Method for manufacturing high-conductivity conductive plastic bipolar plate for vanadium cell

A technology of conductive plastics and high conductivity, which is applied in the direction of battery electrodes, circuits, electrical components, etc. It can solve the problems of difficulty in ensuring the uniformity of material mixing and the difficulty of manual operation in large batches, etc. It is easy to achieve large-area continuous processing , strong continuous processing and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

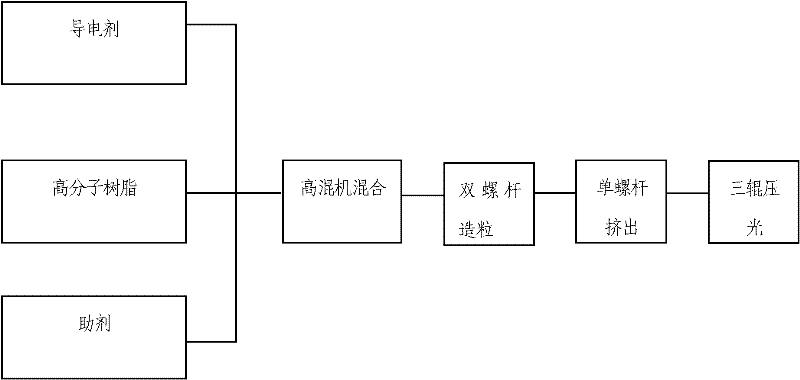

Method used

Image

Examples

Embodiment 1

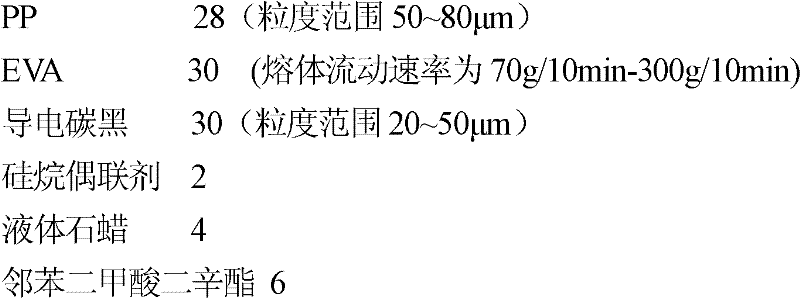

[0039] The high conductivity bipolar plates for vanadium batteries use conductive plastic materials. The quality of the materials is as follows:

[0040]

[0041] Firstly, spray the titanate coupling agent diluted with liquid paraffin into the conductive carbon black under high-speed mixing (the mixer speed is 500 rpm), and stir for 5 minutes; the total mass of the above raw materials is 100g, In the mixer, the stirring speed is 800 rpm for 20 minutes. Then it is pelletized by twin screw, the pellets are added to a single screw, extruded at 190℃~210℃, the screw speed is 220r.min -1 , The twin-screw extruder adopts a two-stage side feeding method.

[0042] The volume resistivity of the prepared conductive bipolar (current collecting) plate is 0.5Ω·cm. As the positive and negative current collectors of the vanadium battery, the battery charge and discharge performance parameters are: Coulomb efficiency 90%, energy efficiency 72%, and voltage efficiency 80%.

Embodiment 2

[0044] The high conductivity bipolar plates for vanadium batteries use conductive plastic materials. The quality of the materials is as follows:

[0045]

[0046] First, spray the silane coupling agent diluted with liquid paraffin into the conductive carbon black under high-speed mixing (the mixer rotation speed is 500 rpm), and stir for 5 minutes; the total mass of the above-mentioned raw materials is 100g and placed in the high-speed mixer Medium, the stirring speed is 800 rpm, stirring for 20 minutes. Then it is pelletized by twin screw, the pellets are added to a single screw, and extruded at 190℃~210℃, the screw speed is 230r.min -1 , The twin-screw extruder adopts a two-stage side feeding method.

[0047] The volume resistivity of the prepared conductive bipolar (current collecting) plate is 0.5Ω·cm. As the positive and negative current collectors of vanadium batteries, the battery charging and discharging performance parameters are: Coulomb efficiency 91%, energy efficiency...

Embodiment 3

[0049] The high conductivity bipolar plates for vanadium batteries use conductive plastic materials. The quality of the materials is as follows:

[0050]

[0051]

[0052] First, spray the titanate coupling agent diluted with liquid paraffin into the conductive carbon black under high-speed mixing (the mixer speed is 500 rpm), and stir for 5 minutes; the total mass of the above raw materials is 100g, In the mixer, the stirring speed is 800 rpm for 20 minutes. Then it is pelletized by twin screw, the pellets are added to a single screw, and extruded at 190℃~210℃, the screw speed is 240r.min -1 , The twin-screw extruder adopts two-stage side feeding method.

[0053] The volume resistivity of the prepared conductive bipolar (current collecting) plate is 0.5Ω·cm. As a vanadium battery positive and negative current collector, the battery charge and discharge performance parameters are: Coulomb efficiency 91%, energy efficiency 73%, voltage efficiency 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder size | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com