Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Solve the size problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

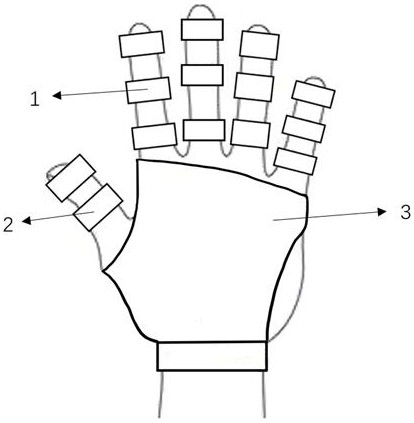

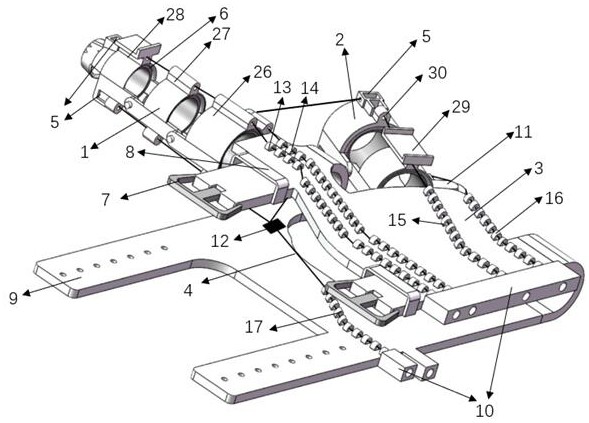

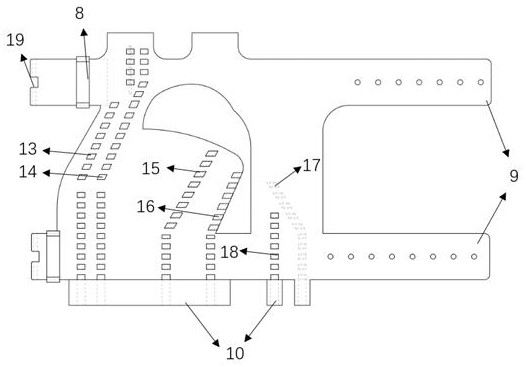

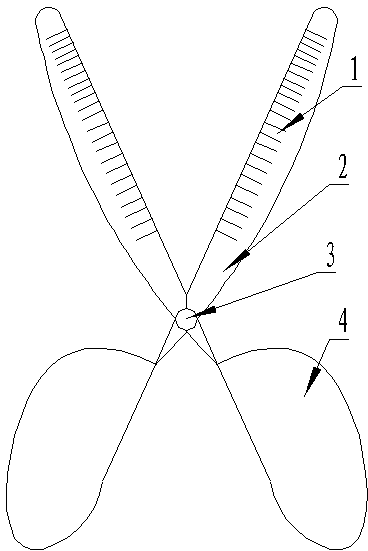

Flexible hand function rehabilitation device based on rope driving

ActiveCN111643315AHigh control precisionSolve the size problemAdditive manufacturing apparatusChiropractic devicesIndex fingerEngineering

The invention provides a flexible hand function rehabilitation device based on rope driving. The flexible hand function rehabilitation device based on rope driving comprises four-finger exoskeleton mechanisms, a thumb exoskeleton mechanism and a soft rubber glove. An index finger exoskeleton mechanism comprises an index finger distal knuckle sleeve ring, an index finger middle knuckle sleeve ringand an index finger proximal knuckle sleeve ring; and each sleeve ring is connected together by a hinge structure. The thumb exoskeleton mechanism comprises a thumb proximal knuckle sleeve ring and athumb distal knuckle sleeve ring which are connected together by a hinge structure. A rope is fixed onto the hand function rehabilitation device through an aluminum sleeve, so that the effect that therope cannot slide down when the rope at the palm side and the hand back side pulls the fingers to bend / extend and outwards extend / inwards collect is ensured. The flexible hand function rehabilitationdevice based on rope driving solves the dimension problem of a traditional rigid exoskeleton. The wearing effect of a user is more compact; the comfortable degree is higher; the adaptation to the hand of the user is more easily to be realized; and a rope passage is arranged on the rehabilitation device, so that when the rope is driven to move by a driver, the hand of a patient is driven to move in a maximum functional region.

Owner:SOUTHEAST UNIV

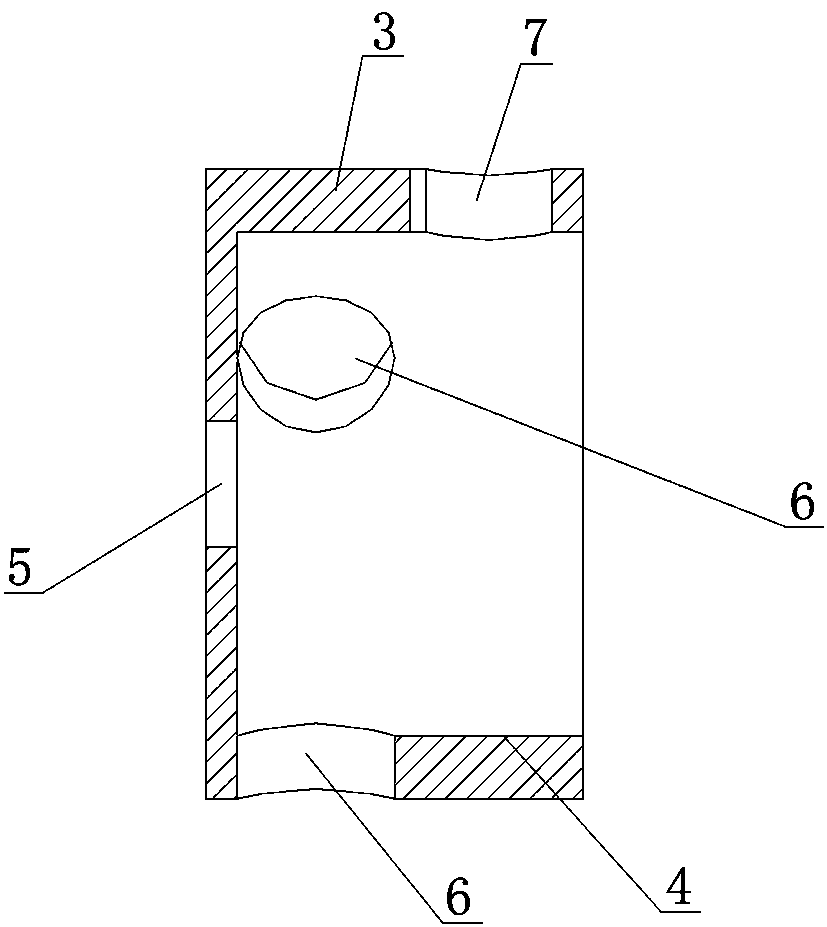

Easy-to-adjust mouth and lip opening device for stomatology

The invention discloses an easy-to-adjust mouth and lip opening device for stomatology, which comprises a mounting plate, wherein a surface of the mounting plate is fixedly provided with an observation port, an inner wall of the observation port and the surface of the mounting plate are both circular, the surface of the mounting plate is fixedly connected with supporting columns, four supporting columns are symmetrically distributed by taking an axis of the mounting plate as a center, one end of each supporting column is fixedly connected with a functional block, the surface of each functionalblock is fixedly provided with a rotating groove, the inner wall of each rotating groove is fixedly provided with an adjusting groove, and four adjusting grooves are distributed in an annular array by taking the axis of the rotating groove as the center of the array. By the adoption of the easy-to-adjust mouth and lip opening device for the stomatology, one end of a liquid storage pipe is in threaded connection with a connector, and the one end of the connector is fixedly communicated with a hose; when the device is used, the connector is in threaded connection with the liquid storage pipe, so that disassembly, cleaning and disinfection of the device are convenient in a later period, and a replacement of mouthwash in the liquid storage pipe, the hose and the functional pipe is facilitated.

Owner:THE SECOND PEOPLES HOSPITAL OF NANTONG

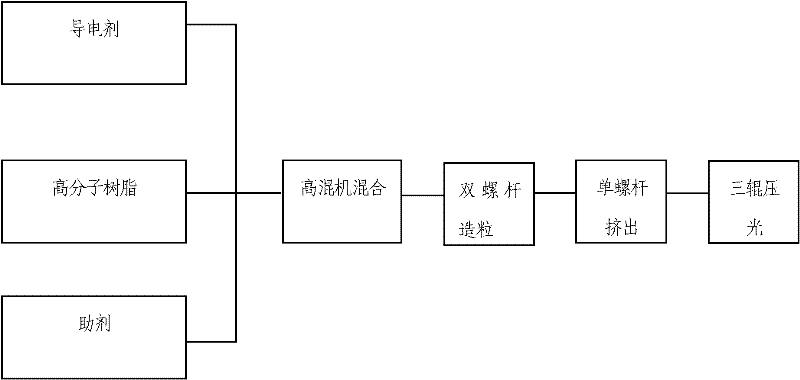

Method for manufacturing high-conductivity conductive plastic bipolar plate for vanadium cell

InactiveCN102683723ASimple processStrong continuous processingCell electrodesEngineeringHigh intensity

The invention relates to the field of manufacturing vanadium cells, in particular to a method for manufacturing a high-conductivity conductive plastic bipolar plate for the vanadium cell. The method comprises the steps of: uniformly mixing a conductive plastic raw material in a high-speed mixing machine, mixing through a double-screw extruder to manufacture master batches, adding the manufactured master batches to a single-screw extruder, and carrying out extrusion molding through the single-screw extruder to manufacture a conductive high-molecular-material collector plate. According to a bipolar plate meeting technique requirements, temperature-resistant resin and a conductive filler are selected, pelletized by the double-screw extruder, and extruded by the single-screw extruder to manufacture a high-strength, anti-corrosion and high-temperature-resistant plastic bipolar plate; and the resistivity of the manufactured high-strength, anti-corrosion and high-temperature-resistant plastic bipolar plate can reach 0.1-0.5 omega per centimeter so as to meet an application index of the vanadium cell. The bipolar plate manufactured by the method disclosed by the invention can be rather thin, has the advantages of large area, good continuity and low cost, and also has the advantages of being capable of reducing the cost of the vanadium cell, ensuring stable operation in cells without releasing chemical groups, and maintaining stability and reliability of an electric pile of the vanadium cell.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

