Gaseous-phase antirust material with long-acting antirust effect and preparation method thereof

A gas-phase anti-rust, long-term technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of insufficient anti-rust time, easy loss, dry cracking and brittleness, etc., achieve good oxidation resistance and storage stability, improve Anti-rust effect, effect of improving anti-rust ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

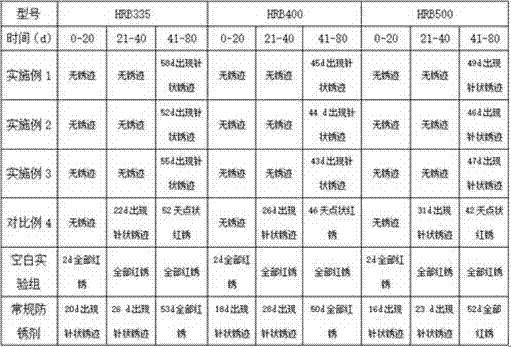

Examples

Embodiment 1

[0039]Example 1 Preparation method of a long-term antirust gas phase antirust material

[0040] 1. Preparation of antirust microcapsules:

[0041] (1) Configure nano-titanium dioxide / gelatin composite solution:

[0042] Configure 4% gelatin solution, add 0.5% nano-titanium dioxide, and carry out high-speed emulsification and dispersion through a homogenizer at 2200r / min at a temperature of 65°C for 20 minutes to prepare a nano-titanium dioxide / gelatin composite liquid;

[0043] (2) Preparation of modified casein solution:

[0044] Add casein to distilled water and stir to form a paste, slowly add 0.15 mol / L NaOH solution until the casein is completely dissolved, and then boil for 5 minutes; dissolve succinate in ethanol to prepare a 10% succinate solution; The prepared succinate solution is dropped into the casein solution until the pH is 7.5-7.7, then stirred with a magnetic stirrer for 20 minutes at a temperature of 45°C, and then cooled to room temperature to make a modif...

Embodiment 2

[0059] Example 2 Preparation method of a long-term antirust gas phase antirust material

[0060] 1. Preparation of antirust microcapsules:

[0061] (1) Configure nano-titanium dioxide / gelatin composite solution:

[0062] Configure 3% gelatin solution, add 0.3% nano-titanium dioxide, and carry out high-speed emulsification and dispersion through a homogenizer at a temperature of 65°C for 15 minutes at a speed of 2000r / min to prepare a nano-titanium dioxide / gelatin composite liquid;

[0063] (2) Preparation of modified casein solution:

[0064] Add casein to distilled water and stir to form a paste, slowly add 0.13mol / L NaOH solution until the casein is completely dissolved, and then boil for 5 minutes; dissolve succinate in ethanol to prepare a 9% succinate solution; The prepared succinate solution was dropped into the casein solution until the pH was 7.7, then stirred with a magnetic stirrer for 10 minutes at a temperature of 45°C, and then cooled to room temperature to prep...

Embodiment 3

[0079] Example 3 Preparation method of a long-term antirust gas phase antirust material

[0080] 1. Preparation of antirust microcapsules:

[0081] (1) Configure nano-titanium dioxide / gelatin composite solution:

[0082] Configure 6% gelatin solution, add 0.8% nano-titanium dioxide, and carry out high-speed emulsification and dispersion through a homogenizer for 20 minutes at a speed of 2500r / min at a temperature of 70°C to prepare a nano-titanium dioxide / gelatin composite liquid;

[0083] (2) Preparation of modified casein solution:

[0084] Add casein to distilled water and stir to form a paste, slowly add 0.15 mol / L NaOH solution until the casein is completely dissolved, and then boil for 10 minutes; dissolve succinate in ethanol to prepare a 10% succinate solution; The prepared succinate solution was dropped into the casein solution until the pH was 7.7, then stirred with a magnetic stirrer for 20 minutes at a temperature of 50°C, and then cooled to room temperature to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com