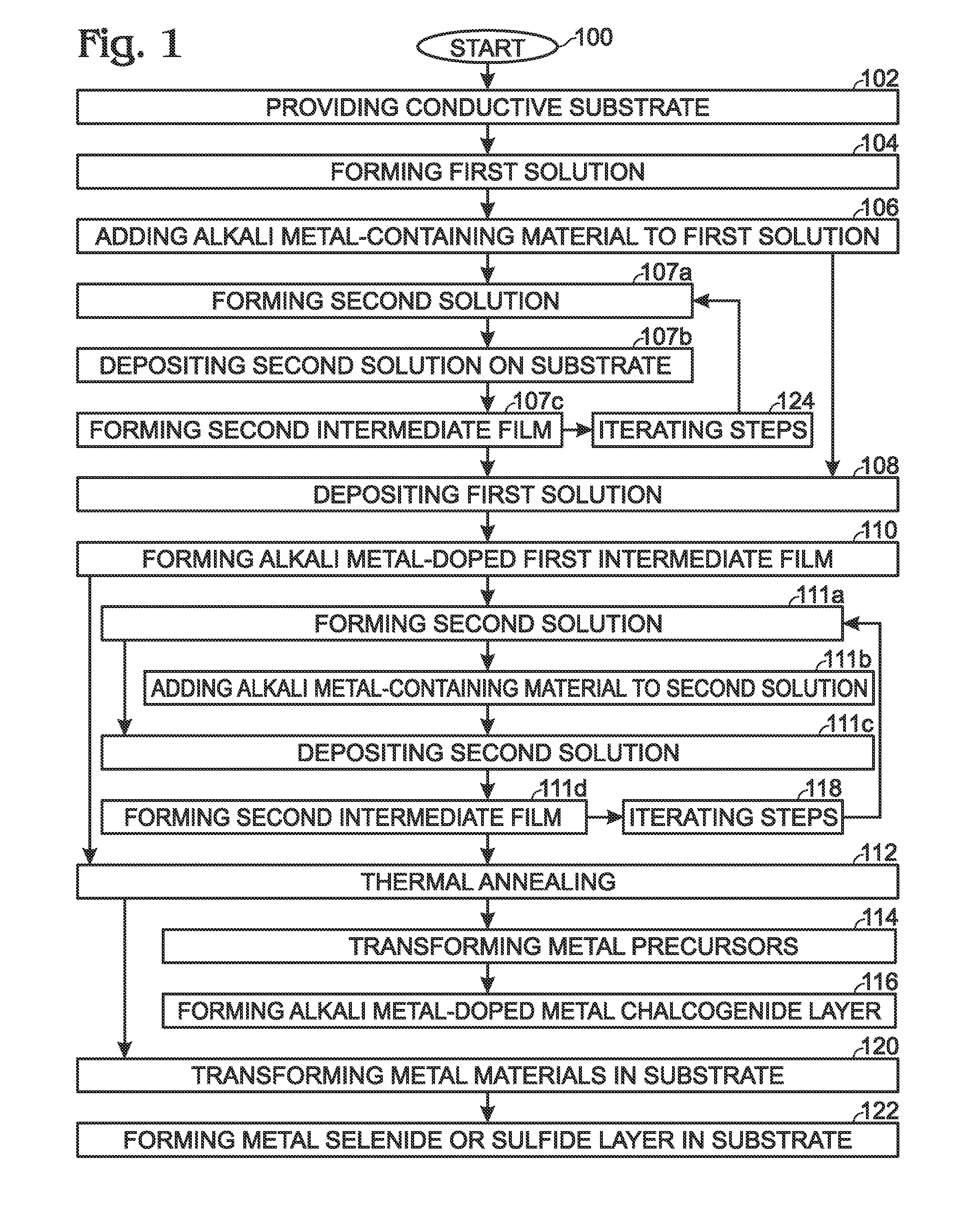

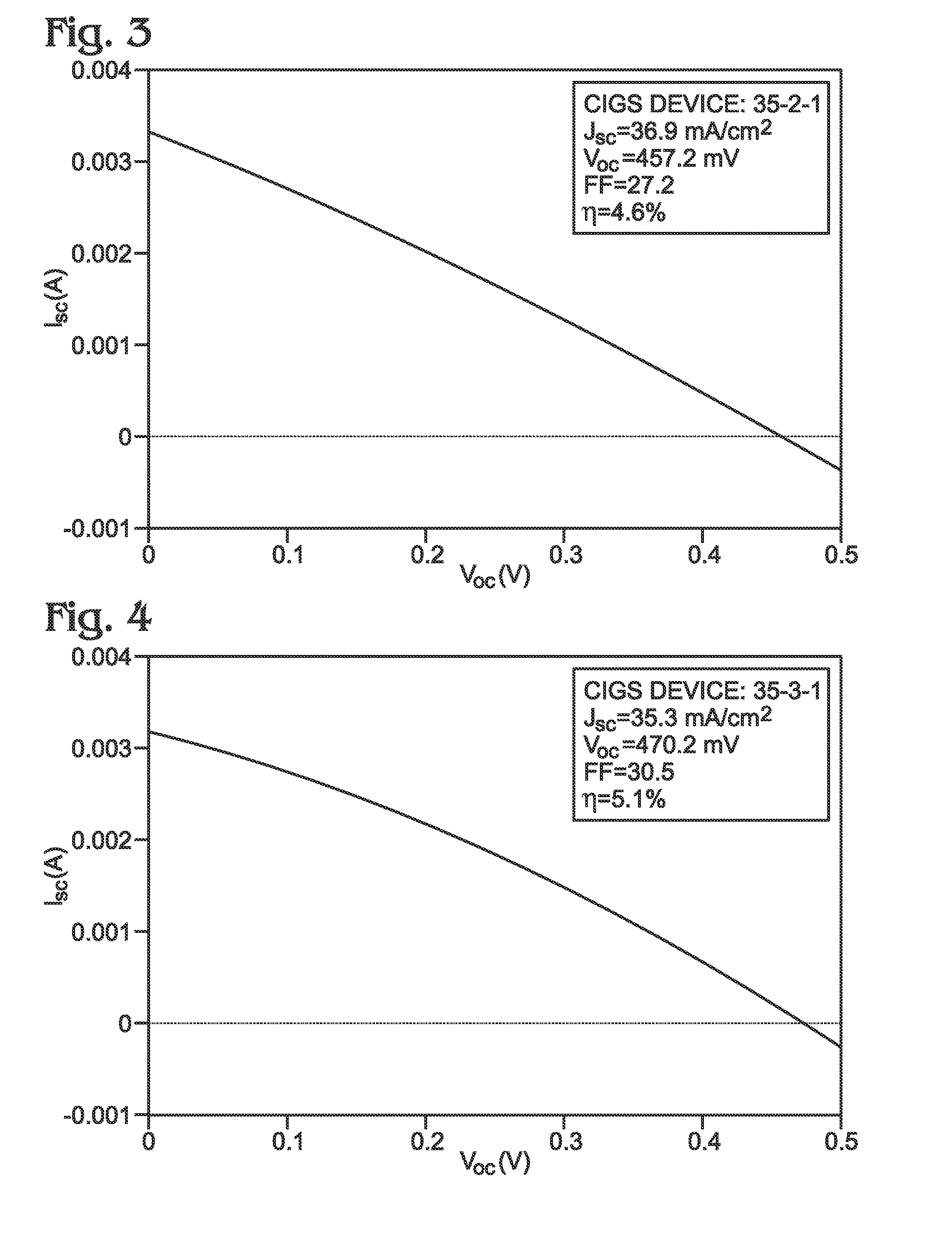

Alkali metal doping method for thin-film solar cell absorption layer

InactiveCN105742412AReduce compoundingIncrease profitFinal product manufacturePhotovoltaic energy generationMixed gasAbsorption layer

The invention provides an alkali metal doping method for a thin-film solar cell absorption layer. The doping method at least comprises the steps as follows: providing a to-be-treated thin-film solar cell absorption layer; preparing a solution containing alkali metal ions; depositing the solution containing the alkali metal ions on the surface of the absorption layer by a non-vacuum coating method and placing the absorption layer in a thermal treatment furnace; and introducing an inert gas or a mixed gas of hydrogen selenide and the inert gas into the thermal treatment furnace, heating the thermal treatment furnace to a set temperature and diffusing the alkali metal ions into the absorption layer. According to the alkali metal doping method provided by the invention, atoms generated on the surface of the absorption layer can be evacuated; Cd atoms in a buffer layer CdS are promoted to diffuse to the surface of the absorption layer to form a shallow-buried PN junction; recombination of current carriers on an interface layer of the absorption layer / buffer layer is reduced; the open-circuit voltage is improved; and the cell conversion efficiency is improved. The preparation method provided by the invention is simple and controllable, does not need expensive vacuum coating equipment and is good in compatibility with a conventional technology; and the alkali metal material is high in utilization rate and low in cost.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

