Antirust agent containing modified sepiolite powder

A technology of sepiolite powder and rust inhibitor, which is applied in the field of metal rust prevention, can solve the problem of inability to form rust protection and the like, and achieve the effects of good gas-phase rust prevention effect, good gas-phase rust-proof effect, and good contact rust-proof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

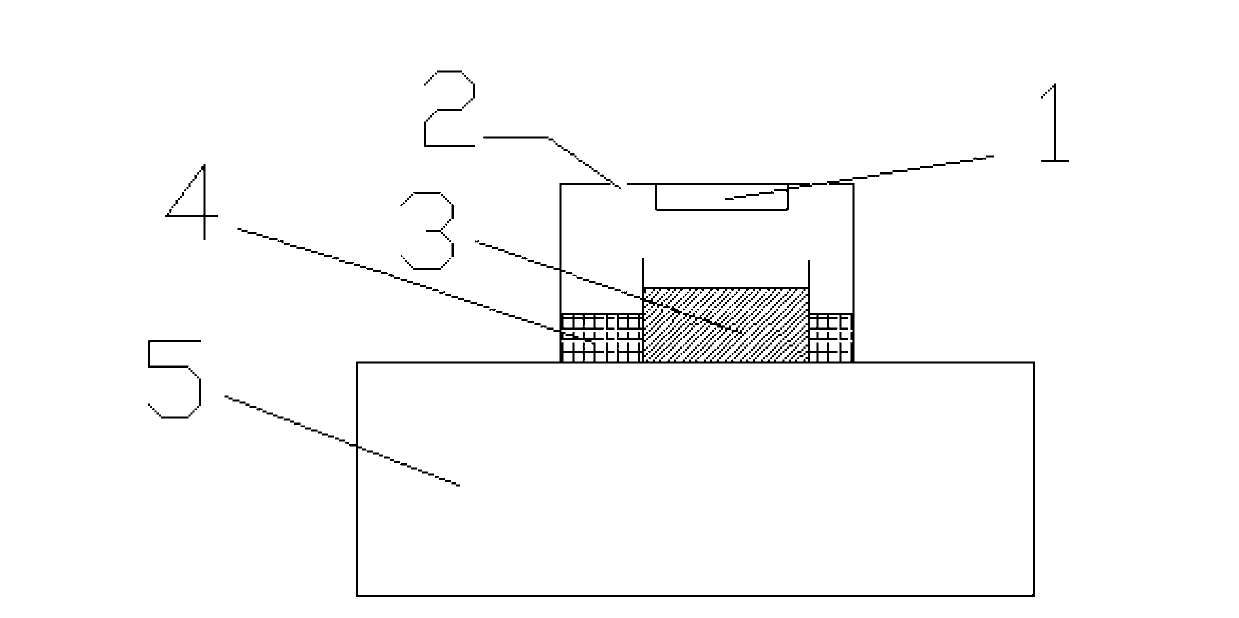

Image

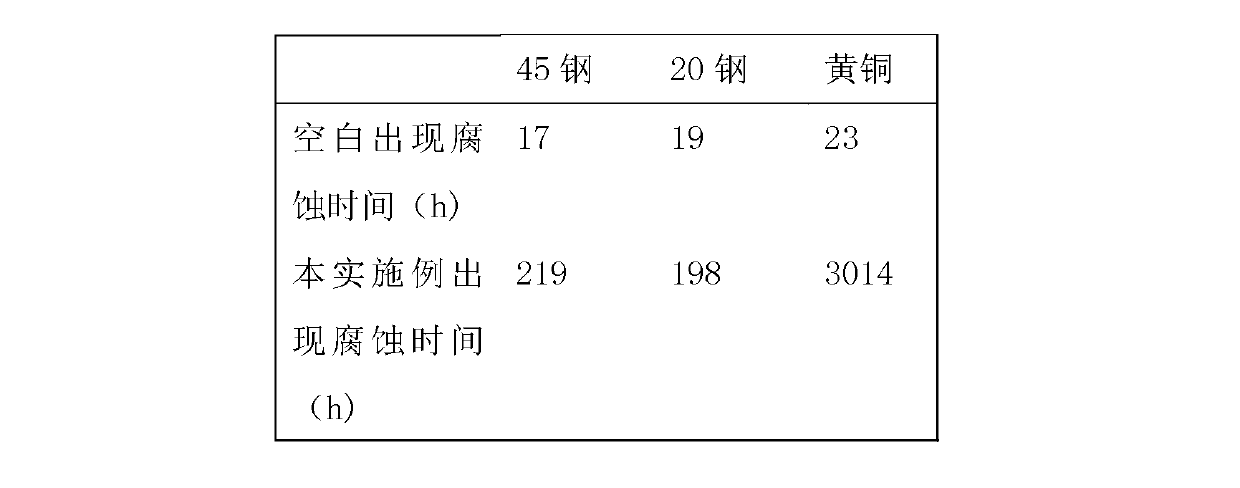

Examples

Embodiment Construction

[0018] A kind of antirust agent containing modified sepiolite powder, it is made by the raw material of following parts by weight (kg):

[0019] Castor oil 99, ferrocene 1.3, polyisobutene 1.6, ammonium dihydrogen phosphate 0.6, ammonium benzoate 1.2, 2-methylimidazole 1.3, β-naphthylamine 0.6, N-phenyl-2-naphthylamine 1.2, dioxane Zinc dithiophosphate 1.1, sodium lauryl sulfate 0.7, polyethylene glycol 1.5, film-forming resin 5.2, modified sepiolite powder 1.2.

[0020] The film-forming resin is prepared from the following raw materials in parts by weight: rosin 5.2, urea 3, zinc powder 1, dimethyl silicone oil 2, liquefied paraffin 10, 3-aminopropyltrimethoxysilane 2.4, acetylcitric acid Tris (2-ethylhexyl) ester 7.3, epoxy linseed oil 12, xylene 13, polyvinyl alcohol 8;

[0021] The preparation method of the modified sepiolite powder is as follows: the sepiolite is calcined at 720°C for 10 hours, ground into powder, soaked in 12% acetic acid solution for 6 hours, washed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com