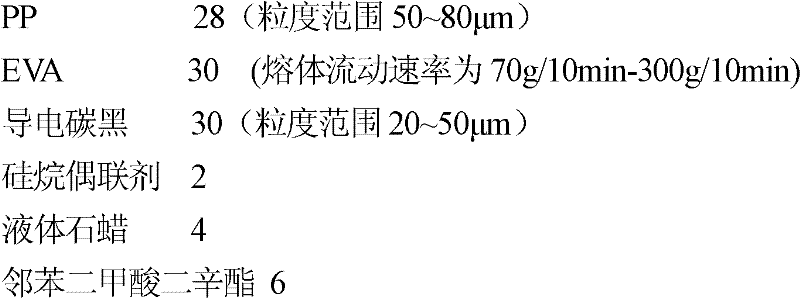

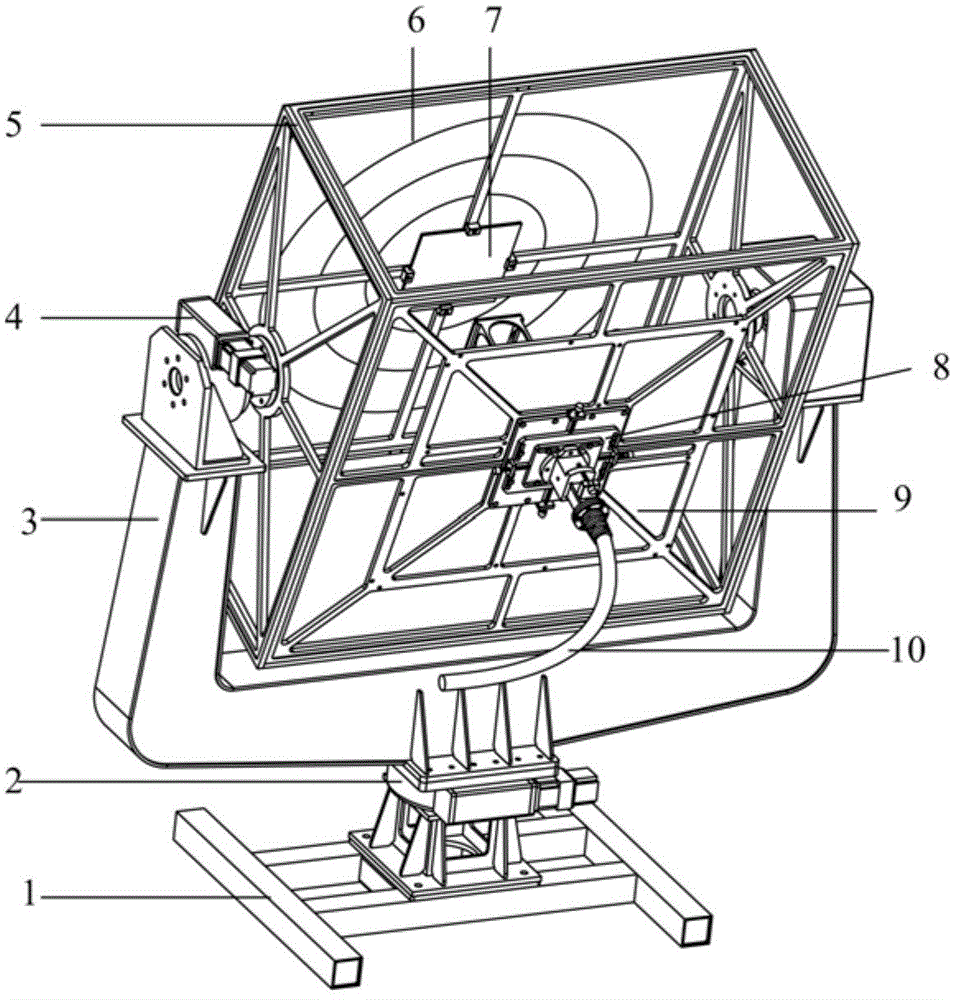

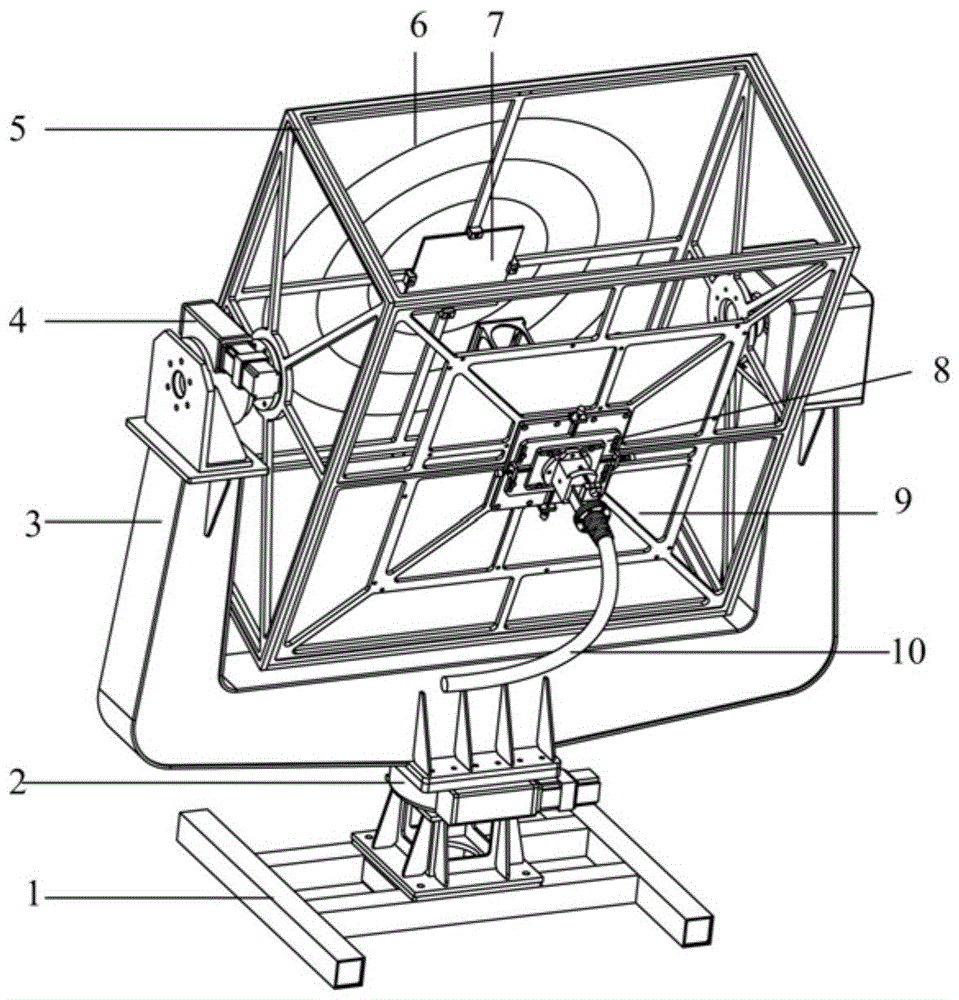

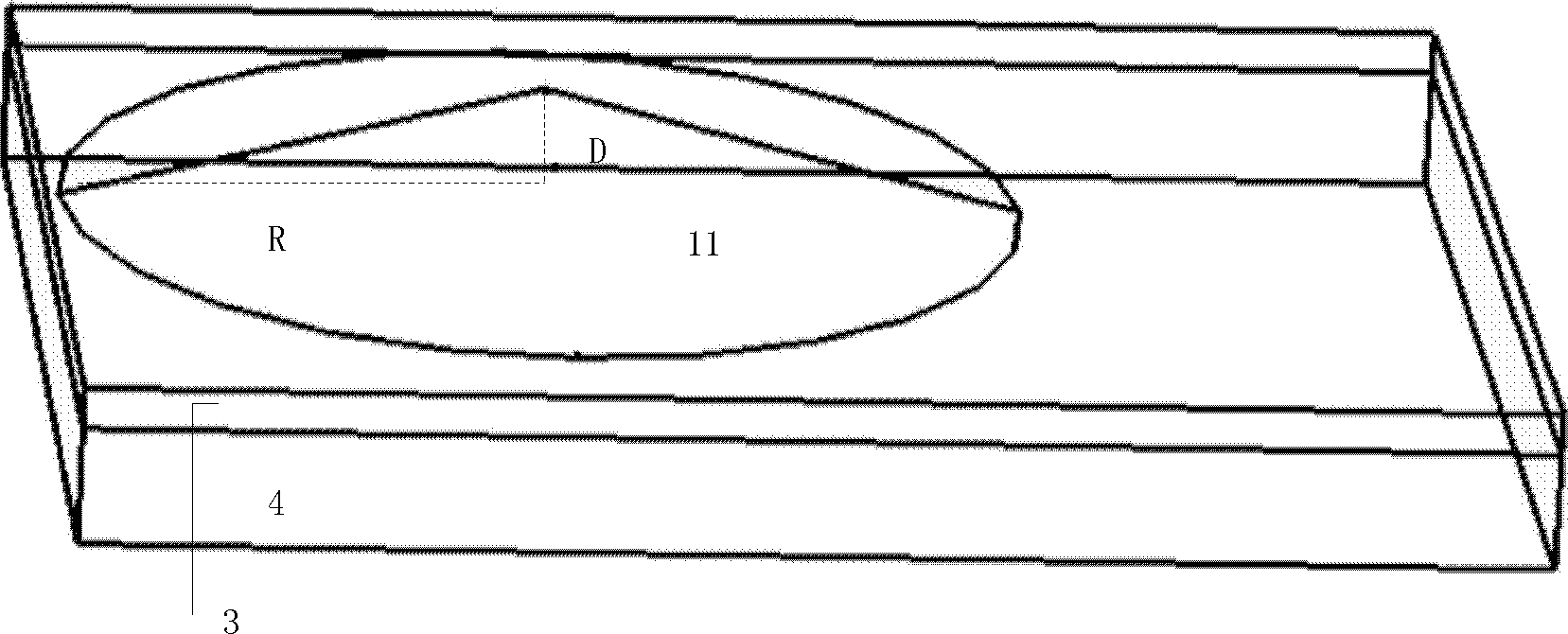

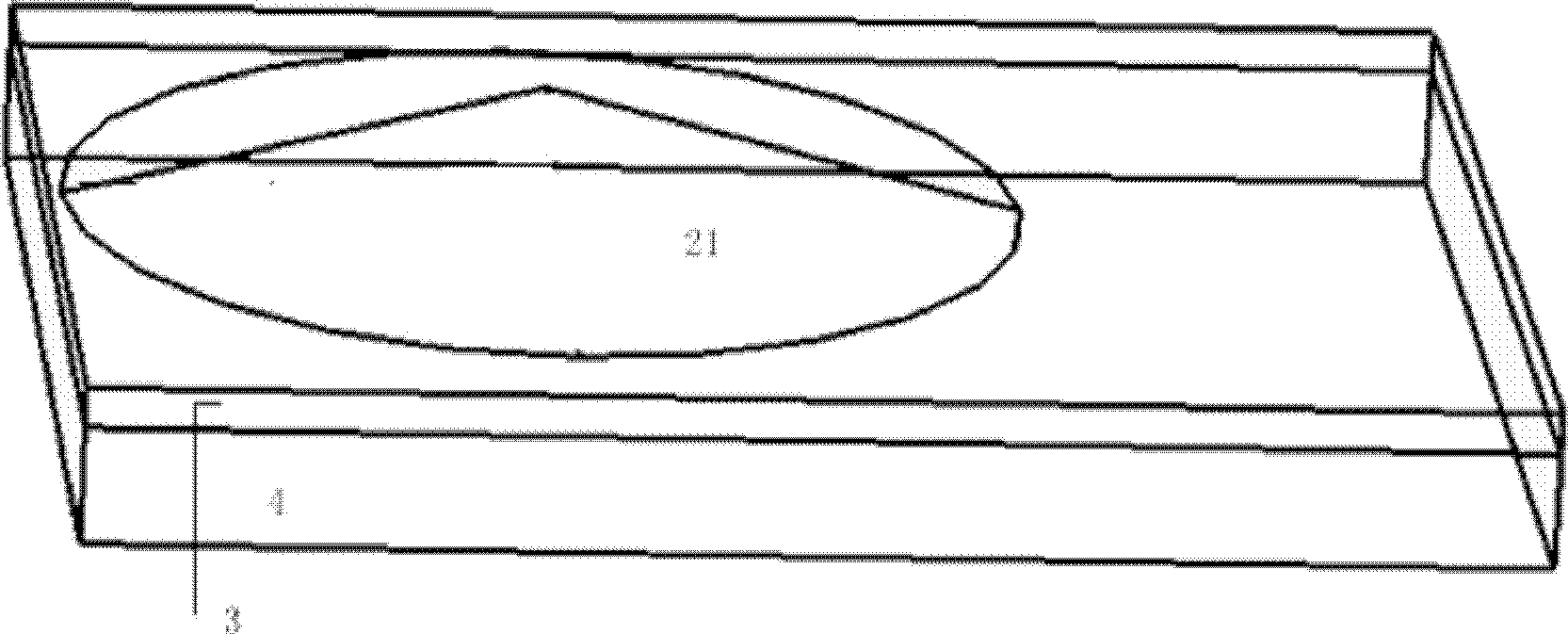

Large-caliber reflection-type light guide machine and working method thereof

InactiveCN104595842AReduce the temperatureExtend your lifeUsing daylightSpectral modifiersFollow-the-sunLight guide

The invention discloses a large-caliber reflection-type light guide machine and a working method thereof, belonging to the technical field of solar energy application. The large-caliber reflection-type light guide machine consists of an azimuth angle drive device, a height angle drive device, a focus lens group, a sun location system, a focusing device and an optical fiber beam. The focusing device is used for adjusting a receiving end surface of the optical fiber beam to a focal point of the focus lens group, and the focus lens group is driven by the azimuth angle drive device and the height angle drive device, so that the focus lens group can follow the sun, the infrared ray in the incidence light is eliminated by utilizing a filter lens of the focus lens group, and the uniformity of the intensity of the focus spot can be realized by virtue of a light homogenizing cavity of the focus lens group; the sun location system adopts a photosensitive element to provide a sun roughly location signal and utilizes a high temperature sensor to provide a precise position signal of the focus spot. By adopting the large-caliber reflection-type light guide machine, the infrared ray in the sun focus light is eliminated, the uniformity of the intensity of the focal spot can be realized, the service life of the optical fiber beam can be greatly prolonged, and the position detection reliability of the focus spot can be improved by utilizing the high temperature sensor.

Owner:宋记锋

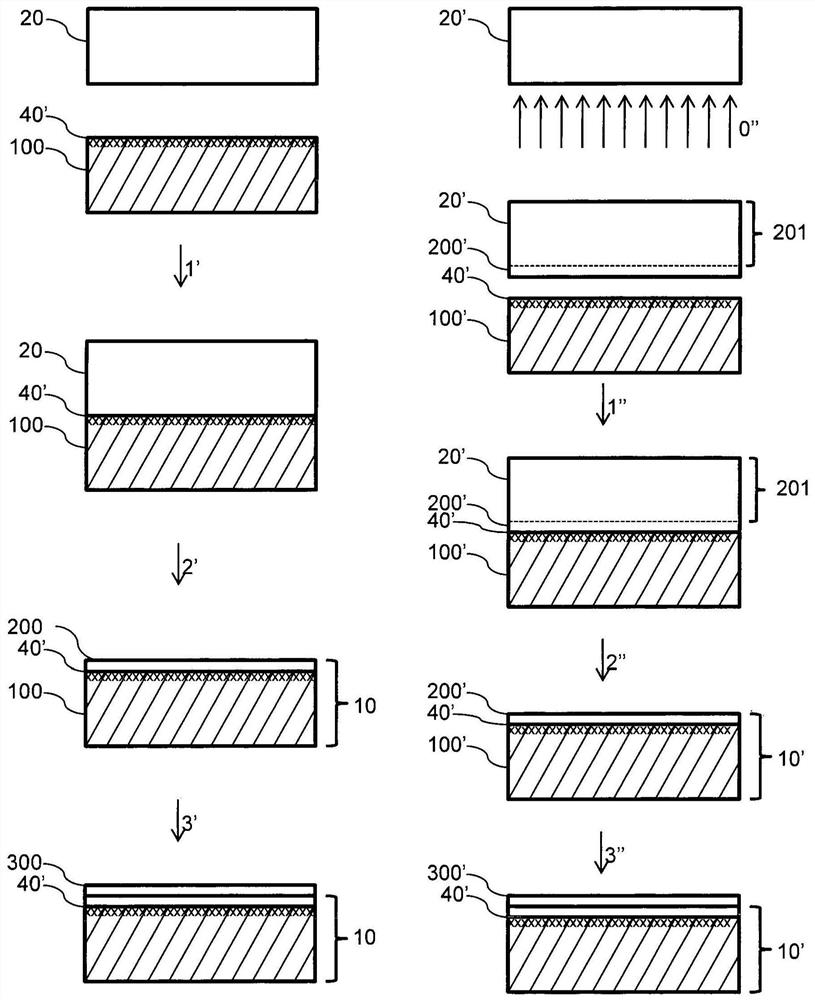

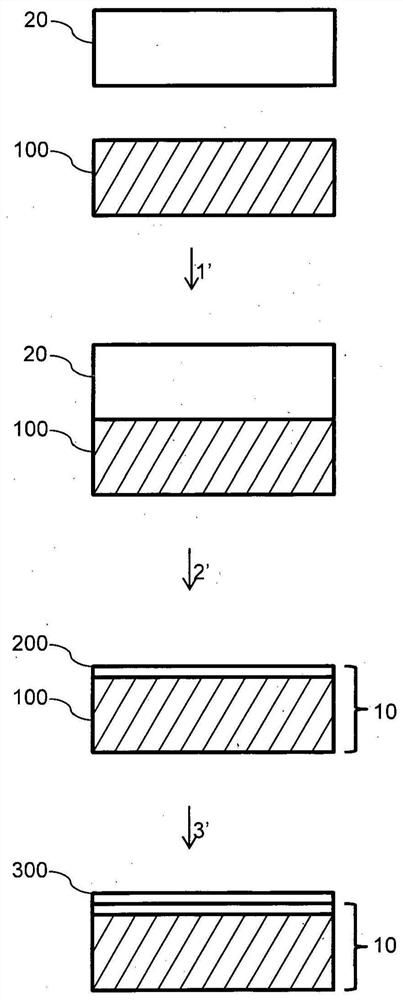

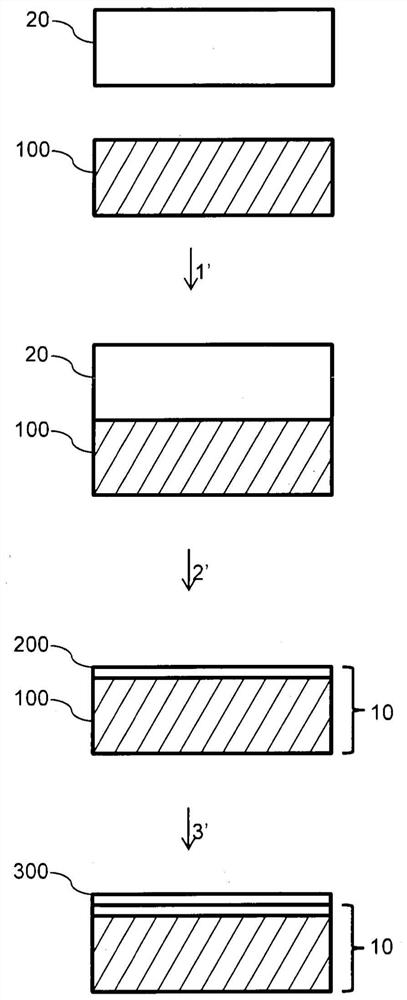

Preparation method of material and/or color gradient mobile phone shell

InactiveCN111491055ARealize integrated moldingSolve the size problemAdditive manufacturing apparatusTelephone set constructionsProcess engineeringMobile phone

The invention relates to a preparation method of a material and / or color gradient mobile phone shell. The preparation method comprises the following steps: S1, preparation of various feeds for 3D printing according to a 3D printing model; S2, mobile phone shell blank printing: dividing the mobile phone shell blank into a plurality of printing areas according to the distribution of materials in the3D printing model, and carrying out continuous printing on the plurality of printing areas to obtain a mobile phone shell blank; S3, degreasing: degreasing the green body to obtain a degreased part;and S4, sintering: sintering the degreased part to form a final product. According to the invention, multiple material printing technologies and indirect printing are combined to realize integrated molding of the mobile phone shell, and the size problem caused by assembly is avoided.

