Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104 results about "Ammonium benzoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

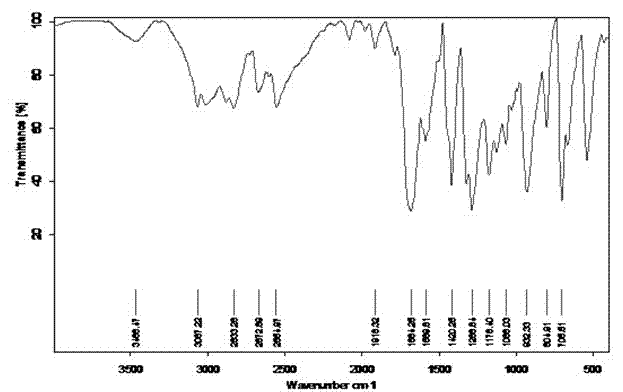

Ammonium benzoate, a white solid, is the ammonium salt of benzoic acid. Ammonium benzoate can possess antimicrobial properties.

Stainless steel degreasing agent

InactiveCN101979711AImprove solubilityImproves the properties of uniform corrosionActive agentBrominated hydrocarbon

The invention provides a stainless steel degreasing agent, which comprises the following components in percentage by weight: 5 to 25 percent of organic solvent, 2 to 5 percent of corrosion inhibitor, 10 to 25 percent of surfactant, 5 to 10 percent of inorganic salt, 1 to 3 percent of defoaming agent and the balance of deionized water, wherein the organic solvent is bromohydrocarbon; the corrosion inhibitor is sodium benzoate, ammonium benzoate, triethanolamine, ethanolamine or benzotriazole; the surfactant is one or more of alkylphenol polyoxyethylene ether and fatty alcohol-polyoxyethylene ether; the inorganic salt is alkaline salt; and the defoaming agent is tributyl phosphate, organic silicon, oleic acid or sodium oleate. The stainless steel degreasing agent can replace the currently used ODS cleaning agents, can achieve the cleaning effect of the ODS cleaning agents, does not damage the surface of the stainless steel, has obvious cleaning effect, can clean a large number of products, and does not harm a human body; and the preparation method is simple, safe, and environment-friendly.

Owner:JIANGSU TIANHENG NANO SCI & TECH

Anti-vein precoated sand and preparation method thereof

InactiveCN103567357AAnti-sticking sand strengthStrong anti-veining abilityFoundry mouldsFoundry coresSesbania gumPhenol

The invention discloses anti-vein precoated sand and a preparation method thereof. The anti-vein precoated sand is prepared from the following raw materials in parts by weight: 80-90 parts of quartz sand, 15-25 parts of menaccanite, 10-15 parts of spodumene, 2-3 parts of boric acid, 2-3 parts of thermoplastic phenolic resin, 0.5-1 part of thermosetting phenol resin, 5-10 parts of cement clinker, 4-7 parts of sulphite liquor, 3-5 parts of corn flour, 2-3 parts of sesbania gum, 1-2 parts of ammonium benzoate, 0.5-0.8 part of gamma-aminopropyl triethoxy silicane, 3-6 parts of dioctyl phthalate, 7-11 parts of urotropine, 2-4 parts of calcium stearate and 3-5 parts of composite powder. The anti-vein precoated sand has strong anti-sand burning and anti-vein capacities, also has the characteristics of high strength, good liquidity, low gas evolution, good heat resistance, good gas permeability and the like, can obviously reduce or eliminate defects of vein, sand burning, pores and the like, effectively improves quality of the inner surface and the outer surface of a casting and is applicable to production of a gray iron bulb iron steel casting.