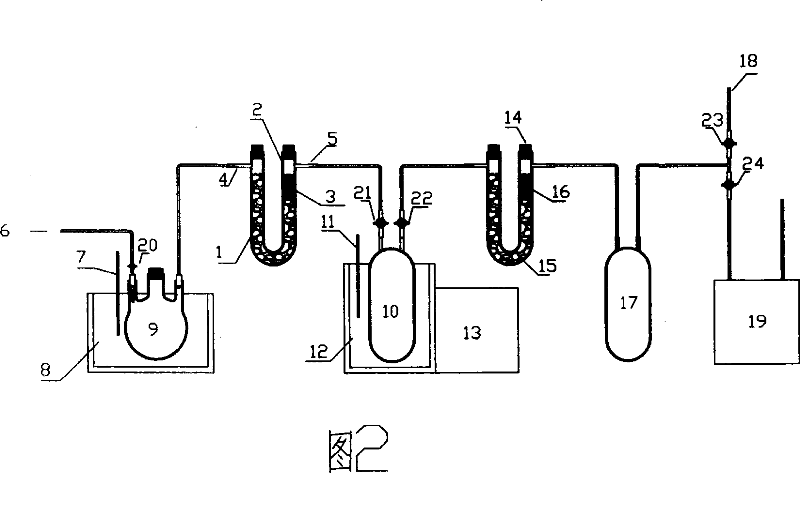

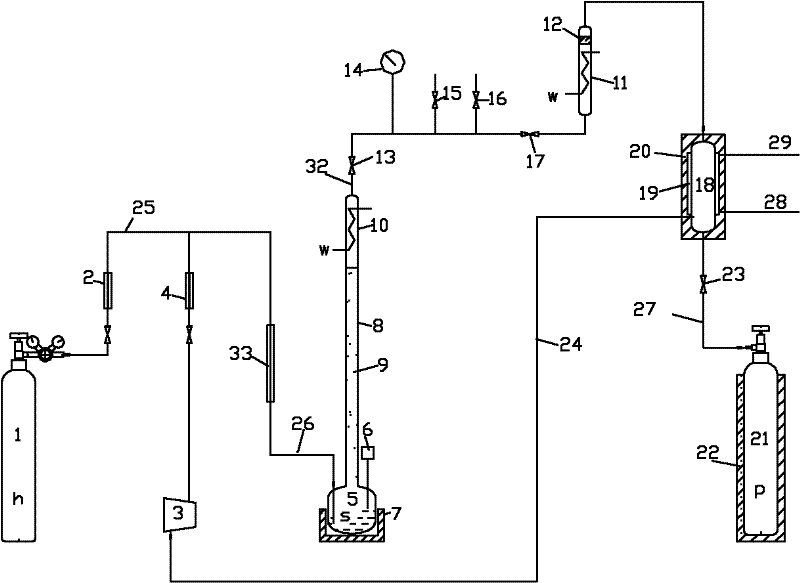

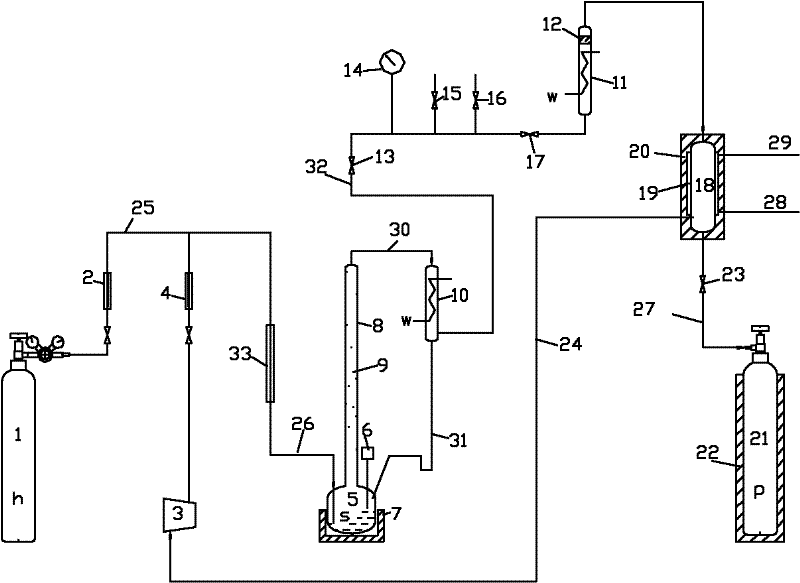

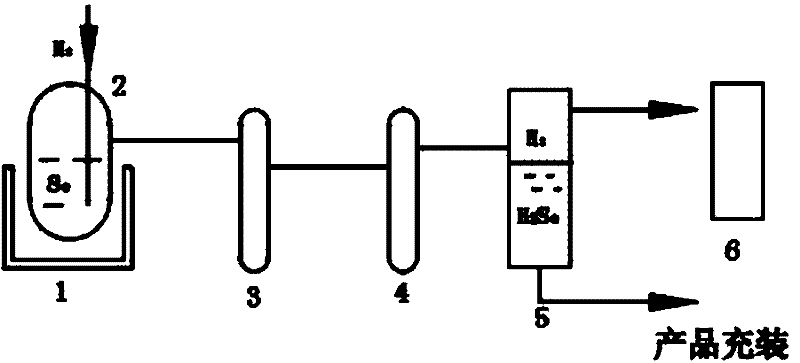

Hydrogen selenide preparation device and method

InactiveCN102674268ALarge surface areaIncrease the chance of meeting and respondingBinary selenium/tellurium compoundsHydrogenStream flow

Disclosed are a hydrogen selenide preparation device and a method. According to the method, the hydrogen selenide is directly synthesized by hydrogen and selenium(Se), a hydrogen inlet pipeline (26) is fed into a selenium liquefaction and vaporization device (5), a primary synthetic reaction between the hydrogen and the selenium is started, synthesized an H2Se / Se / H2 mixing gas-liquid stream is fed into a filling tower-type synthesis reactor (8) and subjected to a continuous synthetic reaction, the Se in a selenium condensation separator (10) is condensed into liquid, then is separated and flows back to the synthesis reactor or the selenium liquefaction and vaporization device for continuing reacting, an H2Se / H2 mixing gas stream flows into a hydrogen selenide condensation separator (18), non-condensable gas hydrogen in the hydrogen selenide condensation separator is separated and conveyed back to the hydrogen inlet pipeline (26), the non-condensable gas hydrogen and the hydrogen are combined for supplying hydrogen, and finally, the H2Se is condensed and collected in the hydrogen selenide condensation separator.

Owner:DALIAN LIFANG CHEM TECH

Method for preparing photocatalytic material from heavy metal ions in biological adsorption solution

ActiveCN104084221ARealize the effect of "three birds with one stone"Increase added valuePhysical/chemical process catalystsWater/sewage treatment by irradiationIndustrial waste waterSodium selenide

The invention provides a method for preparing a photocatalytic material from heavy metal ions in a biological adsorption solution. Based on a biological adsorption technology, the heavy metal ions in industrial wastewater are adsorbed and enriched onto biomass powder particles, then the biomass powder loaded with the heavy metal ions is subjected to a contact reaction with reagents (sodium sulfide, sodium hydrosulfide, thiourea, hydrogen sulphide or sodium selenide, sodium hydrogen selenide, selenourea, hydrogen selenide and the like ) which can provide an S<2-> or Se<2-> source, so that the heavy metal ions adsorbed on the biomass powder particles are in-situ converted into corresponding metal sulfides (selenides). The method realizes a new way of high-valued utilization of various industrial wastewater containing low-concentration valuable metal ions, reaches purposes of economically and efficiently removing the low-concentration metal ions in the industrial wastewater in virtue of biological adsorption, has the highlight advantages of being fast to adsorb, low in cost, short in powder making flow, large in yield, and easy to scale.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for chiral CdSe quantum dot

InactiveCN108251116AEasy to identifyEasy to separateNanoopticsLuminescent compositionsPenicillamineCysteine thiolate

The invention discloses a preparation method for a chiral CdSe quantum dot. The preparation method comprises the following steps: (1) preparing a sodium hydrogen selenide aqueous solution, and carrying out preservation at 4 DEG C or below; (2) dissolving cadmium chloride and a ligand in water, adjusting a pH value of an obtained mixture to 7 to 12 so as to obtain a precursor solution, and subjecting the precursor solution to stirring in an ice bath under the protection of inert gas, wherein the ligand is a combination of two or more selected from the group consisting of penicillamine, cysteine, N-acetyl-cysteine, glutathione or N-isobutyryl-cysteine; and (3) injecting the sodium hydrogen selenide aqueous solution prepared in the step (1) into the precursor solution obtained in the step (2), carrying out heating to 70 to 220 DEG C for 10 to 120 min, and carrying out cooling to a room temperature so as to obtain a chiral CdSe quantum dot solution. The quantum dot provided by the invention can be extensively applied to the fields of enantiomer recognition and separation, nanometer equipment, chiral sensors, asymmetric catalysis, etc.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

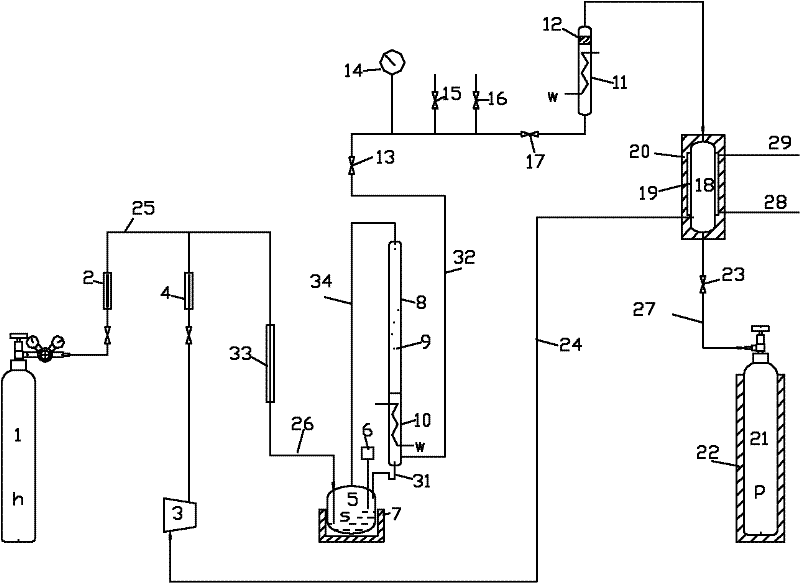

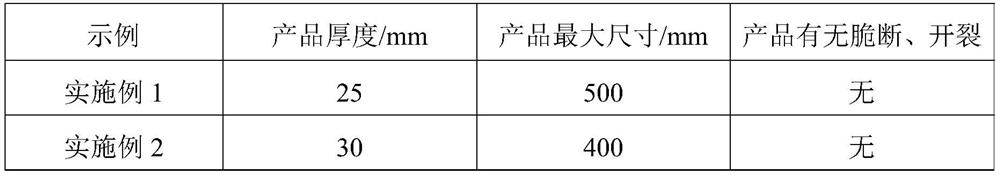

Growth method of zinc selenide

ActiveCN112095150AGood optical performanceSolve the size problemPolycrystalline material growthSingle crystal growth detailsZinc selenideChemical vapor deposition