Owner:CHANGZHOU GIAN TECH

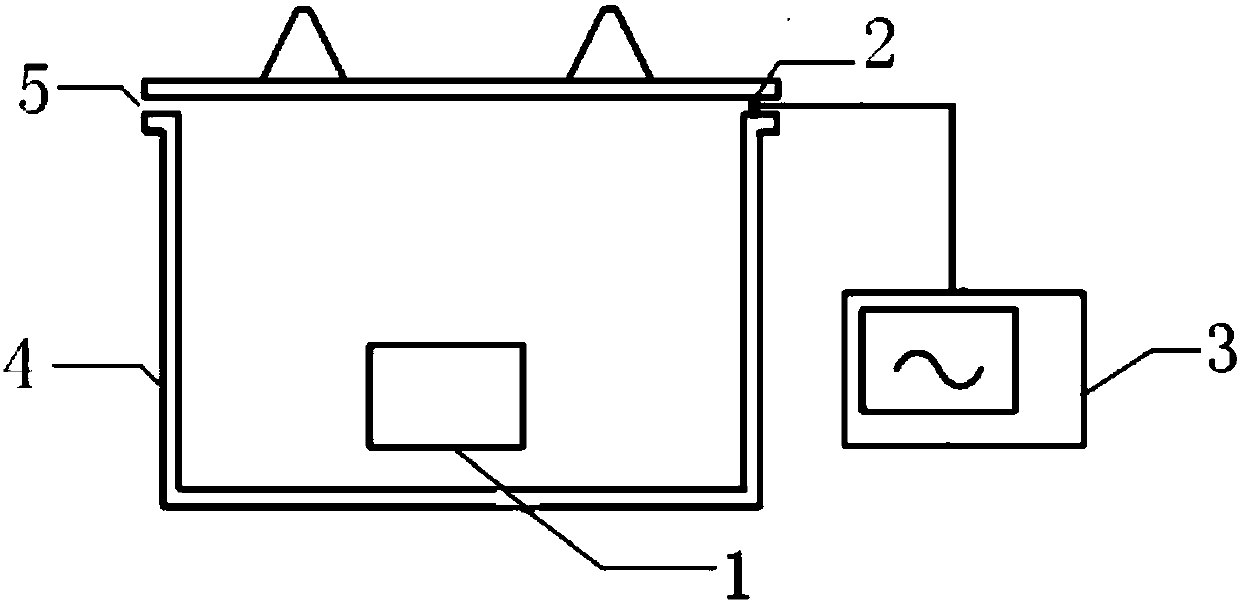

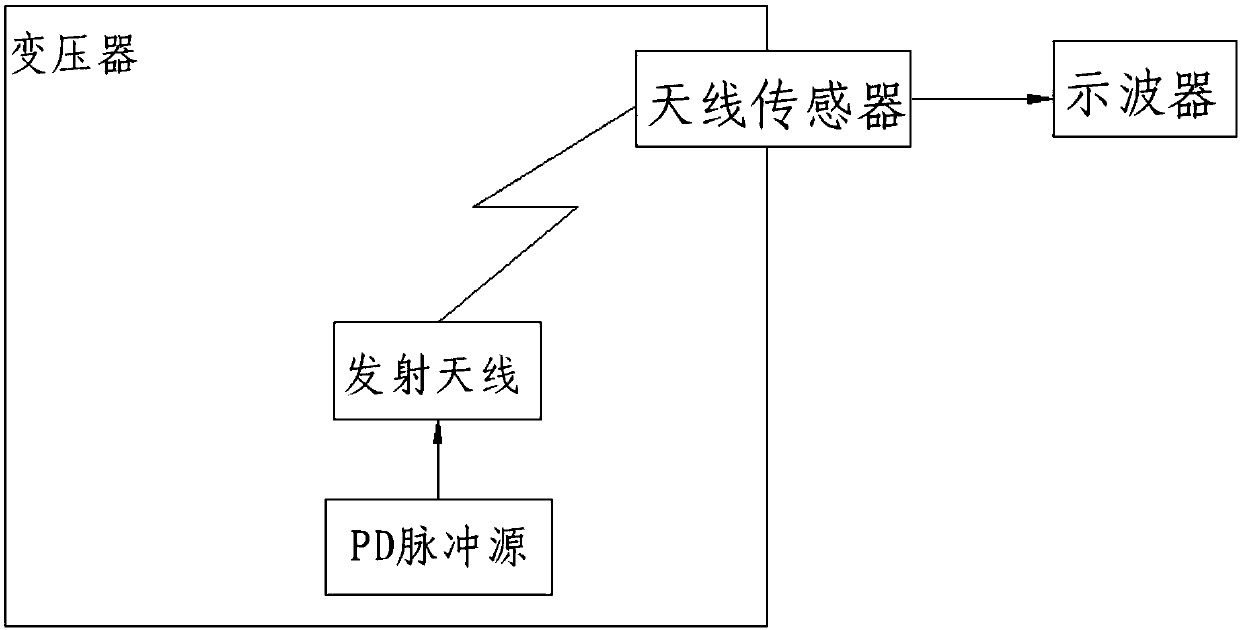

Partial discharge detection system for transformer slot leak electromagnetic waves and method

InactiveCN107907800AOvercome the size problemSolve the size problemTesting dielectric strengthElectromagentic field characteristicsControl equipmentPartial discharge

The invention discloses a partial discharge detection system for transformer slot leak electromagnetic waves and method. The system is composed of a signal source generation device arranged inside thetransformer for generating electromagnetic waves, an electromagnetic wave receiving device arranged in the slot of the transformer for receiving the electromagnetic waves, and a data acquisition device connected with the electromagnetic wave receiving device for acquiring electromagnetic wave signals received by the electromagnetic wave receiving device. In the method, a PD pulse source is adjusted through a control device to output PD pulse signals, electromagnetic wave signals in or inside the power transformer slot are acquired through an antenna sensor and an oscilloscope, and thus, detection on the transformer slot leak electromagnetic waves is completed. The power transformer slot leak PD electromagnetic wave signals can be effectively detected, and a strong support is provided forresearch on an electromagnetic wave distribution law in (inside) the transformer slot.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

