Method for producing a single-crystal film of ALN material and substrate for the epitaxial growth of a single-crystal film of ALN mataleri

A technology of epitaxial growth and single crystal layer, which is applied in the directions of single crystal growth, single crystal growth, polycrystalline material growth, etc., and can solve the problem of not being able to obtain single crystal substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

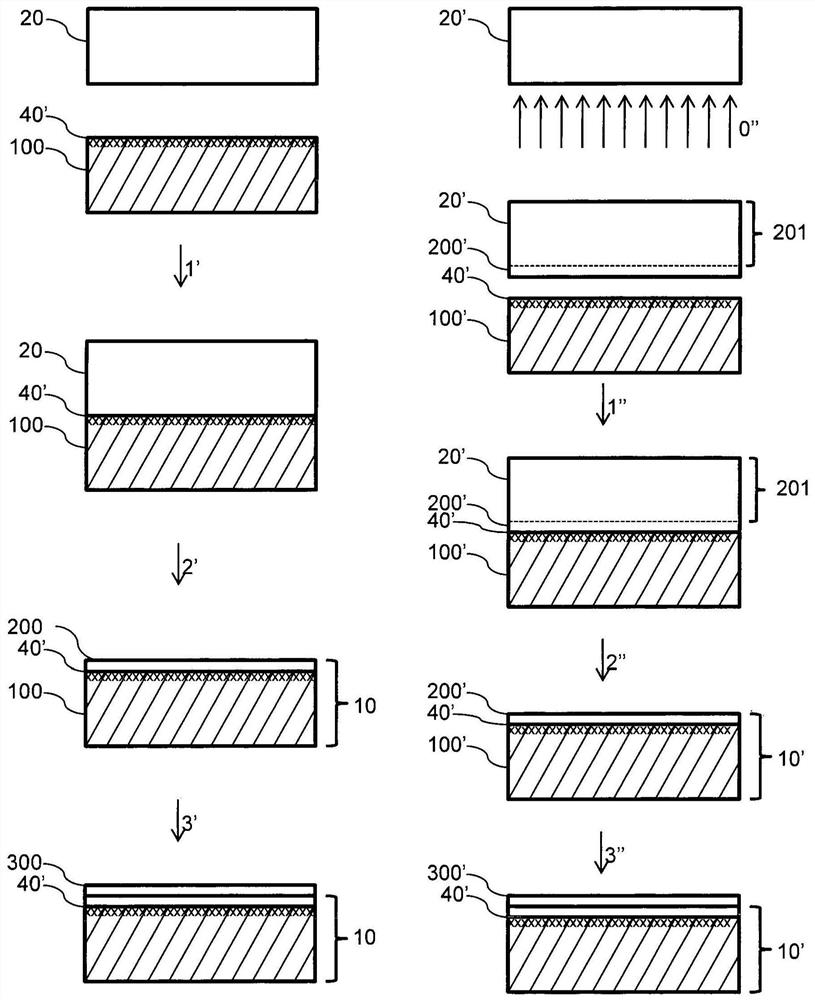

[0026] figure 1 A carrier substrate 100 of silicon material is shown, onto which a single crystal seed layer 200 of SiC-6H material is transferred. The carrier substrate 100 made of silicon material can also be replaced with the carrier substrate 100 made of sapphire material. The advantage of using silicon is that it not only opens up the application field of AlN material film for 300mm type large-scale equipment, but also makes it compatible with the microelectronics industry. For the microelectronics industry, foreign materials other than silicon, Especially AlN has high requirements in terms of acceptance. The step of bonding the single crystal seed layer 200 of SiC-6H material to the carrier substrate 100 of silicon material is preferably performed by a molecular adhesion step. The molecular adhesion step includes a bonding step, preferably performed at ambient temperature, followed by annealing to consolidate the bonding interface, which is usually performed at a high te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com