Owner:TONGLING JINGWEI FLUID SCI & TECH

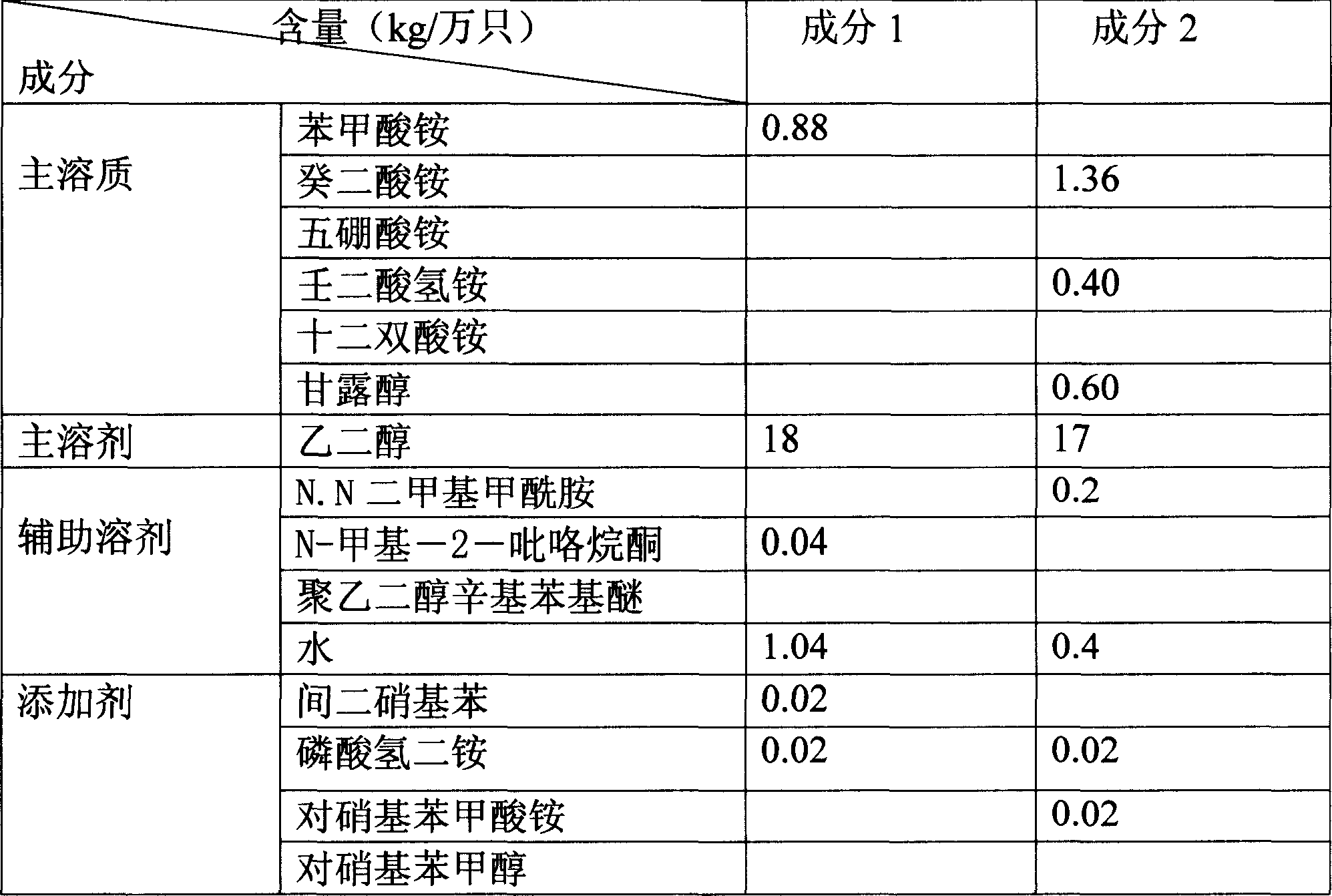

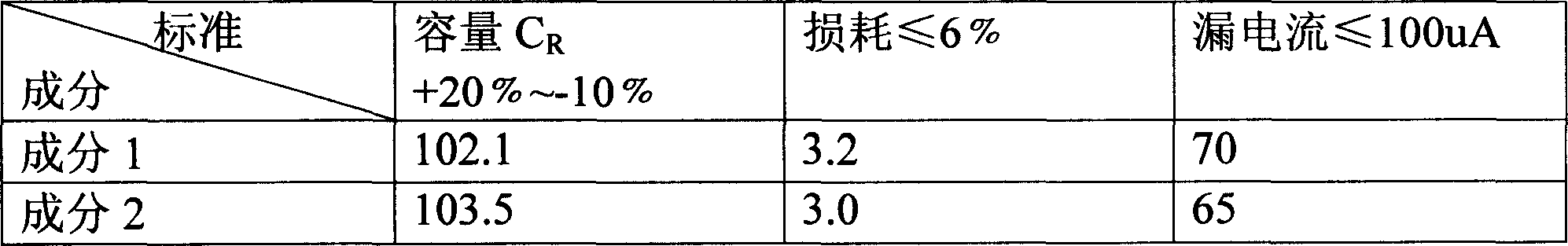

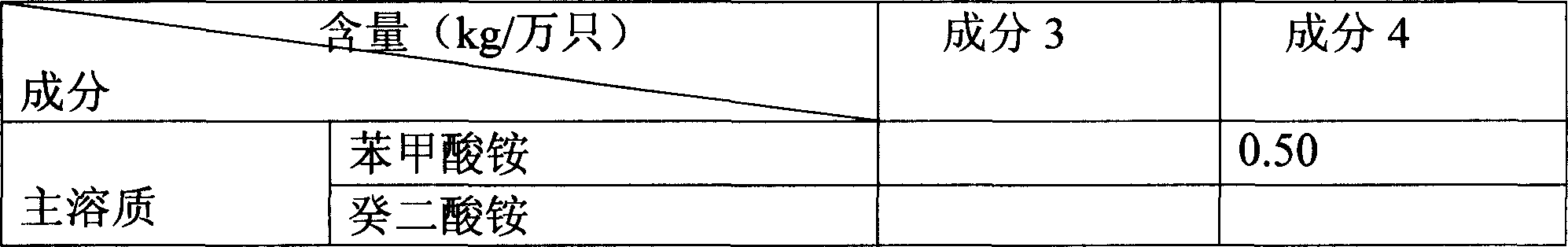

Aluminium electrolytic capacitor for flash lamp and preparing method tereof

ActiveCN1862728AImprove pressure resistanceReduce leakage currentElectrolytic capacitorsPhosphatePolyethylene glycol

This invention relates to aluminum electrolytic capacitor and its preparation method, especially relates to aluminum electrolytic capacitor used in flashing light and its preparation method. Its work electrolyte components is that main solvent is ethylene glycol. Secondary solvent is one or mixture N.N dimethyl formamide, N-methyl-2- pyrrolidone, polyethylene glycol octyl phellyl ether and water. The main solute is one or mixture of ammonium benzoate, ammonium sebacate, ammonium pentaborate, azelaic acid hydrogen ammonium, dodecandioic acid ammonium, mannitol. The additive is one of mixture of m-dinitrobenzene, ammonium dibasic phosphate, nitrodracylic acid ammonium and amphi nitryl benzoic alcohol. The capacitor in this invention is good in pressure resistance, the leakage current is little, the slow leakage rally can be used to make flashing light aluminum electrolytic capacitor of rated voltage keep around 330V.

Owner:横店集团东磁有限公司

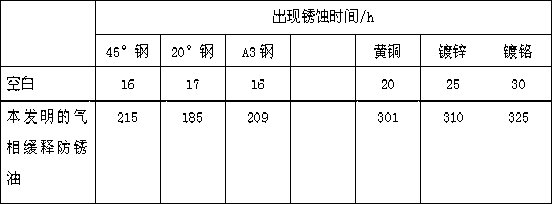

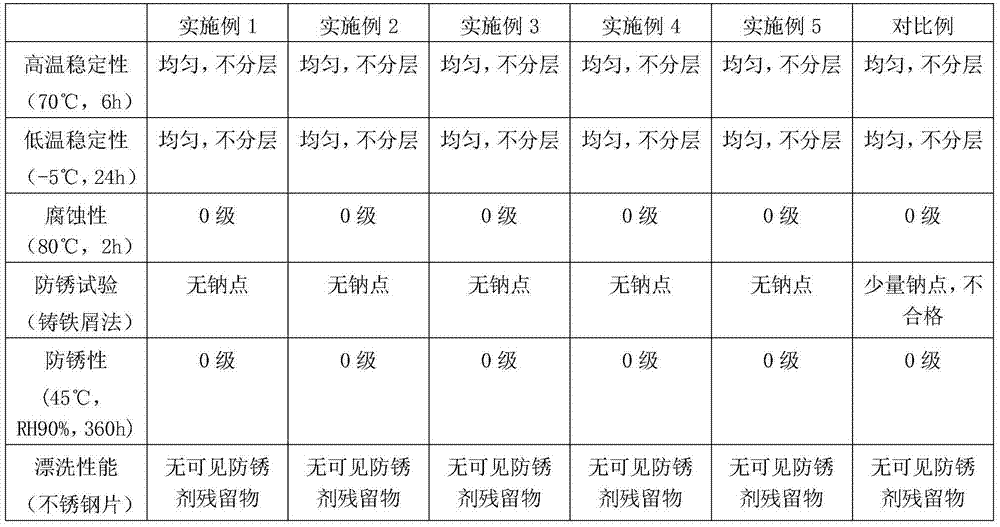

Ammonium benzoate gas-phase slow-release rust preventive oil and preparation method thereof

The invention provides an ammonium benzoate gas-phase slow-release rust preventive oil which is prepared from the following raw materials by weight: 150 parts of No. 120 solvent naphtha, 5 to 8 parts of rosin, 2 to 5 parts of zinc dust, 3 to 5 parts of sodium laureth sulfate, 15 to 18 parts of liquid paraffin, 3 to 5 parts of 3-aminopropyltrimethoxysilane, 10 to 15 parts of triethylenediamine, 10 to 13 parts of epoxidized soybean oil, 10 to 15 parts of xylene, 5 to 8 parts of a cross-linking agent TAIC, 1 to 3 parts of ferrocene, 4 to 6 parts of polyisobutylene, 1 to 2 parts of ammonium benzoate, 1 to 2 parts of benzotriazol, 1 to 2 parts of 2-aminoethyl-heptadecenyl-imidazoline, 1 to 2 parts of triethanolamine, 2 to 4 parts of zinc dialkyl dithiophosphate, 1 to 2 parts of sodium dodecyl benzene sulfonate, 6 to 8 parts of dimethicone, 10 to 12 parts of epoxidized triglyceride, 5 to 6 parts of a film forming resin and 1 to 2 parts of modified attapulgite. The gas-phase rust preventive oil has good antirust performance and an excellent contact antirust effect, so the rust preventive oil can be widely applicable to antirust action on inner cavities or other contact or non-contact metal positions of mechanical equipment.

