A cutting and separating head of a manual ceramic cutting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

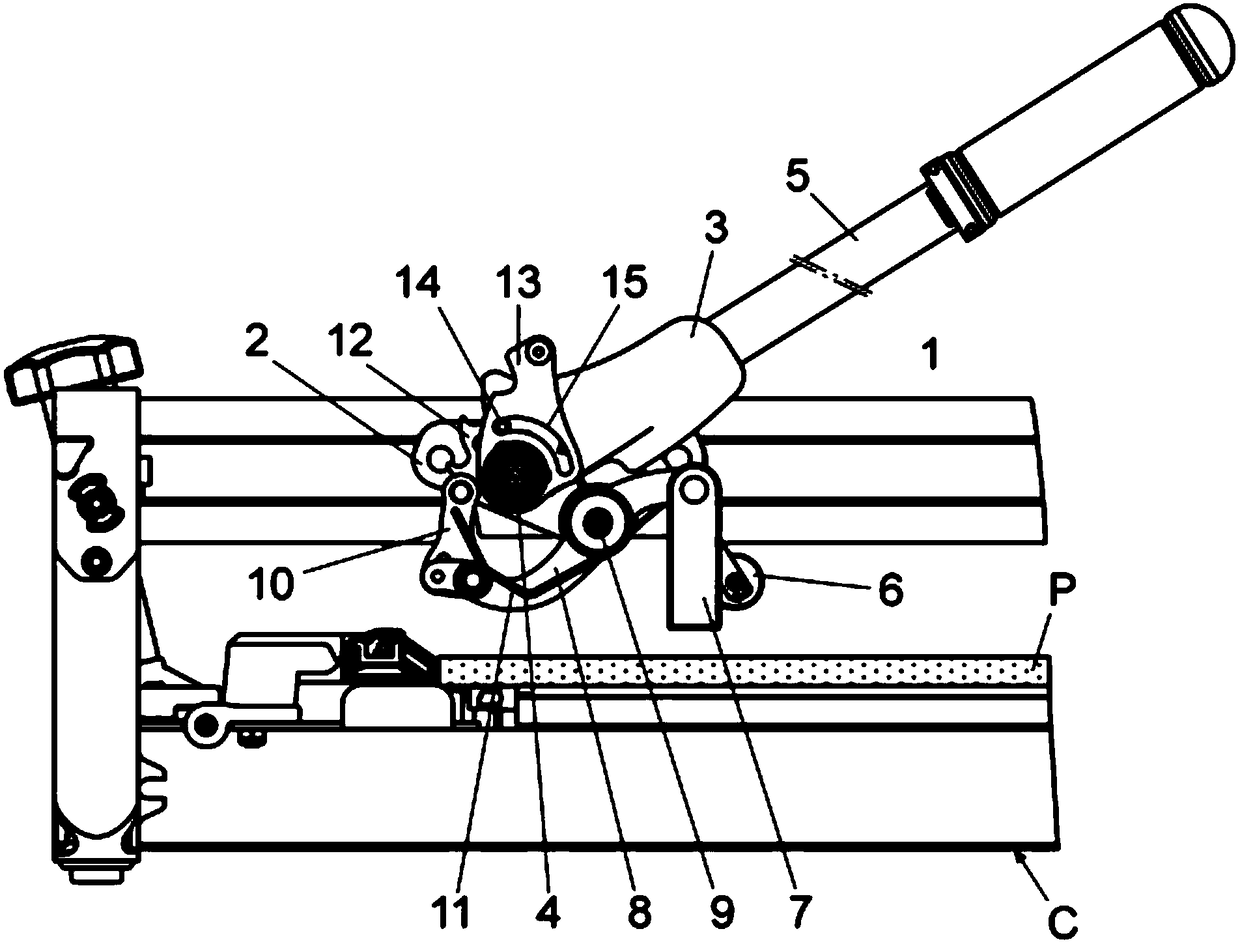

[0028] see figure 1 , which shows a cutting and separating head 1 for ceramic parts in an embodiment, which is installed on a manual ceramic cutting machine C, which can be moved above the cutting machine by longitudinal guide rails arranged in parallel.

[0029] see figure 2 , which shows a cutting and separating head 1 in an embodiment, which includes a support 2 arranged on both sides thereof and a main body 3 mounted on the support 2, in this embodiment, the support is provided with a rotating Wheels are used to move it on the guide rail of the cutting machine, and the main body is rotatable relative to a first transverse rotation axis 4 . A handle 5 is secured at the first end of the body 3 .

[0030] From Figures 3 to 7 It can be seen more clearly that the lower end of the main body 3 is provided with a cutter 6, which is used for longitudinally cutting the ceramic piece placed at the bottom of the cutting machine, so as to carve a cutting line on the ceramic piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com