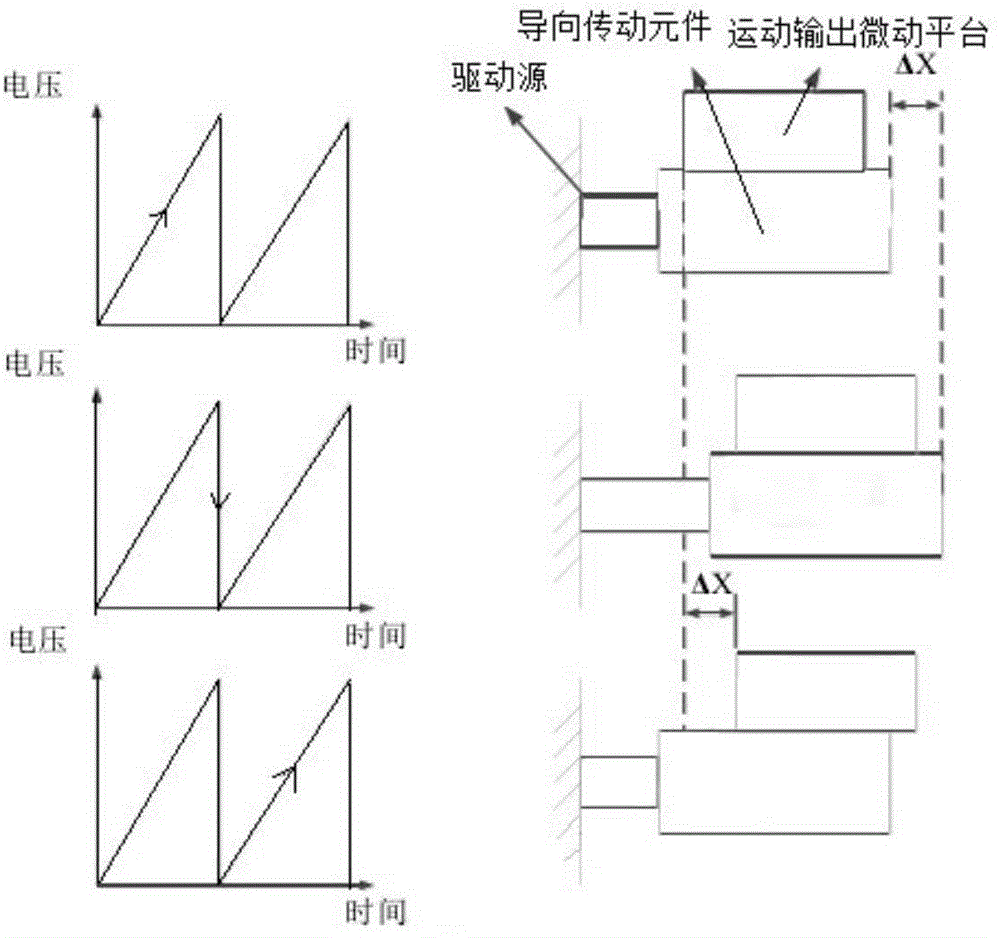

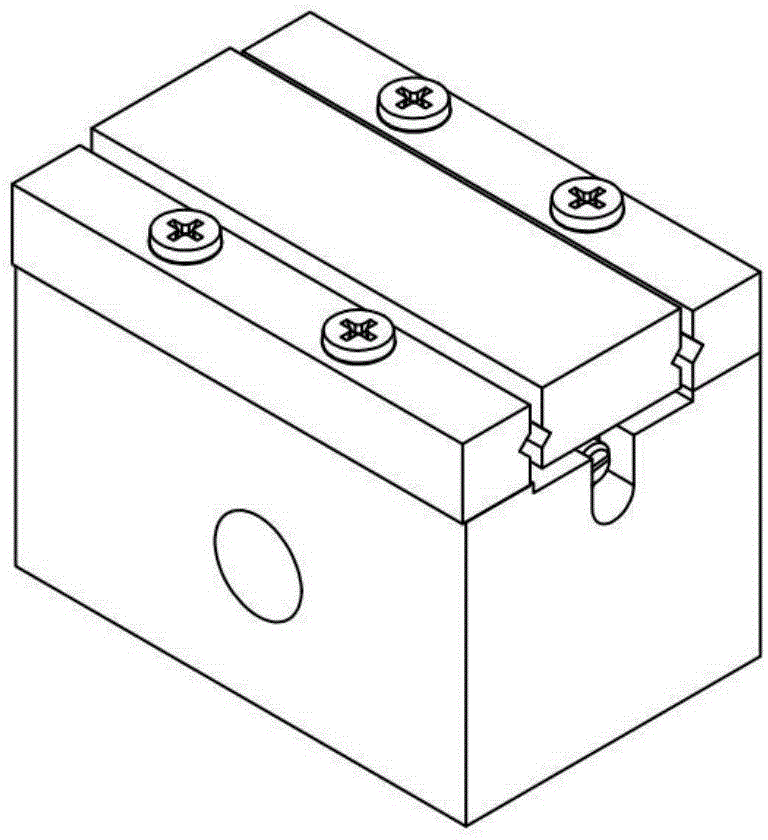

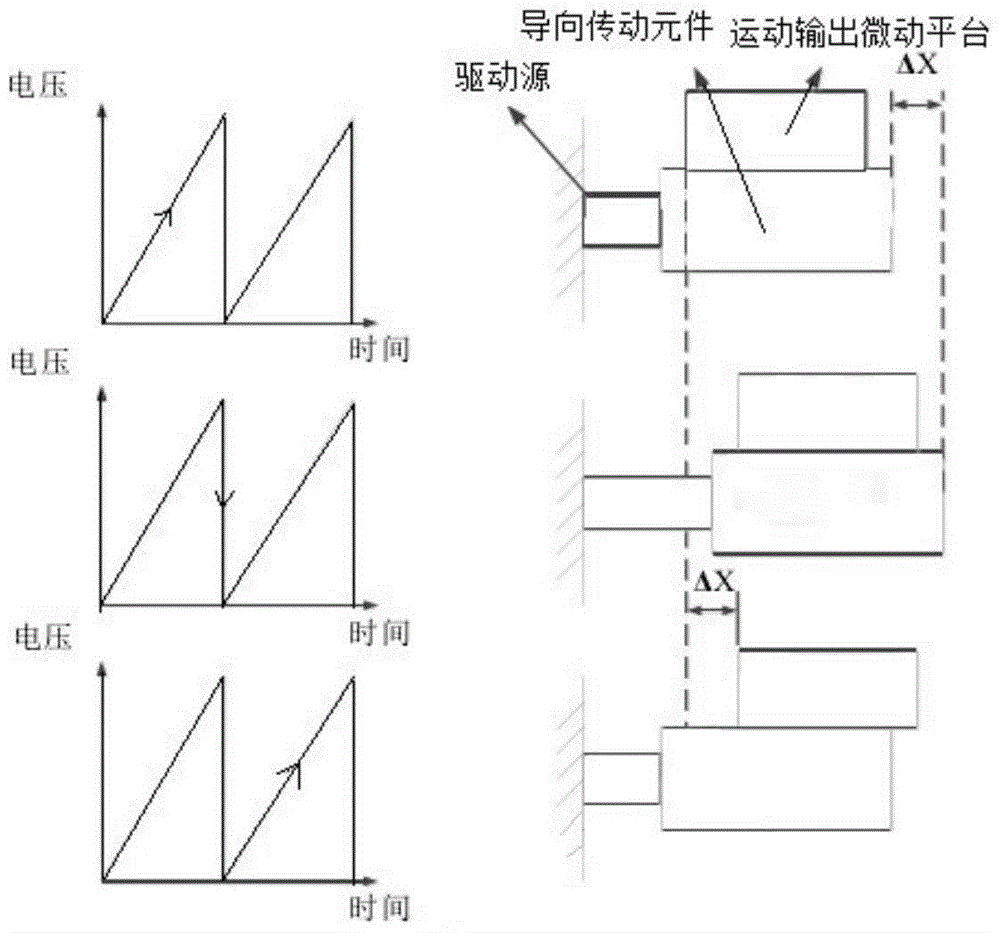

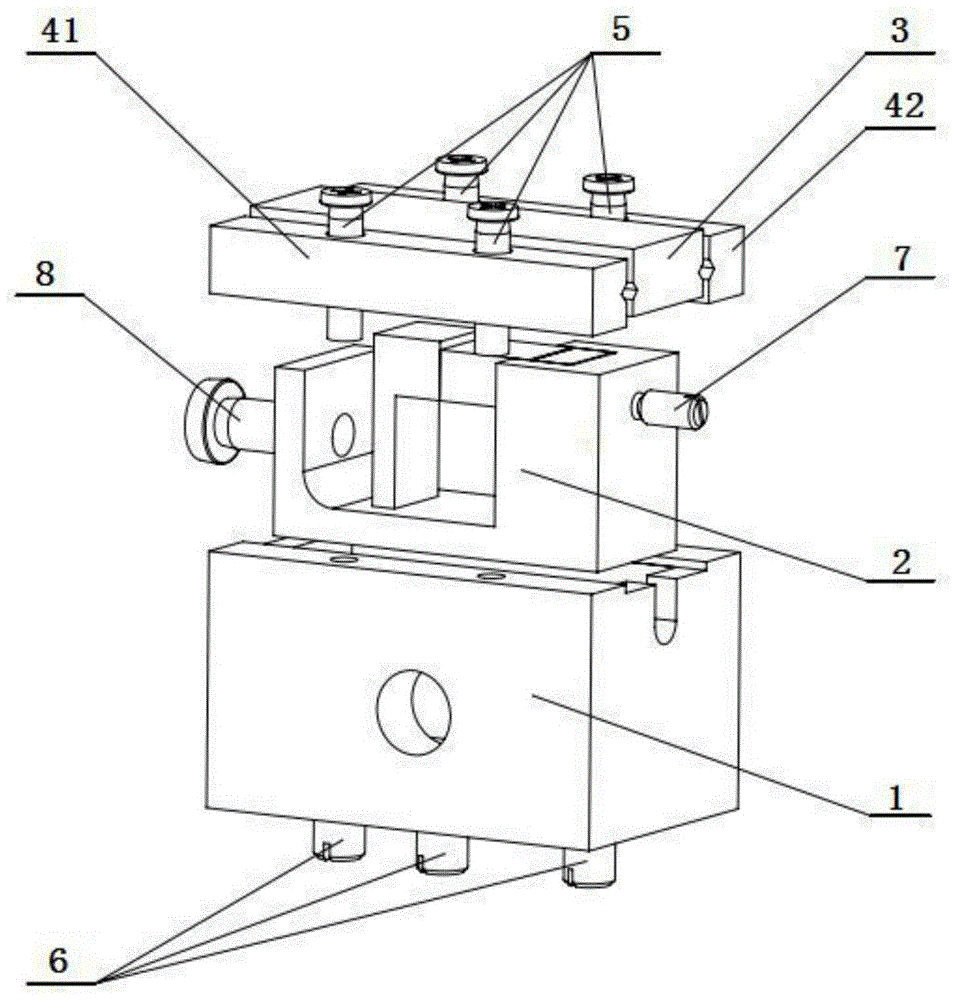

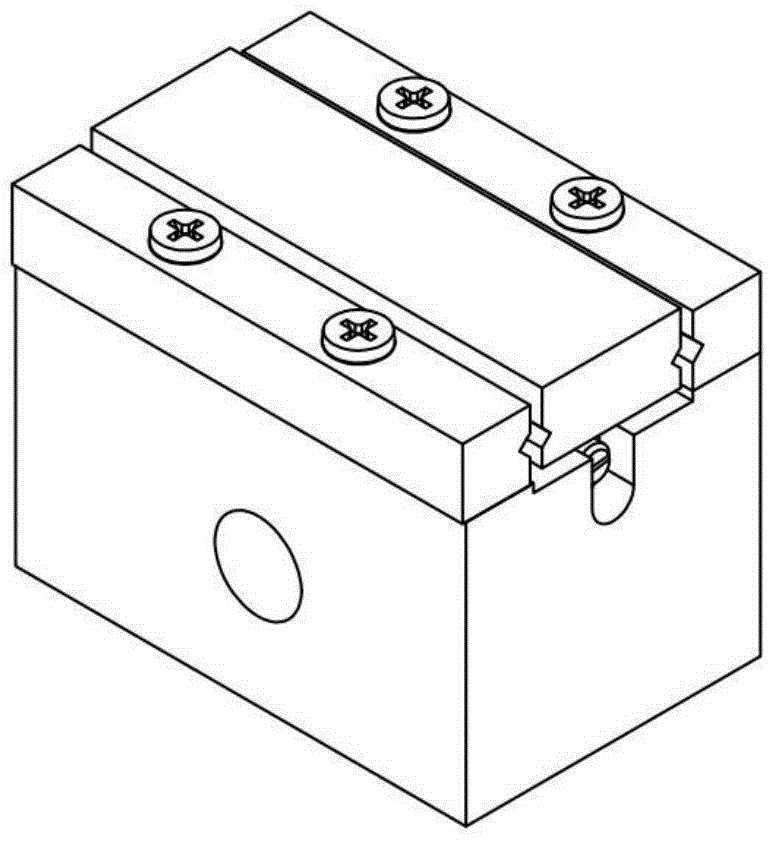

Driving unit modularization stick-slip driving positioning platform

The invention discloses a driving unit modularization stick-slip driving positioning platform which comprises a movement output micro-positioning platform, a platform base and a driving unit module arranged inside the platform base. The driving unit module comprises a module frame, a driving source and a guiding driving element, wherein the driving source is arranged inside the module frame, and the guiding driving element is connected with the driving source and is a flexible hinge. The guiding driving element is perpendicular to the movement output micro-positioning platform. The top of the guiding driving element makes direct contact with the movement output micro-positioning platform. The stick-slip effect is generated between the guiding driving element and the movement output micro-positioning platform, displacement is directly output, the precision is high, and the response speed is high; due to the modularized design, the platform base and the friction adjusting mechanism are greatly simplified, and the machining and manufacturing requirement of the whole positioning platform is lowered.

Owner:JIANGSU JICUI MICRO NANO AUTOMATION SYST & EQUIP TECH RES INST CO LTD

Preparation method of polycrystalline zinc selenide

ActiveCN112795897ASolve the size problemChemical vapor deposition coatingZinc selenidePhysical chemistry

The invention provides a preparation method of polycrystalline zinc selenide. The preparation method comprises the following steps that the surface of a polycrystalline zinc selenide sheet with the thickness of 30-50mm is treated to obtain a zinc selenide polished wafer with the roughness being less than Ra20, the zinc selenide polished wafer is cleaned with plasma, and the cleaned zinc selenide polished wafer is put on a graphite substrate; step 2, the zinc material is installed in a crucible; step 3, a graphite substrate depositor is mounted on a graphite crucible and then put in a chemical vapor deposition vacuum furnace; step 4, argon is introduced into the chemical vapor deposition vacuum furnace at room temperature; step 5, the crucible is heated, and the graphite substrate depositor is heated; step 6, the zinc starts to evaporate, hydrogen selenide gas carried by the argon is introduced into the graphite substrate depositor, and argon is introduced into the crucible; and step 7, after zinc evaporation is finished, introducing of the hydrogen selenide gas is stopped, the crucible is cooled, the graphite substrate depositor is cooled, and the final polycrystalline zinc selenide with the overall thickness of 60-100mm is obtained after being discharged from the furnace. According to the invention, the thick polycrystalline zinc selenide material can be prepared.

Owner:安徽中飞科技有限公司

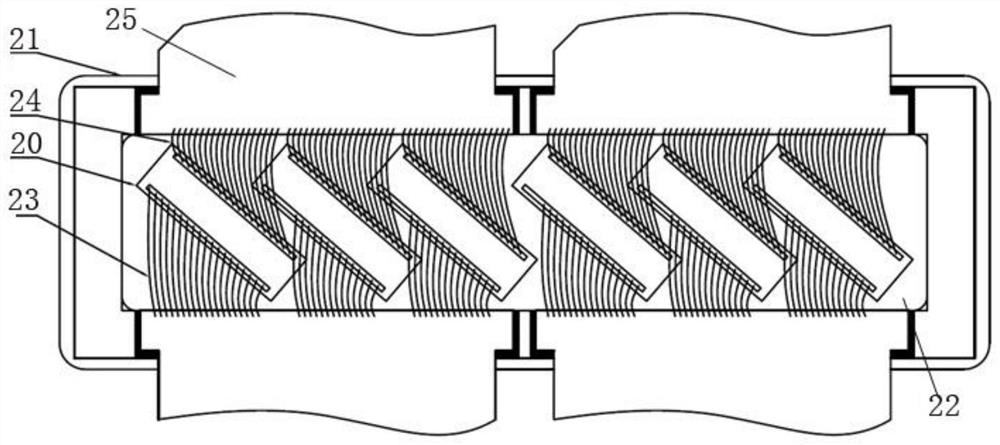

Continuous Teflon press for thermoplastic composite material

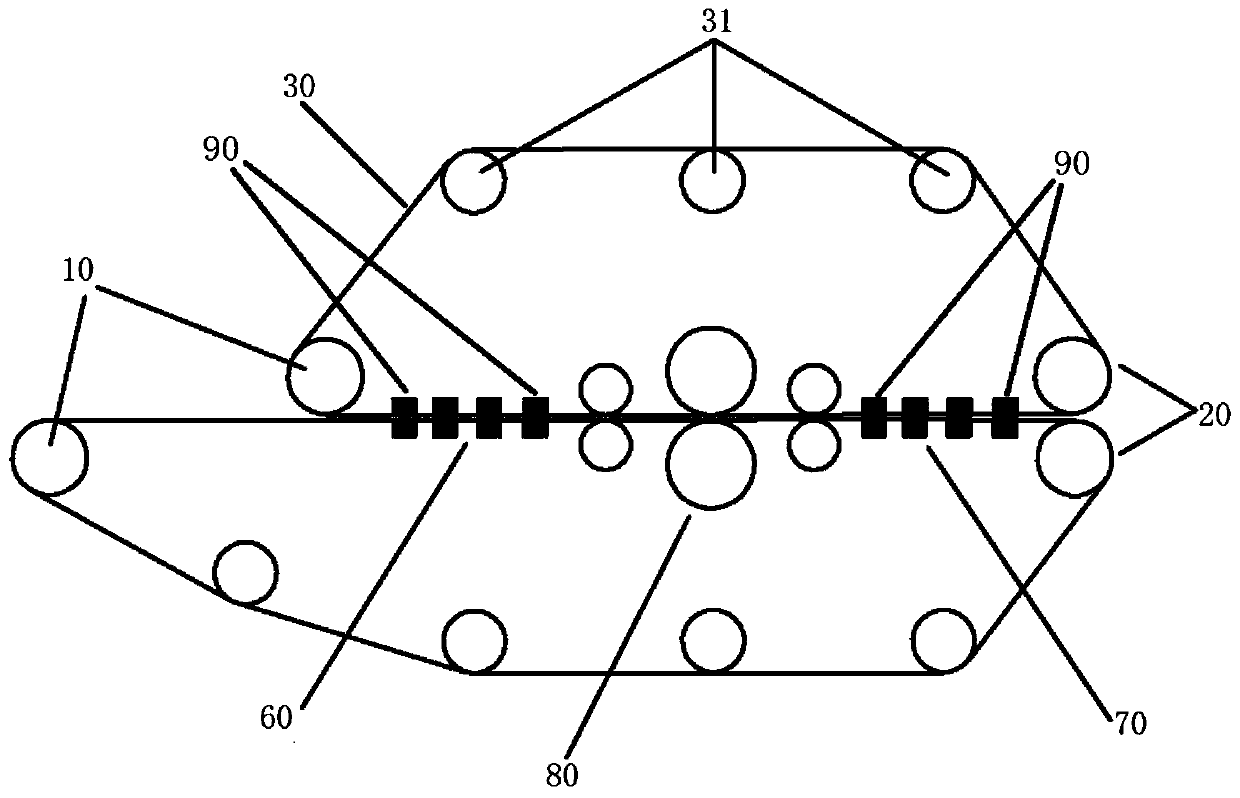

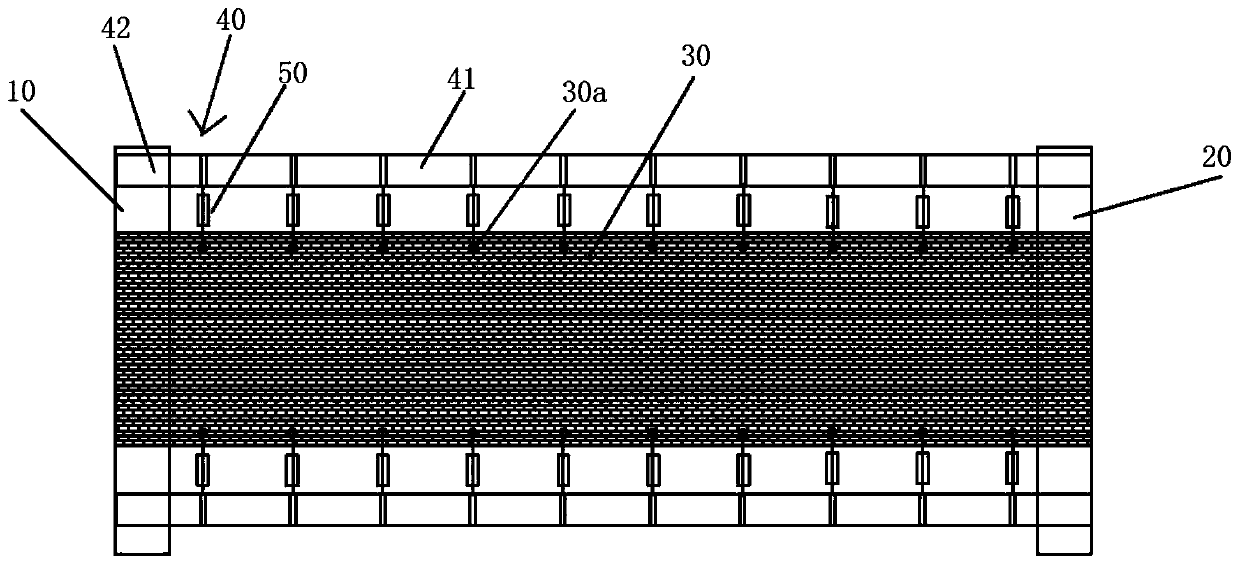

PendingCN110667229ASolve the size problemIncrease productivityLamination ancillary operationsLaminationPolymer scienceThermoplastic composites

The invention discloses a continuous Teflon press for a thermoplastic composite material. The press includes a frame, a group of a driving roller and a tensioning roller which are arranged up and downand a Teflon conveying belt coating the driving roller and the tensioning roller are respectively arranged on the frame, a transmission device for driving the Teflon conveying belt to rotate is arranged between the driving roller and the tensioning roller, the transmission device is connected with the Teflon conveying belt through an elastic part, a heating area for heating a thermoplastic composite material and a cooling area for cooling the thermoplastic composite material are respectively arranged in the frame, and a thickness determining device for determining the thickness value of the thermoplastic composite material is arranged between the heating area and the cooling area.