Owner:TONGLING RELY TECH

700V high-voltage aluminum electrolytic capacitor electrolyte

InactiveCN106252079AHigh molecular weightLow mobilityLiquid electrolytic capacitorsSalicylic acidGluconic acid

Disclosed is a 700V high-voltage aluminum electrolytic capacitor electrolyte. The electrolyte comprises 50-80% of main solvent, 20-50% of auxiliary solvent, 5-20% of main solute, 2-10% of auxiliary solute, 0.1-1% of auxiliary additive and 5-15% of spark additive, wherein the main solute comprises one or more of azelaic acid, ammonium hydrogen azelate, ammonium sebacate, decane dicarboxylic acid, 7, 9-dimethyl-7, 9-dimethoxy carbonyl-1, 11-dodecane dicarboxylic acid, and 7, 8-dimethyl-7, 8-dimethoxy carbonyl-1, 14 tetradecane dicarboxylic acid; and the auxiliary solvent comprises one or more of ammonium salicylate, salicylic acid, oxalic acid, malonic acid, succinic acid, ammonium benzoate, ammonium maleate, ammonium hydrogen maleate, ammonium adipate and hexanedioic acid. The spark voltage of the electrolyte is greater than 700V; and in addition, the electrolyte is simple to prepare, stable in performance and excellent in related parameters.

Owner:HUNAN AIHUA GRP

Antirust agent containing modified vermiculite powder

The invention discloses an antirust agent containing modified vermiculite powder. The antirust agent containing modified vermiculite powder is prepared from the following raw materials by weight: 80-100 parts of castor oil, 5-8 parts of barium petroleum sulfonate, 1-3 parts of ferrocene, 0.8-1.0 part of polyisobutene, 0.5-1.0 part of bitertanol, 1-2 parts of ammonium benzoate, 5-8 parts of fatty acid amide, 8-10 parts of aluminium stearate, 0.8-1.2 parts of 2-aminoethyl heptadecenyl imidazoline, 1-2 parts of decylamine, 1-3 parts of zinc alkyl dithiophosphate, 5-8 parts of sodium citrate, 8-10 parts of phosphoric acid, 2-4 parts of sodium dodecyl benzene sulfonate, 2-3 parts of polyethylene glycol, 5-6 parts of a film-forming resin, 3-5 parts of lanolin, 3-5 parts of 1,3-glutaric acid morpholine and 5-8 parts of modified vermiculite powder. By adding the modified vermiculite powder and adjusting the formula, the antirust agent having a very good gas phase antirust effect is prepared. The antirust agent provided by the invention has excellent antirust performance and is convenient for use; and the production process is simple.

Owner:辽宁宝瑞科技有限公司

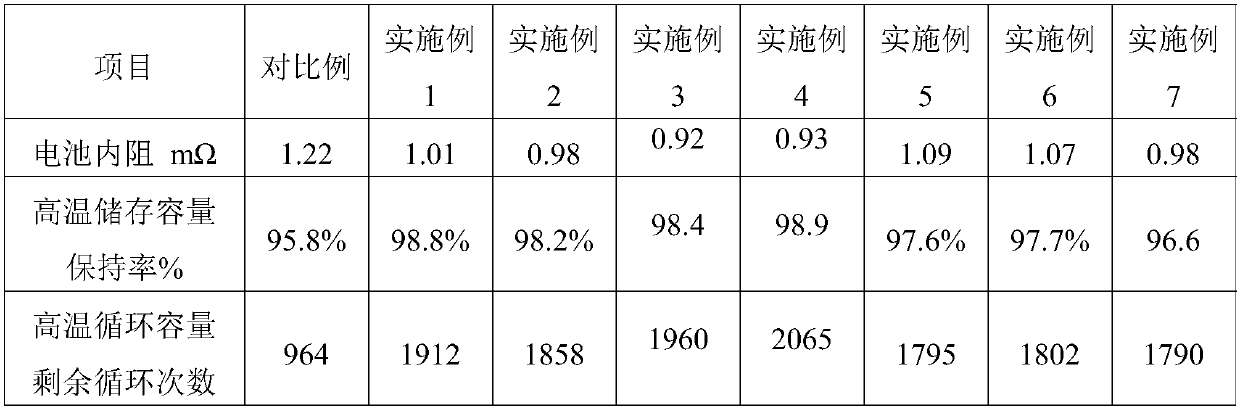

Lithium ion battery electrolyte solution

InactiveCN107749493ALower internal resistanceImprove high temperature storageSecondary cellsPolyethylene glycolSolvent

The invention discloses a lithium ion battery electrolyte solution, and relates to the technical field of manufacturing of lithium ion batteries; the lithium ion battery electrolyte solution comprisesa lithium salt, a solvent, vinylene carbonate, an additive A and an additive B; the additive A is an ether nitrile compound or an aromatic compound, and the additive B is an organic ammonium salt; the ether nitrile compound is one of tetraethylene glycol dimethyl ether, ethylene glycol monobutyl ether, butanedinitrile or 1,3,6-hexanetricarbonitrile, the aromatic compound is one of thiophene, N-methylpyrrole or o-terophenyl, and the organic ammonium salt is ammonium benzoate or methyl ammonium benzoate. Based on the conventional additives, the combined additive of ether nitrile, the aromatic compound and the organic ammonium salt is added, a low-impedance, thin and dense SEI film is formed, and the battery internal resistance, the rate performance and the low-temperature performance are improved.

Owner:WANXIANG 123 CO LTD +1

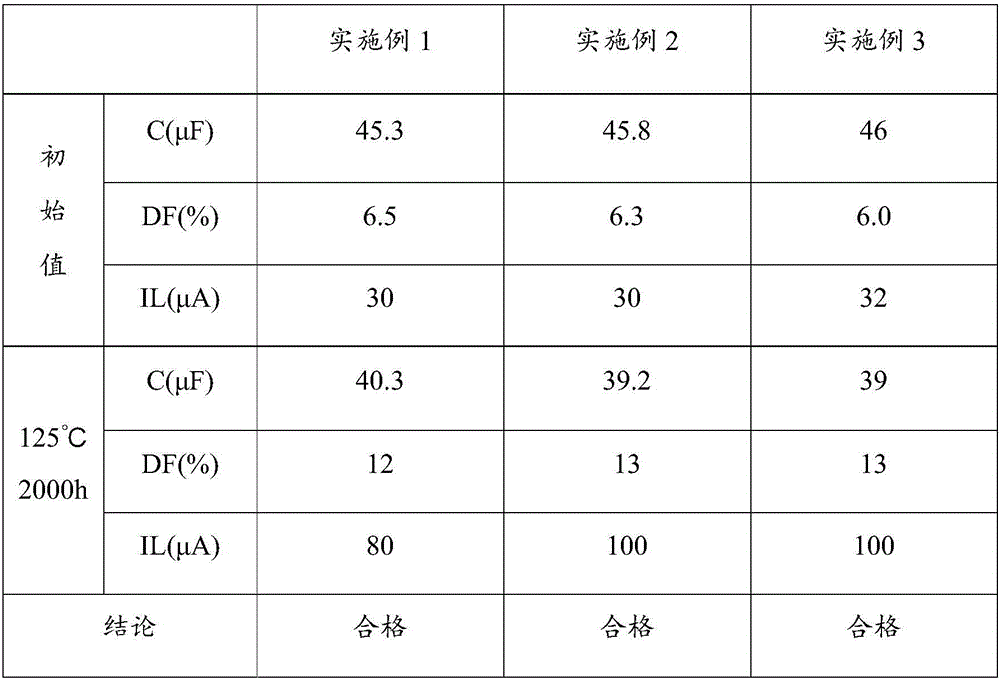

Electrolyte, electrolyte preparation method and aluminum electrolytic capacitor

ActiveCN106098379AImprove temperature resistanceImprove stabilityLiquid electrolytic capacitorsSolventTemperature resistance

The invention discloses an electrolyte, an electrolyte preparation method and an aluminum electrolytic capacitor. The electrolyte comprises, by weight percentage, 50-65w% of solvent, 23-33w% of solute, and 8-19w% of additive. The solute includes boric acid, ammonium benzoate, at least one material selected from ammonium dodecanedioate and 2,7-dibutyl octanedioic acid ammonium, and at least one material selected from ammonium sebate and alkyl ammonium sebate. Through the technical scheme, the temperature resistance performance and stability of the aluminum electrolytic capacitor are improved.