The invention provides a growth method of zinc selenide, which comprises the following steps: a. Putting zinc into a crucible in a chemical vapor deposition furnace, replacing air in the deposition furnace with argon, and vacuumizing until the vacuum degree is 3000Pa-10000Pa; b, heating a deposition chamber in the chemical vapor deposition furnace to a deposition temperature of 700 DEG C to 800 DEG C, and heating the crucible to an evaporation temperature of 650 DEG C to 700 DEG C; c, respectively introducing gas into the crucible and the deposition chamber to carry out a vapor deposition reaction of zinc selenide, introducing argon into the crucible, and introducing argon and hydrogen selenide into the deposition chamber to make the deposition rate of zinc selenide be 50-150 [mu]m / h; andd, after the reaction is finished, maintaining the same pressure and gas flow as those in the deposition process, continuously heating the deposition chamber to 50 DEG C to 170 DEG C, keeping the temperature constant for the first time, cooling to 500 DEG C to 650 DEG C, keeping the temperature constant again, and cooling the reaction product to room temperature to obtain the zinc selenide product. The growth method of zinc selenide provided by the invention can be used for producing the polycrystalline zinc selenide material with large size, thickened size and high optical performance.

Owner:安徽中飞科技有限公司

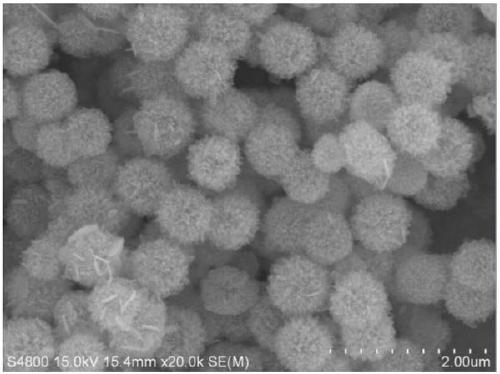

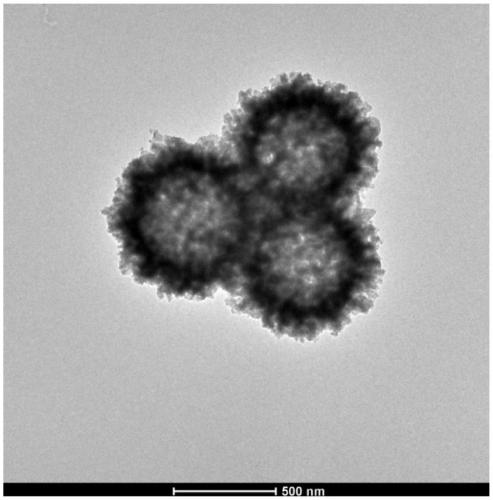

Sea urchin shaped hollow structure nickel, copper and selenium ternary nanometer catalytic material and preparation method and application thereof

ActiveCN109621988AGood catalytic hydrogenation performancePhysical/chemical process catalystsOrganic compound preparationNitrostyrolP-Nitroaniline

The invention provides a sea urchin shaped hollow structure nickel, copper and selenium ternary nanometer catalytic material and a preparation method and application thereof. Copper nitrate trihydrateand nickel nitrate hexahydrate are dissolved into a mixing solvent of ethylene glycol and water, urea and polyvinylpyrrolidone are added, a hydrothermal reaction is performed, and the hollow sea urchin shaped precursor structure is formed; the precursor is dispersed into deionized water, a sodium hydrogen selenide solution is added into the precursor dispersing solution drowse, the precursor is adopted as a template, the hydrothermal reaction is performed, and the sea urchin shaped hollow structure nickel, copper and selenium ternary nanometer catalytic material is obtained. Compared with theprior art, the sea urchin shaped hollow structure nickel, copper and selenium ternary nanometer catalytic material is successfully prepared for the first time through the method which is mild in reaction condition and simple and easy to popularize, the prepared sea urchin shaped hollow structure nickel, copper and selenium ternary nanometer catalytic material can catalyze a hydrogenation reactionof p-nitrophenol, p-nitro-styrene and paranitroaniline, and the material has the good catalytic hydrogenation performance.

Owner:ANHUI NORMAL UNIV

A kind of preparation method of hydrogen selenide

ActiveCN102267690AReduce solubilityAvoid the risk of freezingBinary selenium/tellurium compoundsSolubilityLiquid product

The invention discloses a preparation method of a hydrogen selenide. Selenium and hydrogen are used as reaction raw materials, a hydrogen selenide product is directly produced in a liquid product discharging mode, other impurities are basically not introduced in the reaction process, the reaction product is subjected to gas-liquid separation, the solubility of the hydrogen in low-temperature hydrogen selenide liquid is low, and a hydrogen selenide product with purity of not less than 99.99 percent can be directly produced. In addition, because the liquid product is directly discharged, the re-crystallization process can be cancelled, the temperature of refrigerant only needs to reach 40 DEG C below zero to 60 DEG C below zero, and energy consumption is reduced. Because the condensation temperature is higher than the freezing point (66 DEG C below zero) of the hydrogen selenide, frozen blockage risk of a pipeline product is avoided.

Owner:中昊光明化工研究设计院有限公司

Preparation method of hydrogen selenide

ActiveCN101811676AMild operating conditionsSynthesis process controlBinary selenium/tellurium compoundsZinc selenideReaction temperature

The invention discloses a preparation method of hydrogen selenide, which is synthesized by reacting zinc selenide and acid at the reaction temperature of 50-200DEG C and the mol ratio of the zinc selenide to the acid being 10:(1-0.1):1. The equipment has simple operation; the method for synthesizing the hydrogen selenide by reacting the zinc selenide and the acid has mild operation condition, well controls the synthesizing process as well as solves the problems that a method for synthesizing the hydrogen selenide by reacting the zinc selenide and water causes the pollution to the environment in the process of synthesizing aluminum selenide and in the process of using the aluminum selenide and extremely-high equipment investment is required by other methods.

