Method for preparing CdSe and ZnSe quantum dot nanometer granules

A nanoparticle and quantum dot technology, which is applied in chemical instruments and methods, color-changing fluorescent materials, binary selenium/tellurium compounds, etc., can solve the problem that selenourea cannot be used in the preparation of fat-soluble quantum dots, restricting promotion and application research, and synthesis costs. High photochemical stability, excellent spectral performance, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

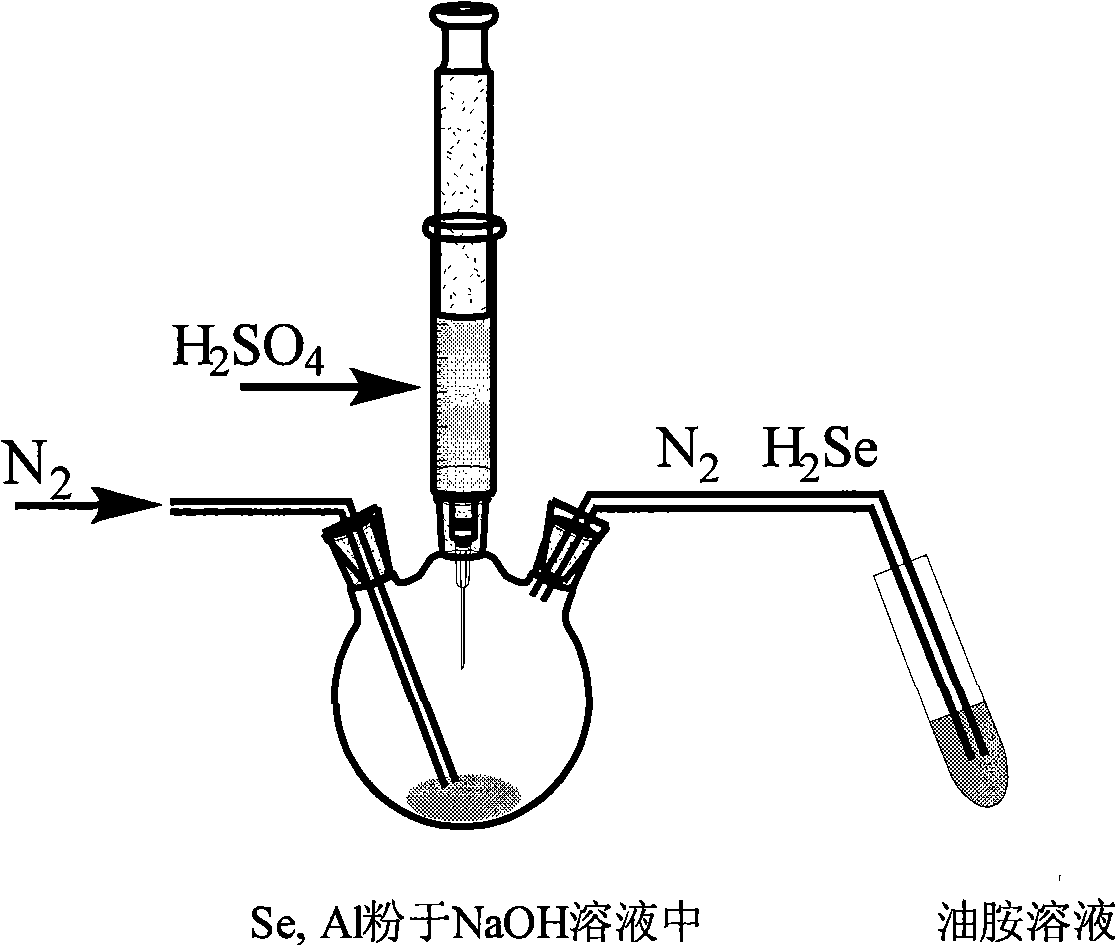

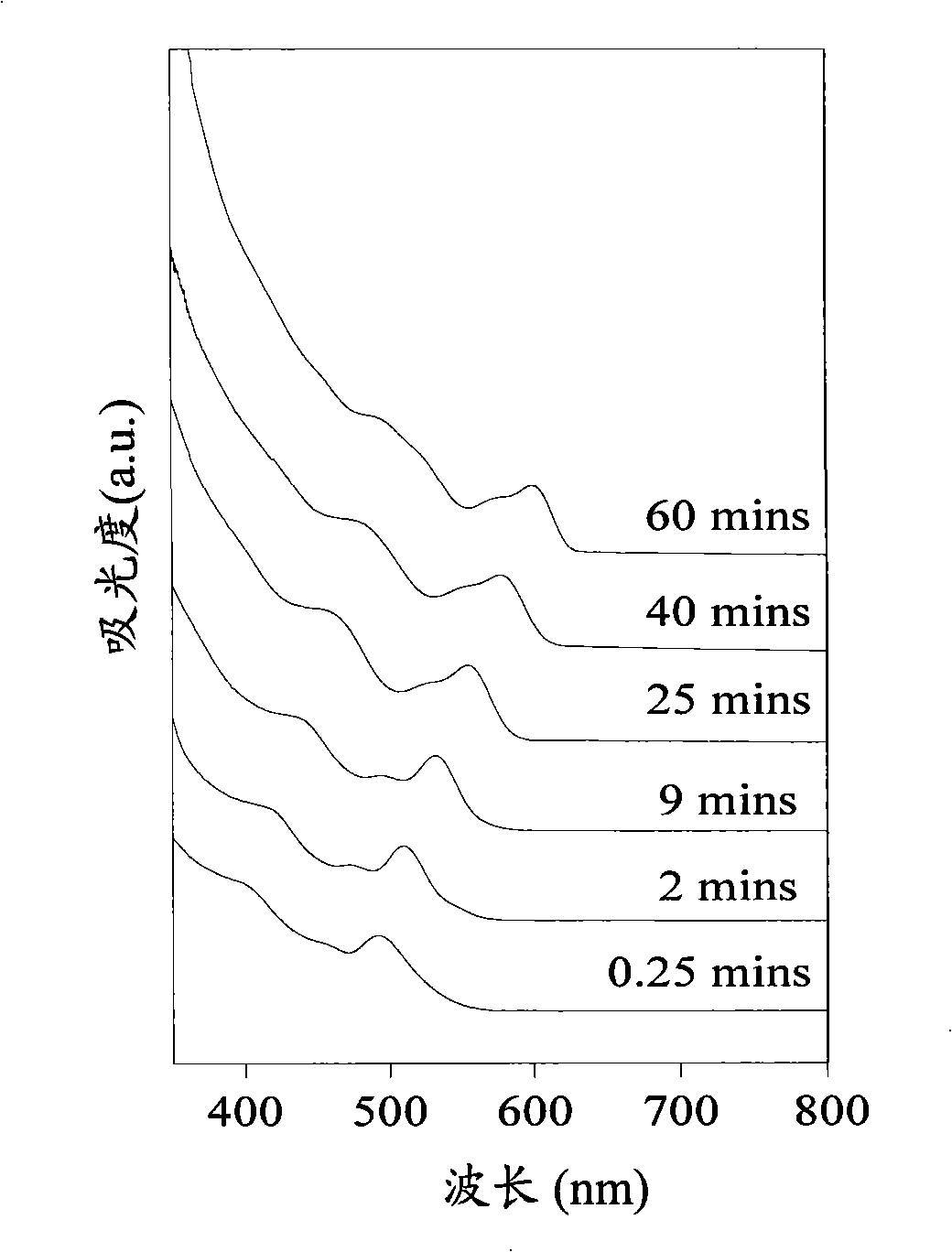

[0030] The NaOH solution, sulfuric acid solution and oleylamine used in the experiment were deoxygenated by passing nitrogen gas for 20 minutes in advance. Such as figure 1 Build the experimental device shown in A, and add 33.2mg of selenium powder, 20mg of aluminum powder and 1mL of 2M NaOH solution to the three-necked flask in sequence under the protection of nitrogen. After 1 min, 2 mL of 2M sulfuric acid solution was injected. The generated gas was taken out under the action of nitrogen flow and introduced into 2 mL oleylamine to obtain oleylamine-hydrogen selenide complex. In another three-necked flask, heat 38.4mg CdO, 0.34g stearic acid and 4mL octadecene to 200°C to obtain a clear cadmium stearate solution, add 2mL oleylamine and 3g octadecylamine to the solution , continue to heat up to 240°C, stop heating, and inject the oleylamine-hydrogen selenide complex prepared above. After adding the precursor of selenium, keep the system temperature at 220°C, and take sampl...

Embodiment 2

[0033]The NaOH solution, sulfuric acid solution and oleylamine used were passed through nitrogen to deoxygenate for 20 minutes in advance. Under nitrogen protection, 30.0 mg of selenium powder, 18 mg of aluminum powder and 1 mL of 2M NaOH solution were sequentially added into the three-necked flask. After 1 min, 2 mL of 2M sulfuric acid solution was injected. The generated gas was taken out under the action of nitrogen flow and introduced into 2 mL oleylamine to obtain oleylamine-hydrogen selenide complex. In another three-necked flask, 24.3mg ZnO, 0.34g stearic acid and 4mL octadecene were slowly heated to 300°C to obtain a clear zinc stearate solution, and 2mL oleylamine and 3g octadecylamine were added to the solution . Continue to heat up to 320° C., stop heating, and inject the oleylamine-hydrogen selenide complex prepared above into the zinc stearate solution. After the precursor of selenium is added, the temperature of the system is maintained at 300°C, and samples a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com