Owner:SHANGHAI LEADGO TECH

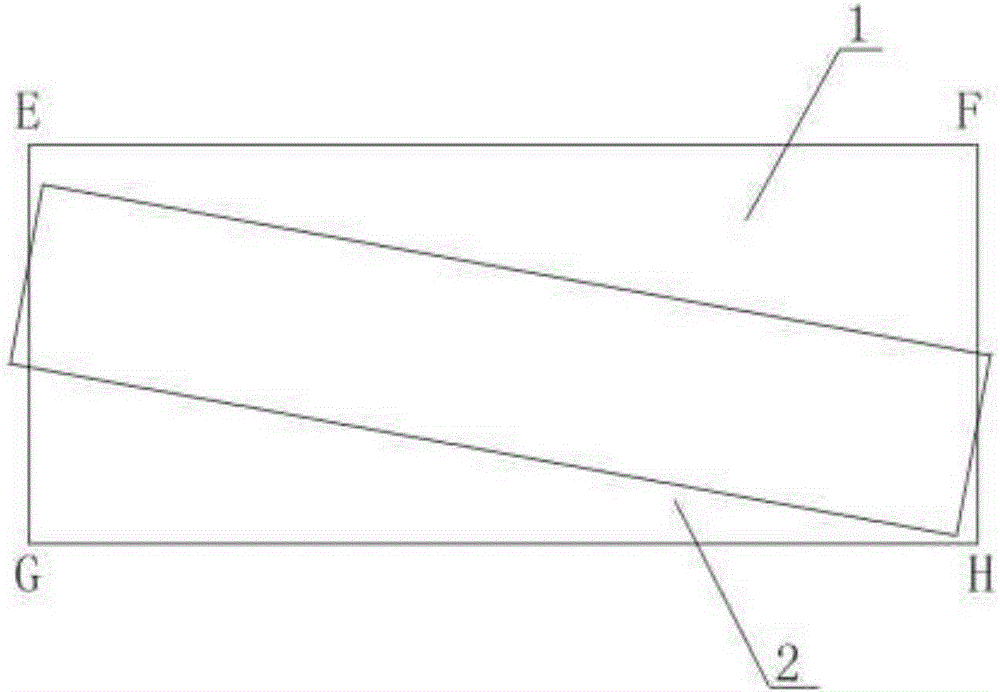

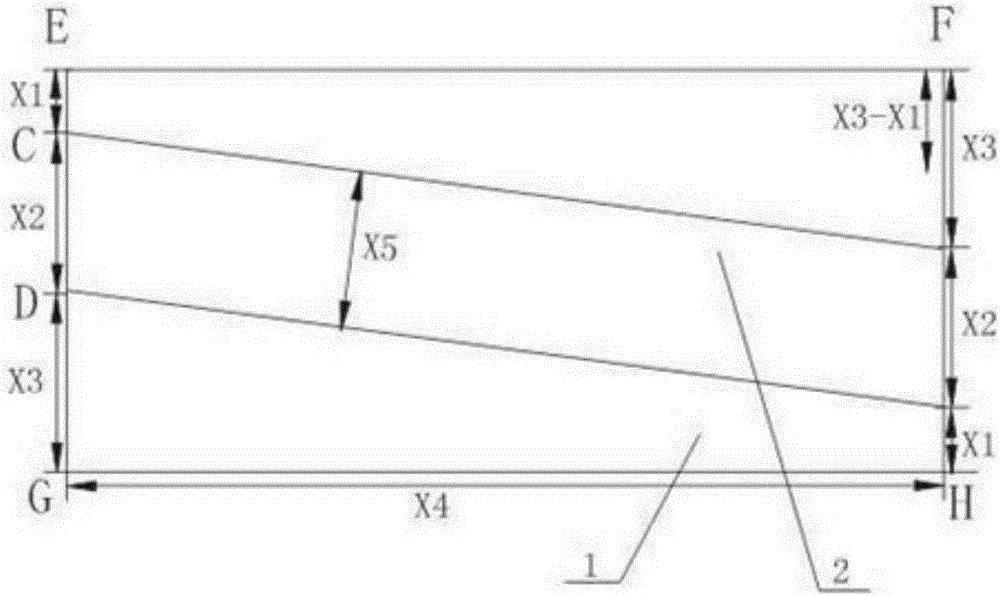

Packaging structure and packaging method of high-power radio frequency device

PendingCN113972201AAvoids problems of directly spanning over adjacent dieAvoid large overlapsSemiconductor/solid-state device detailsSolid-state devicesPower applicationControl theory

The invention discloses a packaging structure of a high-power radio frequency device, which comprises a plurality of radio frequency power chips connected in parallel and a packaging flange. The plurality of radio frequency power chips are obliquely arranged in a packaging inner cavity of the packaging flange, so that the number of input leads of the radio frequency power chips is reduced, and the input leads and output leads are not overlapped in space. The plurality of chips are obliquely arranged on the packaging flange, so that the utilization rate of the packaging space is remarkably improved, and the purpose of higher power output is achieved. By slightly reducing the number of the input leads of the intermediate radio-frequency power chip, the output leads cannot be reduced, the reliability of a high-power application process can be ensured, large-area overlapping of the input leads and the output leads in space is avoided, mutual inductance is reduced, and oscillation of the radio-frequency power device is effectively avoided.

Owner:INNOGRATION SUZHOU

Preparation method of foamed aluminum sandwich panel based on friction stir welding connection

PendingCN112959012AStrong foaming abilityHigh densityNon-electric welding apparatusHeating furnaceSandwich panel

The invention discloses a preparation method of a foamed aluminum sandwich panel based on friction stir welding connection. The preparation method comprises the following steps that (1) two foamed aluminum sandwich panel preforms are prepared; (2) surface treatment is carried out; (3) the end faces, perpendicular to the horizontal plane, of the two surface-treated preforms are in butt joint; (4) friction stir welding is carried out, the rotating speed of a stirring needle is 400-1200 rpm, and the welding speed is 100-200 mm / min; and (5) the welded preforms are put in a heating furnace to be foamed. The method can be used for preparing the foamed aluminum sandwich panel welding preforms with high panel bonding strength and can be used for preparing the foamed aluminum sandwich panel large in size, high in overall expansion rate, good in panel flatness and good in sandwich foam hole continuity; and the method is simple in process route and can be used for large-scale production.

Owner:NORTHEASTERN UNIV

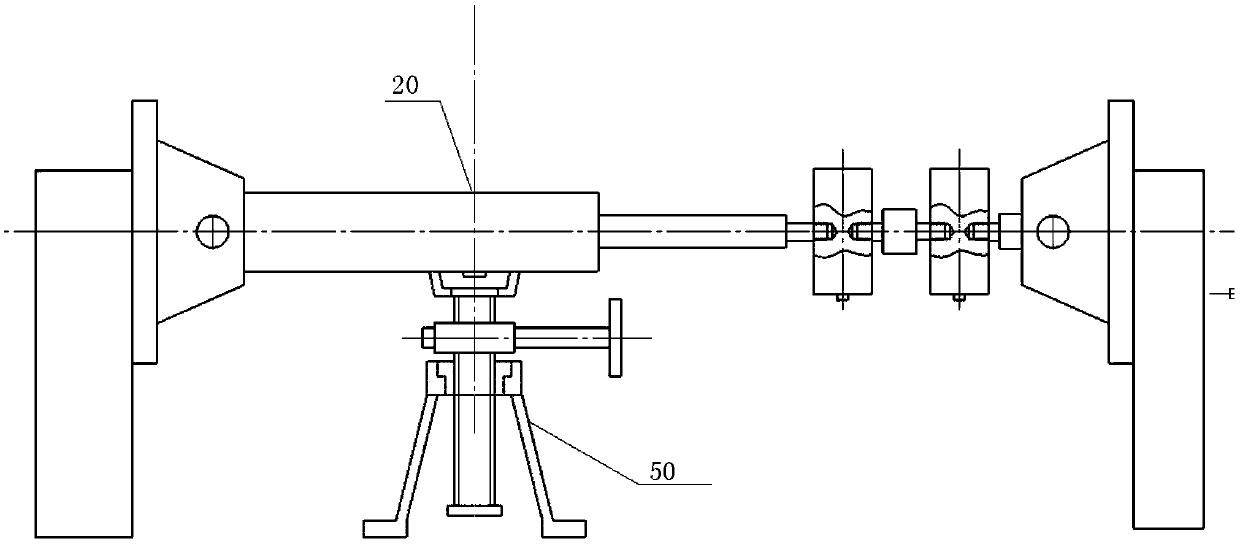

Spraying-free POM composite material with low warpage and high dimensional stability and preparation method of spraying-free POM composite material

InactiveCN110527244ARigid Synergistic ImprovementSynergistically improves impact toughnessElastomerMasterbatch

The invention discloses a spraying-free POM composite material with low warpage and high dimensional stability and a preparation method of the spraying-free POM composite material. The spraying-free POM composite material with low warpage and high dimensional stability specifically comprises the following raw materials in parts by weight: 40-80 parts of POM resin, 1-5 parts of a dispersing agent,2-5 parts of an anti-aging auxiliary agent and 8-25 parts of functionalized masterbatches. The functionalized masterbatches comprise the following components in percentages by weight: 3-15 parts of anelastic ionomer, 2-10 parts of graphene oxide and 3-8 parts of metal toner. Through high-efficiency masterbatch predispersion of the elastic ionomer with high impact resistance modification effect, agraphene oxide sheet layer and the metal toner, the obtained POM composite material has a good surface spraying-free effect, on that basis, the problem of dimensional stability of POM with large forming shrinkage and easiness in warpage is obviously solved, the warpage of prepared sample plates with different wall thicknesses is reduced to be about 1 / 4-1 / 5 of that of a conventional material in ahigh-temperature and long-period testing environment, and moreover, by the high-efficiency composite masterbatch modification mode, the negative influence of the addition of the an elastomer toughening agent on the rigidity and heat resistance of the material can be effectively compensated.

Owner:华合新材料科技股份有限公司

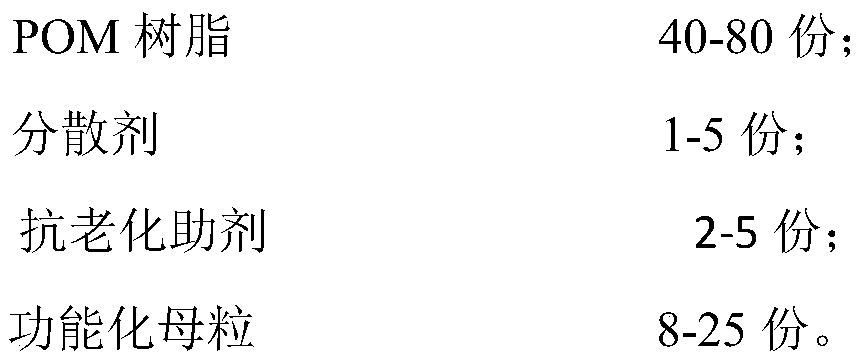

Flight control simulator tensile and compressive load testing system field calibration device

PendingCN109573099AField Calibration ImplementationSolve the size problemAircraft components testingOpen adjustmentEngineering

The invention provides a flight control simulator tensile and compressive load testing system field calibration device which comprises a structural framework, a loading mechanism, a standard measurement unit, an upper computer and a fine adjustment mechanism. The loading mechanism, the standard measurement unit and a calibrated force sensor are sequentially connected and then installed on the structural framework. The fine adjustment mechanism supports the loading mechanism, and through fine adjustment of the position of the loading mechanism, the loading mechanism, the standard measurement unit and the calibrated force sensor are located on the same straight line. The standard measurement unit and the upper computer are wirelessly connected. The calibrated force sensor and a flight control simulator are connected.