Owner:惠州市智胜新电子技术有限公司

Modified steel slag alcohol-based casting coating and making method thereof

ActiveCN104084529AHigh temperature resistantStrong adhesionFoundry mouldsFoundry coresHexamethylenetetramineSlag

The present invention discloses a modified steel slag alcohol-based casting coating, which is characterized by being prepared from the following raw materials by weight: 25-30 parts of steel slag, 55-60 parts of graphite, 0.4-0.7 part of zirconium dioxide, 1.2-2.1 parts of citric acid, 0.5-0.9 parts of sodium borate, 3-4 parts of rosin, 0.2-0.4 part of ammonium polyphosphate, 1-3 parts of nano diatomite powder, 0.6-2.1 parts of ammonium benzoate, 4-8 parts of plant ash, 3-5 parts of phenolic resin, 2-4 parts of hexamethylenetetramine, 40-55 parts of ethanol and 3-7 parts of an additive; by adding of the steel slag, the citric acid and the like, the prepared coating has the advantages of high temperature resistance, strong adhesion, good air permeability, easy brushing, high strength and the like, by use of the coating, separation of a casting from a casting mould can be fast and adhesion-free, and the modified steel slag alcohol-based casting coating is broad in application prospect.

Owner:嘉兴如运建筑科技有限公司

Corrosion inhibitor for steel wire and preparation method thereof

ActiveCN103483998AMaintain colorImprove stabilityAnti-corrosive paintsPolyether coatingsPolyvinyl alcoholThiourea

The invention provides a corrosion inhibitor for a steel wire. The corrosion inhibitor comprises the following components in parts by weight: 20-50 parts of polyvinyl alcohol, 30-70 parts of polyethylene glycol, 2-7 parts of ammonium benzoate, 3-6 parts of trisodium phosphate, 1-5 parts of thiocarbamide, 2-8 parts of sodium thiosulfate, 1-5 parts of triethanolamine, 1-6 parts of undecanedioic acid, 1-4 parts of benzotriazole, 3-9 parts of citric acid, 1-4 parts of sodium molybdate, 3-7 parts of tetrapropyl ammonium acetate and 100-300 parts of water. The preparation method disclosed by the invention comprises the following steps: adding polyvinyl alcohol and polyethylene glycol to water, and heating while stirring, so as to completely dissolve polyvinyl alcohol and polyethylene glycol; then adding other components, and stirring at 40-60 DEG C in a heat-preservation manner; cooling to room temperature after completely dissolving. The corrosion inhibitor for the steel wire disclosed by the invention has the characteristics of being long in anti-rust time, good in anti-corrosion performance, low in cost, environment-friendly and the like.

Owner:WUJIANG JUNDA ELEVATOR PARTS

Electrolyte of high-voltage aluminum electrolytic capacitor and preparation method of electrolyte

The invention discloses electrolyte of a high-voltage aluminum electrolytic capacitor. The electrolyte is characterized by comprising a main solvent, an auxiliary solvent, a solute and a spark voltage increasing agent, wherein the main solvent comprises one or more of ethylene glycol, gamma-butyrolactone, DMF and diglycol monobutylether; the auxiliary solvent comprises two or more of polyethylene glycol 200, polyethylene glycol 400, a nanosilicon dioxide solution, glycerol, propylene carbonate and ethylene carbonate; the solute comprises two or more of ammonium sebacate, ammonium adipate, adipic acid, boracic acid, ammonium pentaborate, ammonium azelate, ammonium dodecanedioate, ammonium formate, ammonium benzoate, mannitol, sorbitol, citric acid and quadrol. The electrolyte can be applied to 600V ultrahigh voltage, is stable in performance, low in viscosity, high in conductivity and beneficial to volume production, and can reduce the production cost.

Owner:HUNAN AIHUA GRP

Composition and method for repairing metal reinforced concrete structures

InactiveUS7048873B1Enhance its ability to migrateEffective controlOther chemical processesLayered productsPotassiumRebar

A composition and method for repairing metal reinforced concrete structures by applying a repair coating to surfaces of such damaged structures. The coating composition is a mortar / aggregate mixture blended with fiber reinforcements and containing a quantity of selected migratory corrosion inhibitors. These inhibitors are a mixture of sodium gluconate together with an auxiliary inhibitor consisting of sodium sebacate, potassium sebacate or ammonium benzoate. The fiber reinforcements consist of polypropylene or polyethylene, and are co-extruded with a quantity of the migratory corrosion inhibitors listed above.

Owner:CORTEC

Biodegradable corrosion inhibitor composition

InactiveUS7297191B1Easy to disassembleLong-term protectionOther chemical processesWater solubleSilicon dioxide

A corrosion inhibitor composition includes between about 95 and about 99 percent by weight ammonium benzoate, and between 1 and about 5 percent by weight of silica. The composition may be water soluble for use in solution-based applications.

Owner:CORTEC CORP

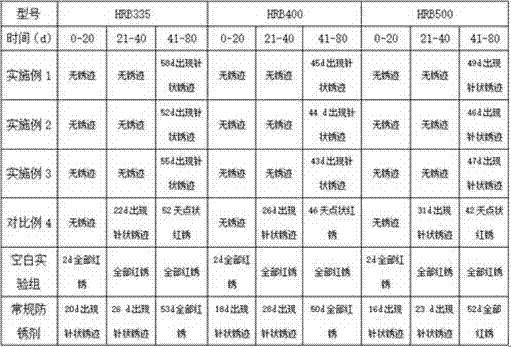

Environmental-friendly volatile corrosion inhibitor for carbon steel and preparation method of environmental-friendly volatile corrosion inhibitor

An environmental-friendly volatile corrosion inhibitor for carbon steel comprises sodium silicate with the mass-volume concentration of 0.8 g / L-1.2 g / L, alanine with the mass-volume concentration of 1.8 g / L-2.3 g / L, sodium benzoate with the mass-volume concentration of 6.8 g / L-8.3 g / L, and ammonium benzoate with the mass-volume concentration of 3.8 g / L-4.5 g / L, dissolved in distilled water. A preparation method of the environmental-friendly volatile corrosion inhibitor comprises the following steps: respectively weighing the sodium silicate, alanine, sodium benzoate and ammonium benzoate according to the mass-volume concentrations; respectively dissolving in distilled water with the volumes of 1 / 4 of those of the solutes, and uniformly stirring; after the four solutions are stilled, mixing and uniformly stirring. The environmental-friendly volatile corrosion inhibitor is formed by compounding the sodium silicate, alanine, sodium benzoate and ammonium benzoate, is environmental-friendly and efficient, has little pollution to the environment, has a good synergistic effect, and solves the problems that the conventional volatile corrosion inhibitor is poor in corrosion-inhibition performance and generates more pollution, adopts the simple preparation method, is convenient to use, and can prolong the service life of the carbon steel.

Owner:西安宇坤实业有限公司

Biodegradable corrosion inhibitor composition

ActiveUS7118615B1Effective long-term protectionEasy to disassembleOther chemical processesSilicon dioxideNuclear chemistry

A corrosion inhibitor composition includes between about 90 and about 99 percent by weight ammonium benzoate, and one or more additive components in an amount of between 1 and about 10 percent by weight of the composition. The one or more additive components are selected from the group consisting of silica, triazoles, and wetting agents.

