Driving unit modularization stick-slip driving positioning platform

A technology of drive unit and positioning platform, which is applied in the direction of machine/bracket, supporting machine, mechanical equipment, etc., and can solve the problems of increasing the size of the micro-positioning platform, increasing the difficulty of assembly, and limiting the application range of the micro-positioning platform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

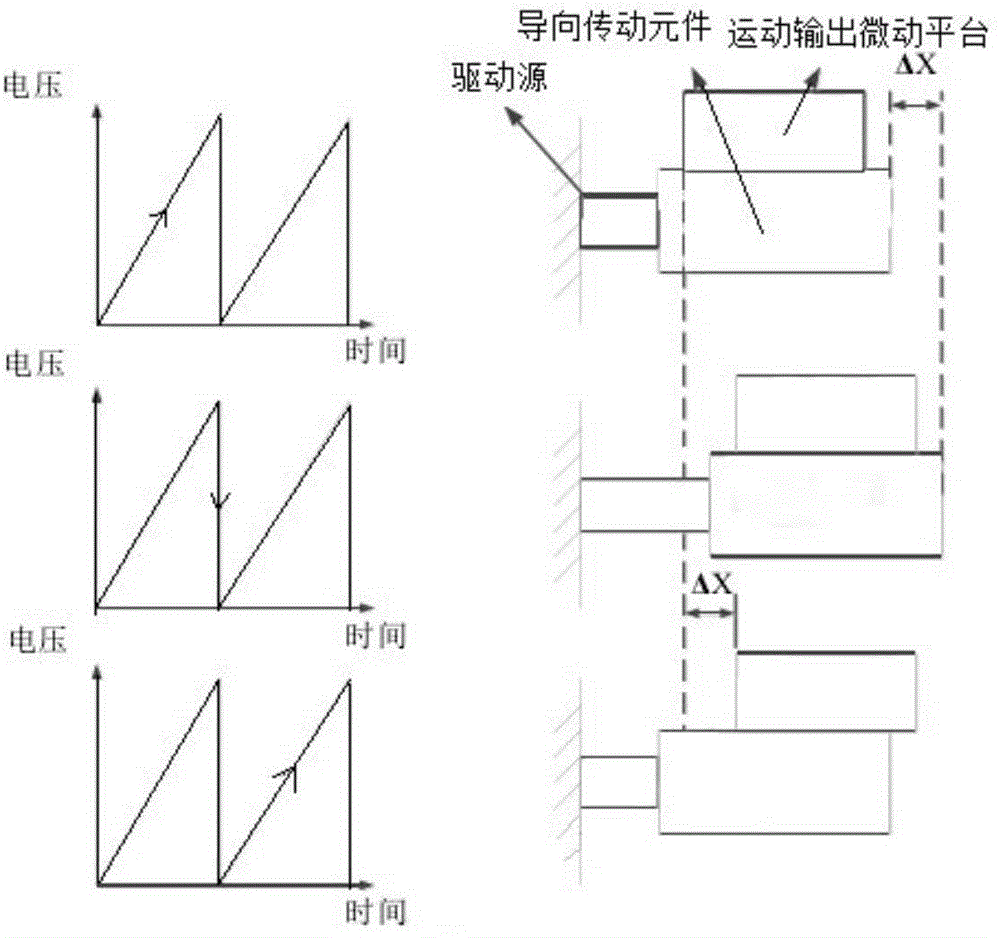

[0029] As mentioned in the background technology, the micro-positioning platform based on the principle of stick-slip uses a flexible hinge as the guiding transmission element and a piezoelectric ceramic actuator as the driving source. It has high resolution, high positioning accuracy, small size, no lubrication, and a structure Simple and reliable, high rigidity, low energy consumption, fast response and other advantages, gradually being widely used.

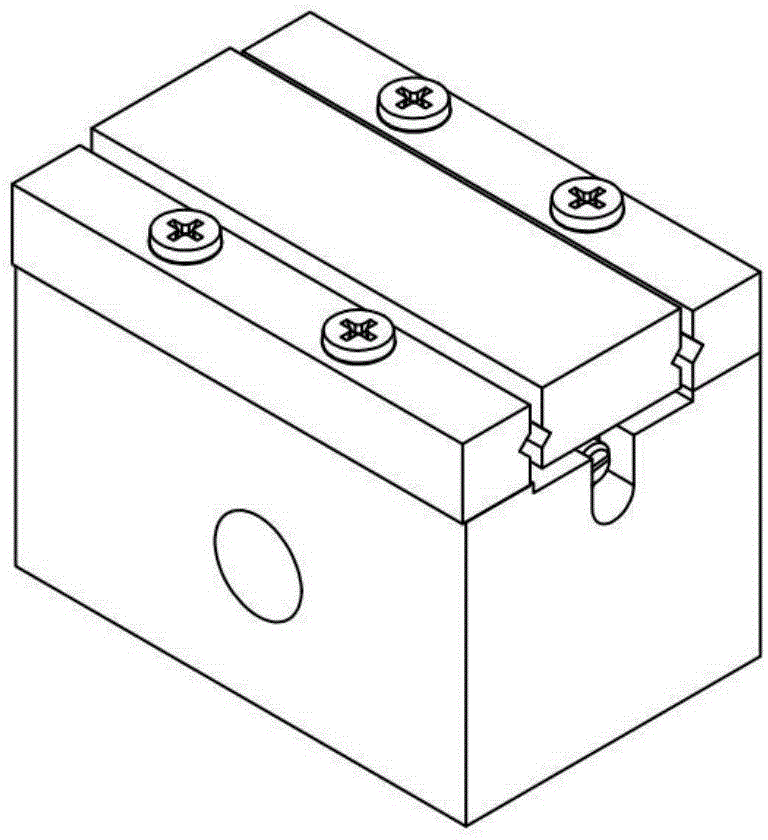

[0030] The invention discloses a drive unit modular stick-slip drive positioning platform, which comprises a motion output micro-motion platform, a platform base and a drive unit module arranged inside the platform base, and the drive unit module includes a module frame and is arranged in the module frame The guide transmission element and the driving source connected to the upper end of the guide transmission element, the guide transmission element is a flexible hinge, the top of the upper end of the guide transmission element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com