Owner:中昊光明化工研究设计院有限公司

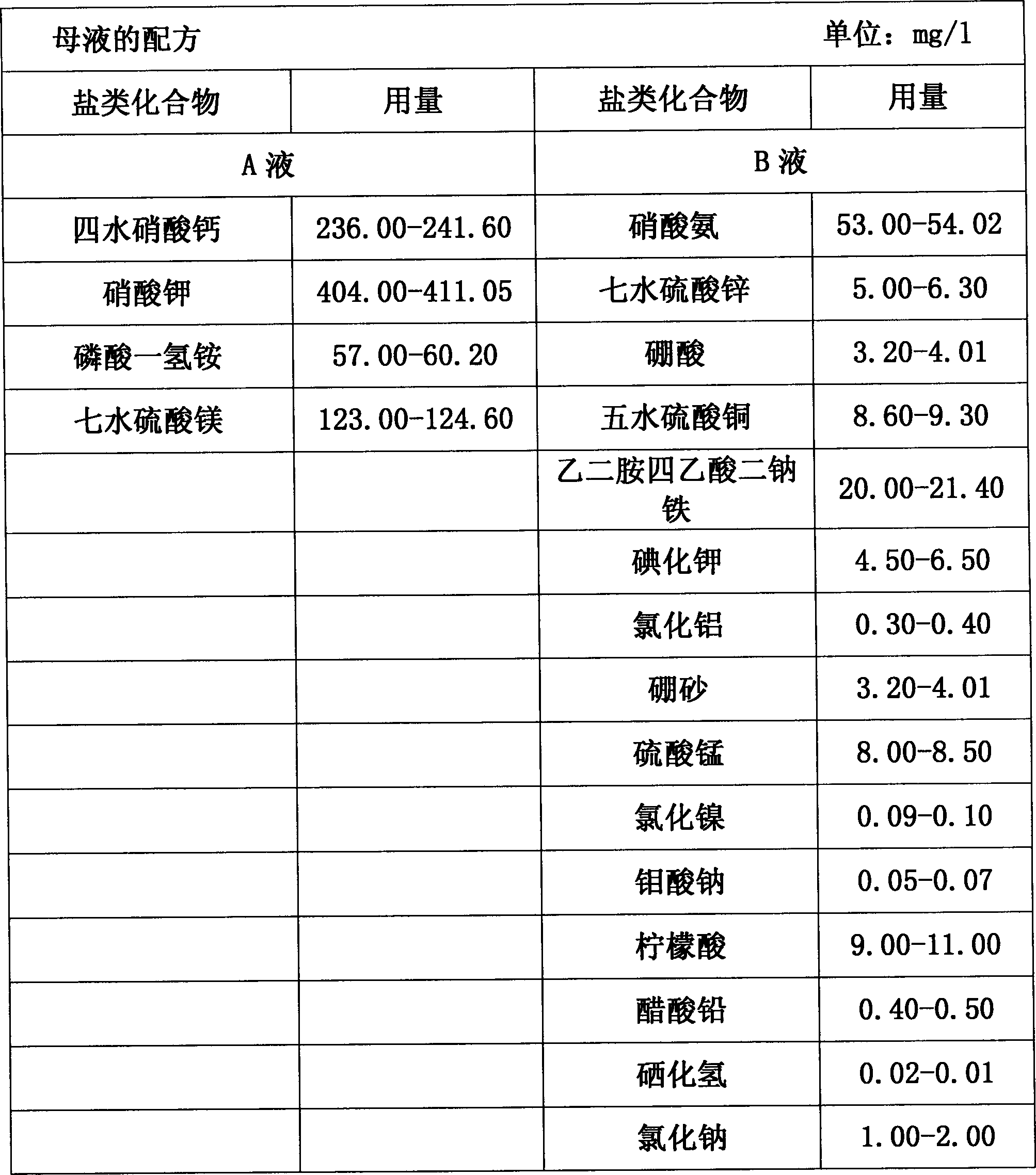

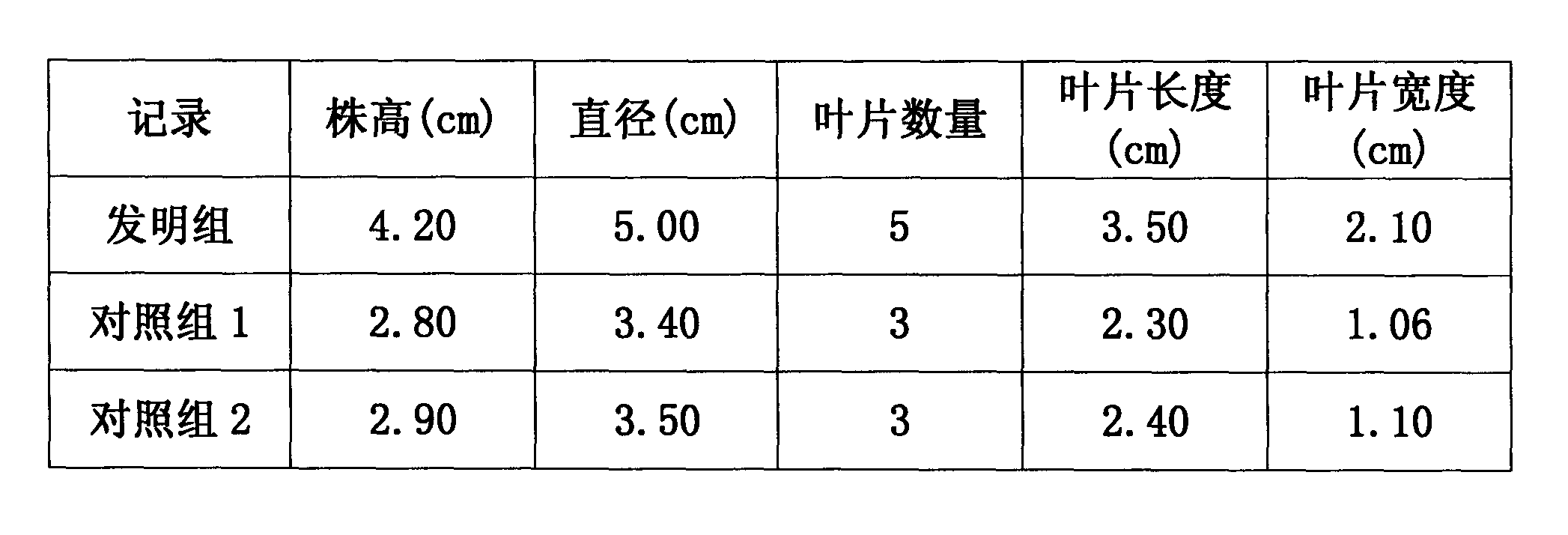

Capsella bursa-pastoris water culture nutrient solution

InactiveCN103288510AShorten the growth cyclePromote growthFertilizer mixturesPotassium iodineCopper sulfate pentahydrate

The invention relates to a capsella bursa-pastoris water culture nutrient solution. The capsella bursa-pastoris water culture nutrient solution comprises major elements, trace elements and water which are required for growth of capsella bursa-pastoris, can be used for replacing soil to provide water, fertilizer, air, heat and other growth factors for the capsella bursa-pastoris, and can meet the conditions required for water culture growth of the capsella bursa-pastoris. The capsella bursa-pastoris water culture nutrient solution is divided into a solution A and a solution B, wherein the solution A comprises the following main components: calcium nitrate tetrahydrate, potassium nitrate, ammonium hydrogen phosphate and magnesium sulfate heptahydrate; and the solution B comprises the following main components: ammonium nitrate, zinc sulfate heptahydrate, boric acid, copper sulfate pentahydrate, ethylenediaminetetraacetic acid disodium ferric salt, potassium iodide, aluminum chloride, borax, manganese sulfate, nickel chloride, sodium molybdate, citric acid, lead acetate, hydrogen selenide and sodium chloride. The capsella bursa-pastoris water culture nutrient solution has the advantages of complete nutritional components, simple preparation, high practicality and certain popularization and application values.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Preparation method of Ag-Mn doped ZnSe and ZnS core-shell structure quantum dot

InactiveCN108048093ALow priceLow costNanoopticsEnergy efficient lightingMANGANESE ACETATEReaction rate

The invention discloses a preparation method of an Ag-Mn doped ZnSe and ZnS core-shell structure quantum dot. The preparation method comprises the following steps of adopting a mixed solution of zincacetate and silver acetate as a core formation precursor, adding high-activity sodium hydrogen selenide at the temperature of 80-100 DEG C to obtain an Ag-doped ZnSe nanocrystal core; and then adopting a mixed solution of zinc acetate and manganese acetate as a shell layer precursor, adding sodium sulfide at the temperature of 80-100 DEG C to obtain an Mn-doped ZnS shell layer. According to the preparation method provided by the invention, by adopting the zinc acetate, the silver acetate and the manganese acetate, the cost is low, and the reaction rate is easily controlled; only by adding a very small amount of an alkaline solution, a pH value can be regulated into a strong alkaline range; the nanocrystal core and the shell layer are prepared by adopting a one-pot method respectively, so that the operation step is simplified, and the preparation method is liable to popularization and large-scale production; the core and the shell adopting a ZnSe / ZnS quantum dot are doped with Ag+ and Mn2+ respectively, and an Ag:ZnSe / Mn:ZnS quantum dot is prepared; a single fluorescence peak, different double fluorescence peak combination or three fluorescence peaks are provided, so that white fluorescence can be modulated; the structure has a white light emitting ability, and a fluorescence material is provided to the field of white light LED.

Owner:HUBEI UNIV

Synthesizing method of selenium-doped zirconium oxide catalyst

ActiveCN109317168ALower synthesis costLow in seleniumPhysical/chemical process catalystsWater contaminantsBeta-CaroteneSodium hydride

The invention discloses a synthesizing method of a selenium-doped zirconium oxide catalyst. The synthesizing method comprises the following steps of mixing zirconium dioxide, an ammonium fluoride additive and an ethanol solution of sodium hydrogen selenide according to a ratio of (30 to 70 mmol) to (0.05 to 0.15 mmol) to 10 mmol, stirring for 12 to 36h at the room temperature, filtering, and washing by water, so that the concentration of sodium hydrogen selenide in the ethanol solution of sodium hydrogen selenide is 0.2 mol / L. The selenium-doped zirconium oxide catalyst is used for catalyzingthe oxidizing and degrading of carotene, and has the advantages that the synthesizing cost is low, no metal is contained, the content of selenium is low, and the catalyzing effect is good; when the beta-carotene is catalyzed to degrade, the low-cost, safe and environment-friendly oxygen gas is used as an oxidant, so that the practicality is good.