Owner:CORTEC

Corrosion inhibitor materials for use in combination with cathodic protectors in metallic structures

A corrosion inhibitor composition for use in combination with cathodic protection of metallic structures includes between about 5 and 80 percent by weight cyclohexylammonium benzoate; between about 1 and 10 percent by weight monoethanolammonium benzoate; between about 5 and 90 percent by weight dicyclohexylammonium nitrate; and up to about 5 percent by weight fumed silica, and may further include about 2 percent by weight tolyltriazole.

Owner:CORTEC

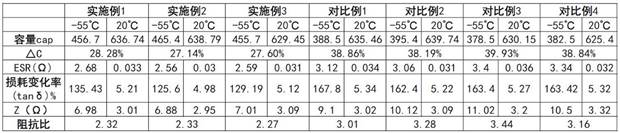

Ultralow-temperature aluminum electrolytic capacitor and manufacturing method thereof

ActiveCN111653431AIncrease temperatureImprove stabilityPlastic/resin/waxes insulatorsLiquid electrolytic capacitorsElectrolytic agentBenzoic acid

The invention discloses an ultralow-temperature aluminum electrolytic capacitor and a manufacturing method thereof. The manufacturing method comprises the following steps: (1), winding a core package;to be specific, intervening electrolytic paper between an anode foil and a cathode foil to wind the anode foil and the cathode foil into a core cladding; (2), performing an impregnation step; to be specific, immersing the wound core cladding into an electrolyte for impregnation treatment; (3), performing a packaging step; to be specific, wrapping the impregnated core cladding into a shell and sealing the shell with a rubber plug; (4), performing aging; to be specific, preparing the electrolyte from the following components, by weight: 47 to 62 percent of solvent, 20 to 35 percent of solute and 10 to 18 percent of additive, preparing the solvent from a main solvent, an auxiliary solvent and a secondary solvent, and preparing the solute from ammonium formate, ammonium acetate, ammonium diacid and ammonium benzoate. The aluminum electrolytic capacitor manufactured through the manufacturing method has good temperature performance and stability so as to adapt to complex and changeable natural environments, electrolyte in the capacitor cannot be frozen, and the electrical performance cannot be weakened.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Anti-tear cable material used for high-speed railway motor train unit and preparation method of anti-tear cable material

The invention discloses an anti-tear cable material used for a high-speed railway motor train unit and a preparation method of the anti-tear cable material. The anti-tear cable material used for the high-speed railway motor train unit comprises the following raw materials in parts by weight: 67 to 89 parts of polyurethane rubber, 22 to 36 parts of styrene-butadiene rubber, 15 to 25 parts of thermoplastic polyester elastic bodies, 4 to 8 parts of vinyl silicone oil, 17 to 26 parts of fumed silica, 3 to 6 parts of cadmium carbonate, 2 to 3 parts of lauroyl peroxide, 1.5 to 2.5 parts of triallyl isocyanurate, 1 to 2 parts of ammonium benzoate, 3 to 5 parts of poly-alpha-olefin, 5 to 10 parts of tert-butyl phenolic tackifying resin, 2 to 4 parts of triethylhexanoin, 10 to 15 parts of methylpentachlorostearate, 14 to 18 parts of carbon nano tubes, 10 to 15 parts of a diopside powder, 1 to 2 parts of 4,4'-dithiodimorpholine, 0.5 to 1 part of P-tert-butylphenol, and 20 to 25 parts of a composite flame retardant. The cable material provided by the invention combines the advantages of the raw materials such as the polyurethane rubber, the styrene-butadiene rubber, and the thermoplastic polyester elastic bodies, the tearing strength of a conventional cable material is improved, and the cable material is enabled to have excellent tear resistance, has the effect of bearing relatively great mechanical external force, and has the advantages of excellent chemical stability, heat resistance and age resistance, and long service life.

Owner:ANHUI KANGLIYA CO LTD

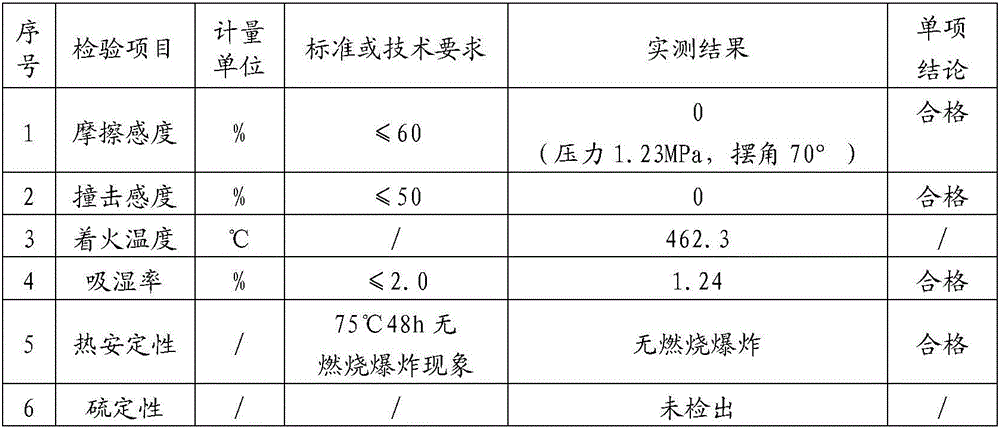

Organic carbon powder explosive reducing agent

The invention discloses an organic carbon powder explosive reducing agent, which is prepared from the following ingredients in parts by weight: 28 to 32 parts of terephthalic acid, 8 to 12 parts of ammonium benzoate, 8 to 12 parts of calcium benzoate, 38 to 42 parts of hydrogen potassium terephthalate and 8 to 12 parts of simple substance carbon. The reducing agent provided by the invention has the advantages of safety, stability and environment protection.

Owner:杨厚煌 +1

Method for preparing hydrogen sulfide corrosion inhibitor used in offshore oilfield produced oil pipeline

InactiveCN104498958APlay the role of hydrogen sulfide corrosion inhibitionDrilling compositionBenzoic acidOil additive

The invention relates to a method for preparing a hydrogen sulfide corrosion inhibitor used in an offshore oilfield produced oil pipeline and belongs to the technical field of petroleum additives. The method comprises the following steps: uniformly mixing an imidazoline compound, SPAN-80, rosin amine polyoxylethylene ether, sodium alga acid, methyl propanediol and ethanol, thereby obtaining a mixture I; uniformly mixing sodium chromate, sodium nitrite, sodium pyrrolidone carboxylate, hydroxyl ethyl benzoate, zinc borate, magnesium borate, dipentaerythritol, hydrogenated soya bean lecithin, triethylamine and propyl alcohol, thereby obtaining a mixture II; and uniformly mixing the mixture I, the mixture II, sodium benzoate, ammonium benzoate, sodium gluconate, sodium acrylate, thiosemicarbazide, carboxymethyl chito-oligosaccharide vanillic aldehyde Schiff base, thereby obtaining the hydrogen sulfide corrosion inhibitor. The corrosion inhibitor provided by the invention can effectively achieve a corrosion inhibition effect on the hydrogen sulfide in the pipeline under high salt conditions.

