A method of using cold wax block and ceramic core for wax mold pressing at the same time

A technology for ceramic cores and wax blocks, applied in the directions of cores, molds, mold components, etc., can solve the problems of insufficient core support, fracturing of ceramic cores, position deviation, etc., and is conducive to placement. and positioning, solving size problems, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

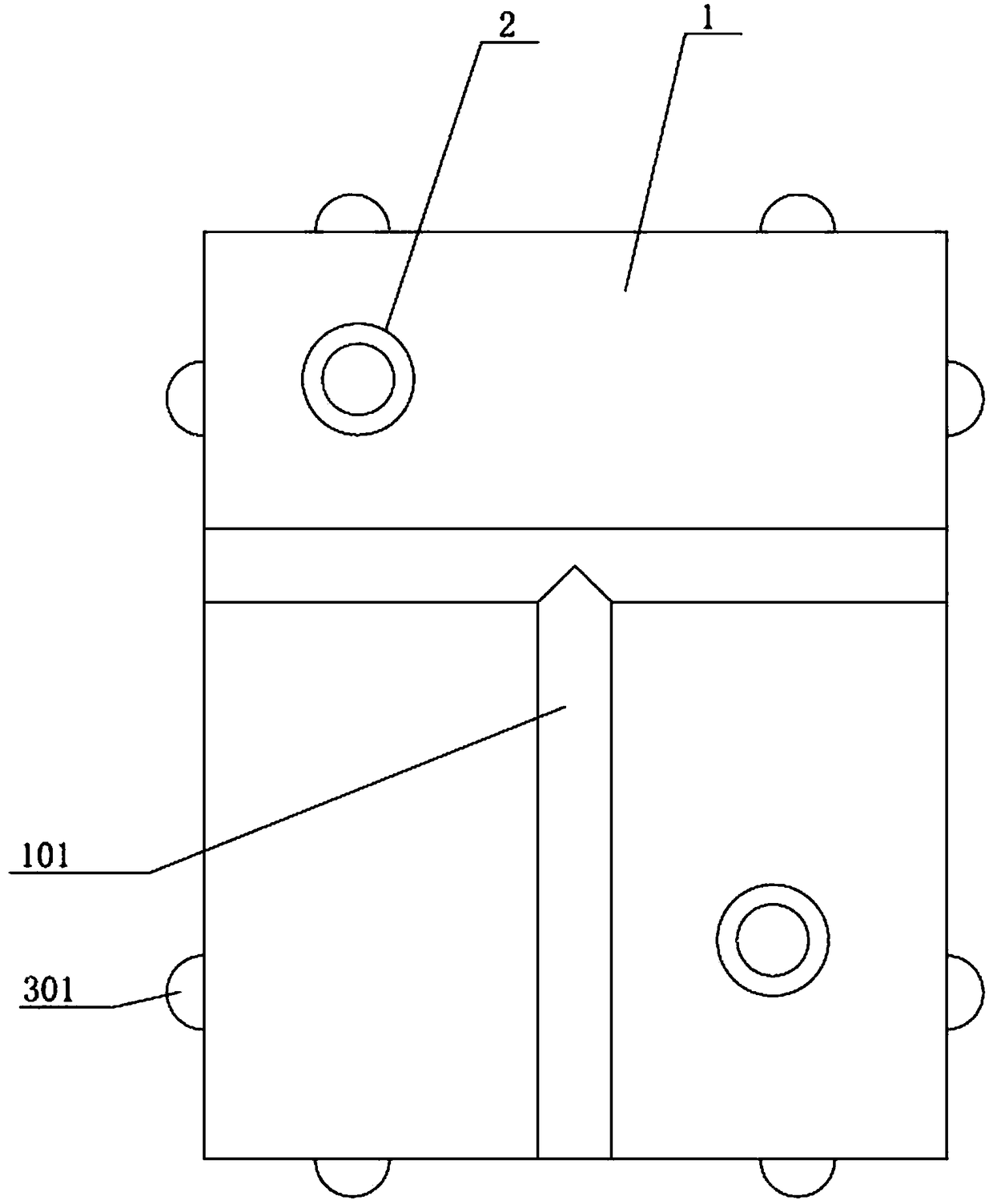

[0036] The method that the cold wax block and the ceramic core are used for wax mold pressing in the present embodiment comprises the following steps: figure 1 , figure 2 As shown, the first step: the lower mold cold wax block 1 and the upper mold cold wax block 3 are respectively pressed by the wax press machine through the cold wax block mold, and then the pressed lower mold cold wax block 1 and the upper mold cold wax block are pressed 3 Place them in the shaper to cool for 8 hours; in this step, the wax press machine adopts a 50-ton MPI wax press machine. The temperature of the upper and lower templates of the wax press machine is 20°C, the temperature of the wax tank is 75°C, and the wax injection temperature is 52°C. ℃, the pressure of the wax press is 8bar, the flow rate is 50cc / sec, the filling time is 30s, and the holding time is 60s.

[0037] The second step: if image 3 As shown, prepare the ceramic core 4 that needs to be put into the cooling wax block of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com