Owner:YANGZHOU UNIV

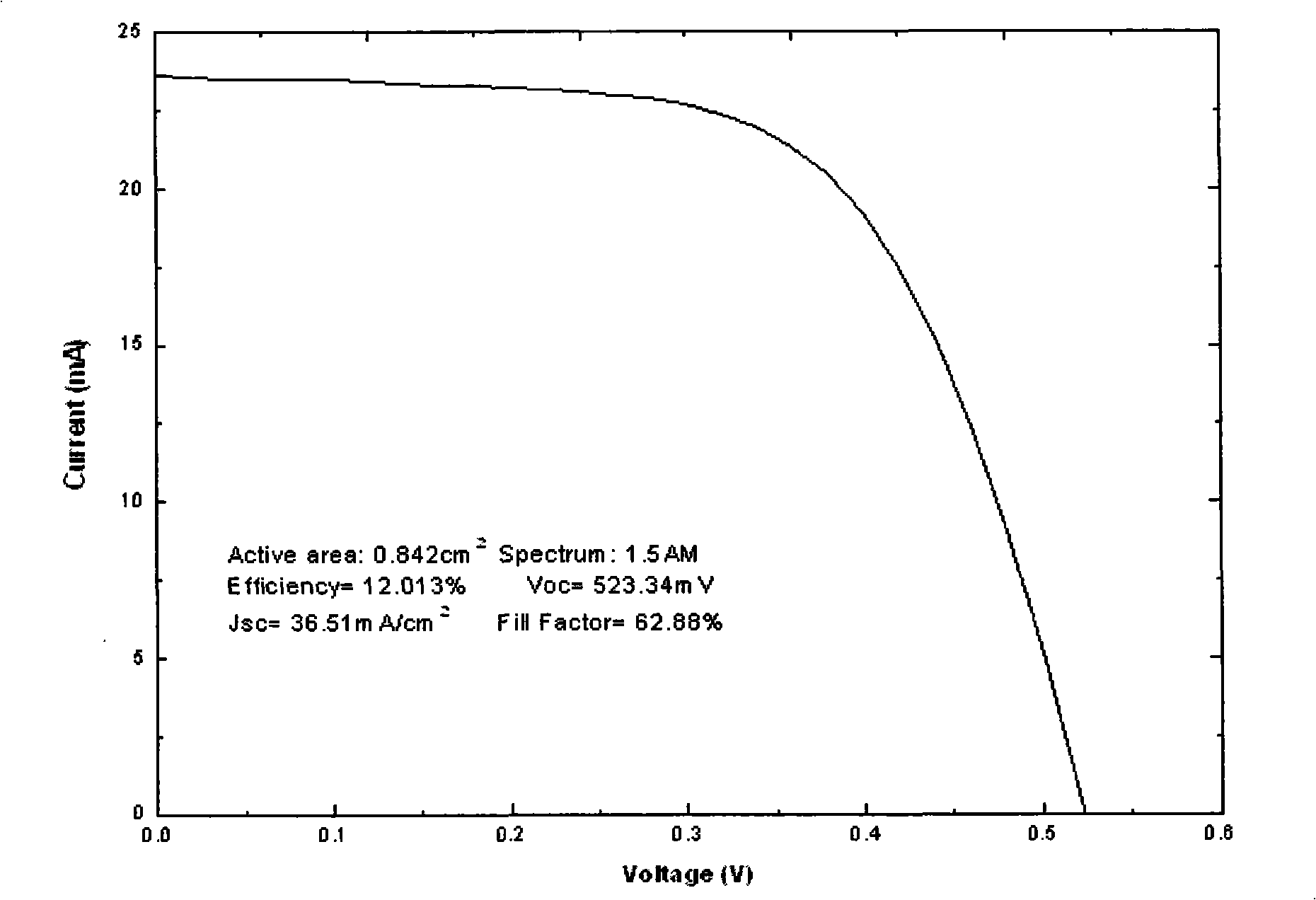

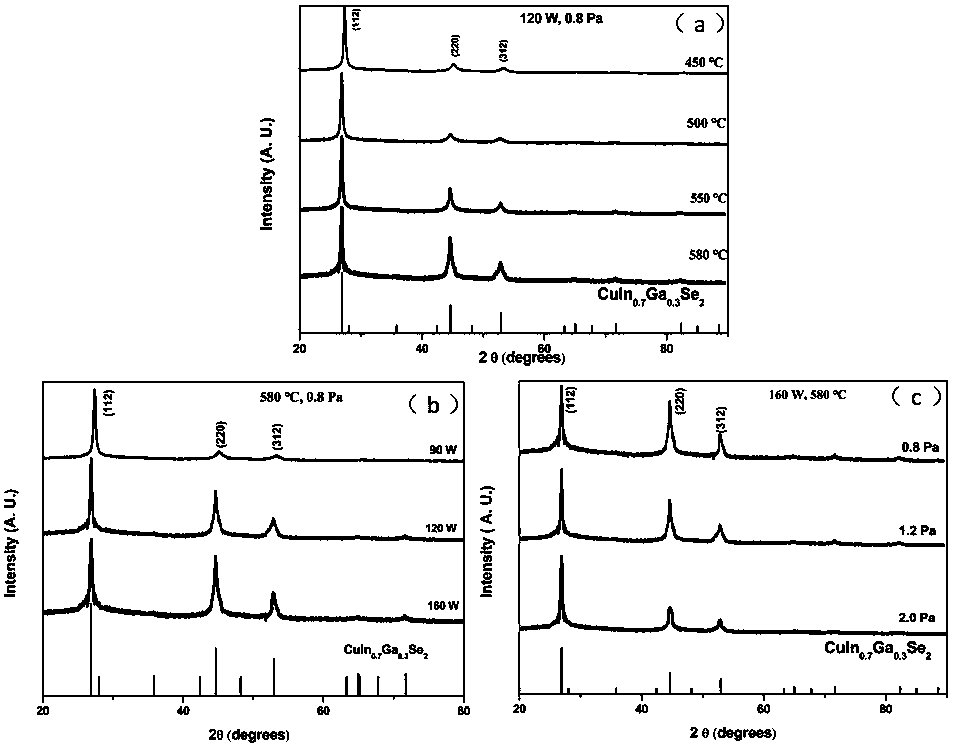

Method for preparing GIGS solar cell by applying one-step sputtering method

InactiveCN108389934AImprove conversion efficiencyImprove stabilityFinal product manufacturePhotovoltaic energy generationHydrogenEvaporation

The invention provides a method for preparing a GIGS solar cell by applying a one-step magnetron sputtering method. According to the invention, soda-lime glass is taken as a substrate, Mo / CIGS / CdS / i-ZnO:Al / Ni:Al target materials are sequentially adopted, and a CIGS solar cell with the film thickness being about 1-2 microns through using direct current sputtering and radio frequency sputtering, wherein the Mo target adopts direct current sputtering, the CIGS / CdS / i-ZnO / ZnO:Al sequentially adopt radio frequency sputtering, and the Ni:Al adopts direct current sputtering. Content control for each element is realized through adjusting various parameters in the sputtering process, and a CIGS solar cell with the conversion efficiency reaching 5.77% at most can be obtained. The magnetron sputteringmethod provided by the invention is different from the traditional quaternary co-evaporation, sputtering and post-selenization method, so that there is no need of using a toxic hydrogen selenide gasto prepare a CIGS absorption layer by applying the post-selenization method, but the absorption layer is directly prepared by adopting the selenium-rich CIGS target material, thereby enabling the production process to be simpler to operate, green, environment-friendly and easy to control. In addition, the commercial production can be enabled to be equivalent to laboratory production in productionefficiency, and the method has wide commercial application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

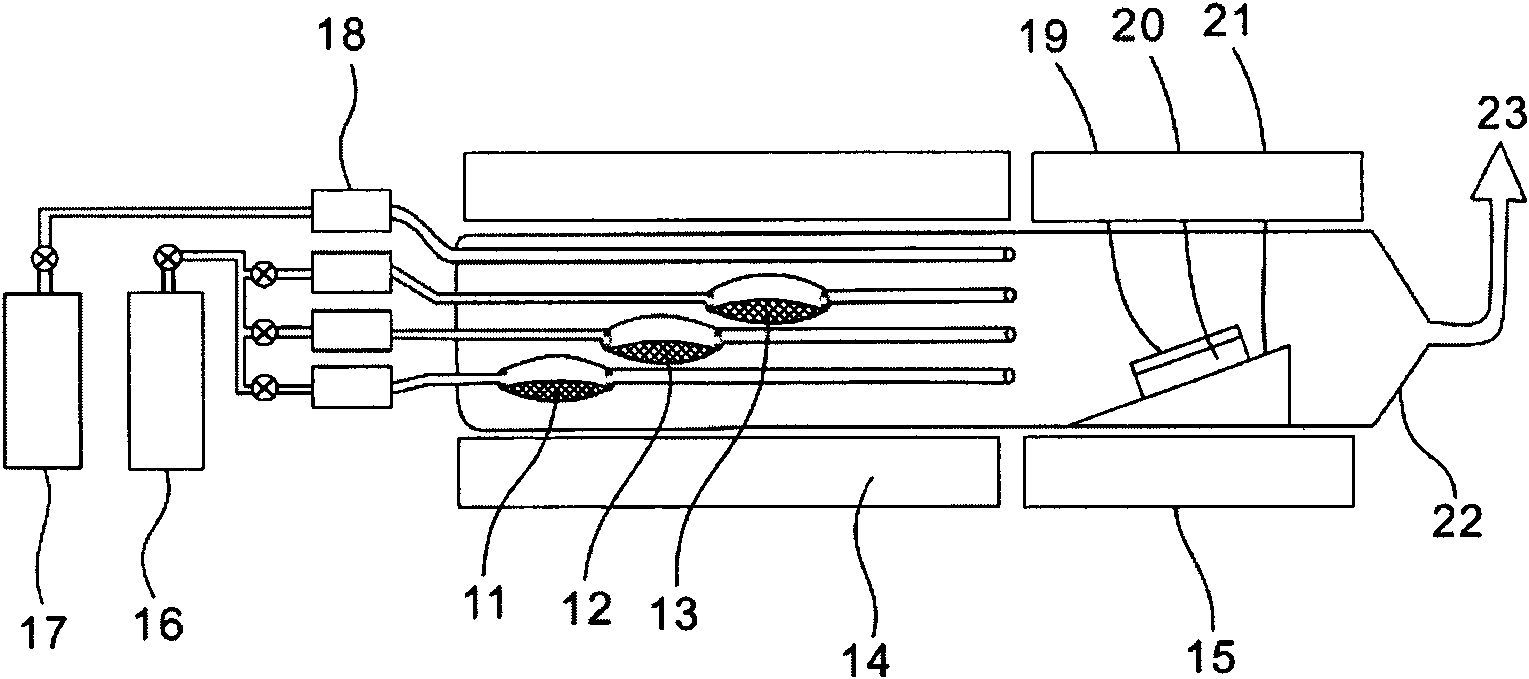

System for enhancing selenium reaction activity by hydrogenating selenium source of flexible CIGS solar cell

ActiveCN110739370AReduce clustersHigh reactivityFinal product manufactureVacuum evaporation coatingProcess engineeringSolar battery

The invention discloses a system for enhancing selenium reaction activity by hydrogenating a selenium source of a flexible CIGS solar cell. The system comprises a selenium source, a hydrogen storage tank, an automatic gas mixing device and a mixed gas output pipeline, wherein the automatic gas mixing device comprises a selenium steam control valve, a hydrogen control valve and a gas conveying pipeline, a selenium steam outlet of the selenium source is connected with an inlet of the selenium steam control valve, a hydrogen outlet of the hydrogen storage tank is connected with an inlet of the hydrogen control valve, an outlet of the selenium steam control valve is connected with a selenium steam inlet of the gas conveying pipeline, an outlet of the hydrogen control valve is connected with ahydrogen inlet of the gas conveying pipeline, an outlet of the gas conveying pipeline is connected with an inlet of the mixed gas output pipeline, and the selenium steam control valve is linked with the hydrogen control valve. The system is advantaged in that automatic and uniform mixing of a selenium steam and hydrogen can be realized, the cluster Se can be effectively opened, a small amount of hydrogen selenide is generated, the reaction activity is increased, and defects of the film are reduced.