Owner:刘旸 +14

Electrolyte for high-conductance and long-life aluminum electrolytic capacitor and preparation method thereof

ActiveCN105575665ASimple processEasy to operate and controlElectrolytic capacitor manufactureElectrolysisPolyethylene glycol

The invention relates to the technical field of electrolytes and particularly relates to an electrolyte for a high-conductance and long-life aluminum electrolytic capacitor and a preparation method thereof. The electrolyte is composed of the following raw materials in weight part: 8-12 parts of ammonium benzoate, 6-10 parts of ammonium adipate, 4-6 parts of polyethylene glycol, 1.5-2.5 parts of mannitol, 2-3 parts of boric acid, 2.5-3.5 parts of ammonium sebacate, 0.2-0.4 part of ammonium hypophosphite, 0.6-1.0 part of p nitrophenol, 3-5 parts of ammoniacal liquor, 0.1-0.3 part of EDTA and 55-75 parts of glycol. According to the technical scheme of the invention, based on the interaction of the above-described materials, the weight proportion of all the raw materials is strictly controlled, and the scintillation voltage of the prepared electrolyte is up to 380V. The conductivity of the prepared electrolyte is up to 5.5ms / cm. meanwhile, the electrolyte is good in electrochemistry characteristics, high in conductivity and long in service life, thus being applied to the manufacture of aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

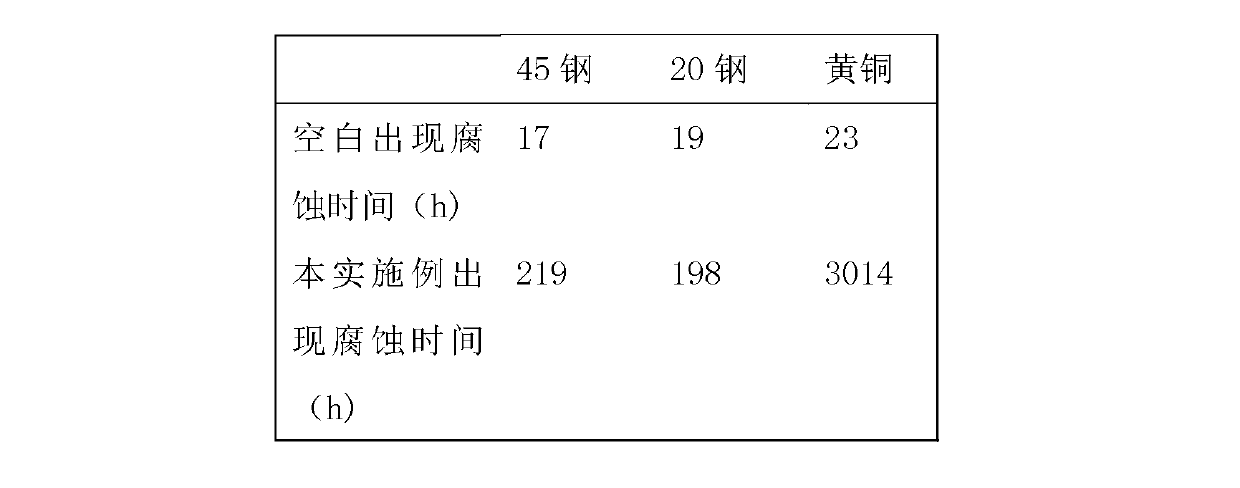

Antirust agent containing modified sepiolite powder

ActiveCN103103529AGood gas phase anti-rust effectGood vapor phase antirust effectGas phasePolyethylene glycol

The invention discloses an antirust agent containing modified sepiolite powder. The antirust agent is prepared from the following raw materials in parts by weight: 97-103 parts of castor oil, 1-2 parts of ferrocene, 1-2 parts of polyisobutene, 0.5-0.7 part of ammonium dihydrogen phosphate, 0.9-1.8 parts of ammonium benzoate, 1-2 parts of 2-methylimidazole, 0.4-0.8 part of beta-naphthylamine, 0.7-1.6 parts of N-phenyl-2-naphthylamine, 1-2 parts of zinc dialkyl dithiophosphate, 0.7-1.3 parts of sodium dodecyl sulfate, 1-1.8 parts of polyethylene glycol, 4.4-5.6 parts of film-forming resins and 0.8-1.6 parts of modified sepiolite powder. The antirust agent has excellent contact antirusting performance and good gas-phase antirusting effect and has good gas-phase antirusting effect and contact antirusting effect on steels and brasses.

Owner:GUANGXI HONGFA BUILDING MATERIALS TECH

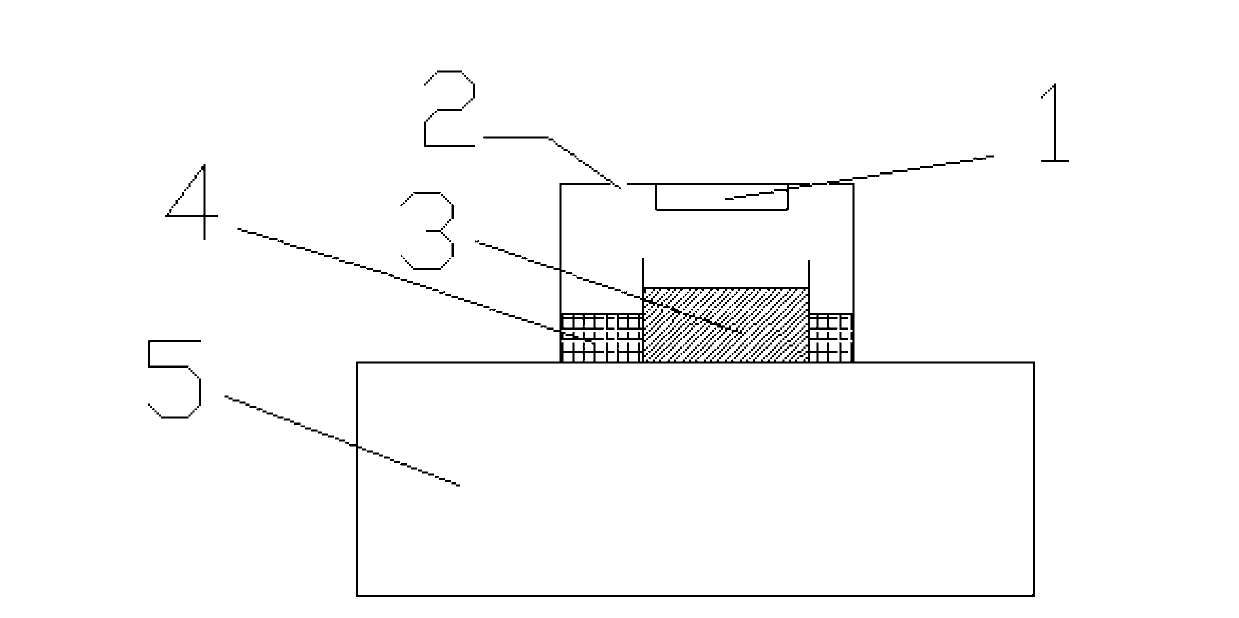

Gas-phase antirust dispersing body

The invention discloses a gas-phase antirust dispersing body, which belongs to the technical field of gas-phase corrosion inhibitors and metal protection. The dispersing body comprises an outer protection box, an air-permeable packaging material and a gas-phase antirust corrosion inhibitor; a gas-phase antirust protection agent is arranged inside the outer protection box after being coated with the air-permeable packaging material; the outer protection box is provided with a plurality of air holes; the air-permeable packaging material can be packaging materials such as high-permeability paper and air-permeable nonwoven fabric; the gas-phase antirust corrosion inhibitor consists of 1 to 10 percent of sodium nitrite, 10 to 30 percent of ammonium benzoate, 10 to 30 percent of triazole and 10 to 30 percent of sodium benzoate. The gas-phase antirust dispersing body is convenient and simple to use, takes effect for a long time, is novel and attractive and can be widely applicable to the corrosion protection of metal products in an airtight space.

