Corrosion inhibitor for steel wire and preparation method thereof

A technology of anti-rust agent and steel wire, which is applied in the direction of anti-corrosion coating, coating, polyether coating, etc., can solve the problems of high cost, corrosion of steel wire, serious environmental pollution, etc., achieve good stability and maintain the original color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

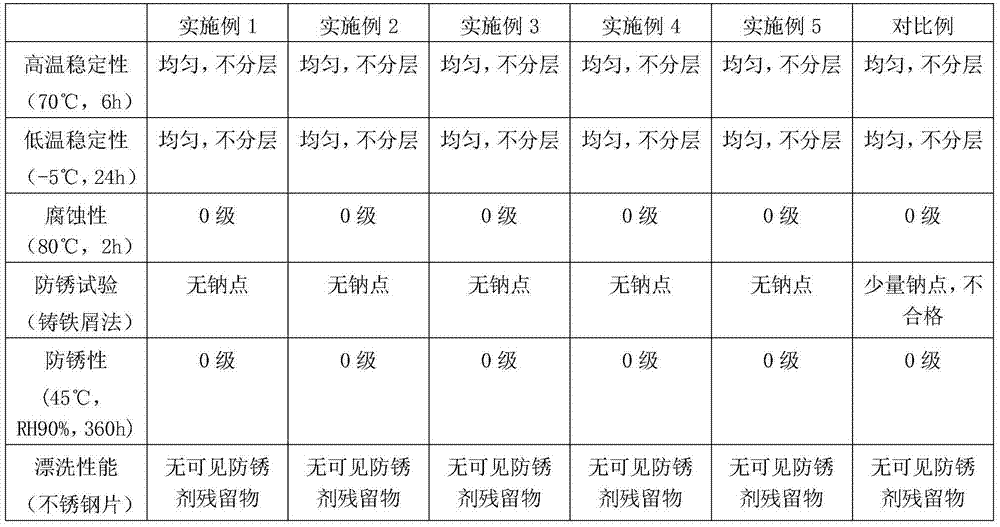

Examples

Embodiment 1

[0010] A kind of antirust agent for steel wire, comprising by weight components: 20 parts of polyvinyl alcohol, 100030 parts of polyethylene glycol, 2 parts of ammonium benzoate, 3 parts of trisodium phosphate, 1 part of thiourea, and 2 parts of sodium thiosulfate , 1 part of triethanolamine, 1 part of undecanedibasic acid, 1 part of benzotriazole, 3 parts of citric acid, 1 part of sodium molybdate, 3 parts of tetrapropylammonium acetate, and 100 parts of water.

[0011] Add polyvinyl alcohol and polyethylene glycol into water, heat while stirring to dissolve completely, then add other components, keep stirring at 40°C, and cool to room temperature after complete dissolution.

Embodiment 2

[0013] A kind of antirust agent for steel wire, comprising by weight components: 30 parts of polyvinyl alcohol, 200040 parts of polyethylene glycol, 3 parts of ammonium benzoate, 3 parts of trisodium phosphate, 2 parts of thiourea, 3 parts of sodium thiosulfate , 2 parts of triethanolamine, 2 parts of undecanedibasic acid, 1 part of benzotriazole, 4 parts of citric acid, 1 part of sodium molybdate, 4 parts of tetrapropylammonium acetate, and 150 parts of water.

[0014] Add polyvinyl alcohol and polyethylene glycol into water, heat while stirring to dissolve completely, then add other components, keep stirring at 40°C, and cool to room temperature after complete dissolution.

Embodiment 3

[0016] A kind of antirust agent for steel wire, comprising by weight components: 38 parts of polyvinyl alcohol, 200050 parts of polyethylene glycol, 5 parts of ammonium benzoate, 4 parts of trisodium phosphate, 3 parts of thiourea, and 5 parts of sodium thiosulfate , 3 parts of triethanolamine, 4 parts of undecanedibasic acid, 3 parts of benzotriazole, 6 parts of citric acid, 2 parts of sodium molybdate, 5 parts of tetrapropylammonium acetate, and 200 parts of water.

[0017] Add polyvinyl alcohol and polyethylene glycol into water, heat while stirring to dissolve completely, then add other components, keep stirring at 40°C, and cool to room temperature after complete dissolution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com