Owner:SHANGHAI PRECISION METROLOGY & TEST RES INST +1

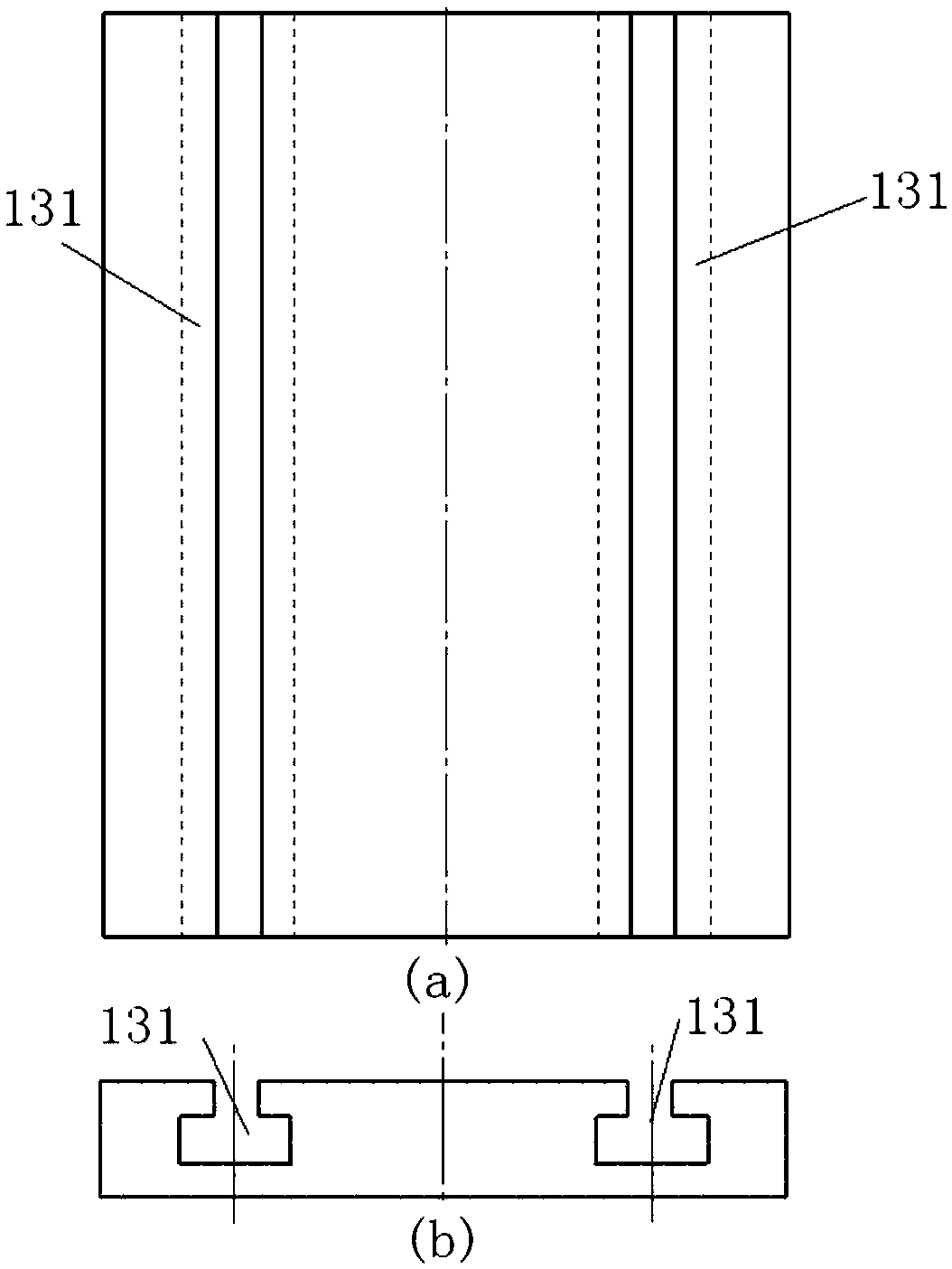

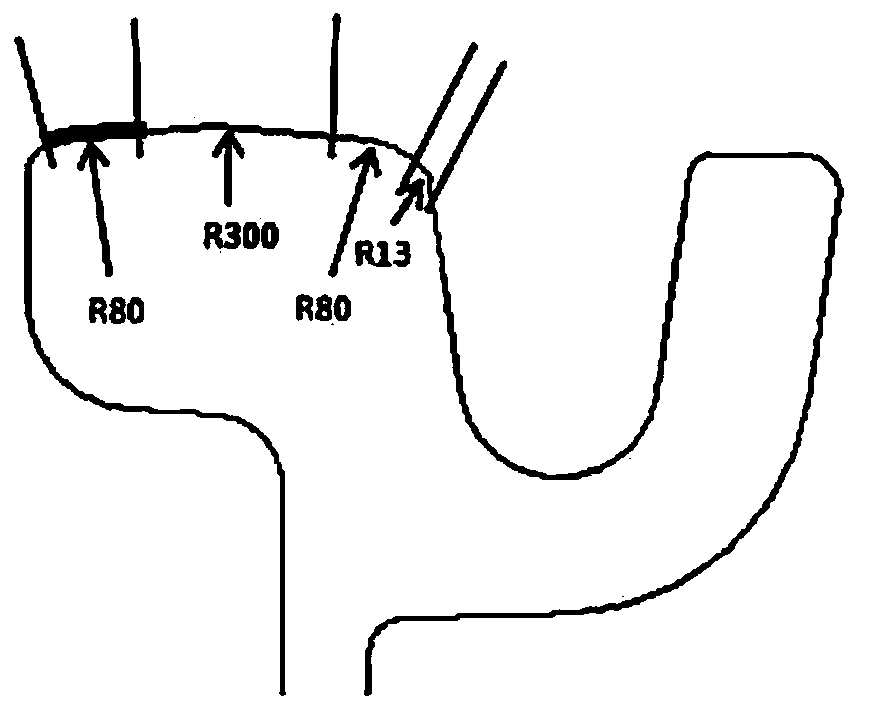

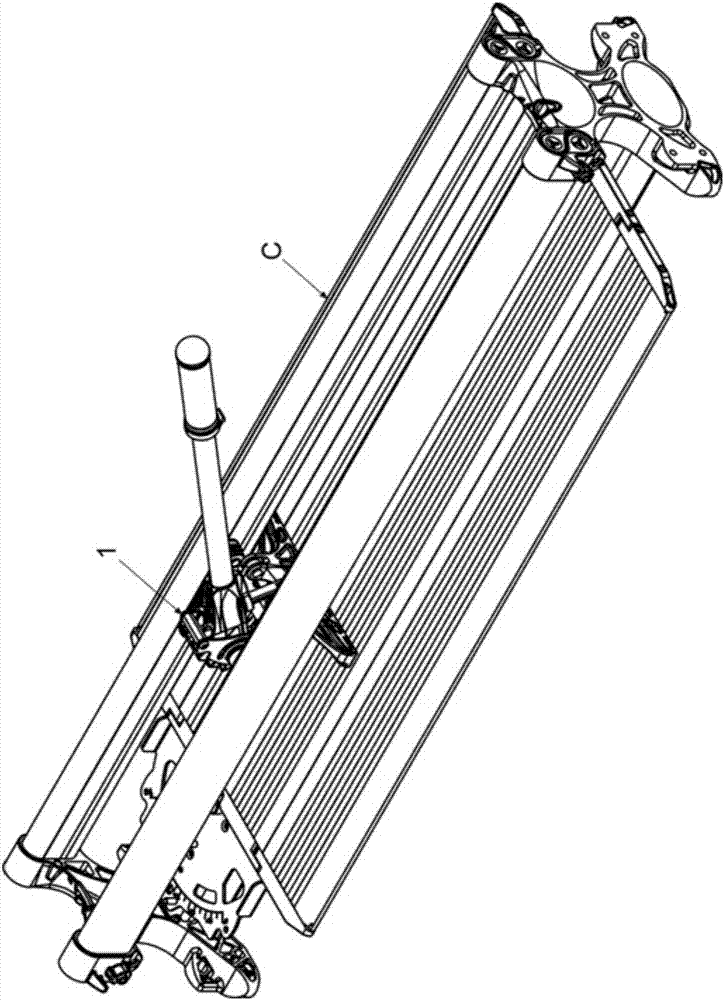

Groove-shaped rail grinding device and method utilizing curved surface grinding machine

PendingCN111535095AEliminate or control defectsSolve the size problemRailway track constructionEngineeringSurface grinding

The invention provides a grooved rail grinding device and method utilizing a curved surface grinding machine, relates to the technical field of rail grinding maintenance, and solves technical problemsthat existing grinding equipment cannot effectively grind a grooved rail, and maintenance and repair purposes are difficult to achieve. The grinding device comprises a curved surface grinding machine, and the curved surface grinding machine makes contact with a profile surface of the grooved rail through a circumferential surface of a grinding wheel and can carry out forward and reverse bidirectional grinding. The curved surface grinding machine comprises a first grinding unit, a second grinding unit, a third grinding unit and a fourth grinding unit. The first grinding unit, the second grinding unit, the third grinding unit and the fourth grinding unit are connected in sequence and can grind different positions of the profile surface of the grooved rail, and complete envelope grinding canbe performed on the profile surface of the grooved rail after combination. Grinding quality and efficiency are ensured through combination of the multiple grinding units, the maintenance and repair purposes are achieved, and a problem that a large grinding machine cannot carry out grinding due to a size reason is solved.

Owner:一路行(北京)科技有限公司

Large-diameter reflective light guide machine and its working method

InactiveCN104595842BReduce the temperatureExtend your lifeUsing daylightSpectral modifiersFollow-the-sunLight guide

The invention discloses a large-caliber reflection-type light guide machine and a working method thereof, belonging to the technical field of solar energy application. The large-caliber reflection-type light guide machine consists of an azimuth angle drive device, a height angle drive device, a focus lens group, a sun location system, a focusing device and an optical fiber beam. The focusing device is used for adjusting a receiving end surface of the optical fiber beam to a focal point of the focus lens group, and the focus lens group is driven by the azimuth angle drive device and the height angle drive device, so that the focus lens group can follow the sun, the infrared ray in the incidence light is eliminated by utilizing a filter lens of the focus lens group, and the uniformity of the intensity of the focus spot can be realized by virtue of a light homogenizing cavity of the focus lens group; the sun location system adopts a photosensitive element to provide a sun roughly location signal and utilizes a high temperature sensor to provide a precise position signal of the focus spot. By adopting the large-caliber reflection-type light guide machine, the infrared ray in the sun focus light is eliminated, the uniformity of the intensity of the focal spot can be realized, the service life of the optical fiber beam can be greatly prolonged, and the position detection reliability of the focus spot can be improved by utilizing the high temperature sensor.

Owner:宋记锋

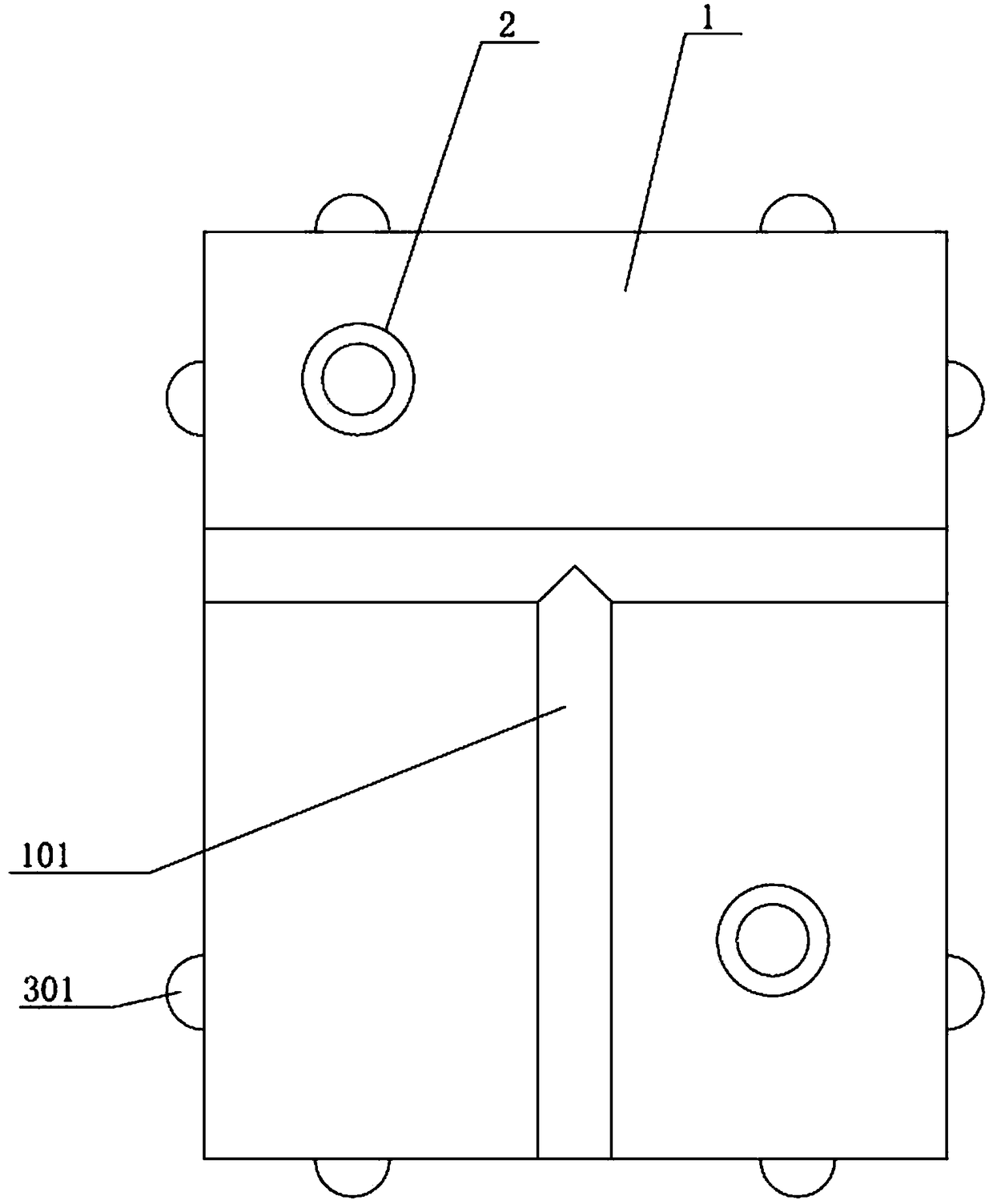

Shape correcting device

PendingCN113102561ASolve the size problemImprove pass rateMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

Owner:SHANXI FENXI HEAVY IND

A kind of vertical stack package chip and preparation method thereof

ActiveCN110335858BSolve the size problemRealize interconnection communicationSemiconductor/solid-state device detailsSolid-state devicesThree-dimensional spaceEngineering

A vertical stack package chip comprises: a first substrate, a second substrate, ..., and an nth substrate, wherein n>1; and a plurality of connectors interconnecting the adjacent substrates, the connectors being connection pins or flexible boards, the hollow space between the adjacent substrates being adjusted by controlling the depth of the connectors placed in the substrates, or the height of the connectors. The vertical stack package chip solves the technical problem of space limitation of the original chip structure, fully utilizes the three-dimensional space of the substrate, achieves interconnection communication among multiple layers of substrates and improves the flexibility of the chip structure.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

A cable three-coordinate axis positioning tool

ActiveCN109015481BSolve the size problemImprove assembly efficiencyLine/current collector detailsWork holdersBoard footEngineering

The invention relates to a cable three-coordinate-axis positioning tool, and belongs to the technical field of mechanical assembly. The cable three-coordinate-axis positioning tool comprises an X-axiscoordinate positioning guide rail (1), a Y-axis coordinate positioning guide rail (2), a moving positioning module (4), Z-axis coordinate positioning guide rails (5), a U-shaped mounting module (6),a Z-axis coordinate plane (7) and a base (8). Compared with an original mode of correspondingly measuring the size of cables by using a board foot, the advantages of high assembly efficiency, reducedassembly difficulty, good assembly consistency, avoidance of cable contact pin shrinkage, device cost saving and labor cost saving are achieved.