Owner:沈阳防锈包装材料有限责任公司

Vapor phase corrosion inhibitor under high-humidity chlorine-containing environment and preparation method thereof

The invention relates to a vapor phase corrosion inhibitor under a high-humidity chlorine-containing environment and a preparation method of the vapor phase corrosion inhibitor. The vapor phase corrosion inhibitor comprises the following components of 3-7 wt% of ammonium molybdate, 2-5wt% of sodium benzoate, 6-10wt% of methyl benzotriazole, 5-8wt% of ammonium benzoate, 3-6wt% of flavone, 6-8wt% oforganic solvents, 20-26wt% of natrium nitrosum, 15-20wt% of urea and 10- 40wt% of distilled water. The vapor phase corrosion inhibitor prepared according to the method has the advantages of high efficiency and little environmental pollution, has a good synergistic corrosion inhibition effect and good corrosion inhibition performance for common carbon steel and non-ferrous metals, solves the problem that a current vapor phase corrosion inhibitor is low in corrosion inhibition rate and can only play a protection role for a single metal, is simple to prepare and convenient to use and can improvethe corrosion inhibition rate, and the service life can be prolonged.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for preparing aluminium benzoate from calcium-free chromium slag

InactiveCN103757419ARecycling not consideredImprove use valueGroup 3/13 element organic compoundsProcess efficiency improvementSlagPhysical chemistry

Owner:陕西绿泉环保科技有限公司

Rubber sealing material and preparation method thereof

InactiveCN106117682AStrong wear resistanceImprove high temperature resistanceGlycerolTemperature resistance

The invention discloses a rubber sealing material. The rubber sealing material is prepared from components in parts by mass as follows: 45-70 parts of chloroprene rubber, 12-22 parts of melamine, 10-20 parts of trimethyl siloxane, 3-6 parts of nano calcium phosphate, 4-8 parts of ammonium benzoate, 3-8 parts of calcium oxide, 15-30 parts of acrylate rubber, 0.5-0.9 parts of stannous octoate, 5-10 parts of allyl alcohol, 7-12 parts of diacetyl peroxide, 4-9 parts of zinc oxide, 0.6-1.5 parts of an anti-aging agent, 3-5 parts of sulfur, 2-7 parts of vinyl silicone resin, 0.6-1.5 parts of zinc stearate, 5-9 parts of glycerol triacetate, 4-9 parts of maleic anhydride, 3-8 parts of dodecylbenzene sulfonic acid, 3-6 parts of calcium propionate and 0.3-0.8 parts of a coupling agent. Compared with the prior art, the rubber sealing material is high in abrasion resistance and high-temperature resistance and can bear relatively high pressure, and the service life of the rubber sealing material can be prolonged.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

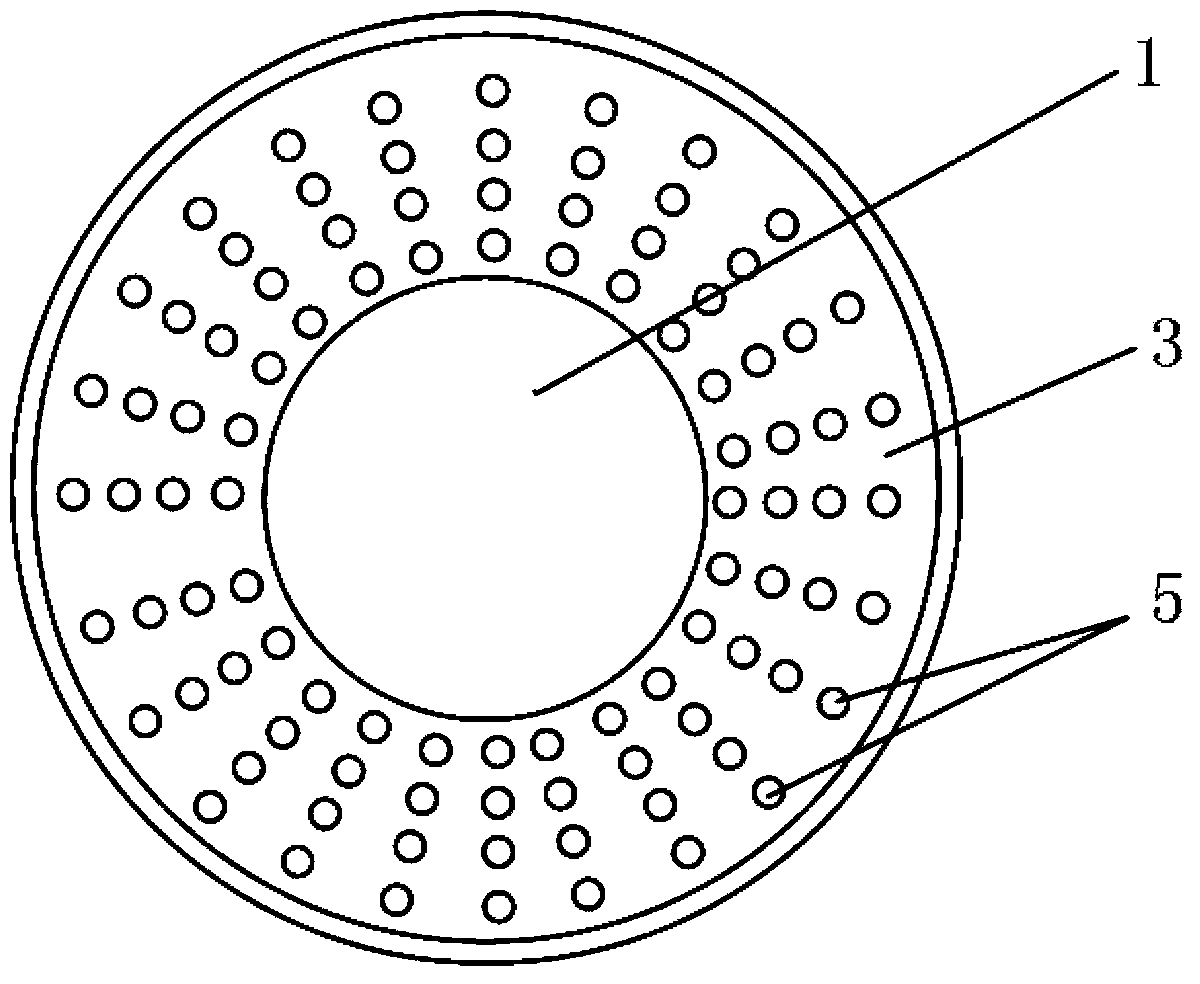

Gas phase rust-proofing plastic sealing bag

The present invention discloses a gas-phase antirust plastic sealing bag. It includes a bag body, said bag body has a rust-resisting film internal layer, the exterior of said rust-resisting film internal layer is covered with a baffle layer, in which the rust-resisting film internal layer is formed from cyclohexane benzoate, ammonium benzoate, benzene triazole and polyethylene.

Owner:刘永余

Gaseous-phase antirust material with long-acting antirust effect and preparation method thereof

The invention provides a gaseous antirust material with a long-acting antirust effect. The gaseous antirust material comprises the following materials in parts by weight: 2.2-6.5 parts of ammonium benzoate, 15.5-25.5 parts of sodium nitrite, 72.5-81.5 parts of distilled water, 0.2-0.6 part of an emulgator, 5.5-8.5 parts of an enhancer and 3.5-5.5 parts of antirust microcapsules. The invention also provides a preparation method for the gaseous-phase antirust material with the long-acting antirust effect. The gaseous antirust material prepared in the manner of adding a gaseous slow-release material into the microcapsule according to the invention is capable of slowly releasing the stored gaseous slow-release material and has controllability. According to the invention, the enhancer is added in the process of preparing the gaseous antirust material, so that the adhesion of the antirust material on a thin oil film is greatly promoted, the antirust material is difficult to dry, crack, becomes crispy and falls off, the influence that the antirust effect become poor due to outdoor exposure and cold temperature can be reduced and the antirust effect is promoted.