Owner:ZHEJIANG SHANGYUE OPTOELECTRONICS TECH +1

Non-vacuum manufacturing method of CIGS and/or CIGSS (copper-indium-gallium-selenium and/or sulphur) solar cell

InactiveCN101820029AStir wellWidely used valueFinal product manufactureSemiconductor devicesIndiumSlurry

The invention relates to a manufacturing method of a CIGS and / or CIGSS (copper-indium-gallium-selenium and / or sulphur) solar cell, in particular to a non-vacuum manufacturing method of the CIGS and / or CIGSS solar cell. The method comprises the following steps of: (1) mixing two / three / four parts of powders containing IB, IIIA and VIA groups of elements according to the proportion of formula so as to form a raw mixed powder containing CIGS and / or CIGSS; (2) adding additive VIA group of element powder to the raw mixed powder and mixing to form the finally mixed powder; (3) adding a solvent to the finally mixed powder and stirring to form slurry; (4) coating the slurry on a molybdenum metal layer under a non-vacuum condition and softly baking to form a prefabricating layer; (5) rapidly heating, annealing and crystallizing to form a light absorbing layer; (6) depositing cadmium sulfide or zinc sulfide on the light absorbing layer; and (7) finally depositing ZnO and AZO again to obtain the CIGS and / or CIGSS solar cell. The invention avoids using dangerous hydrogen selenide and has low cost.

Owner:昆山正富机械工业有限公司

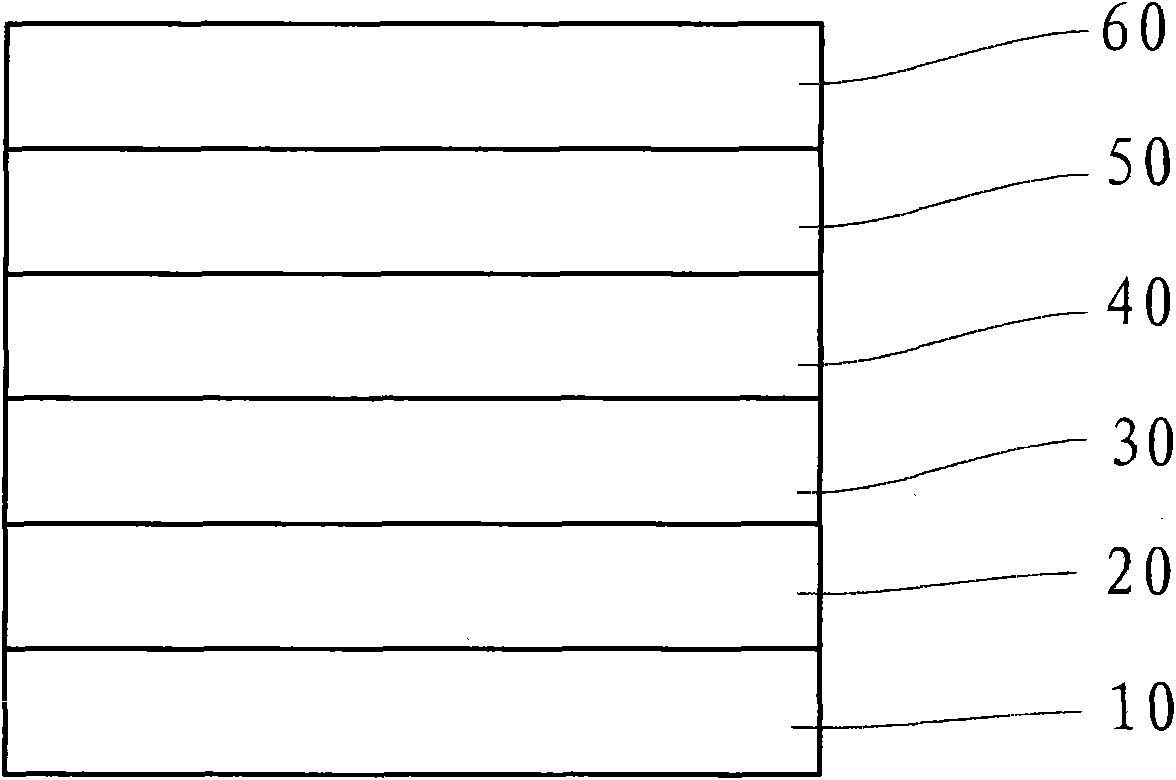

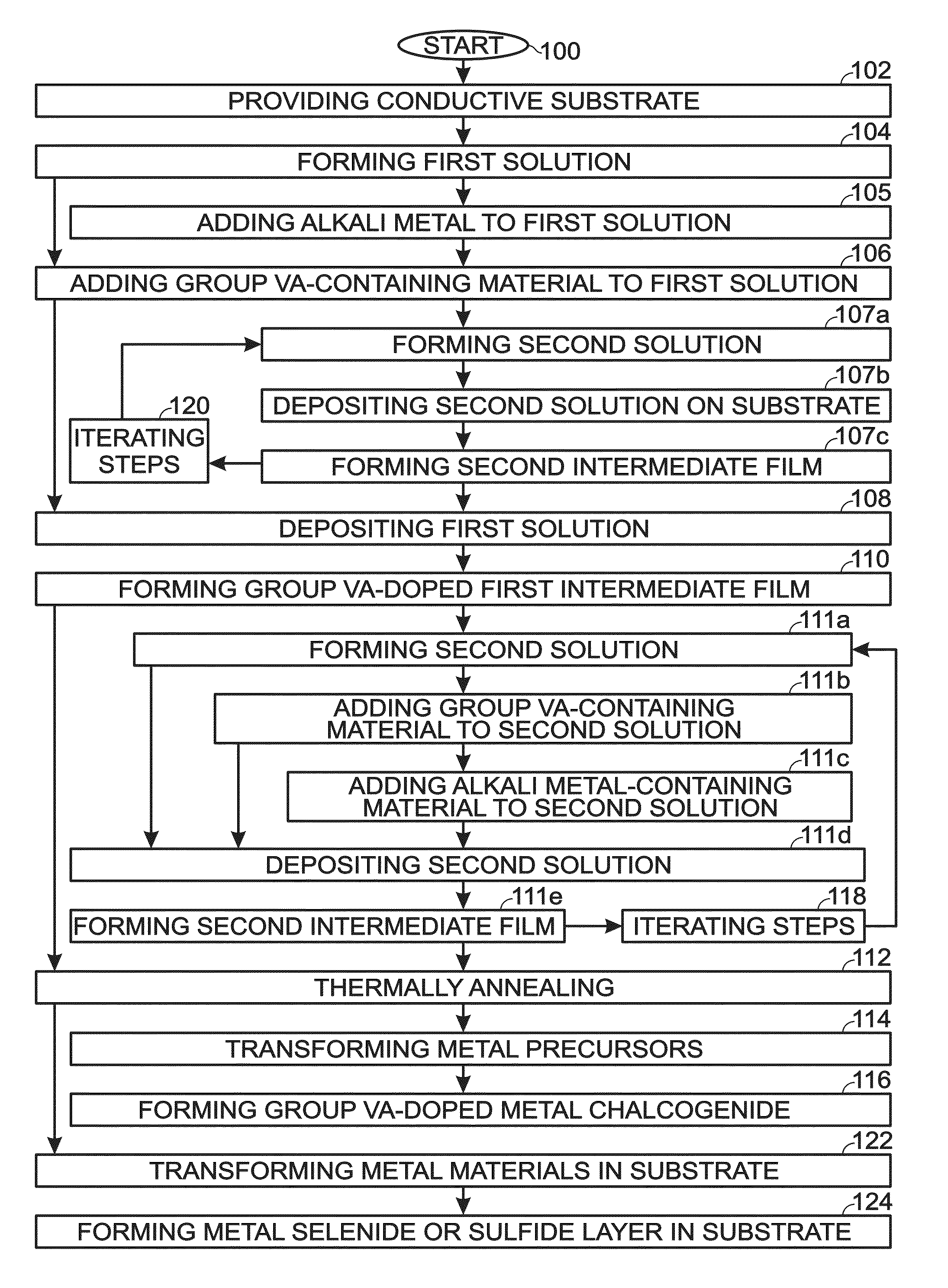

Group VA-doped solution-processed metal chalcogenides

InactiveUS8685779B1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationHydrogenMetal chalcogenides

A method is provided for forming a Group VA-doped solution-processed metal chalcogenide. The method forms a first solution including a first material group, dissolved in solvent. A Group VA-containing material is added to the first solution. The Group VA-containing material may include arsenic (As), antimony (Sb), bismuth (Bi), or combinations thereof. The first solution is deposited on a conductive substrate, and a Group VA-doped first intermediate film is formed comprising metal precursors from corresponding members of the first material group. Thermal annealing is performed in an environment of selenium (Se), Se and hydrogen (H2), hydrogen selenide (H2Se), sulfur (S), S and H2, hydrogen sulfide (H2S), or combinations thereof. As a result, the metal precursors in the Group VA-doped first intermediate film are transformed, forming a Group VA-doped metal chalcogenide layer. In one aspect, an antimony-doped Cu—In—Ga—Se chalcogenide (CIGS) is formed.