Owner:XIAN FLIGHT SELF CONTROL INST OF AVIC

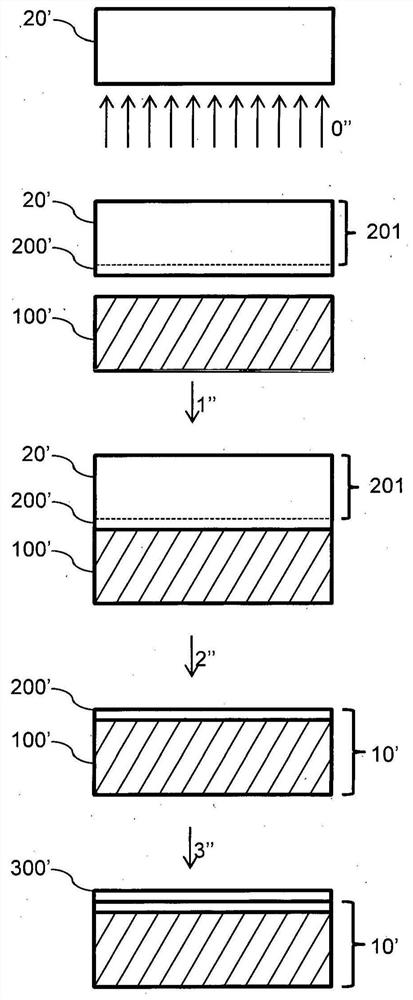

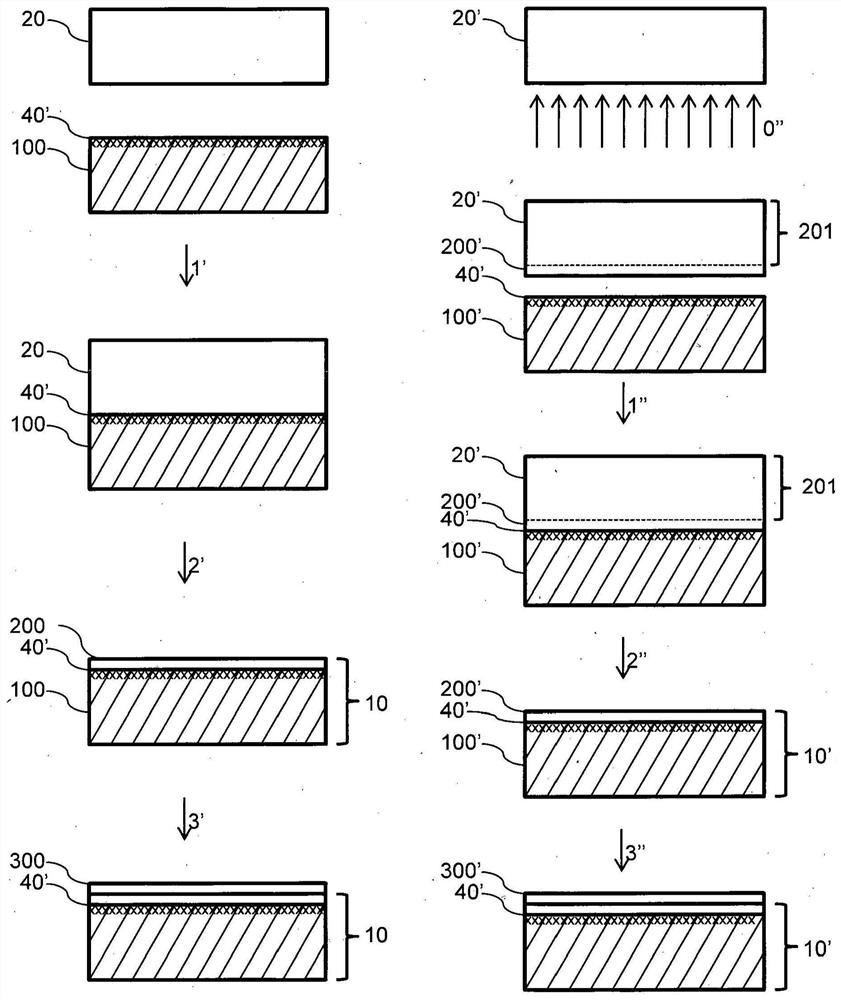

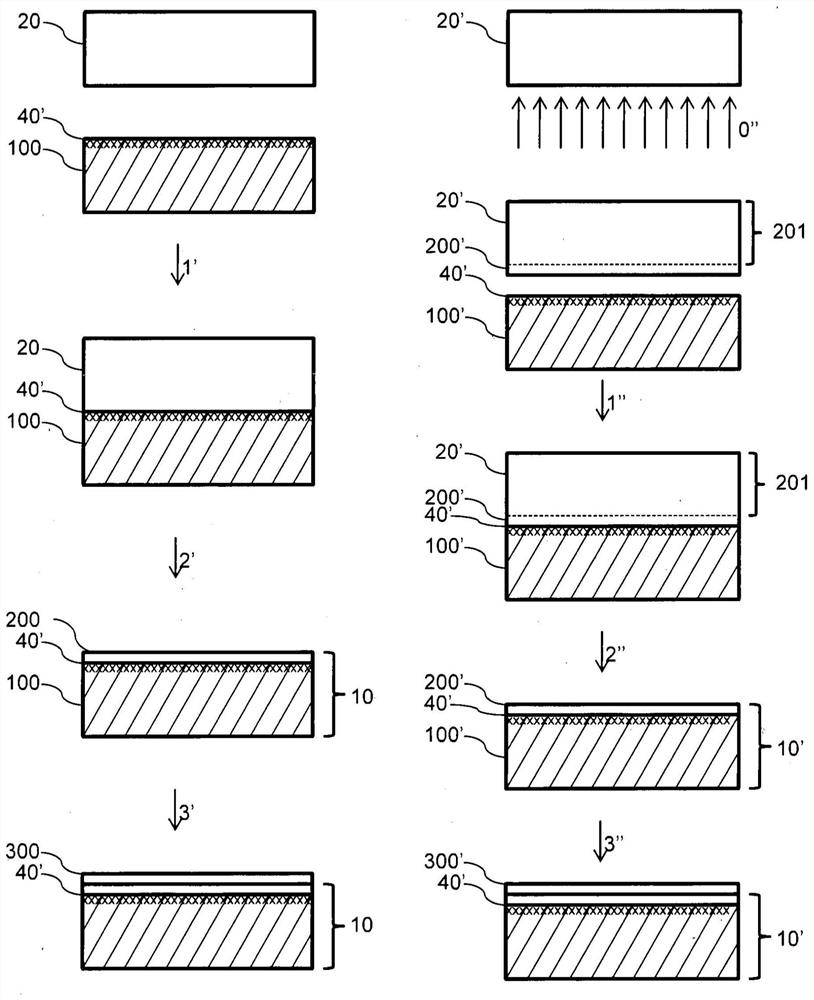

Method for producing a single-crystal film of ALN material and substrate for the epitaxial growth of a single-crystal film of ALN mataleri

PendingCN111902571ASolve the size problemPolycrystalline material growthAfter-treatment detailsSingle crystalCondensed matter physics

Owner:SOITEC SA

Scissors

InactiveCN104290105ASolve the size problemImprove work efficiencyMetal working apparatusEngineeringRivet

The invention relates to scissors, in particular to further improvement of scissors. The scissors comprise scissor blades, a rivet and scissor handles. The scissor blades and the scissor handles are connected through the rivet, and scale marks are arranged on the scissor blades. The scissors are convenient and simple to use and convenient to carry, and is mainly used for clipping occasions where specific dimensions are needed.

Owner:韦会松

Drive unit modular stick-slip drive positioning platform

ActiveCN104864230BSimple structureCompact structureNanostructure manufacturePiezoelectric/electrostriction/magnetostriction machinesModularityDriven element

Owner:JIANGSU JICUI MICRO NANO AUTOMATION SYST & EQUIP TECH RES INST CO LTD

Method for manufacturing monocrystalline layer of GaAs material and substrate for epitaxial growth of a monocrystalline layer of GaAs material

PendingCN111954730ASolve the size problemPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalCondensed matter physics

The invention relates to a method for manufacturing a monocrystalline layer of GaAs material comprising the transfer of a monocrystalline seed of SrTiO3 material onto a support substrate of silicon material followed by epitaxial growth of a monocrystalline layer of GaAs material.

Owner:SOITEC SA

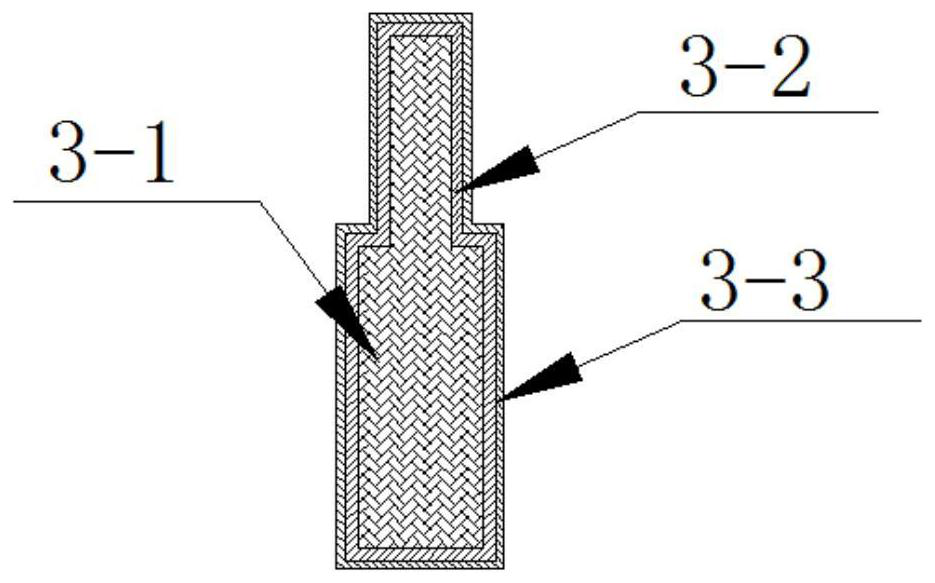

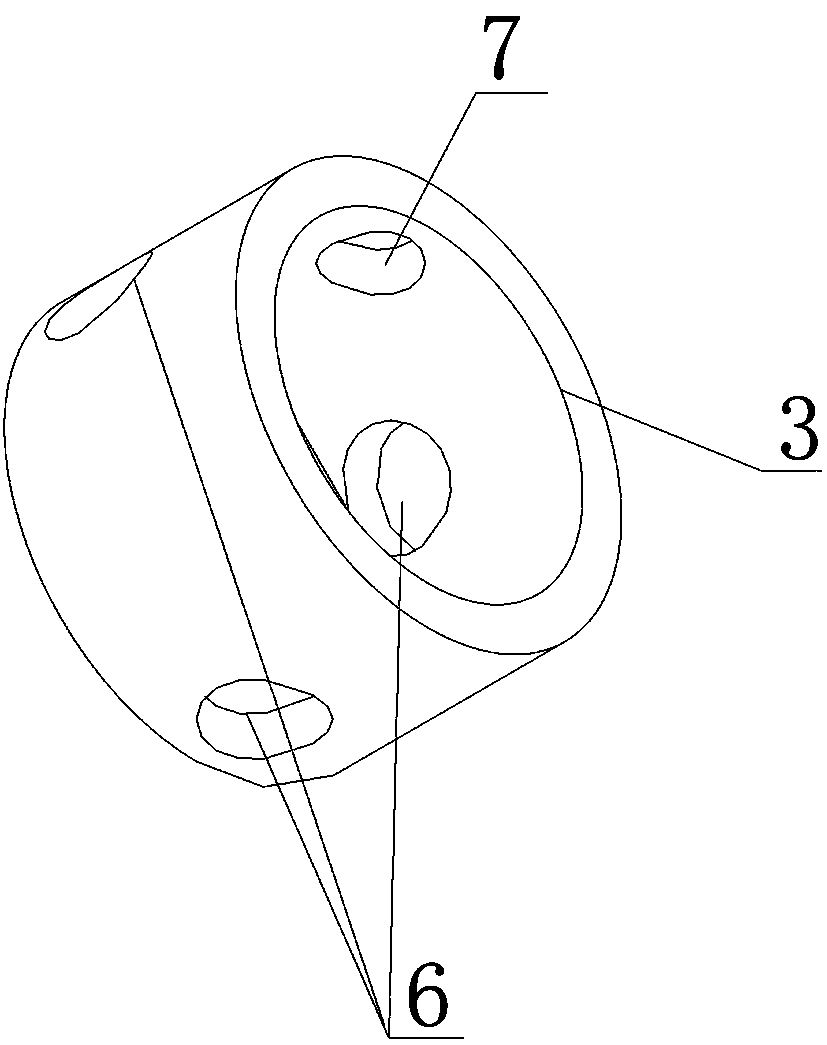

Soft claw mandrel adjuster

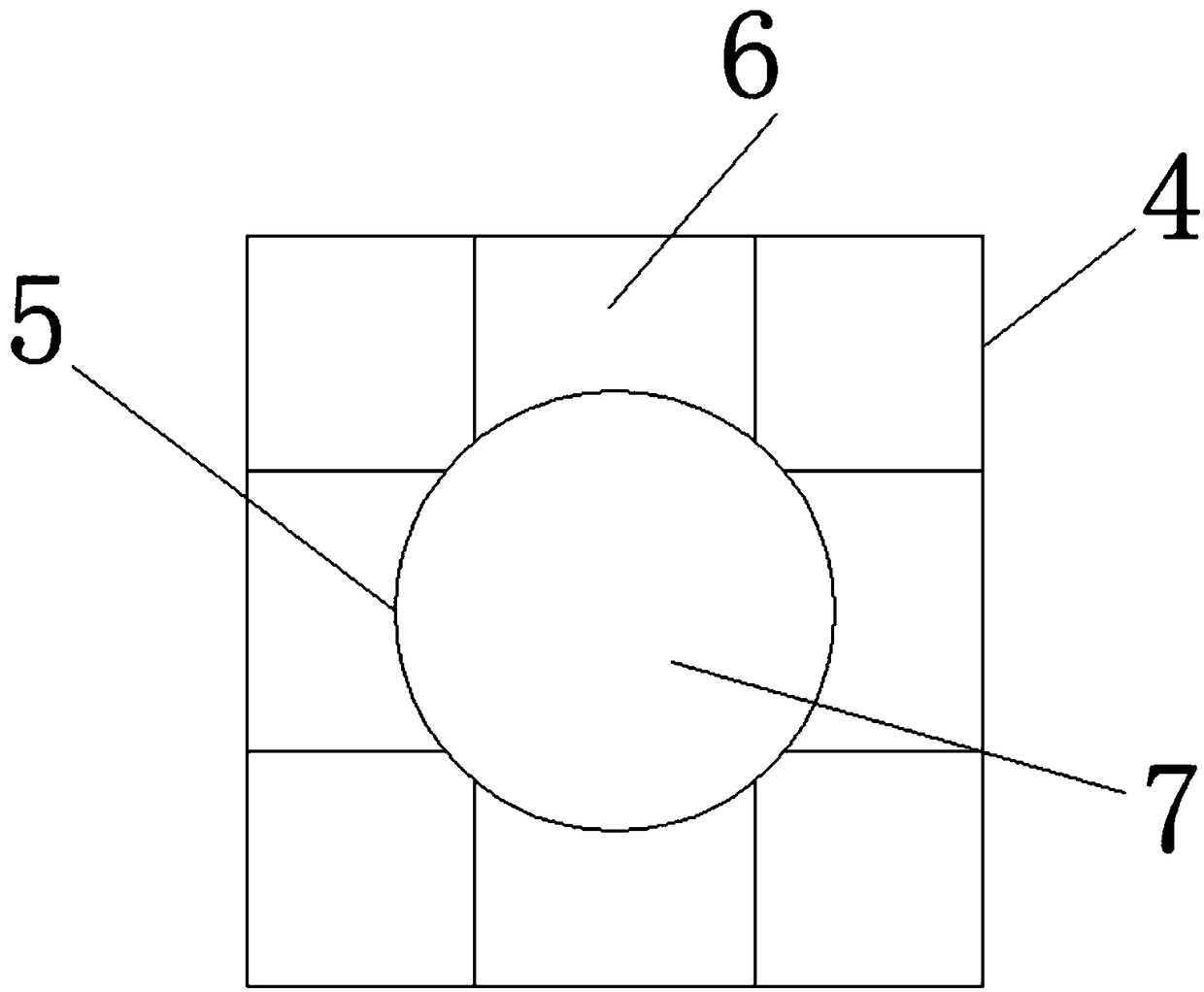

ActiveCN109128234ASolve the size problemAvoid managementChucksPositioning apparatusImpellerIsoetes triquetra

The invention discloses a soft claw mandrel adjuster. The soft claw mandrel adjuster comprises a supporting adjuster, a locking screw (1), a supporting rod (2) and a barrel body (3), one end of the barrel body (3) is closed, the other end of the barrel body (3) is provided with a cylindrical cavity (4), the closed end of the barrel body (3) is provided with a through hole (5) communicating with the cylindrical cavity (4), the cylindrical surface of the barrel body (3) is uniformly provided with three guide holes (6) communicating with the cylindrical cavity (4) in the circumferential directionof the cylindrical surface, the cylindrical surface of the barrel body (3) is further provided with a threaded hole (7) communicating with the cylindrical cavity (4), the supporting adjuster comprises a rotating shaft (8), an impeller (9) and a guide wheel (10), and the impeller (9) is composed of three blades which are in an equilateral triangle and fixedly arranged on one end face of the guidewheel (10). The soft claw mandrel adjuster has the beneficial effects that the structure is compact, the use is convenient, the size can be adjusted, the production preparation time can be shortened,and customized management can be facilitated.

