Continuous Teflon press for thermoplastic composite material

A technology of Teflon presses and composite materials, applied in lamination, lamination devices, lamination auxiliary operations, etc., can solve the problems that the thickness of rubber and plastic materials cannot be effectively guaranteed, and the thickness of slabs cannot be effectively guaranteed, so as to achieve production The effect of fast efficiency and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

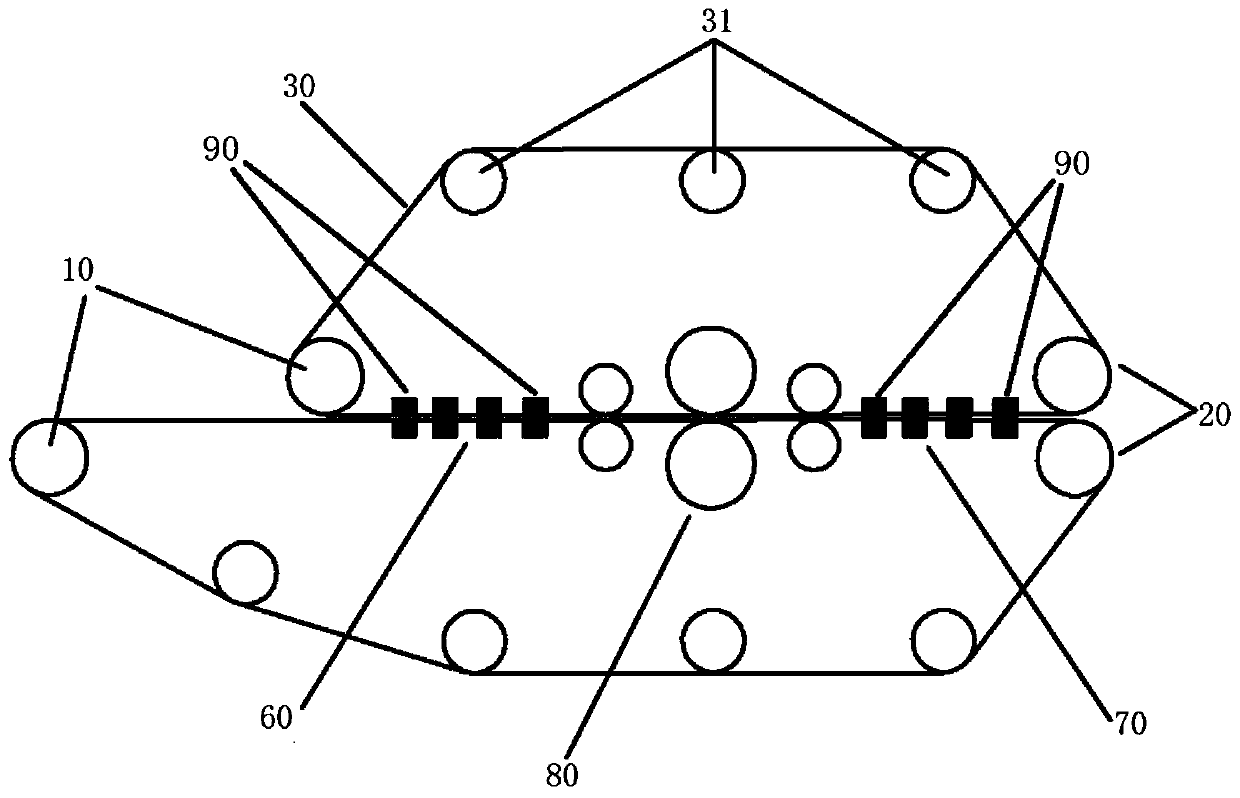

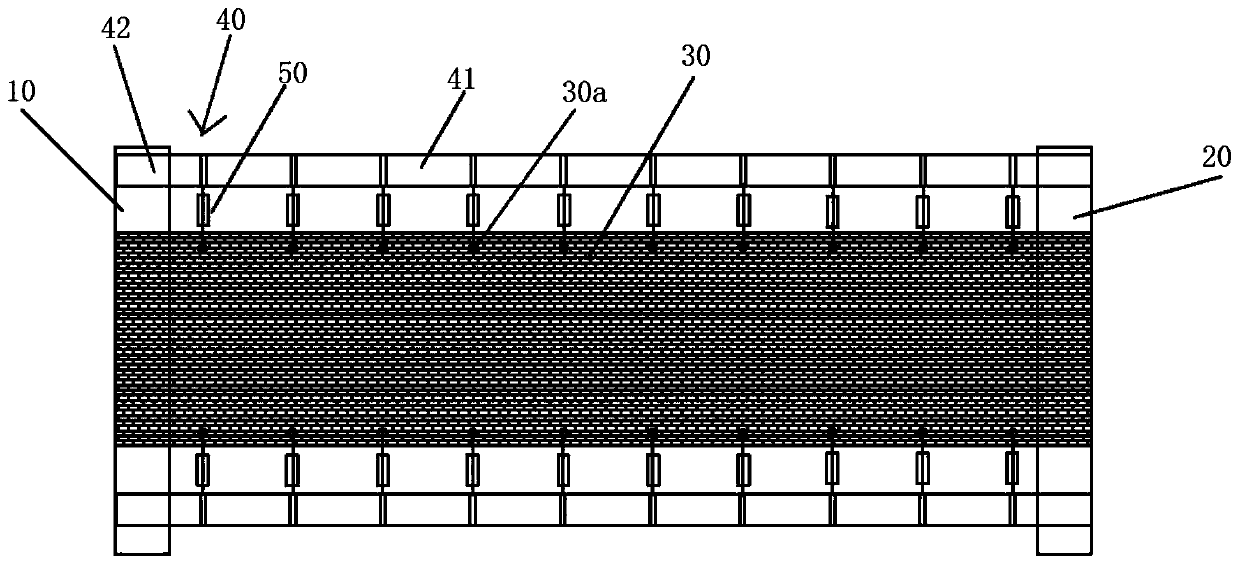

[0021] see Figure 1 to Figure 4 A continuous Teflon press for thermoplastic composite materials is shown, including a frame (not shown in the figure). A group of driving rollers 10 and tensioning rollers 20 arranged up and down and a Teflon conveyor belt 30 covered on the driving rollers 10 and tensioning rollers 20 are respectively arranged on the frame, and there are two Teflon conveyor belts 30 Ring-shaped Teflon conveyor belt, Teflon conveyor belt 30 is prepared by impregnating high-performance glass fiber cloth with Teflon emulsion, the thickness of Teflon conveyor belt 30 is 0.4-0.6mm, and the structure of Teflon conveyor belt 30 The zigzag seam makes the Teflon conveyor belt 30 temperature resistant up to 300°C.

[0022] The diameters of the driving roller 10 and the tens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com