Owner:SHARP KK

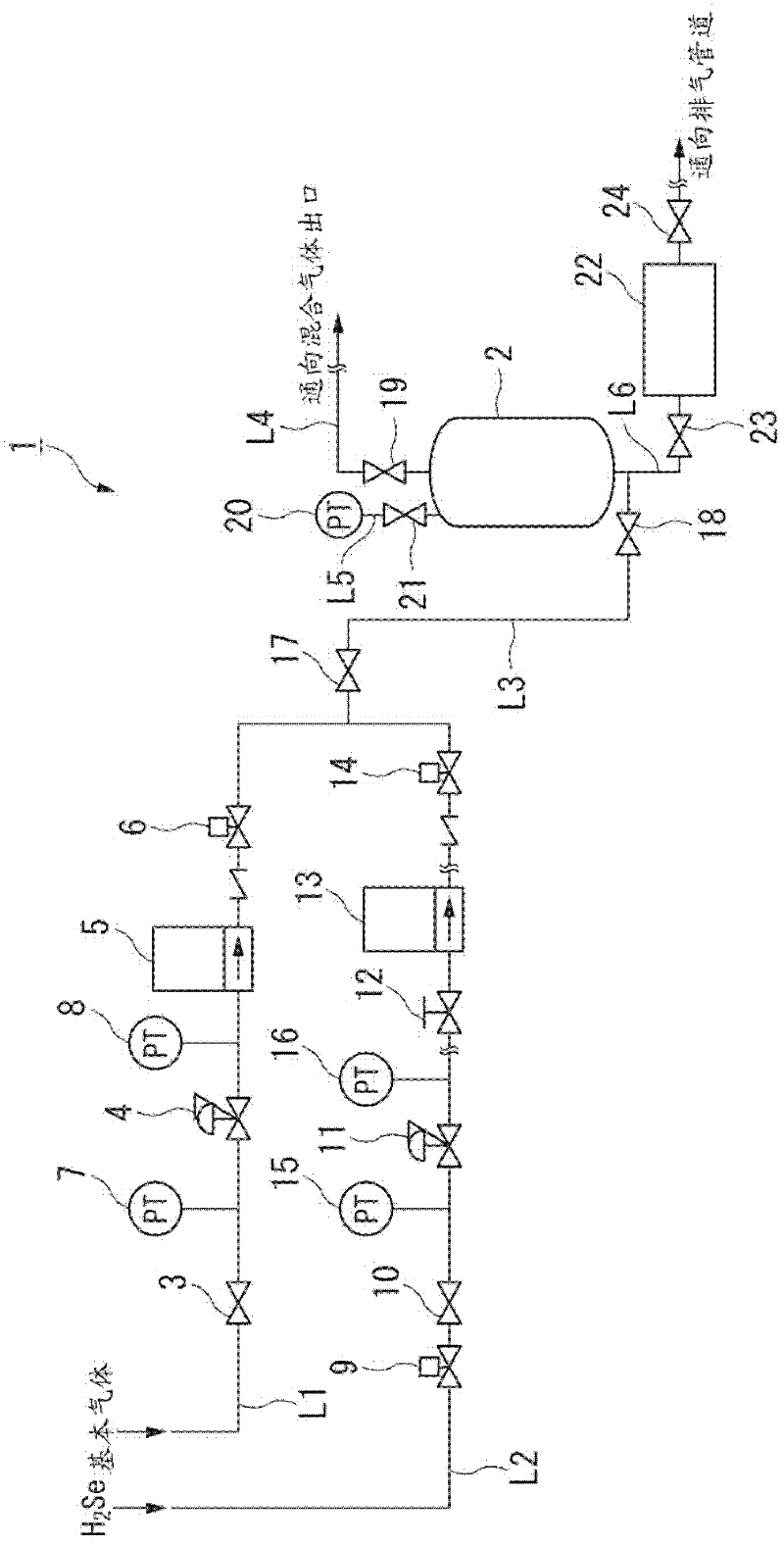

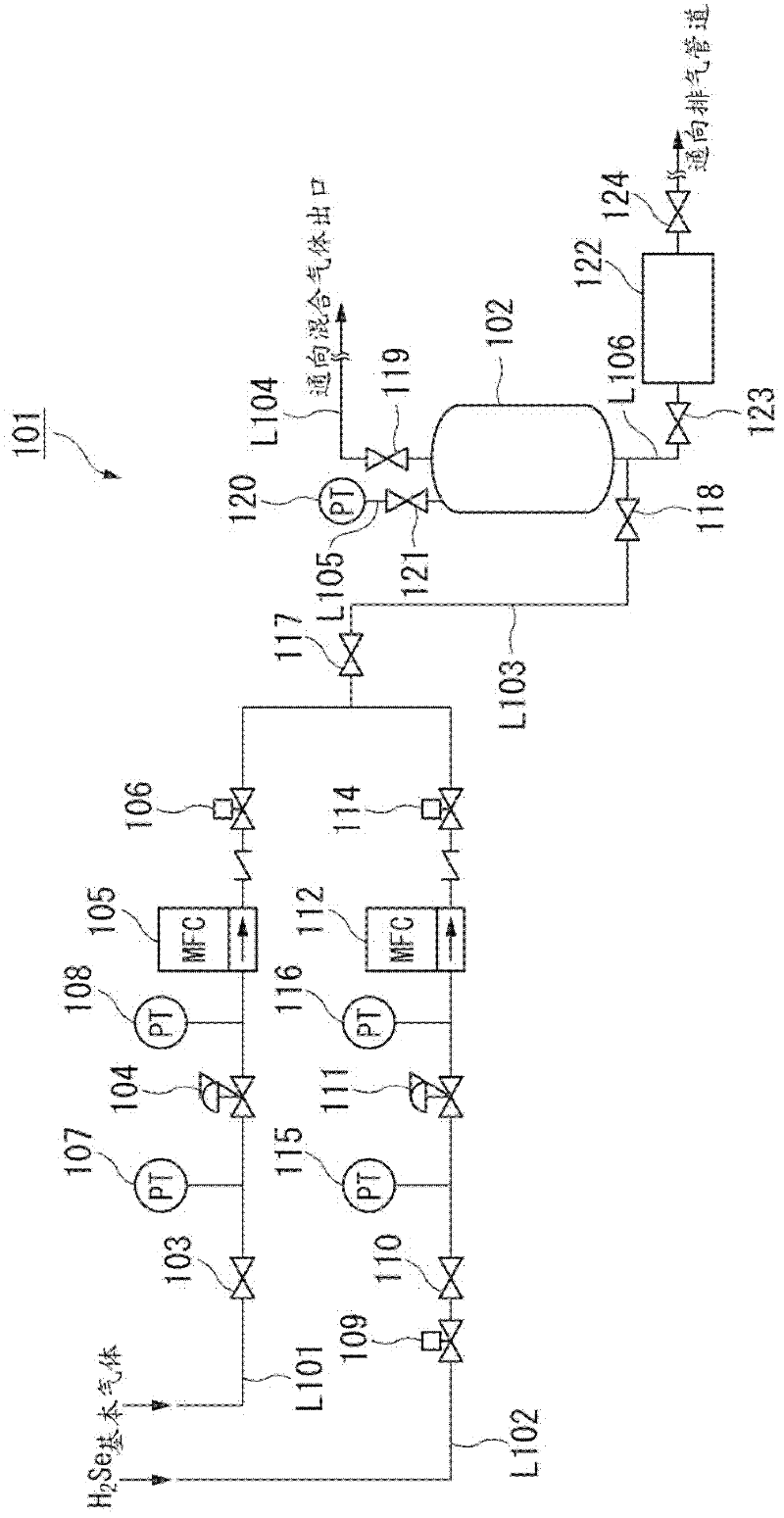

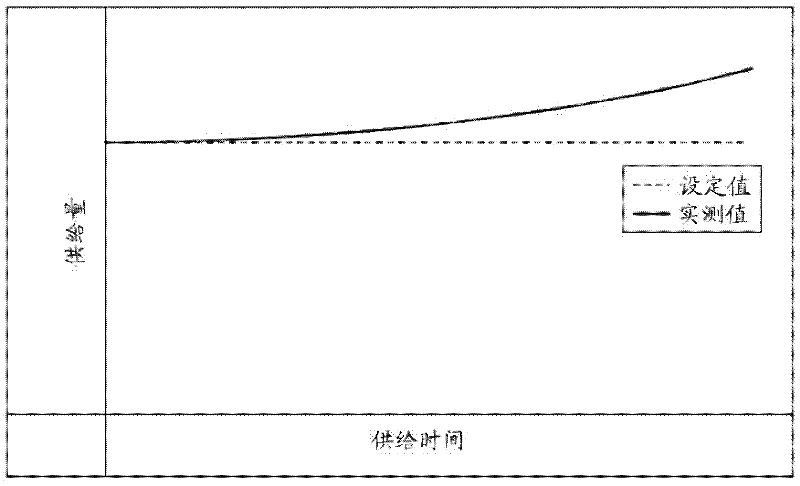

Method and apparatus for supplying hydrogen selenide mixed gas for solar cell

InactiveCN102471061AContinuous concentrationControl flowFinal product manufacturePhotovoltaic energy generationHydrogenSolar cell

Disclosed is a method for supplying a hydrogen selenide mixed gas for a solar cell, which comprises a step of supplying a hydrogen selenide mixed gas having a predetermined concentration, said hydrogen selenide mixed gas being prepared by mixing an inert gas that is supplied from a base gas supply channel (L1) and a 100% hydrogen selenide gas that is supplied from a raw material gas supply channel (L2). In the supplying step, the flow rate of the 100% hydrogen selenide gas is controlled to a predetermined flow rate by a flow rate control means (12) that is provided in the raw material gas supply channel (L2), and the pressure of the 100% hydrogen selenide gas between the flow rate control means (12) and a pressure control means (13), which is provided in the downstream of the flow rate control means (12), is controlled to a predetermined pressure by the pressure control means (13).