Owner:CHENGDU HOLY AVIATION SCI & TECH CO LTD

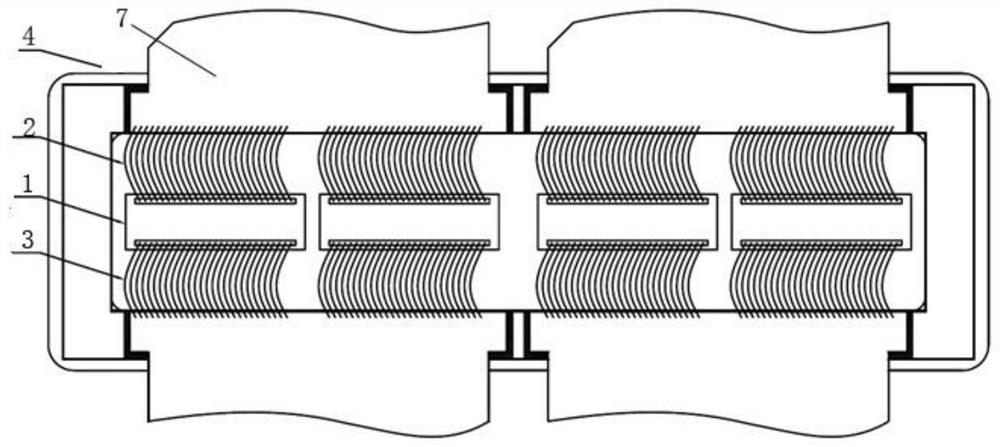

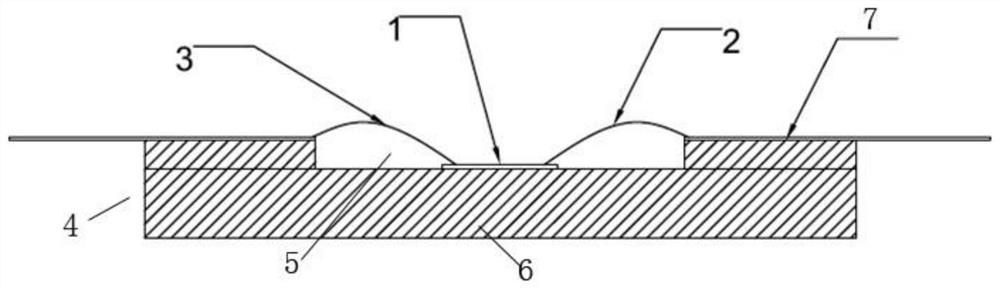

Vertical closed iron yoke end ring for transformer and manufacturing method thereof

ActiveCN112802670BConsistent forceImprove adhesionTransformers/inductances coils/windings/connectionsCoils manufactureCardboardTransformer

The invention provides a vertical closed iron yoke end ring for a transformer and a manufacturing method thereof. The end ring includes an outer closed tube, an inner tube with more than two layers arranged in the outer closed tube, and an inner tube for bonding between layers. layer of glue. The method includes ①calculating the unfolded perimeter of the outer closed tube and each inner tube; ②making the outer closed tube; ③adding 1 mm length cutting to the cardboard of each inner tube on the basis of the theoretically calculated perimeter; ④ Spread the glue layer on the inner end surface of the outer closed tube; ⑤Set the outermost inner tube in the outer closed tube; ⑥In the same way, set the remaining inner tubes sequentially from outside to inside; After the inner layer tube of the first layer is set, a support made of cardboard that is in close contact with the inner wall of the inner layer tube located on the innermost layer is set; ⑧The product is put into the oven for regular drying, and the support made of cardboard is taken out after completion. The invention can reduce the manufacturing cost of the end ring, shorten the manufacturing period and improve the electrical performance of the end ring.

Owner:常州市英中电气有限公司

Method for producing a monocrystalline layer of an LNO material and substrate for epitaxial growth of a monocrystalline layer of an LNO material

PendingCN111902572ASolve the size problemPolycrystalline material growthAfter-treatment detailsSingle crystalCondensed matter physics

The invention relates to a method for producing a monocrystalline layer of an LNO material, comprising the transfer of a monocrystalline seed layer of a YSZ material to a support substrate of a silicon material followed by epitaxial growth of the monocrystalline layer of LNO material.

Owner:SOITEC SA

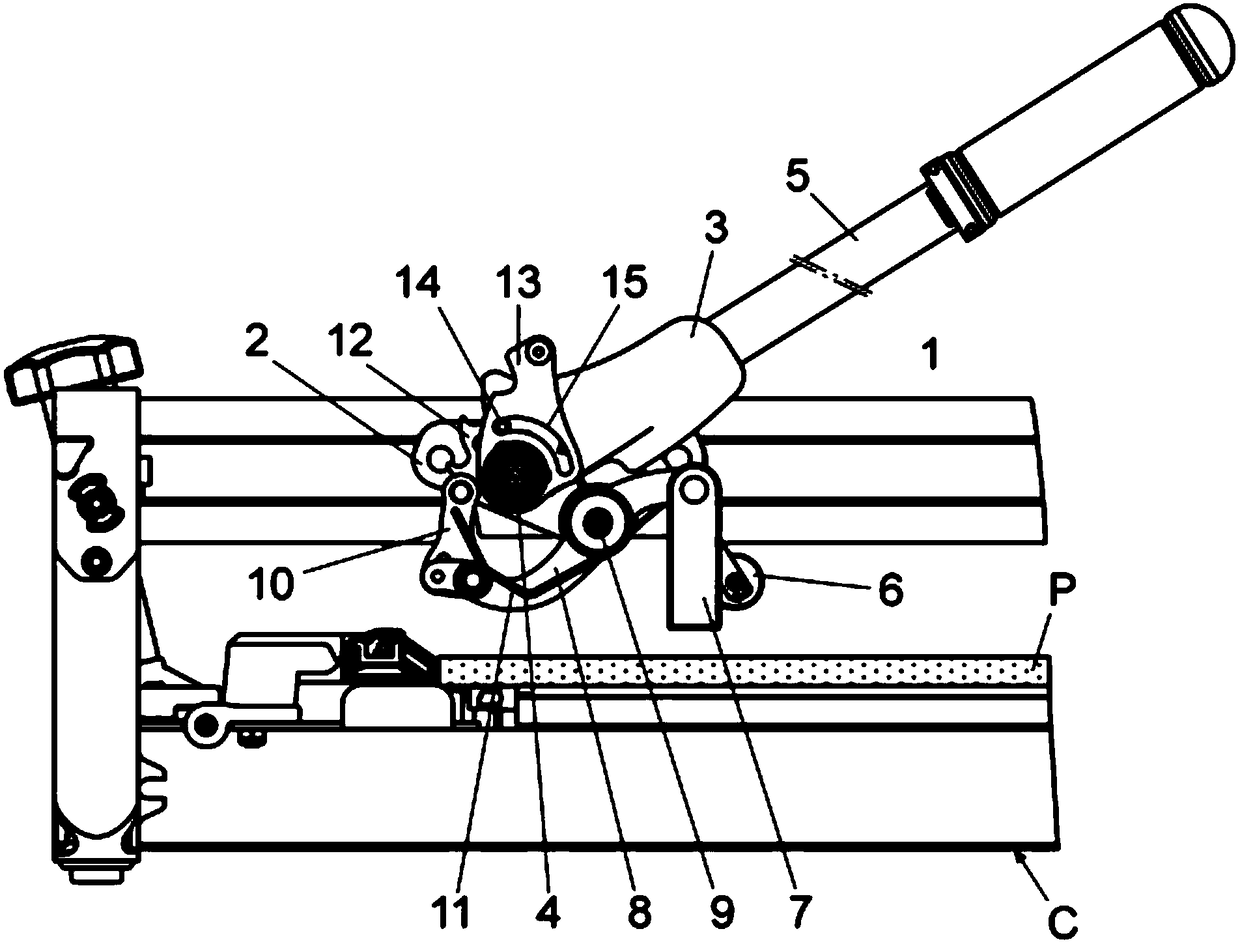

Cutting and separation head for manual ceramic cutters

The invention relates to a cutting and separation head for manual ceramic cutters, comprising: a body (3) that carries a grip handle (5) and a cutting tool (6), is mounted on movable supports (2) on longitudinal guides of the cutter (C), and is able to rotate with respect to a first transverse rotary shaft (4); a separator provided with a foot (7), a class 1 lever (8), and a first coupling element (10) in the separator that is couplable to a second coupling element (12) in the body (3) of the head (1); and a cam (13) for releasing the first and second coupling elements (10, 12), the cam being mounted on the body (3) and relatively rotatable between a first position and a second position.

Owner:GERMANS BOADA SA

A cutting and separating head of a manual ceramic cutting machine

The invention relates to a cutting and separating head of a manual ceramic cutting machine, comprising a main body (3) provided with a handle (5) and a knife (6) mounted on a movable support (2), which The part (2) is installed on the longitudinal guide rail of the cutting machine (C), and the main body (3) can rotate relative to a first transverse rotation axis (4); a separator with a foot (7), a stage 1 Lever (8), and a first coupling (10) arranged on the separator with a second coupling (10) arranged on the body (3) of the cutting and separating head (1) part (12) coupling; and a cam (13), which is used to release the first coupling part (10) and the second coupling part (12), the cam is installed on the main body (3), it can be in a first Rotate between a first position and a second position.

Owner:GERMANS BOADA SA

A method of using cold wax block and ceramic core for wax mold pressing at the same time

ActiveCN106734885BGood size controlPlay a protective effectFoundry mouldsFoundry coresWaxMaterials science

The invention relates to a method for simultaneously using a cold wax block and a ceramic core for wax mold pressing. According to the method for simultaneously using the cold wax block and the ceramic core for the wax mold pressing, the cold wax block is divided into an upper mold cold wax block body and a lower mold cold wax block body so that the complex structure of the whole mold design of the cold wax block can be avoided, the manufacturing cost can be reduced, and the size and the shape of the cold wax block can be controlled conveniently; the upper mold cold wax block body and the lower mold cold wax block body play a role in protecting the ceramic core so that problems that the ceramic core is deviated and broken due to direct strong impact of liquid wax in the wax pressing process can be avoided, and meanwhile, the upper mold cold wax block body and the lower die cold wax block body are used so as to protect the ceramic core against breakage caused by the cooling shrinkage of the liquid wax; the ceramic core is placed between the upper mold cold wax block body and the lower mold cold wax block body so that the ceramic core can be placed and positioned in a wax mold conveniently; and meanwhile, an inner cavity of a required part can be obtained, and the size problem of the thicker and larger part of the wax mold caused by large shrinkage quantity of the liquid wax can be solved.

Owner:江苏永瀚特种合金技术股份有限公司

Method and device for adjusting transmission of surface plasma polarized wave on graphene

ActiveCN102681214BLower breakdown voltageRefractive index range limitNon-linear opticsSurface plasmonSilicon oxide

The invention provides a method for adjusting the transmission of a surface plasma polarized wave on the graphene, which comprises the following steps: arranging a silicon-oxide or alumina cone on the graphene, wherein the a substrate for supporting the graphene is arranged below the graphene; putting the graphene with the substrate and the silicon-oxide or alumina cone on the graphene in air; and inputting the spherical wave into the graphene, and converting the spherical wave into the plane wave under the joint action of the silicon-oxide or alumina cone and the graphene. The invention further provides a device for adjusting the transmission of the surface plasma polarized wave on the graphene, which comprises the grapheme and the substrate for supporting the grapheme, wherein the upper surface of the grapheme is provided with the alumina cone and a silicon-oxide dielectric layer is arranged on the alumina cone, or the upper surface of the grapheme is provided with the silicon-oxide cone and an alumina dielectric layer is arranged on the silicon-oxide cone.

Owner:SOUTHEAST UNIV

A Bevel Cutting Method of Smaller Size Silicon Block

InactiveCN104400919BSolve the size problemReduce scrap rateFine working devicesBorder lineRejection rate

The invention discloses a manner for beveling a silicon block of the small size. The manner comprises the following steps: firstly, the silicon block required to be beveled is selected, and the side length of the small side of the silicon block is measured and recorded; secondly, according to the side length of the small side of the silicon block, the bonding opposite position of a crystal holder and a glass plate is calculated; thirdly, according to data obtained by calculation, a crystal holder border line is drawn on the glass plate, and according to the crystal holder border line, the crystal holder is bonded on the glass plate; fourthly, the silicon block is bonded on the glass plate; and fifthly, the silicon block is fixed, and then can be cut, wherein the cutting line is parallel to the short side of the crystal holder. According to the manner, through beveling, the size problem of the small silicon block can be effectively solved; the rejection rate of the silicon block of the small size can be reduced to the greatest extent, and the cyclic utilization rate of the silicon block is improved; and the production cost is reduced.

Owner:TIANWEI NEW ENERGY HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com