Owner:诸城大业金属制品有限公司

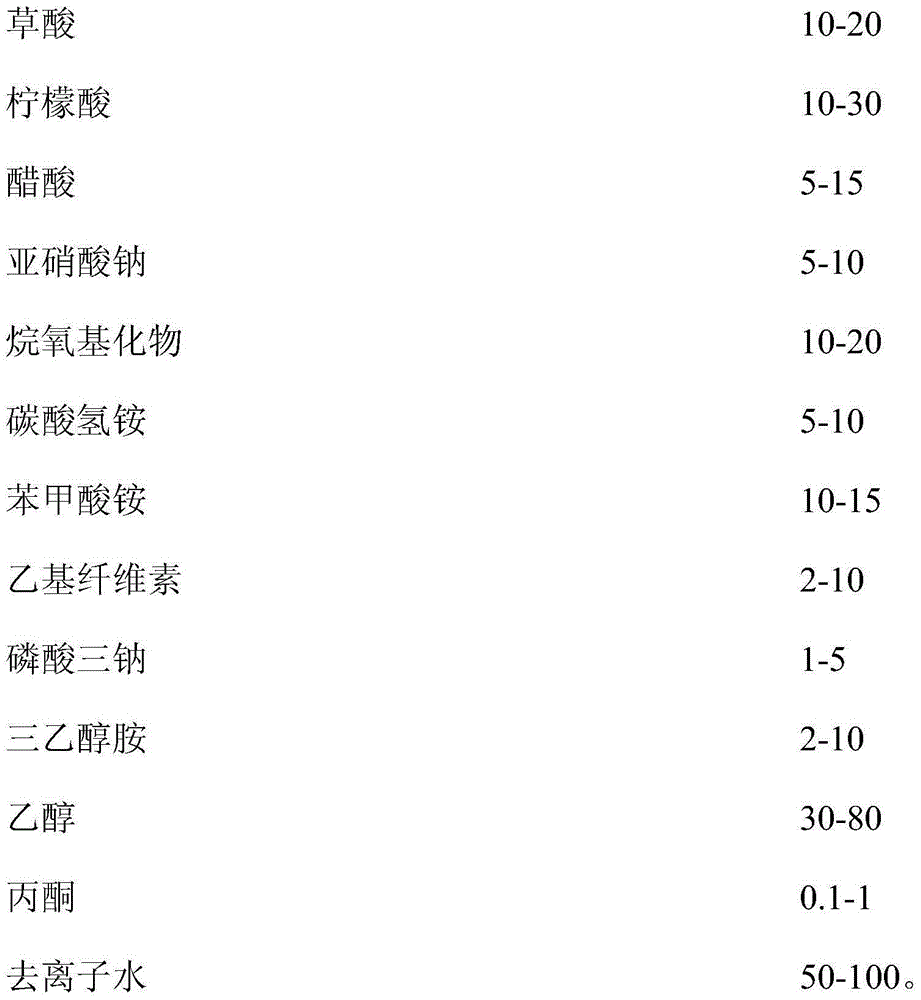

Textile rust remover

The invention relates to a textile rust remover. The textile rust remover is prepared from the following ingredients in parts by mass: 10-20 parts of oxalic acid, 10-30 parts of citric acid, 5-15 parts of acetic acid, 5-10 parts of sodium nitrite, 10-20 parts of alkoxyl compound, 5-10 parts of ammonium hydrogen carbonate, 10-15 parts of ammonium benzoate, 2-10 parts of ethyecellulose, 1-10 parts of trisodium phosphate, 2-10 parts of triethanolamine, 30-80 parts of ethyl alcohol, 10-20 parts of acetone and 100-200 parts of deionized water. The textile rust remover is in a solution form, can be conveniently filled in a vessel as required, can be used for scrubbing a part of the surface of the textile, which requires rust removal, and can be used for directly infiltrating the textiles requiring rust removal in batches, and the deionized water can be used for washing repeatedly, and therefore, the textile rust remover has a good rust removal effect and cannot damage the surface of the textile. The raw materials are easily available, the preparation process is simple, the cost is low and the textile rust remover is suitable for promotion and application.

Owner:艾和美

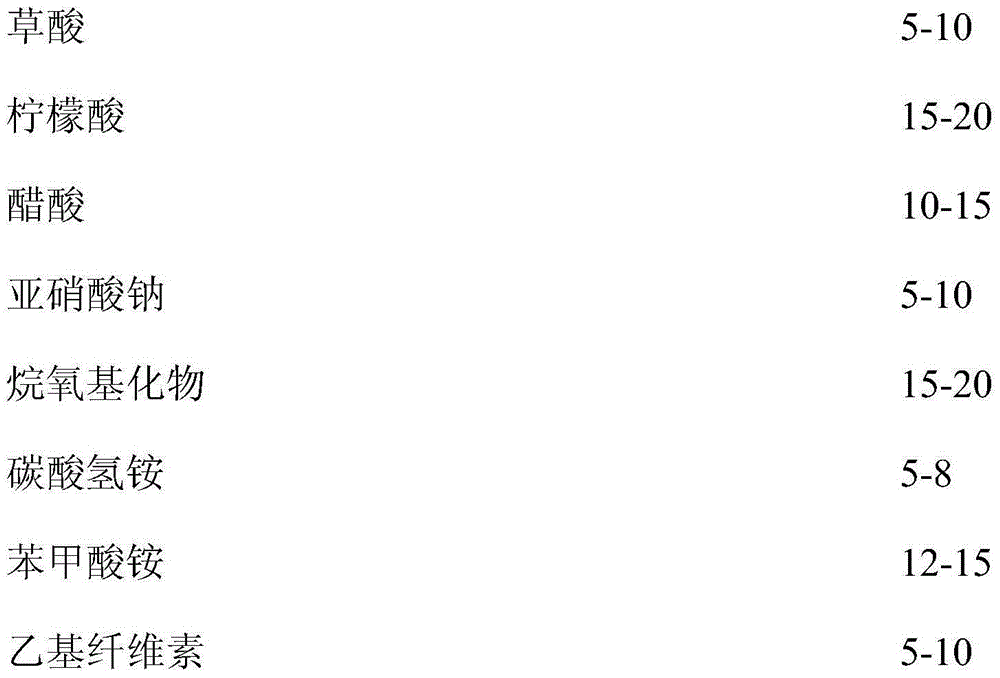

Fabric rust remover

InactiveCN105133310ACreate pollutionSimple preparation processFibre treatmentSodium nitriteRust remover

The invention relates to a fabric rust remover, which comprises the following ingredients in parts by weight: 10 to 20 parts of oxalic acid, 10 to 30 parts of citric acid, 5 to 15 parts of acetic acid, 5 to 10 parts of sodium nitrite, 10 to 20 parts of alkoxy compounds, 5 to 10 parts of ammonium bicarbonate, 10 to 15 parts of ammonium benzoate, 2 to 10 parts of ethocel, 1 to 5 parts of trisodium phosphate, 2 to 10 parts of triethanolamine, 30 to 80 ethanol and 0.1 to 1 parts of acetone. The fabric rust remover has the advantages that the rust removing effect is good; the environment cannot be polluted; the fabric surfaces cannot be damaged; for places requiring rust removal on the fabric surfaces, the fabrics only need to be soaked into the fabric rust remover for a period of time, and are then repeatedly flushed in clean water; the excellent rust removal effect is achieved. The fabric rust remover has the advantages that the use method is simple; the preparing process is simple; the cost is low; the popularization and the application are easy.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com