Owner:NIPPON SANSO CORP

Synthesis method of selenium-containing copolymer catalyst for catalyzing oxidative chemical degradation of olefin

ActiveCN110102345ASimple processHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsSynthesis methodsRoom temperature

The invention discloses a synthesis method of a selenium-containing copolymer catalyst for catalyzing oxidative chemical degradation of olefin. The method comprises the following steps that benzylidene chloride and sodium hydrogen selenide are mixed uniformly in a molar ratio of (1.2-1.4):1, stirring is performed at the room temperature for 2 hours, then perfluoroethylene glycol with 0.1-0.2 timeof the molar weight of the sodium hydrogen selenide and ethylene glycol with 0.2-0.4 time of the molar weight of the sodium hydrogen selenide are added, after heating and stirring are performed at 40DEG C for 2 hours, cooling is performed to the room temperature, standing is performed for 24 hours, a precipitate is obtained, filtered and dried, and the selenium-containing copolymer catalyst material is obtained. The material has strong catalytic activity and can catalyze the oxidative chemical degradation reaction of the olefin.

Owner:YANGZHOU UNIV

Method for separating and recovering valuable metal from material containing copper, indium, gallium and selenium

InactiveCN112375909ACraft briefHigh recovery rateProcess efficiency improvementElemental selenium/telluriumIndiumElectrolysis

The invention relates to a method for separating and recovering valuable metal from a material containing copper, indium, gallium and selenium. The method mainly comprises the steps that hydrochloricacid and sodium chlorate are adopted for controlling potential leaching to obtain crude selenium, zinc powder is added into leachate for replacement to obtain spongy copper, zinc powder continues to be added for replacement to obtain spongy indium, a solution obtained after replacement is neutralized, and then 4N gallium is obtained through liquid preparation electrolysis. The method for separating and recovering the valuable metal from the material containing copper, indium, gallium and selenium is easy to carry out, efficient, short in process, high in recovery rate, free of toxic hydrogen selenide gas and environmentally friendly.

Owner:FIRST RARE MATERIALS CO LTD

Manufacturing apparatus and method for large-scale production of thin-film solar cells

InactiveCN100530701CLow costFinal product manufactureSemiconductor/solid-state device manufacturingIndiumManufactured apparatus

A method of fabricating an improved thin film solar cell entirely by sputtering comprising a high efficiency back contact / reflective multilayer comprising at least one barrier layer composed of a transition metal nitride. Copper indium gallium diselenide (Cu(InxGa1-X)Se2) absorber layers (X ranging from 1 to about 0.1) were co-sputtered from specially prepared electrically conductive targets using the dual cylinder rotating magnetron technique. By varying the gallium content, the bandgap of the absorber layer can be graded. Alternating absorber layers were reactively sputtered from a metal alloy target in hydrogen selenide gas. RF sputtering was used to deposit the cadmium-free ZnS window layer. Reactive sputtering top transparent electrode ZnO doped aluminum. A dedicated modular vacuum-to-roll sputtering machine is described. The machine is adapted to be integrated with a double-cylindrical rotating magnetron in a single route to fabricate improved solar cell materials.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

Method for preparing chalcopyrite thin-film solar cells

InactiveCN102610689AHigh purityReduce manufacturing costFinal product manufactureSemiconductor devicesIndiumOxygen

The invention discloses a method for preparing chalcopyrite thin-film solar cells. The method comprises the following steps of: (a) by using a non-vacuum manufacture procedure, carrying out in-situ reaction on metals such as copper, indium, gallium and the like and hydrogen chloride or chlorine so as to form reaction precursors, and then reacting the reaction precursors with hydrogen selenide or hydrogen sulfide; (b) preparing light absorption layers of selenium / copper-indium-gallium sulfide and selenium / copper-zinc-tin sulfide thin-film solar cells in cooperation with a vapor-phase epitaxial growth technique; and (c) preparing buffer layers and transparent conductive layers of the thin-film solar cells in cooperation with oxygen. By using the method disclosed by the invention, high-purity chalcopyrite thin-film solar cells can be prepared, and the production cost is greatly saved.

Owner:黄崇哲

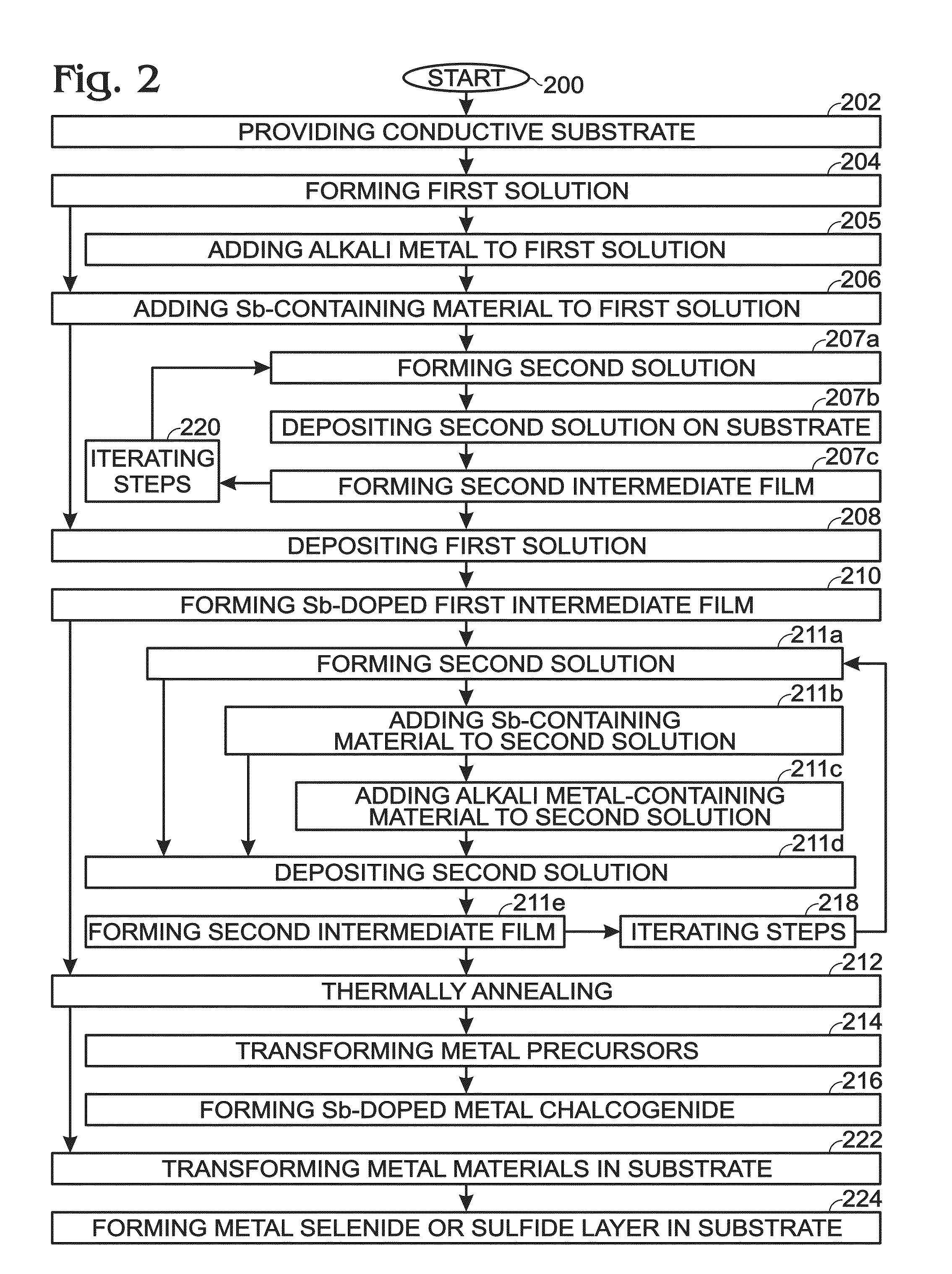

Alkali Metal-Doped Solution-Processed Metal Chalcogenides

InactiveUS20140162400A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationIndiumMetal chalcogenides

A method is provided for forming an alkali metal-doped solution-processed metal chalcogenide. A first solution is formed that includes a first material group of metal salts, metal complexes, or combinations thereof, dissolved in a solvent. The first material group may include one or more of the following elements: copper (Cu), indium (In), and gallium (Ga). An alkali metal-containing material is added to the first solution, and the first solution is deposited on a conductive substrate. The alkali metal-containing material may be sodium (Na). An alkali metal-doped first intermediate film results, comprising metal precursors from corresponding members of the first material group. Then, thermally annealing is performed in an environment of selenium (Se), Se and hydrogen (H2), hydrogen selenide (H2Se), sulfur (S), S and H2, hydrogen sulfide (H2S), or combinations thereof. The metal precursors in the alkali metal-doped first intermediate film are transformed, and an alkali metal-doped chalcogenide layer is formed.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com